W-Ni-Cu gradient material and preparation method thereof

A gradient material, w-ni-cu technology, applied in the field of gradient materials and its preparation, can solve the problems of gradient layer pores, many cavities, difficulty in preparing gradient materials, complex process conditions, etc., and the thickness of the gradient layer can be controlled at will, The effect of short preparation time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

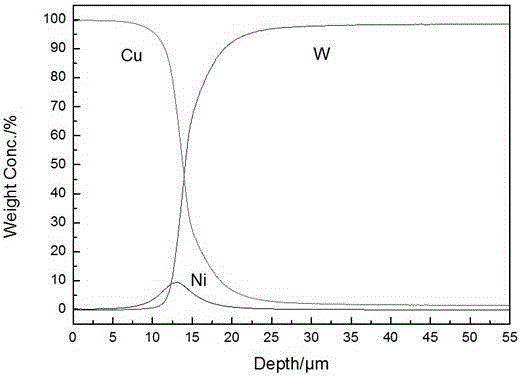

[0038] Embodiment 1: The specific production process of this W-Ni-Cu gradient material is as follows.

[0039] Put the NaCl-KCl-NaF-NiO molten salt system into a graphite crucible, put it into an electric furnace and heat it up to 700°C, and keep the temperature constant for 40 minutes; put the cathode W plate (20×20×2mm) and the anode Ni plate (20×20×2mm ) into the molten NaCl-KCl-NaF-NiO molten salt at the same time, applying a DC pulse current with a current density of 50mA·cm -2 At this time, after electrodeposition at 700°C for 10 minutes, take out the cathode material from the molten NaCl-KCl-NaF-NiO molten salt system, put it into boiling water and cook for 10 minutes, so that there is no obvious molten salt attachment on the W plate substrate, and then use Rinse the sample with deionized water and alcohol to obtain the W-Ni gradient material. CuSO 4 ·5H 2 O, CuCl 2 、H 2 SO 4 Put the mixed reagent into a glass container, add distilled water, dissolve at room tempe...

Embodiment 2

[0041] Embodiment 2: The specific production process of this W-Ni-Cu gradient material is as follows.

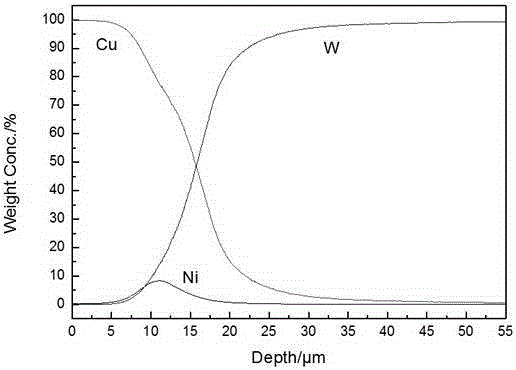

[0042] Put the NaCl-KCl-NaF-NiO molten salt system into a graphite crucible, put it into an electric furnace and heat it up to 750°C, and keep the temperature constant for 60 minutes; put the cathode W plate (20×20×2mm) and the anode Ni plate (20×20×2mm ) into the molten NaCl-KCl-NaF-NiO molten salt at the same time, applying a DC pulse current with a current density of 70mA cm -2 At this time, after electrodeposition at 750°C for 20 minutes, the cathode material was taken out from the molten NaCl-KCl-NaF-NiO molten salt system, put into boiling water and boiled for 20 minutes, so that there was no obvious molten salt attachment on the W board substrate, and then used Rinse the sample with deionized water and alcohol to obtain the W-Ni gradient material. CuSO 4 ·5H 2 O, CuCl 2 、H 2 SO 4 Put the mixed reagent into a glass container, add distilled water, dissolve at room...

Embodiment 3

[0044] Embodiment 3: The specific production process of this W-Ni-Cu gradient material is as follows.

[0045] Put the NaCl-KCl-NaF-NiO molten salt system into a graphite crucible, put it into an electric furnace and heat it up to 800°C, and keep the temperature constant for 80min; put the cathode W plate (20×20×2mm) and the anode Ni plate (20×20×2mm ) into the molten NaCl-KCl-NaF-NiO molten salt at the same time, applying a DC pulse current with a current density of 100mA·cm -2 After electrodeposition at 800°C for 30 minutes, the cathode material was taken out from the molten NaCl-KCl-NaF-NiO molten salt system, put into boiling water and boiled for 30 minutes, so that there was no obvious molten salt attachment on the W board substrate, and then used Rinse the sample with ion water and alcohol to obtain W-Ni gradient material. CuSO 4 ·5H 2 O, CuCl 2 、H 2 SO 4 Put the mixed reagent into a glass container, add distilled water, dissolve at room temperature, and let it sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com