Nanometer paper material and preparation method thereof

A nano-paper and polymer technology, applied in the field of nano-paper materials, can solve problems such as low efficiency, difficulty in controlling the thickness, density and surface morphology of nano-paper, and difficulty in large-scale production, achieving high strength and reproducible product quality Good performance and easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

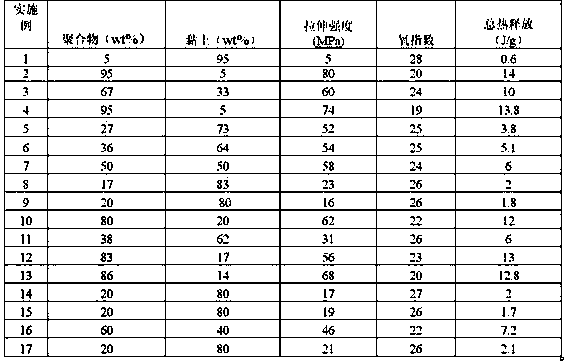

Examples

Embodiment 1

[0024] Firstly, 0.8 g of polyvinyl alcohol (Mw 31,000~50,000, degree of alcoholysis 99%) was heated and dissolved in 100 mL of deionized water, and 15 g of montmorillonite was added and stirred at high speed until it became a homogeneous colloid. The product was stored at -78 °C (dry ice ethanol bath) was quickly frozen until the ice crystals grew completely, then vacuum freeze-dried at room temperature until completely dry, and finally the obtained low-density material was pressed into nanopaper with a pressure of 40 MPa.

Embodiment 2

[0026] First, add 1 g of montmorillonite into 100 mL of deionized water, stir at high speed until it becomes a uniform suspension, then heat and dissolve 20 g of polyvinyl alcohol (Mw 31,000~50,000, degree of alcoholysis 99%) into the above suspension, and dissolve The product was quickly frozen at -78 °C (dry ice ethanol bath) until the ice crystals grew completely, then vacuum freeze-dried at room temperature until completely dry, and finally the resulting low-density material was pressed into nanopaper with a pressure of 40 MPa.

Embodiment 3

[0028] Firstly, 10 g of polyvinyl alcohol (Mw 31,000~50,000, degree of alcoholysis 99%) was heated and dissolved in 100 mL of deionized water, and 5 g of cumulated clay was added and stirred at high speed until it became a homogeneous colloid. The product was stored at -78 °C (dry ice ethanol bath) was quickly frozen until the ice crystals grew completely, then vacuum freeze-dried at room temperature until completely dry, and finally the obtained low-density material was pressed into nanopaper with a pressure of 40 MPa. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com