Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Smooth material surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

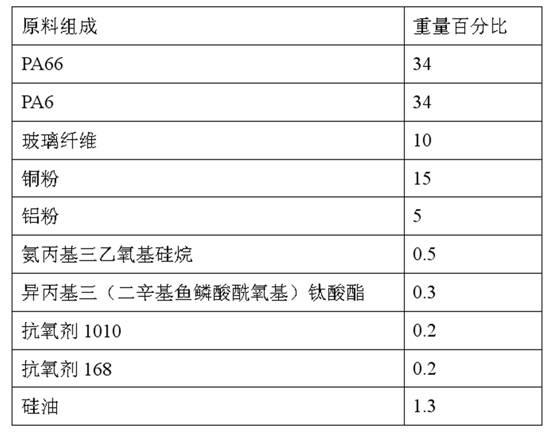

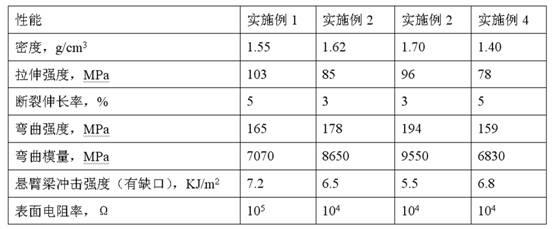

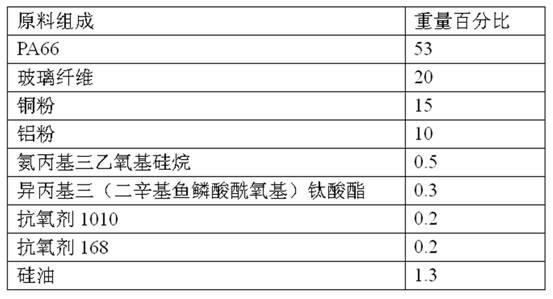

Enhanced conductive nylon material and preparation method thereof

InactiveCN101955653AGood dispersionEvenly dispersedNon-conductive material with dispersed conductive materialGlass fiberNylon material

The invention relates to an enhanced conductive nylon material and a preparation method thereof. The enhanced conductive nylon material comprises the following raw materials in percentage by weight: 40 to 70 percent of nylon, 10 to 40 percent of glass fibers, 10 to 40 percent of metal powder, 0.1 to 5 percent of coupling agent, 0.1 to 0.5 percent of antioxidant and 0.5 to 5 percent of silicone oil. The invention provides a method for thermoplastic conductive plastics by attaching the metal powder to the glass fibers twice and mixing the glass fibers, the metal powder and plastics for pelleting by utilizing the characteristics of easy machining and dispersion of the glass fibers in the plastics, and the prepared thermoplastic conductive plastics have the characteristics of simple and convenient production process, uniform dispersion of the metal powder, small addition amount, controlled conductivity and smooth surfaces of products.

Owner:NANJING HONGRUI PLASTIC PROD

Composite electroforming preparing process for nano silicon carbide particle reinforced nickel base composite material

InactiveCN1683600AEffective control of content uniformityEffective control of distribution uniformityElectrolytic coatingsElectroforming processesDc voltageNickel ions

The composite electroforming process of preparing nanometer silicon carbide particle reinforced nickel base composite material has electrolytic nickel block as anode material, stainless steel sheet as cathode deposition body, silicon carbide particle of 10-50 nm as reinforcing particle and ammonium cetyl bromide as co-deposition promoter. Through mixing silicon carbide particle and co-deposition promoter solution through stirring, pouring the mixed solution into electroforming solution of nickel amino sulfonate, applying DC voltage while stirring the electroforming solution to make nickel ion and reinforcing particle deposit together onto the cathode mother body and stripping the composite electroformed layer, integrated nanometer silicon carbide particle reinforced nickel base composite material is produced. The produced composite material has high hardness, high strength, high ductibility and relatively great thickness, and may be used as functional structure material.

Owner:SHANGHAI JIAO TONG UNIV

Organic Li-based bentonite-WPU (waterborne polyurethane) leather finishing agent and preparation method thereof

InactiveCN102251400AImprove surface microenvironmentImprove wettabilityFibre treatmentPigment treatment with organosilicon compoundsIn situ polymerizationWater vapor permeability

The invention discloses an organic Li-based bentonite-WPU (waterborne polyurethane) leather finishing agent and a preparation method thereof. The method comprises the following steps: firstly, carrying out organic modification on Li-based bentonite so as to prepare organic Li-based bentonite; and then, dispersing the organic Li-based bentonite into a WPU matrix in nano scale by using a latex commixing or in-situ polymerization method so as to obtain the organic Li-based bentonite-WPU leather finishing agent. In the invention, because quaternary ammonium salts, organic amines, a coupling agentand polyisocyanates are selected to carry out organic modification on Li-based bentonite, the surface microenvironment of a chain-connected silicate layer of the Li-based bentonite and the wetting action (on polymers) of the Li-based bentonite are improved, thereby enhancing the dispersibility of the Li-based bentonite in organic polymers and the compatibility of the Li-based bentonite and the organic polymers, and better facilitating the expression of nano effects; and because the Li-based bentonite with a two-dimensional nanostructure is introduced into the WPU matrix by using a latex commixing or in-situ polymerization method, therefore, due to the unique structure and properties of a nano-clay, while the transparency of a finishing material is not affected, the thermal stability, friction-resistant strength and water vapor permeability of the finishing material can be improved markedly, and the mechanical properties of the finishing material are also enhanced and toughened.

Owner:SICHUAN UNIV

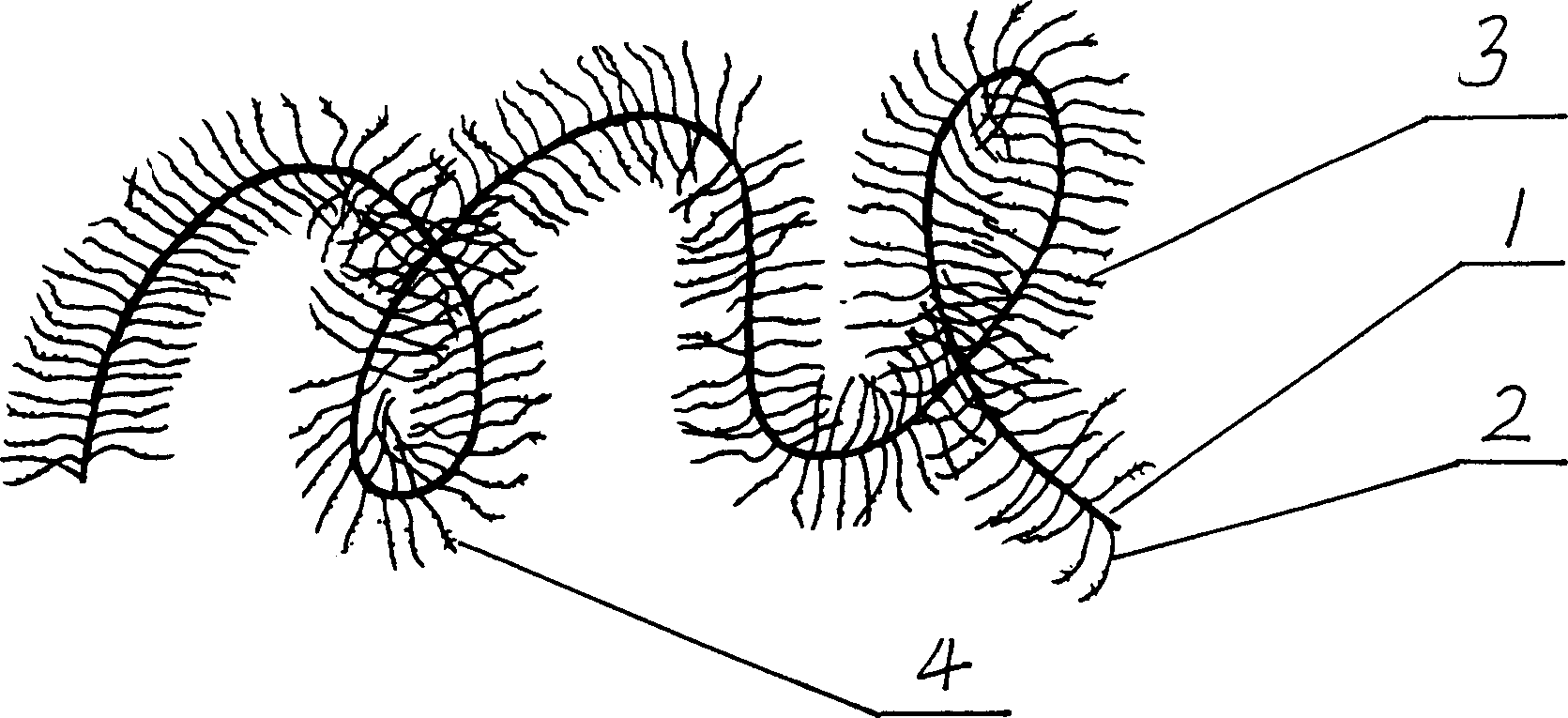

Non-woven fabric of down with crimped fiber and its production process

The present invention discloses a non-woven fabric of down with crimped fiber and its production process. Down is twisted together via its crimped stem, small branches, nodes and stabs on the branches. The non-woven fabric is produced through preparation of fiber down, chemical softening modification and / or mechanical kneading deformation, hot extruding to set, down setting, carding, air flow netting or mechanical netting, and knitting through needling, hydro-entangled, hot bonding, chemical bonding or sewing. The non-woven fabric has high elasticity, high tensile strength, high heat insualting performance, etc.

Owner:佛山神羽纺织有限公司

Halogen-free fire-retardant thermoplastic elastomer material and preparation method thereof

The invention provides a halogen-free fire-retardant thermoplastic elastomer and a preparation method thereof. The halogen-free fire-retardant thermoplastic elastomer material comprises the following raw materials in part by weight: 15 to 25 parts of styrene-ethylene-ethylene / propylene-styrene (SEEPS), 10 to 20 parts of polypropylene, 10 to 15 parts of polyolefin elastomer (POE), 30 to 40 parts of halogen-free fire retardant, 10 to 15 parts of compatilizer, 0.1 to 0.3 part of antioxidant and 15 to 25 parts of mineral oil. The SEEPS with larger cohesive energy is taken as a modification base material and is matched with low-hardness polypropylene and the compatilizer, the halogen-free fire-retardant thermoplastic elastomer material is low in hardness, is high in elastic resilience, tensile strength and elongation at break, and has a smooth surface.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

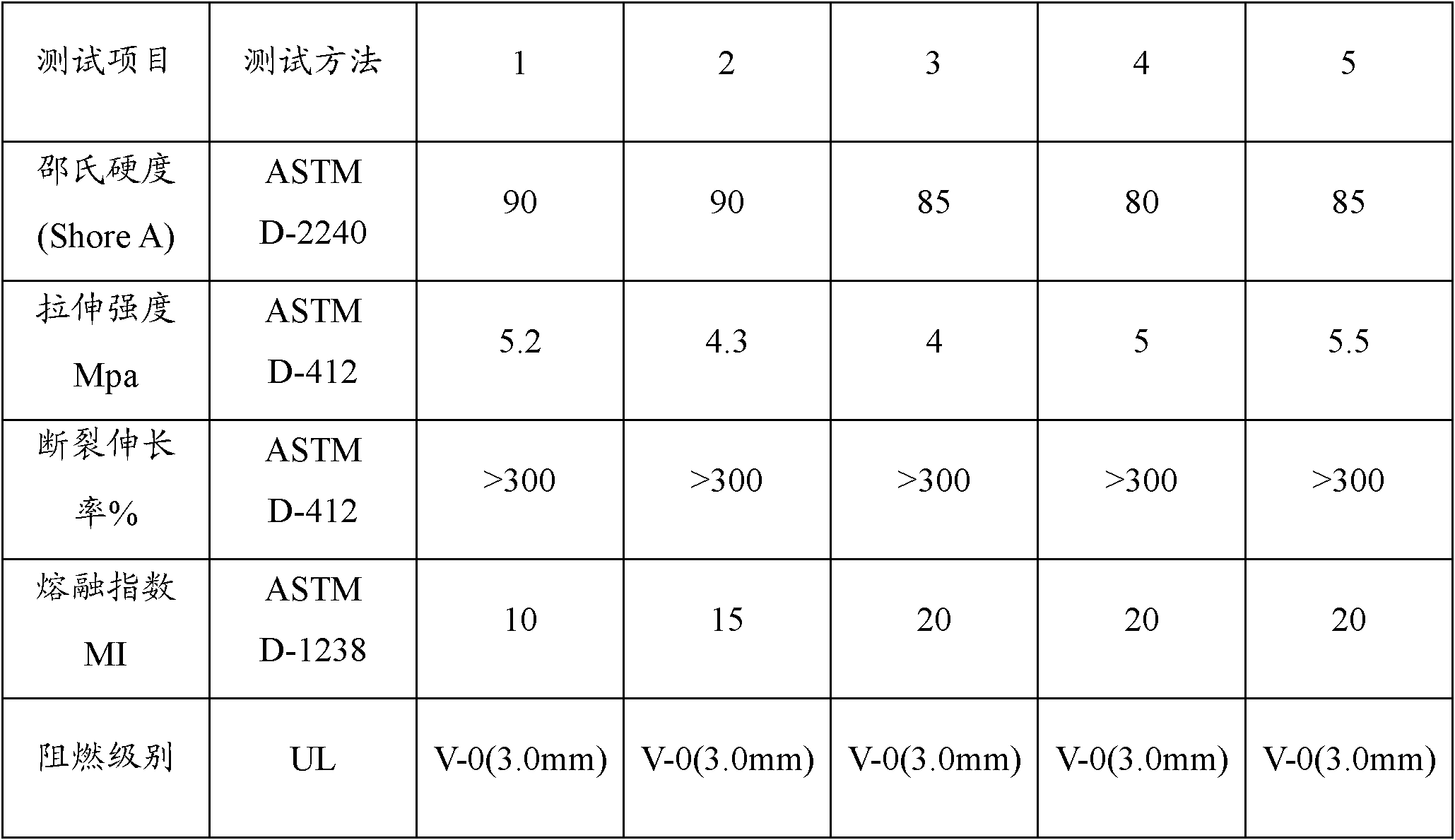

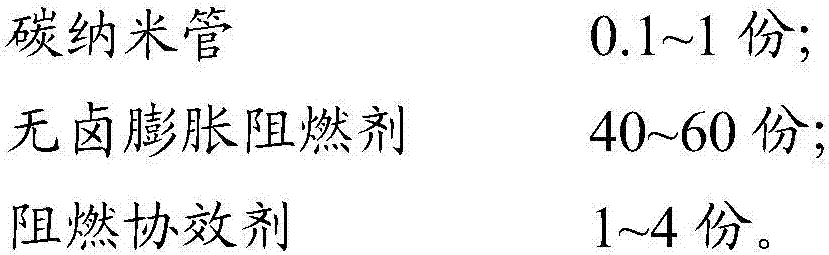

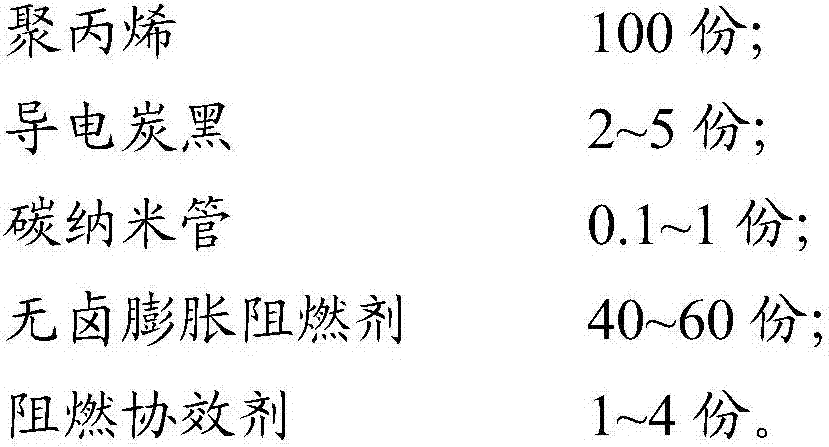

Polypropylene halogen-free flame-retardant anti-static material, and preparation method and applications thereof

The invention provides a polypropylene halogen-free flame-retardant anti-static material, and a preparation method and applications thereof. According to the preparation method, a halogen-free intumescent flame retardant is adopted for flame retardant treatment, the halogen-free intumescent flame retardant contains no halogen, is more safe, and is more friendly to the environment; reasonable adjustment of the formula of the halogen-free intumescent flame retardant is carried out, so that flame resistance is improved, material oxygen index is capable of reaching 32%, vertically burning is capable of reaching V0 grade; conductive carbon black and carbon nanotube are capable of providing the polypropylene halogen-free flame-retardant anti-static material with permanent antistatic performance, the antistatic performance is excellent, and cost is relatively low; adding of carbon nanotube is capable of increasing the electrical conduction efficiency of conductive carbon black, and improving the antistatic performance; and material surface resistance is capable of reaching 106omega at an extremely low conductive filling material content.

Owner:应急管理部四川消防研究所

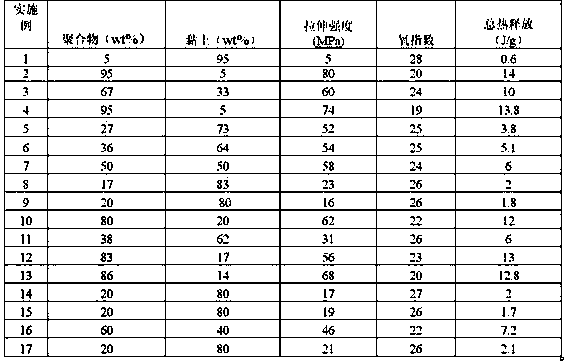

Nanometer paper material and preparation method thereof

InactiveCN103850152AIncrease productivityFlat surfacePaper/cardboardInorganic compound additionSolventMechanical press

The invention provides a nanometer paper material and a preparation method thereof. Nanometer paper is prepared by blending a polymer and clay in a water solution, freeze-drying, and then, mechanically pressing the mixture, wherein the polymer contains 5-95% of nanometer paper, and the clay contains 95-5% of nanometer paper. As the nanometer paper material provided by the invention is prepared by taking the polymer and clay as raw materials, only water is adopted as a solvent in a preparation process, and the freeze-drying and mechanical pressing processes are adopted, so that the preparation processes are environment-friendly, and the production efficiency is high. The freeze-drying and mechanical pressing processes for preparing the nanometer paper material are more efficient, and the obtained material is smooth in surface, relatively high in strength, good in flame retardance and good in product quality repeatability. The preparation method is simple in process operation, low in cost and easy to popularize.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

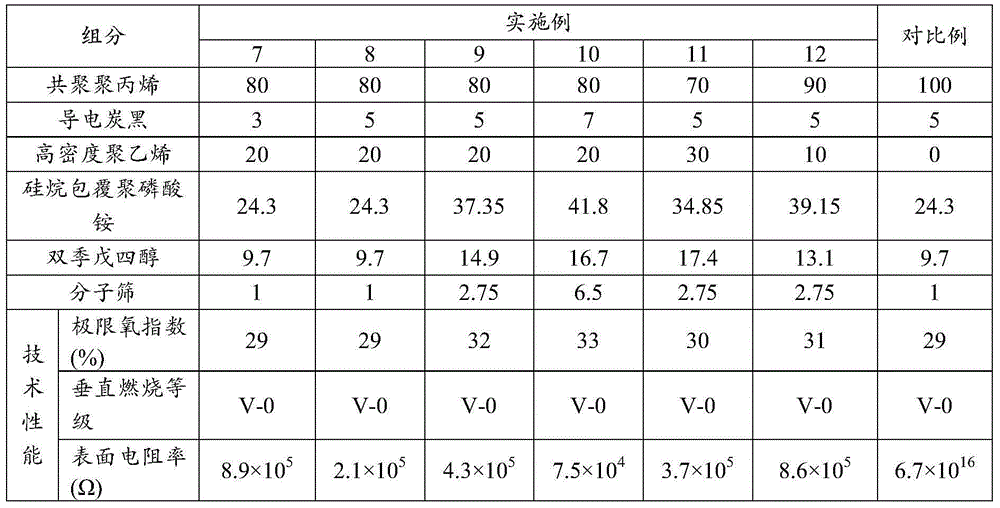

Halogen-free flame-retardance anti-static polypropylene composite material and preparation methods thereof

InactiveCN104140598AImprove flame retardant performancePermanent antistaticPolypropylene compositesHalogen

The invention provides a halogen-flame-retardance anti-static polypropylene composite material, belonging to the field of material chemistry. The composite material is prepared from the following raw materials in parts by mass: 70-90 parts of polypropylene, 3-7 parts of inorganic conductive filler, 10-30 parts of conductive promoter and 35-65 parts of halogen-free inrumescent flame retardant. The invention further provides two methods for preparing the composite material. Compared with a traditional flame-retardant anti-static polypropylene composite material, the material is prepared by a halogen-free flame-retardant technology and has permanent anti-static capability, excellent mechanical performance and excellent processing performance.

Owner:应急管理部四川消防研究所

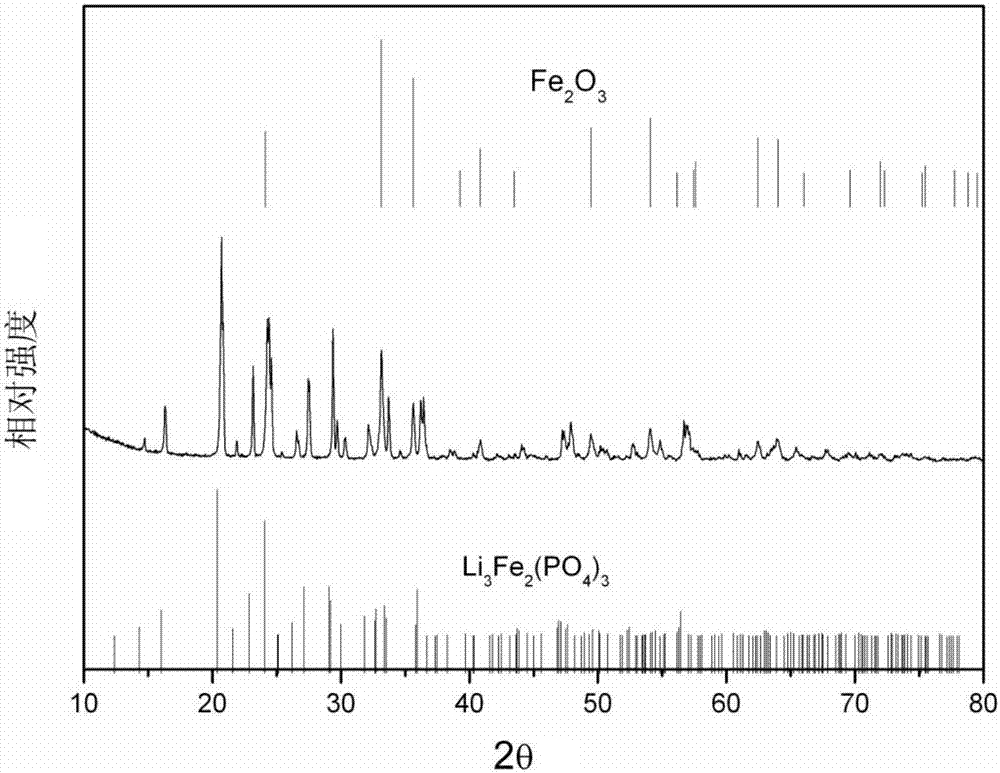

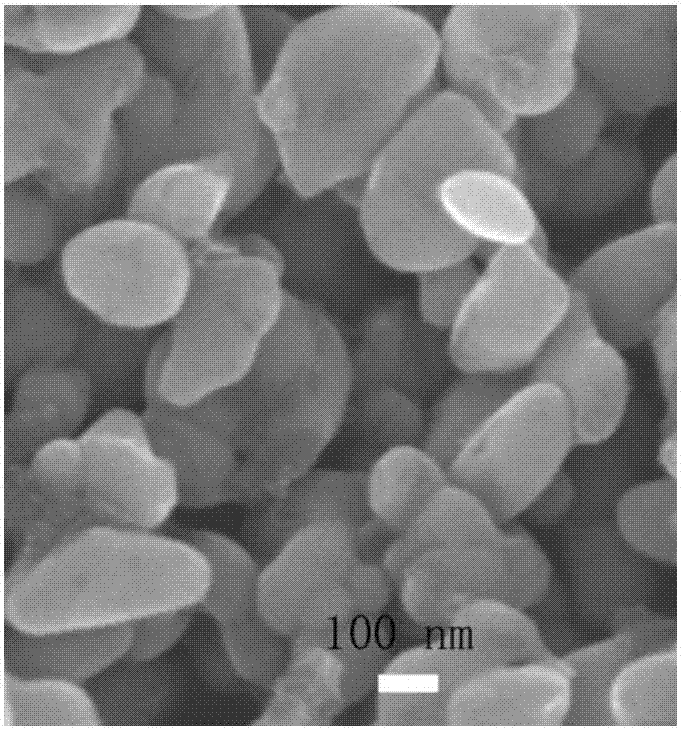

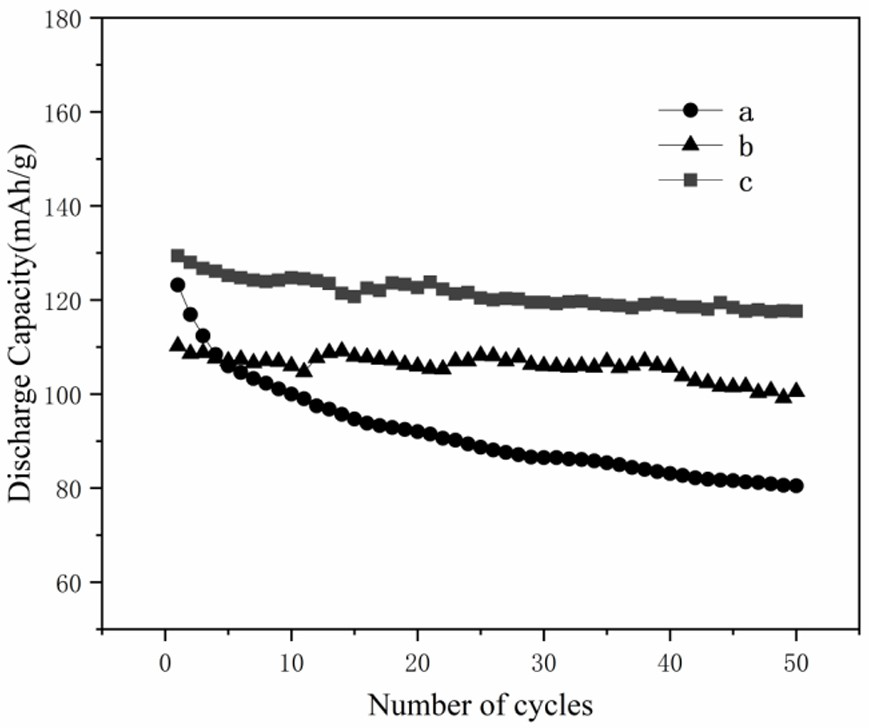

Preparation method of lithium ion battery positive electrode material

InactiveCN107994211ARelieve stressReduce complexityMaterial nanotechnologyCell electrodesLithium-ion batteryCarbon source

The invention provides a preparation method of a lithium ion battery positive electrode material. The preparation method comprises the steps of mixing a lithium source, an iron source and a phosphatesource according to a mole ratio of Li, Fe and P being (1-1.02):(0.955-1):1, and performing pre-sintering in air to obtain a mixture of Li3Fe2(PO4)3 and Fe2O3, wherein the sintering time is 4-5 hours,and the sintering temperature is 500-700 DEG C; and mixing the mixture and a carbon source of which the mass accounts for 3-10% of Li3Fe2(PO4)3, grinding in a grinding medium, and performing secondary sintering under a non-oxidization or reduction atmosphere after drying to obtain an LFP / C positive electrode material, wherein the sintering time is 5-6 hours, and the sintering temperature is 600-800 DEG C. By the method, the smoothness of synthesis particle and the batch stability and the cycle stability of a product can be effectively improved.

Owner:PULEAD TECH IND

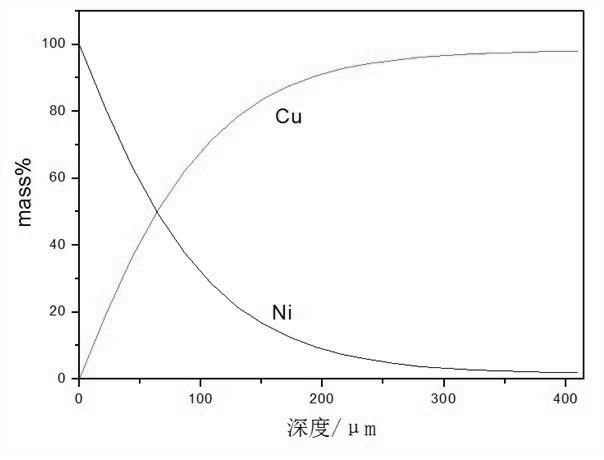

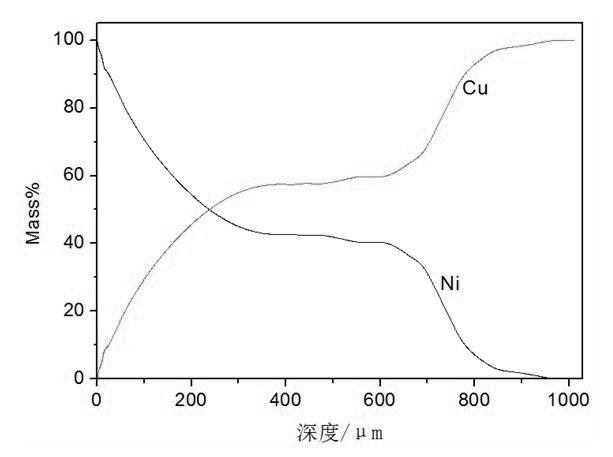

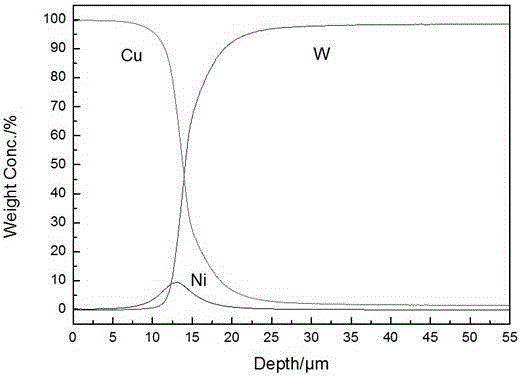

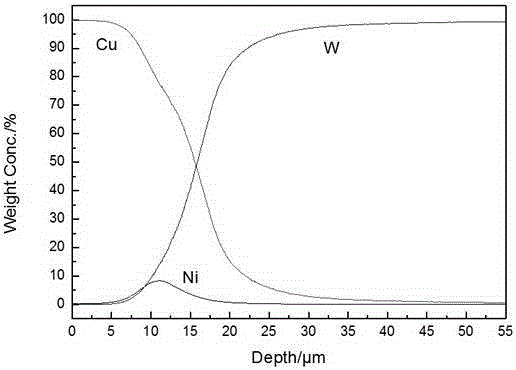

Cu-Ni functionally gradient material and preparation method thereof

InactiveCN102673040AStrong bending resistancePrevent oxidationMetal layered productsHigh surfaceFunctionally gradient material

The invention discloses a Cu-Ni functionally gradient material and a preparation method thereof. The functionally gradient material comprises an intermediate copper layer and two side nickel layers, wherein a gradient distribution layer is arranged between the copper layer and each nickel layer; and the copper content of the gradient distribution layer is decreased gradually and the nickel content is increased gradually to the directions of the nickel layers. The material is high in bending resistance, electric conductivity, heat conductivity and mechanical performance; various parts of the material are linked closely; the surface structure of the material is dense and flat; a stable NiO protective film can be formed on the surface of the material in the air at the temperature of 700 to 900 DEG C, so that substrate copper is effectively prevented from being oxidized; and therefore, the material has the characteristic of high surface oxidation resistance. According to the preparation method, aiming at the characteristics of the conventional Cu-Ni functionally gradient material, according to a diffusion basic theory, the method of electrodepositing Ni and interfusing Ni and Cu at the same time under the action of an electric field is adopted to accelerate the thickening of a gradient layer. The preparation method has the advantages that the formation speed of the gradient layer is high; the time required for preparing a thick gradient layer is short; and the method is easy to control and simple in process and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

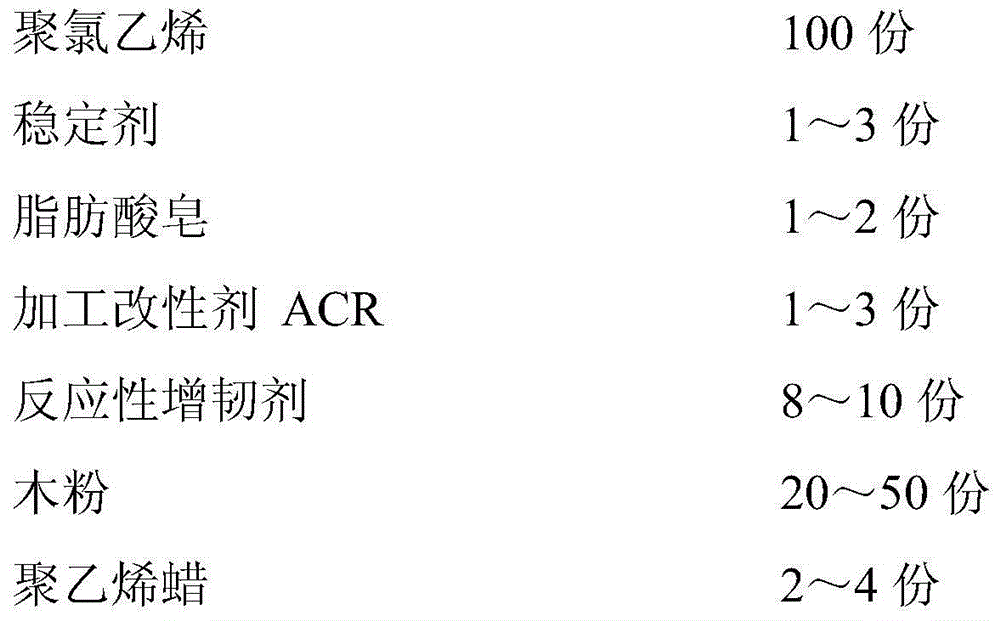

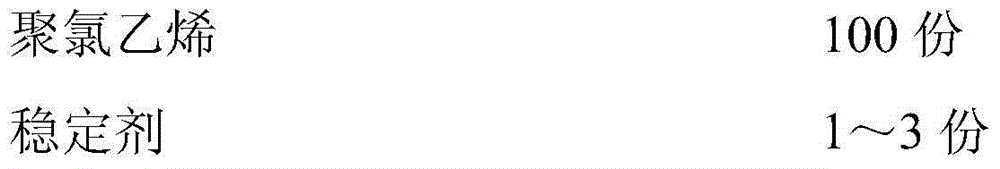

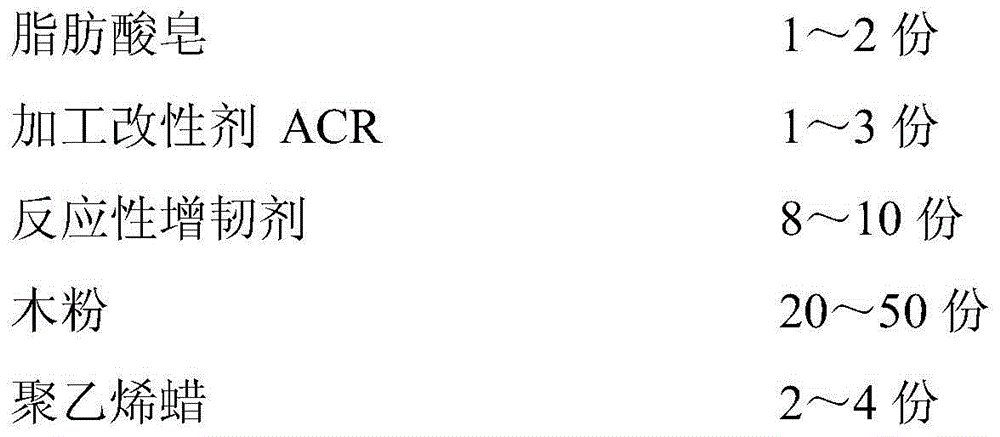

PVC (polyvinyl chloride)-base wood-plastic composite material and preparation method thereof

The invention provides a PVC (polyvinyl chloride)-base wood-plastic composite material and a preparation method thereof, belonging to the field of PVC-base wood-plastic composite materials. The invention solves the problems of poor mechanical properties and high cost in the existing PVC-base wood-plastic composite material. The PVC-base wood-plastic composite material comprises the following components in parts by weight: 100 parts of PVC, 1-3 parts of stabilizer, 1-2 parts of fatty acid soap, 1-3 parts of processing modifier ACR, 8-10 parts of reactive toughener, 20-50 parts of wood meal and 2-4 parts of polyethylene wax. The invention also provides a preparation method of the PVC-base wood-plastic composite material. The reactive toughener is a polyacrylate core-shell toughener containing epoxy groups and other active groups on the surface. While reacting with the hydroxy groups on the wood meal surface, the reactive toughener can reduce the polarity of the wood meal, promotes the dispersion of the wood meal in the PVC and enhance the filling amount of the wood meal. The mechanical properties of the composite material are enhanced.

Owner:CHANGCHUN UNIV OF TECH

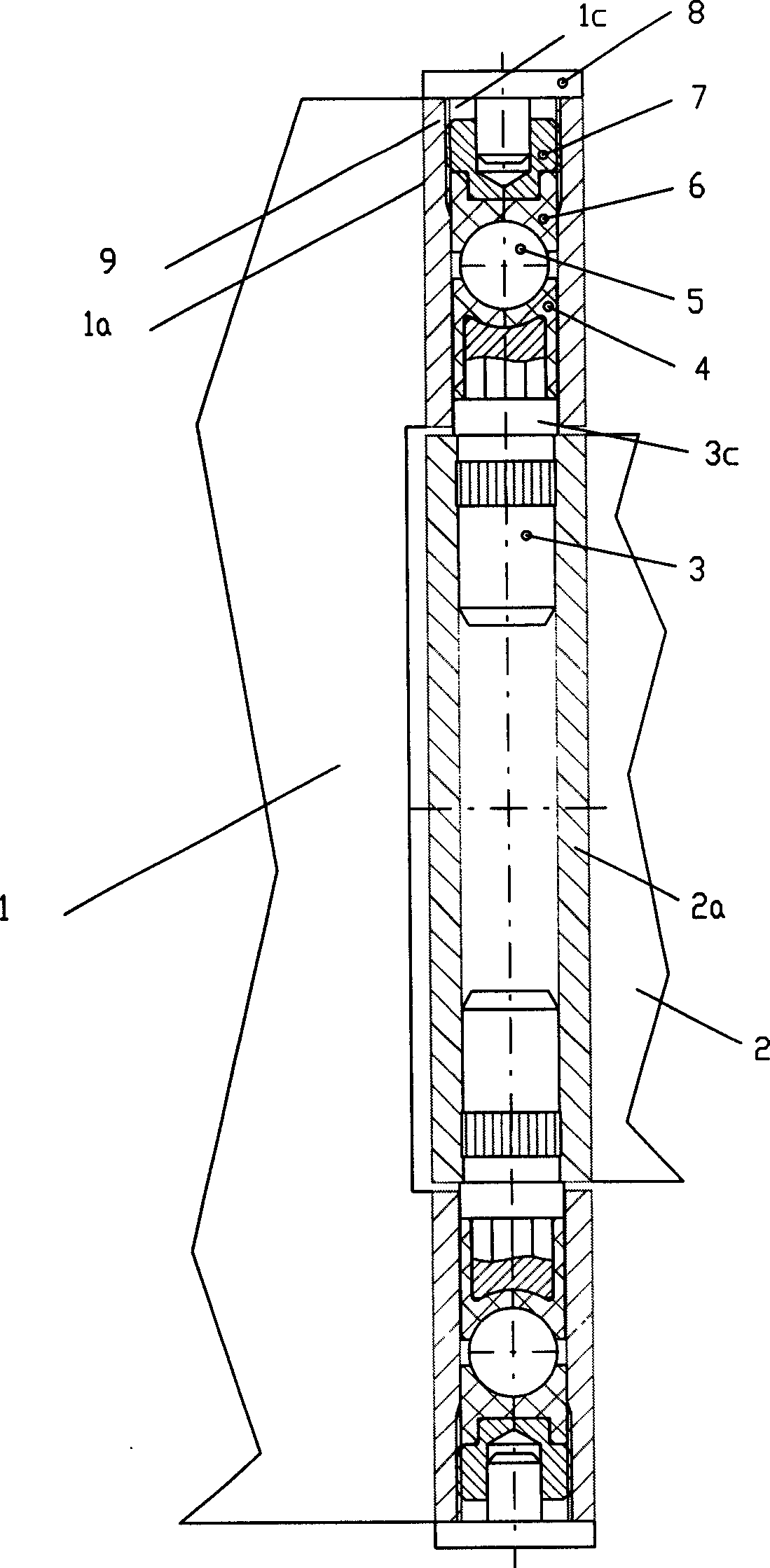

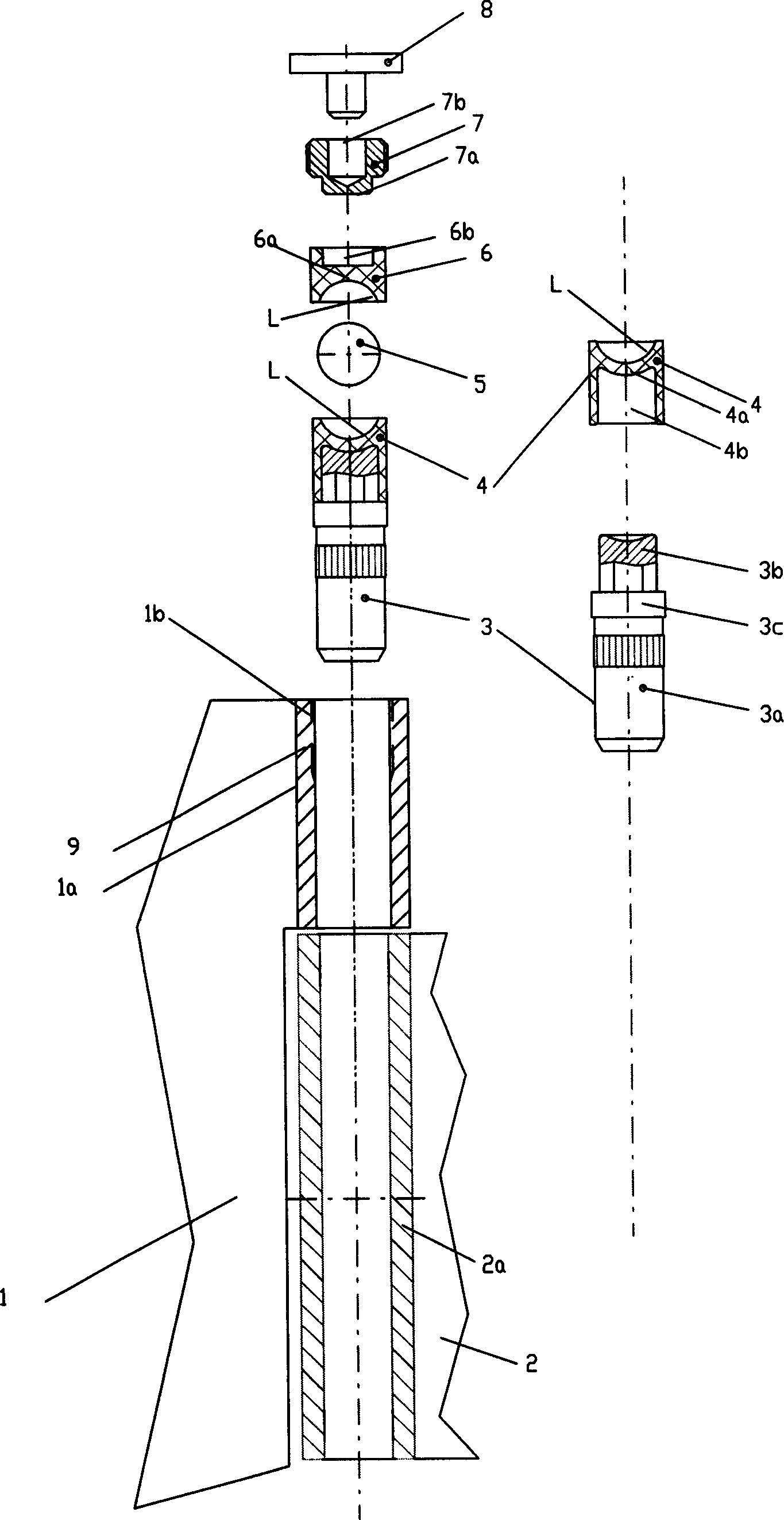

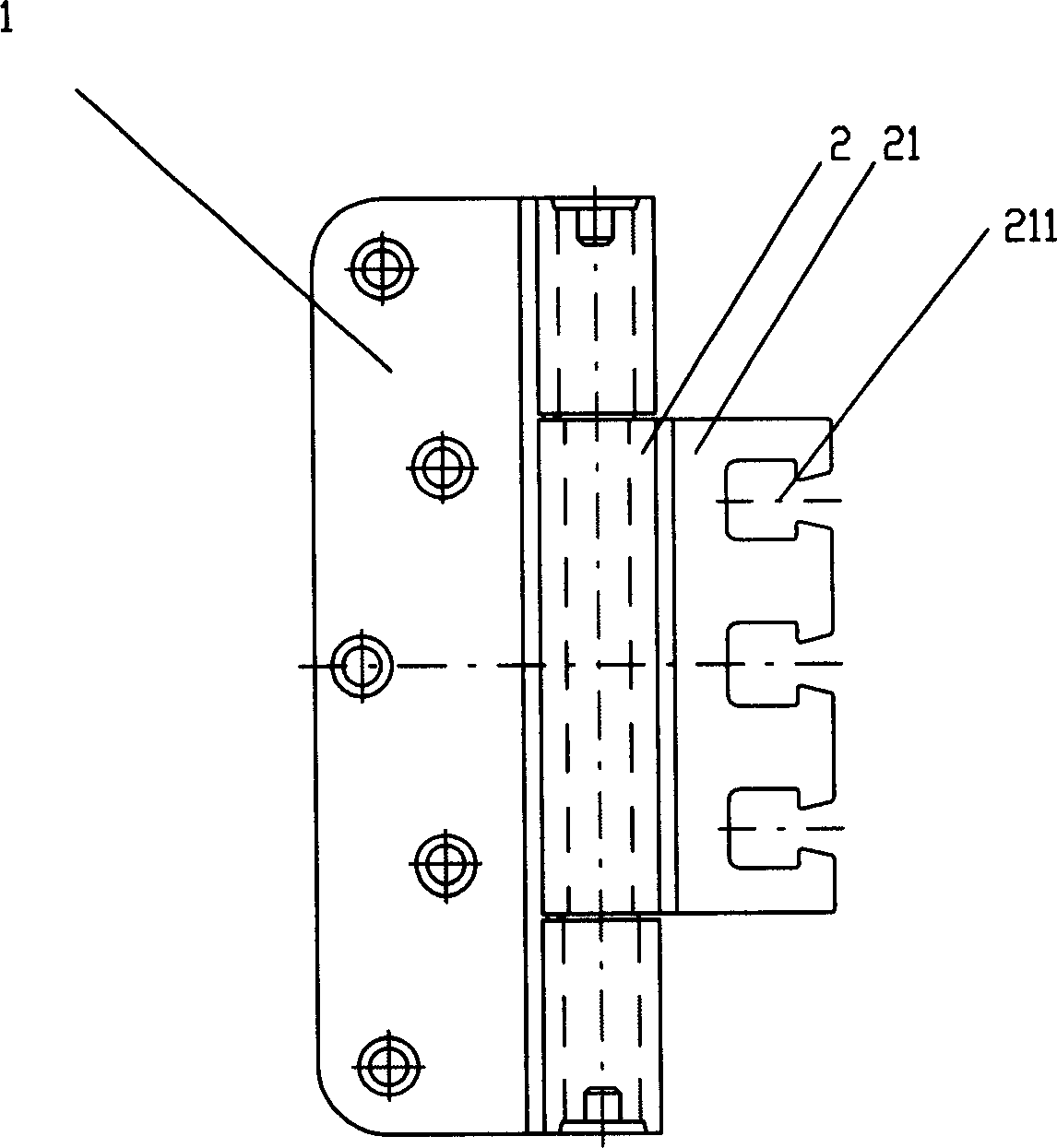

Door hinge with concealed bearing

ActiveCN1641177AImprove wear resistanceImprove performanceWing accessoriesHingesHinge angleEngineering

The plate has outer and inner parts (1, 2) with a fastening unit for mounting the plate on a door frame. The inner part is placed between two cylindrical supporting sections (1a), which are placed on the outer part. Two supporting parts (4, 6) made up of rugged plastic such as Teflon, are placed between the sections. A ball (5) made of steel is arranged between the parts (4, 6), and a set screw (7) is screwed into the sections. - The support part (6) exerts pressure against the ball (5) using the set screw, where the ball exerts the pressure against the support part (4).

Owner:ECO SCHULTE

Method for improving selected area epitaxial growth interface

InactiveCN106024588AImprove crystal qualityImprove performanceSemiconductor/solid-state device manufacturingLithographic artistDielectric layer

The invention relates to the technical field of semiconductor epitaxial technology, specifically to a method for improving a selected area epitaxial growth interface. The method includes the steps of providing a substrate for epitaxial growth, depositing a stress buffer layer and a GaN buffer layer sequentially on the substrate, obtaining a selected area epitaxial template, depositing a dielectric layer on the template as a mask layer, eroding and removing the dielectric layer on the area where epitaxial AlGaN is needed through lithography development technology and a wet method to realize patterns on the mask layer, depositing low pressure grown GaN interposed layer on the areas which do not masked, and normally growing a GaN channel layer and an AlGaN barrier layer. The method is simple in process, the performance of a selected area epitaxial interface can be effectively improved, and the quality selected area epitaxial layer is also improved. Body leakage current in the epitaxial layer and reverse leakage current of a schottky diode can be reduced.

Owner:SUN YAT SEN UNIV

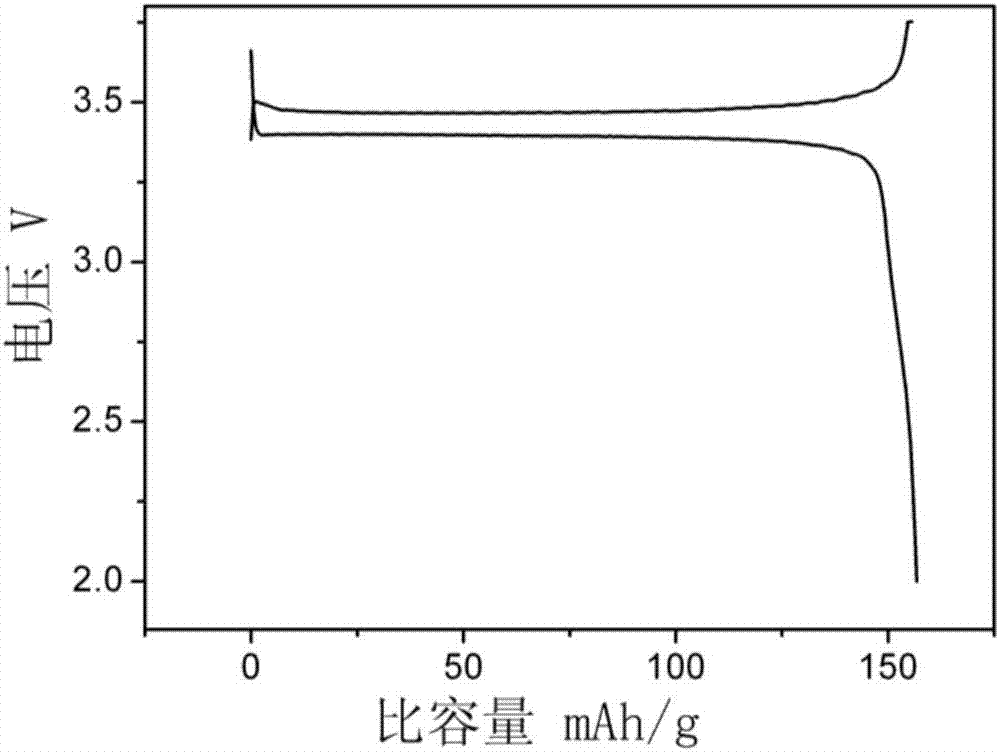

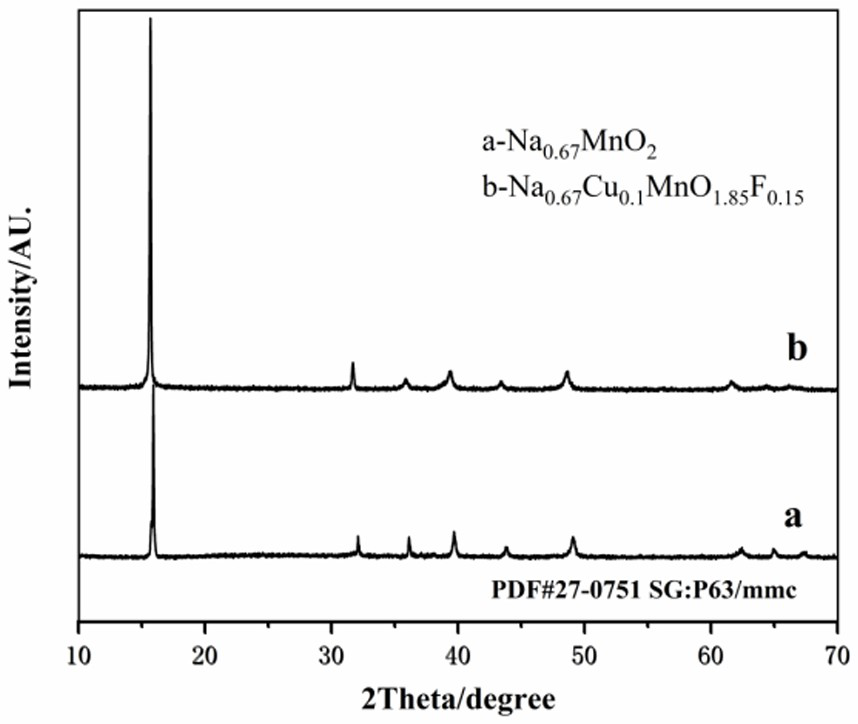

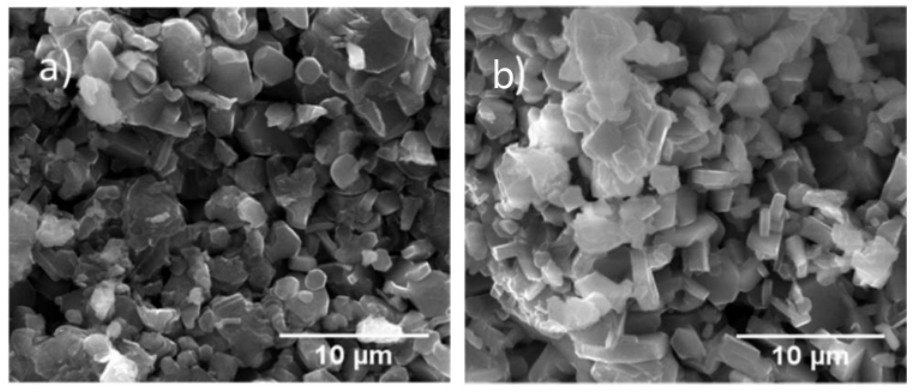

Anion-cation doped P2 type sodium ion battery positive electrode material

PendingCN113517433AExcellent electrochemical performanceHigh specific capacitySecondary cellsPositive electrodesIonSodium fluoride

The invention relates to an anion-cation doped P2 type sodium ion battery positive electrode material and a preparation method thereof. The chemical formula of the cathode material is Na0.67CuxMn1-xO2-yFy, x is more than 0 and less than or equal to 0.35, y is more than 0 and less than or equal to 0.3, a manganese salt, a copper salt and sodium fluoride are weighed according to the molar ratio of Mn, Cu and F elements and dissolved in deionized water, then a sodium salt is added and stirred to be dissolved, a mixed metal salt solution is prepared, and a citric acid solution is used as a complexing agent; the mixed metal salt solution is added into the complexing agent, ammonia water is added to adjust the PH value of the solution to be 8-11, the heating temperature is 60-90 DEG C, and gel is obtained after drying by distillation under the stirring condition; and the obtained gel is dried and crushed, presintered in an air atmosphere, sintered, and cooledto room temperature to obtain the positive electrode material. Through the synergistic effect of Cu ions and F ions, excellent electrochemical performance is shown, for example, the specific capacity of the material is improved, and the rate capability and the cycling stability are good.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

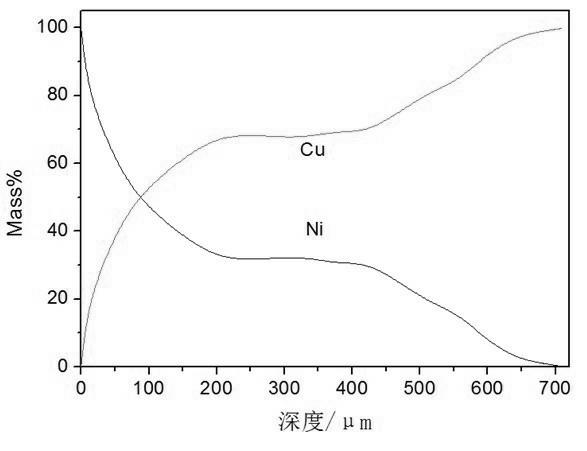

W-Ni-Cu gradient material and preparation method thereof

InactiveCN105177633AImprove impact performanceImprove heat resistanceCopper platingGradient material

The invention discloses a W-Ni-Cu gradient material and a preparation method thereof. The method comprises the following steps: taking a molten salt system of NaCl-KCl-NaF-NiO as an Ni leakage source and taking a copper-plating aqueous solution as a Cu leakage source; electrically depositing and leaking nickel on a pure W plate through molten salt, electrically depositing and leaking Cu through an aqueous solution; and finally diffusing and annealing to obtain the W-Ni-Cu gradient material. The material is high in thermal shock resistance and thermal fatigue resistance; all the components of the material are combined closely; the material surface structure is compact and smooth; the material has high electrical conductivity, high thermal conductivity and high mechanical performance. The method is capable of simultaneously carrying out mutual diffusion between W and Ni and carrying out mutual diffusion between Ni and Cu under the action of an electric field and a temperature field by using an electric deposition method according to the basic diffusion theory (the electric field can accelerate the diffusion of solid metals, and the diffusion speed of the opposite party can also be mutually improved when carrying out multi-element diffusion in the solid diffusion); the thickening of gradient layers can be accelerated; the W-Ni-Cu gradient material has the characteristics of rapid forming speed of the gradient layers, short preparation time, randomly controllable thickness of the gradient layers, compact surface structure of the material, high thermal conductivity and simple process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

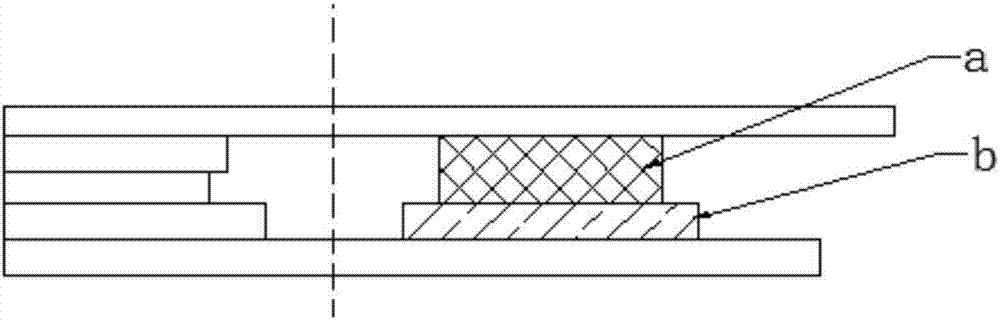

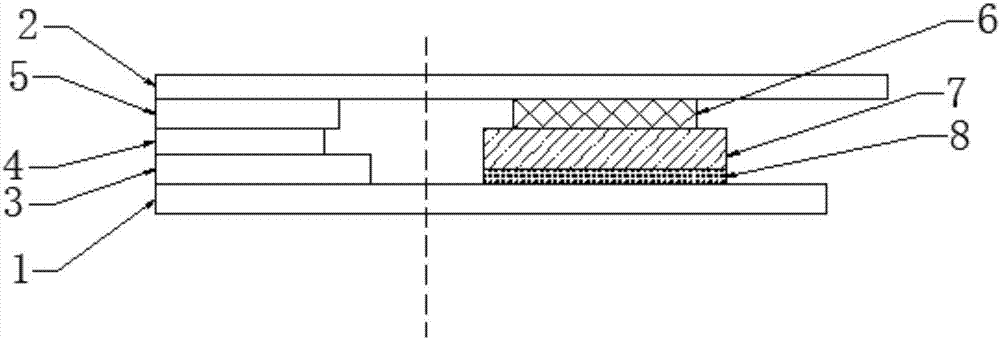

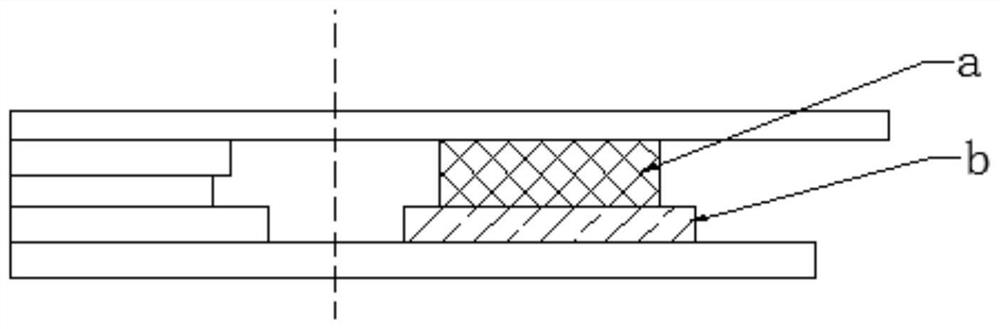

Touch display device

ActiveCN107422898AImprove flatnessStrong flatnessInput/output processes for data processingColor filmDisplay device

The invention discloses a touch display device. The touch display device comprises a first substrate and a second substrate opposite to the first substrate; a color film substrate is arranged at a part of the area, toward one side of the second substrate, of the first substrate; a polaroid is arranged on the color film substrate; a cementing layer is arranged on the polaroid; the areas of the first substrate and the second substrate are greater than the area of the color film substrate, the area of the polaroid and the area of the cementing layer; a gap is formed between the first substrate and the second substrate; and a rigid material layer is arranged in the gap, so that the strength of a single-layer area of the first substrate can be effectively increased and the local deformation resisting ability is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Composite electroforming preparing process for nano silicon carbide particle reinforced nickel base composite material

InactiveCN100336940CImprove physicsImprove mechanical propertiesElectrolytic coatingsElectroforming processesDc voltageNickel ions

Owner:SHANGHAI JIAOTONG UNIV

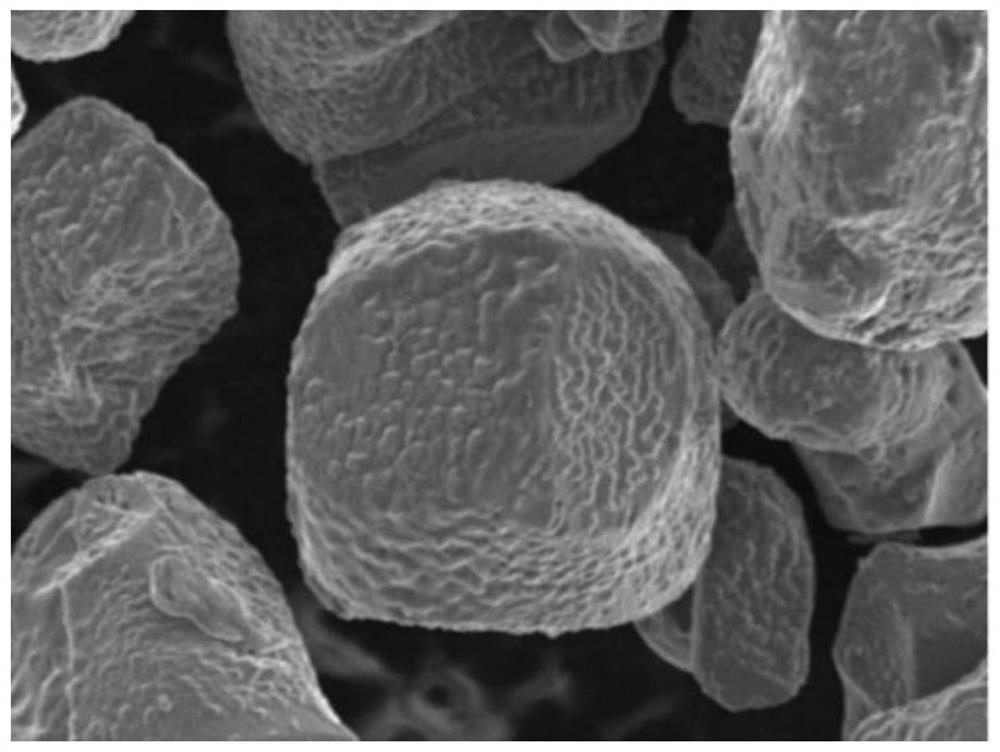

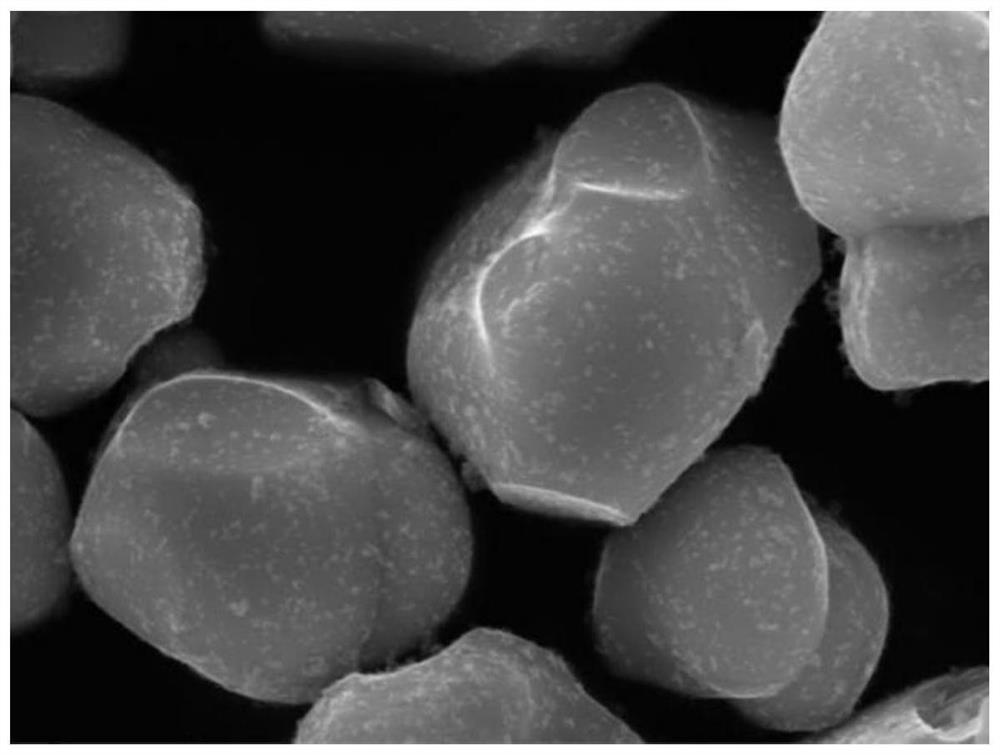

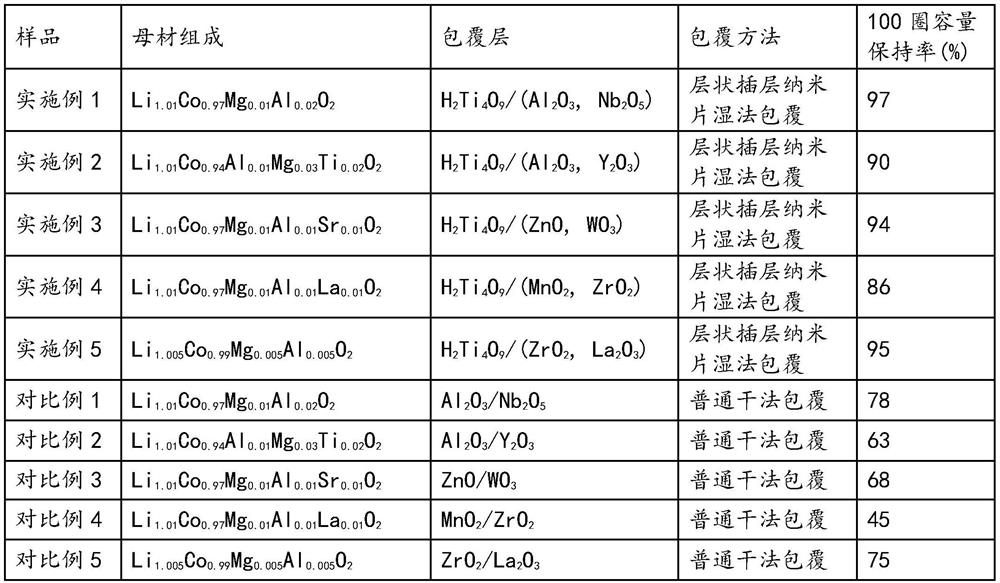

Layered composite oxide coated positive electrode material and preparation method and application thereof

ActiveCN113443655AImprove cycle lifeReduce capacityMaterial nanotechnologyCell electrodesPhysical chemistryComposite oxide

The invention relates to a layered composite oxide coated positive electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing cobalt salt and M salt or oxide according to a ratio, conducting sintering to obtain a bulk phase material precursor, mixing the bulk phase material precursor with lithium salt and an additive according to a ratio, conducting sintering at a high temperature, and conducting crushing to obtain gradient-doped modified lithium cobalt oxide; ultrasonically dispersing layered protonated titanate nanosheets in a uniformly dispersed dispersion liquid containing a metal oxide, transferring the dispersion liquid to a high-pressure reaction kettle for reaction, and conducting washing after separation to obtain intercalated layered titanate; carrying out dispersion and ultrasonic treatment on the intercalated layered titanate to obtain a stripped intercalated layered titanate nanosheet colloidal solution; and adding the modified lithium cobalt oxide into the intercalated layered titanate nanosheet colloidal solution, carrying out rotary evaporation to remove the solvent, carrying out vacuum drying, and carrying out heat treatment on the dried material to form the intercalated layered titanate nanosheet-coated modified lithium cobalt oxide layered composite oxide-coated positive electrode material.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

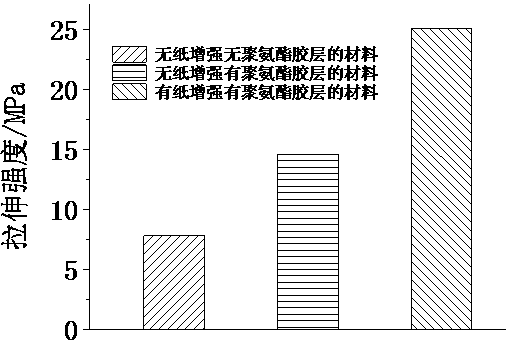

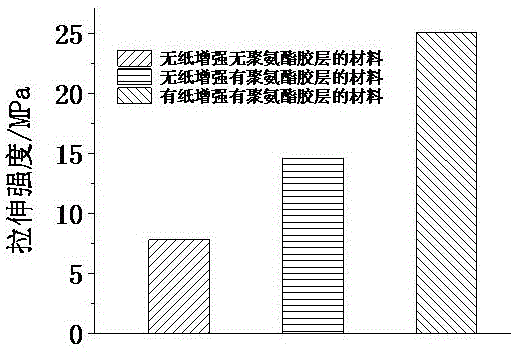

Paper reinforcement plant-based composite material and preparation method thereof

InactiveCN103481622AClear hierarchical structureAvoid surface damageLamination ancillary operationsSynthetic resin layered productsCelluloseMaterials science

The invention relates to a novel paper reinforcement plant-based composite material and a preparation method thereof. The composite material consists of plants, paper, bonding agents and polyurethane. The reinforcement method is characterized in that a paper reinforcement inner layer is introduced based on the reinforcement of the surface layer of polyurethane, paper reinforcement raw materials are easily available, waste resources can be recycled, the intensity of the composite material is improved effectively, the hygroscopicity is lowered, and the water resistance is intensified, so that the composite material is ordered in structure and universal in formation. By the preparation method of the composite material provided by the invention, raw materials are simple to treat, and dewaxing and washing are not needed; cellulose is not required to be separated individually, and thus a separation step is omitted; the diffusion of dust in an environment is reduced, and thus the health of operators in the field is protected; the preparation method is high in adaptability and easy to implement. The composite material provided by the invention has wide application, and can replace wood and plastics for manufacturing furniture, toys, containers, automobile decorative parts, daily necessities and the like.

Owner:JIUJIANG UNIVERSITY

PP calcium plastic material for improving printing suitability for packaging box and preparation method of PP calcium plastic material

The invention provides a PP calcium plastic material for improving printing suitability for a packaging box body and a preparation method of the PP calcium plastic material. The PP calcium plastic material for improving the printing suitability for the packaging box body is prepared from the following raw materials in parts by mass: 30-60 parts of PP resin, 1-5 parts of PE resin, 40-65 parts of ground calcium carbonate, 1-3 parts of borate multifunctional additive and 0.5-1 part of anti-aging agent. The PP calcium plastic material for improving the printing suitability for the packaging box body is obtained by conducting uniform stirring, conducting granulating by a double-screw extruder and finally conducting extruding and molding by a single screw. According to the PP calcium plastic material for the packaging box body and the preparation method thereof, the formula is simple, printing coloring is obviously improved, and the mechanical property is good; and the preparation method issimple in process, convenient to operate and control, high in production efficiency and low in production cost.

Owner:烟台融晟新材料有限公司

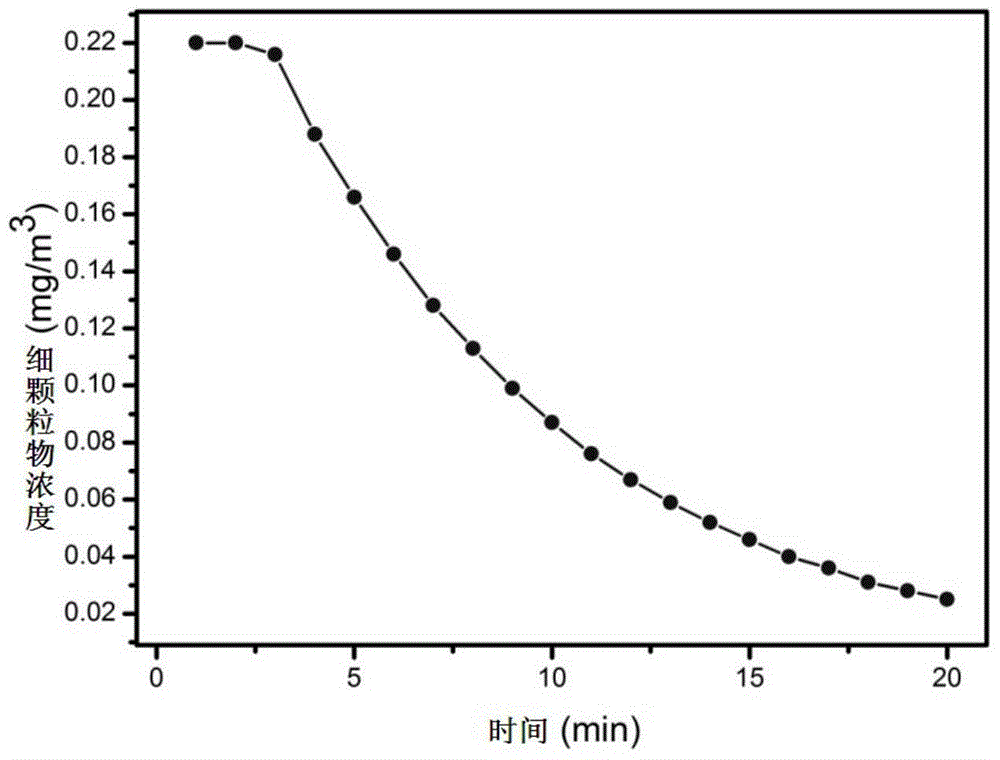

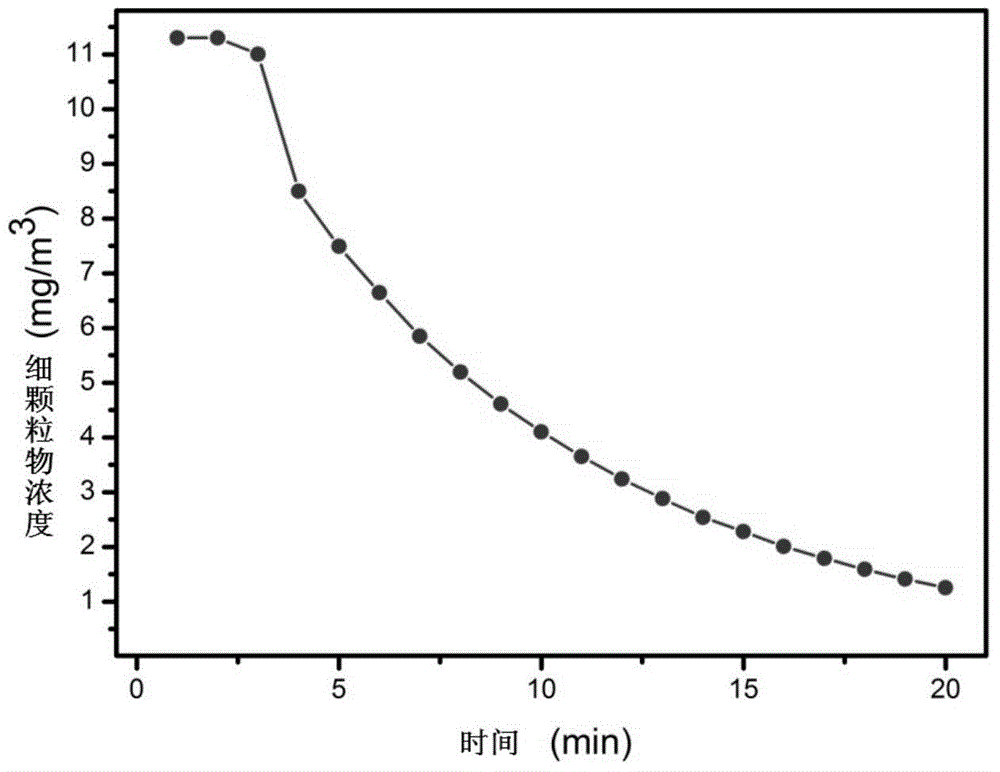

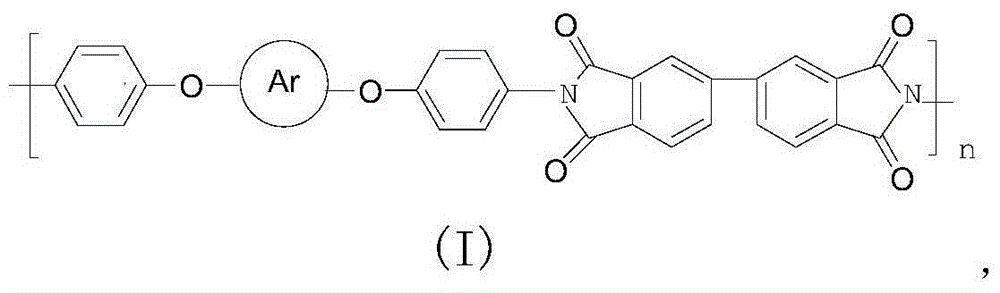

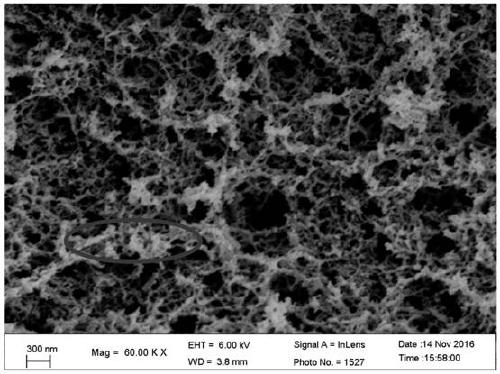

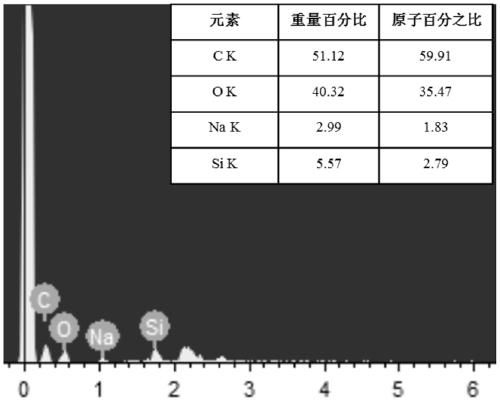

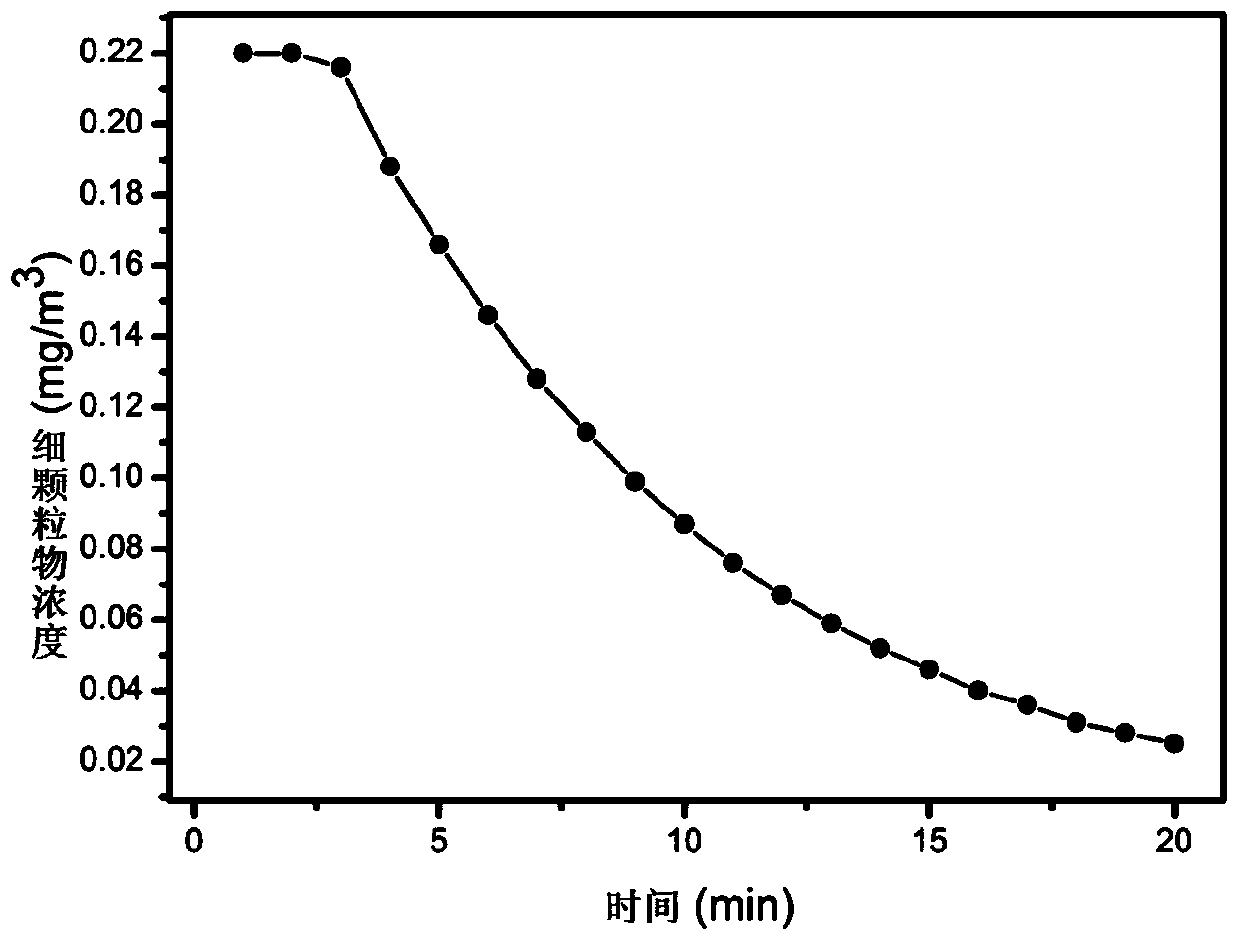

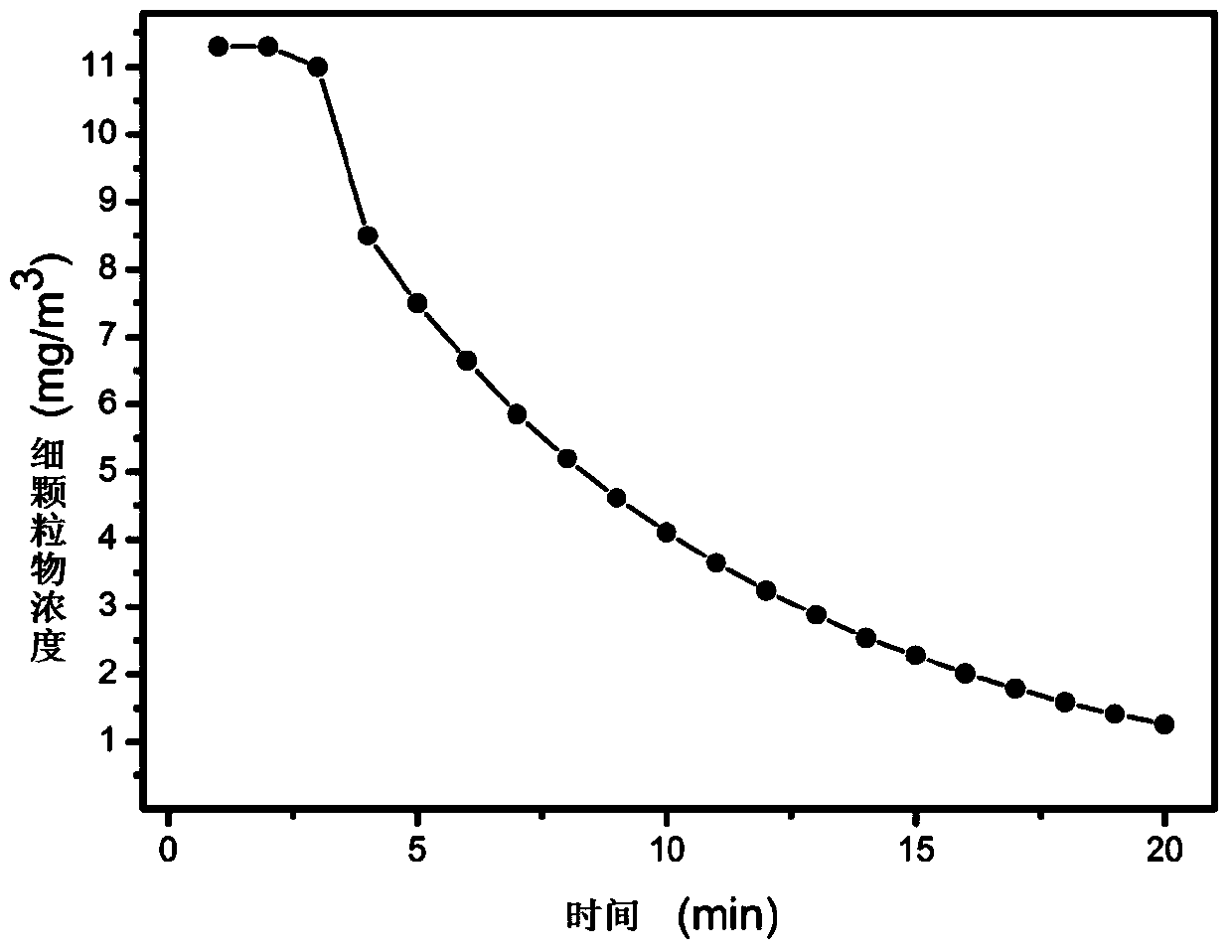

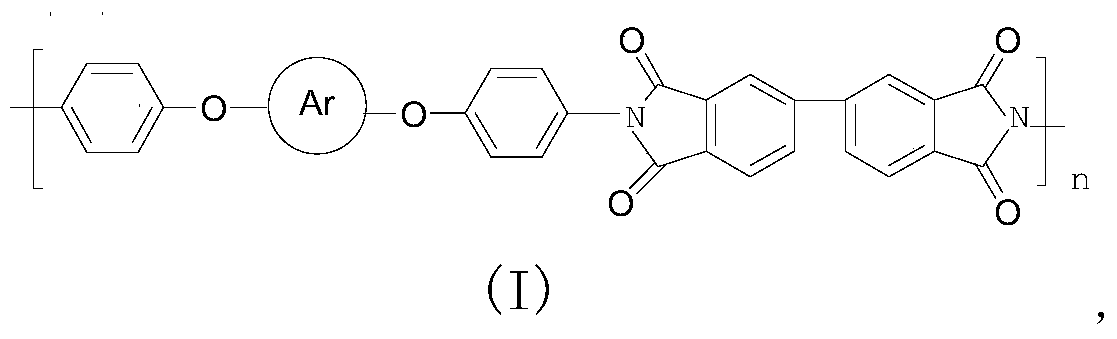

Polyimide filter membrane, and preparation method and application thereof

InactiveCN106268373ALow costStrong bonding forceSemi-permeable membranesDispersed particle filtrationCompound aFiber

The invention is applicable to the technical field of membraneous materals, and provides a polyimide filter membrane, and a preparation method and application thereof. The polyimide filter membrane is composed of compounds A disclosed as the chemical structural formula (I) in the specification, wherein the number-average molecular weight of the compounds A is 80000-100000. In the chemical structural formula (I), Ar is disclosed as one of the structural formulae in the specification. The polyimide filter membrane provided by the invention has the advantages of small pore size and high entrapment rate for fine particles in air. The polyimide filter membrane material has the characteristics of high compactness and smooth surface; and the formed fibers can not easily shed and have favorable stability. Besides, the polyimide filter membrane is low in cost, and is only less than one-fifth of the price of the same mass of commercially available sampled filter membrane.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

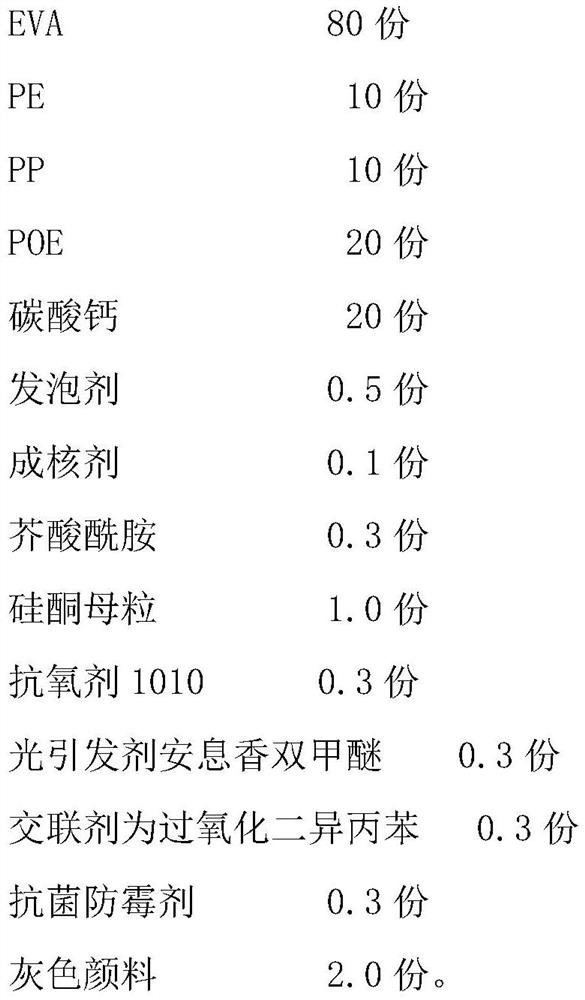

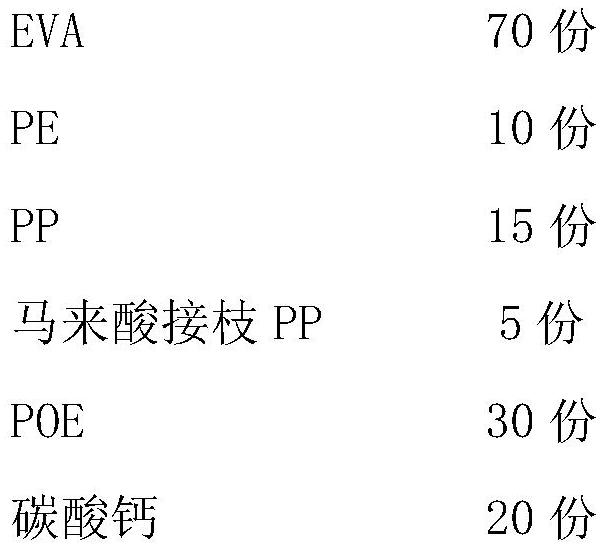

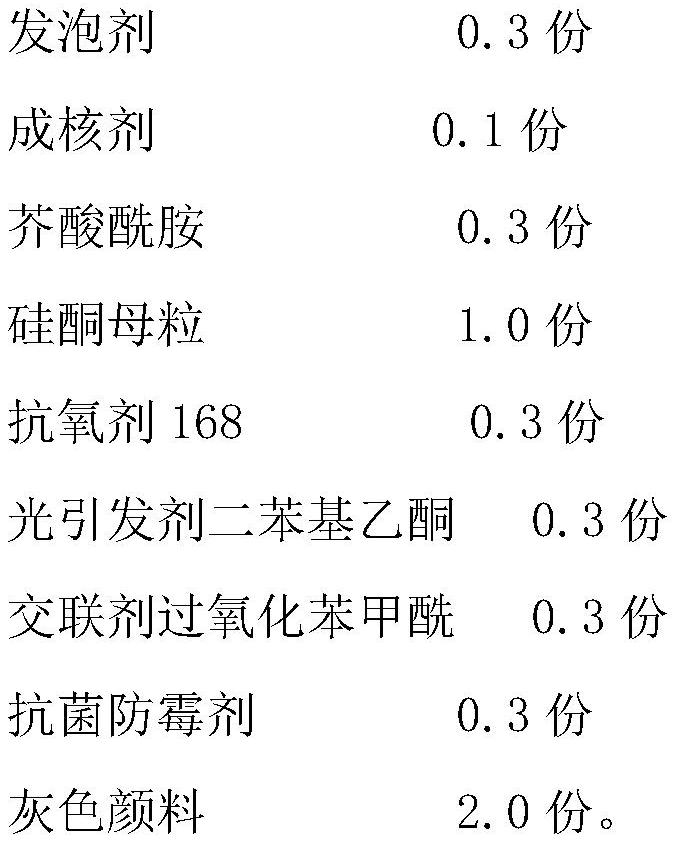

Ethylene-ethylene acetate copolymer (EVA) refrigerator door seal particle and preparation method thereof

The invention discloses an ethylene-ethylene-vinyl acetate copolymer (EVA) refrigerator door seal particle which is composed of an EVA, polyethylene (PE), modified polyethylene, polypropylene (PP), modified polypropylene, an ethylene-olefin copolymer (POE), a mineral filler, a foaming agent, a nucleating agent, a lubricant, an antioxidant, a photoinitiator, a cross-linking agent, an antibacterial and mildew-proof agent, a pigment and the like. The invention further discloses a preparation method of the micro-foaming type EVA refrigerator door seal particles capable of being directly extruded. The preparation method comprises the steps of weighing, grinding, pre-crosslinking, mixing, banburying and extruding granulation. The material is ground and pre-crosslinked, and the foaming agent and the nucleating agent are added, so that when the material is used for producing the refrigerator door sealing strip, direct extrusion molding can be realized, high-temperature vulcanization and mold pressurization are not needed, and the micro-foaming refrigerator door sealing material can be prepared. The product is smooth in surface, contains a large number of microbubbles in the middle, and is high in material tearing strength, large in weld fillet tension, good in rebound resilience, resistant to low temperature, resistant to aging, good in sealing performance and good in heat preservation effect.

Owner:上海新上化高分子材料有限公司

Composite electroforming process of copper-base composite material

InactiveCN1132967CImprove physicsImprove mechanical propertiesElectrolytic coatingsElectroforming processesTetramineFluorocarbon

The metal copper is used as anode material and the metal copper plate is used as cathode deposition mother body, in the electroforming plating liquor the reinforcing body and codeposition promotor prepared with cationic fluorocarbon surfactant, triethanlamine, hexamethyne tetramine and sulfourea are added, then powdered on to make metal copper ions and reinforcing body copeposit on the cathode mother body, then the composite electroformed plating layer can be stripped from cathode to obtain the integrally-reinforced copper base composite material with low cost and excellent performance.

Owner:SHANGHAI JIAOTONG UNIV

One-pot preparation of sio 2 - Method for cellulose composite airgel material

The invention relates to a method for preparing a SiO2-cellulose composite aerogel material with a one-pot method. The method comprises the following steps: taking cellulose as a raw material and dissolving the cellulose with a green alkaluria solvent; taking organic sodium silicate as a silicon source, and stirring and dispersing to obtain a uniformly mixed aqueous solution of the cellulose and the sodium silicate; combining a sol-gel method to obtain regenerated cellulose wet gel containing a silicon source; taking cellulose gel as a framework and taking inorganic acid as a reaction solvent, and inducing to generate SiO2; finally, drying through a CO2 supercritical drying process to obtain the SiO2-cellulose organic-inorganic composite aerogel. The method has the advantages that the process is simple and rapid, has high feasibility and is green and environment-friendly; the problems in an in-situ immersion method that the SiO2 has poor dispersity, low complex content, poor complex stability and the like in a cellulose porous network structure are effectively solved; the prepared inorganic-organic composite aerogel has relatively low coefficient of heat conductivity and good heat insulation performance and has good application prospect in the aspects of low-temperature cold insulation materials, middle-temperature and low-temperature heat insulation and heat preservation materials and adsorption materials.

Owner:NANJING TECH UNIV

A touch display device

ActiveCN107422898BImprove flatnessStrong flatnessInput/output processes for data processingColor filmDisplay device

The invention discloses a touch display device. The touch display device comprises a first substrate and a second substrate opposite to the first substrate; a color film substrate is arranged at a part of the area, toward one side of the second substrate, of the first substrate; a polaroid is arranged on the color film substrate; a cementing layer is arranged on the polaroid; the areas of the first substrate and the second substrate are greater than the area of the color film substrate, the area of the polaroid and the area of the cementing layer; a gap is formed between the first substrate and the second substrate; and a rigid material layer is arranged in the gap, so that the strength of a single-layer area of the first substrate can be effectively increased and the local deformation resisting ability is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

A kind of reinforced polylactic acid-based composite material and its preparation method

The invention discloses a reinforced polylactic acid-based composite material and a preparation method thereof. The present invention uses polylactic acid as the base material, modified nano-calcium carbonate and modified nano-fibrillated cellulose as reinforcing agents, carboxymethyl cellulose and guar gum as dispersants and compatibilizers, and adds chitosan as Antibacterial agent, through high-speed shear dispersion, water bath evaporation, drying, extrusion granulation and tape casting, etc., to prepare a reinforced polylactic acid-based composite material. The reinforced polylactic acid-based composite material of the present invention uses natural raw materials, which are all biodegradable, and is a green and environmentally friendly composite material; the source of raw materials is wide, which reduces production costs and is conducive to industrial production; the use of modified Nano-scale material modified nano-calcium carbonate and modified nano-fibrillated cellulose can effectively improve the mechanical properties of polylactic acid and endow composite materials with excellent comprehensive properties.

Owner:HANGZHOU CHANGGANG PAPER IND

A polyimide filter membrane, its preparation method and application

InactiveCN106268373BLow costStrong bonding forceSemi-permeable membranesDispersed particle filtrationChemical structureFiber

The invention is applicable to the technical field of membraneous materals, and provides a polyimide filter membrane, and a preparation method and application thereof. The polyimide filter membrane is composed of compounds A disclosed as the chemical structural formula (I) in the specification, wherein the number-average molecular weight of the compounds A is 80000-100000. In the chemical structural formula (I), Ar is disclosed as one of the structural formulae in the specification. The polyimide filter membrane provided by the invention has the advantages of small pore size and high entrapment rate for fine particles in air. The polyimide filter membrane material has the characteristics of high compactness and smooth surface; and the formed fibers can not easily shed and have favorable stability. Besides, the polyimide filter membrane is low in cost, and is only less than one-fifth of the price of the same mass of commercially available sampled filter membrane.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

Preparation method of paper reinforced plant-based composite material

InactiveCN103481622BClear hierarchical structureAvoid surface damageLamination ancillary operationsSynthetic resin layered productsCelluloseSurface layer

The invention relates to a novel paper-reinforced plant-based composite material and a preparation method thereof. The composite material is composed of plants, paper, adhesives and polyurethane. The reinforcement method is to introduce the inner layer of paper reinforcement on the basis of polyurethane surface layer reinforcement. The source of paper reinforcement raw materials is convenient, which can realize the reuse of waste resources, and effectively improve the strength of composite materials, reduce hygroscopicity, and enhance water resistance. The structure of the composite material is more orderly and the composition is more diverse. The preparation method of the composite material in the present invention has simple raw material treatment, no dewaxing, no washing, no separate separation of cellulose, reduced separation steps, reduced dispersion of powder in the environment, and protected the health of on-site operators. Strong and easy to implement. The composite material of the present invention has wide applications, and can be used in the manufacture of furniture, toys, containers, automobile decoration parts, daily necessities, etc. instead of wood and plastics.

Owner:JIUJIANG UNIVERSITY

A multi-scale composite thermally reversible cross-linked porcelainable PVC material

The invention relates to a multi-scale composite thermally reversible cross-linked porcelainable PVC material. Raw materials include PVC, wollastonite, montmorillonite, talc powder, porcelain-forming additives, thermally reversible crosslinking agents and other additives; the particle size of the montmorillonite, talc, wollastonite and porcelain-forming additives There is a gradient difference. The nano-montmorillonite of the present invention has good reinforcing and sintering-assisting effects; wollastonite plays a good skeleton supporting role in the sintering process of PVC; Torque and friction, improve the mixing efficiency and reduce the requirements on the twin-screw equipment and wear on the equipment; the gradient change of particle size between different fillers can make the small particle size filler fill the gap formed by the large particle size filler Among them, the "filling" effect formed between the various fillers can effectively reduce the melt index of the PVC melt after filling, so that the extrusion process of porcelainable PVC is easier to control, and the surface of the material is smoother and has fewer defects.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +2

Organic Li-based bentonite-WPU (waterborne polyurethane) leather finishing agent and preparation method thereof

InactiveCN102251400BImprove surface microenvironmentImprove wettabilityFibre treatmentPigment treatment with organosilicon compoundsIn situ polymerizationWater vapor permeability

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com