Ethylene-ethylene acetate copolymer (EVA) refrigerator door seal particle and preparation method thereof

A technology of ethylene acetate and copolymer, which is applied in the field of magnetic door seal particles, can solve the problems of low welding corner tension, poor sealing performance, and corrosion of equipment, and achieve the effects of large welding corner tension, good heat preservation effect, and good sealing performance

Pending Publication Date: 2022-03-01

上海新上化高分子材料有限公司

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the general soft PVC material is limited by the characteristics of its own material, and has the following problems: (1) not environmentally friendly; (2) poor elasticity; (3) corrosion of equipment

[0004] The invention solves the problems of non-environmental protection, poor elasticity, oil leakage, low pulling force of welding corners and poor sealing performance existing in the refrigerator door seal materials currently on the market.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

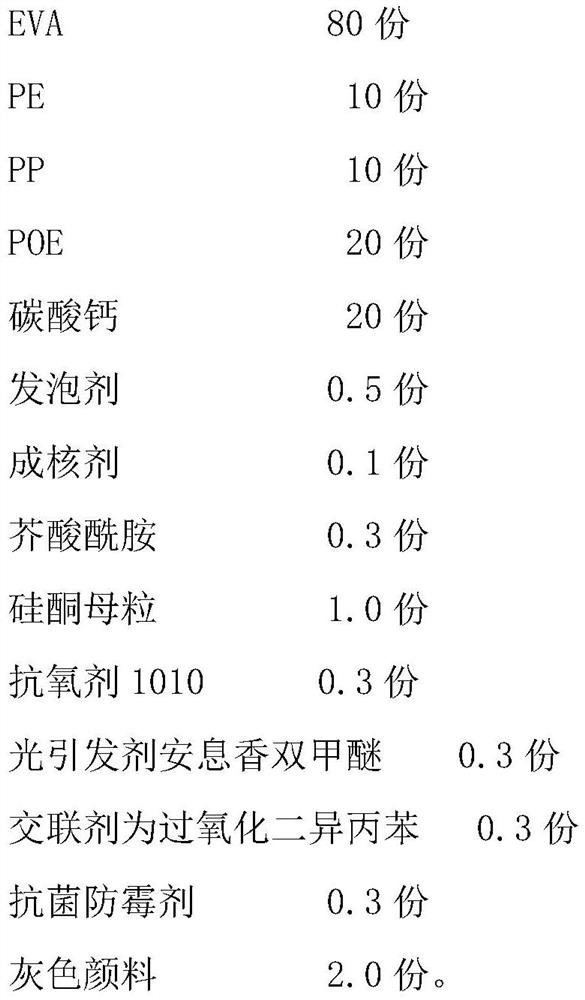

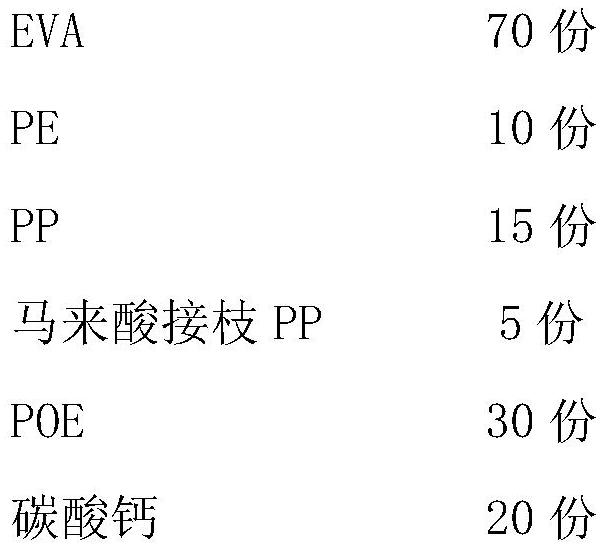

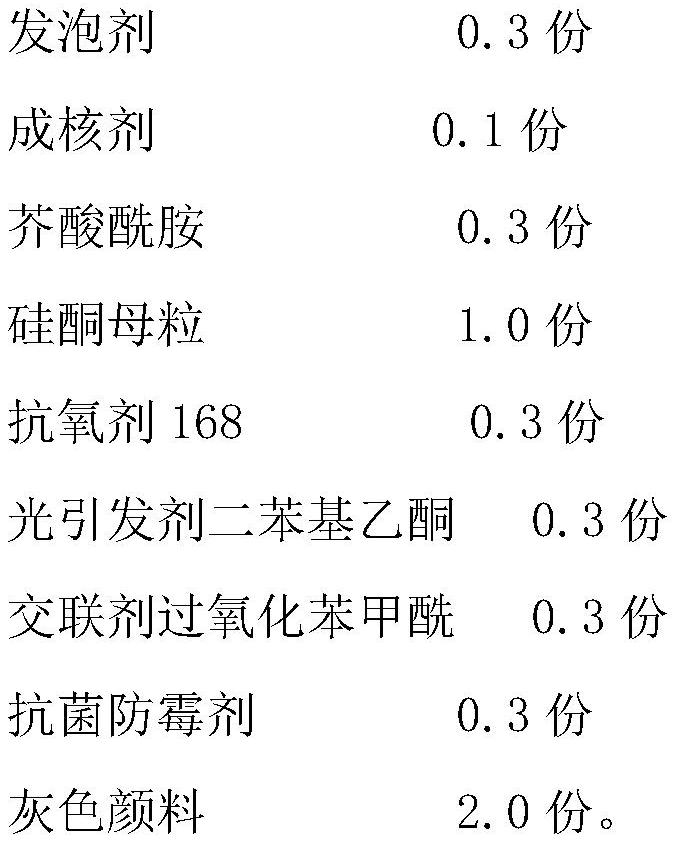

The invention discloses an ethylene-ethylene-vinyl acetate copolymer (EVA) refrigerator door seal particle which is composed of an EVA, polyethylene (PE), modified polyethylene, polypropylene (PP), modified polypropylene, an ethylene-olefin copolymer (POE), a mineral filler, a foaming agent, a nucleating agent, a lubricant, an antioxidant, a photoinitiator, a cross-linking agent, an antibacterial and mildew-proof agent, a pigment and the like. The invention further discloses a preparation method of the micro-foaming type EVA refrigerator door seal particles capable of being directly extruded. The preparation method comprises the steps of weighing, grinding, pre-crosslinking, mixing, banburying and extruding granulation. The material is ground and pre-crosslinked, and the foaming agent and the nucleating agent are added, so that when the material is used for producing the refrigerator door sealing strip, direct extrusion molding can be realized, high-temperature vulcanization and mold pressurization are not needed, and the micro-foaming refrigerator door sealing material can be prepared. The product is smooth in surface, contains a large number of microbubbles in the middle, and is high in material tearing strength, large in weld fillet tension, good in rebound resilience, resistant to low temperature, resistant to aging, good in sealing performance and good in heat preservation effect.

Description

technical field [0001] The invention belongs to the technical field of magnetic door seal particles for refrigerators, freezers and other electrical appliances, and in particular relates to a preparation method for directly extruding microfoamed ethylene-ethylene acetic acid copolymer EVA refrigerator door seal particles. Background technique [0002] The refrigerator door seal is a kind of refrigerator accessory used to seal between the refrigerator door and the cabinet, and also plays a role in heat preservation. The quality of its sealing and heat insulation effects directly affects the performance and energy consumption of the refrigerator. At present, most of the usual refrigerator door seals are made of soft PVC material or TPE material. However, the general soft PVC material is limited by the characteristics of its own material, and has the following problems: (1) not environmentally friendly; (2) poor elasticity; (3) corrosion of equipment. For TPE materials based o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/08C08L23/06C08L23/12C08L51/06C08K3/26C08J9/10C08J9/00

CPCC08J9/102C08J9/0095C08J9/0066C08J2323/08C08J2423/06C08J2423/12C08J2423/08C08J2451/06C08J2203/04C08K2003/265

Inventor 麻孝勇王芹陆帅羽唐艳芳徐永卫

Owner 上海新上化高分子材料有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com