Polyimide filter membrane, and preparation method and application thereof

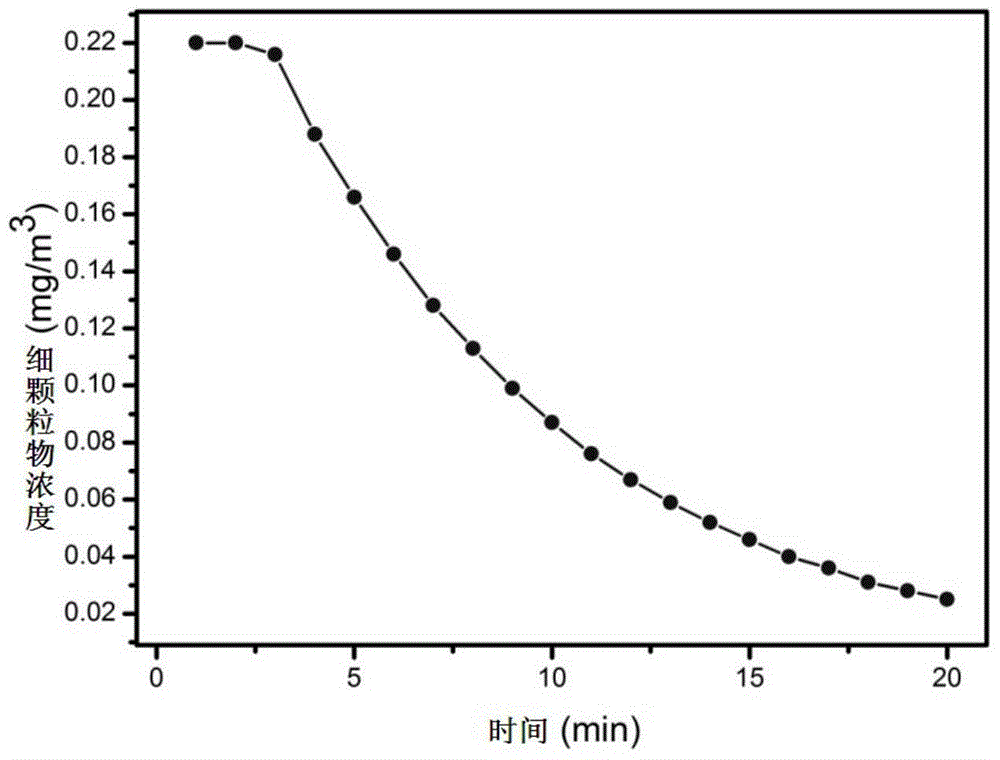

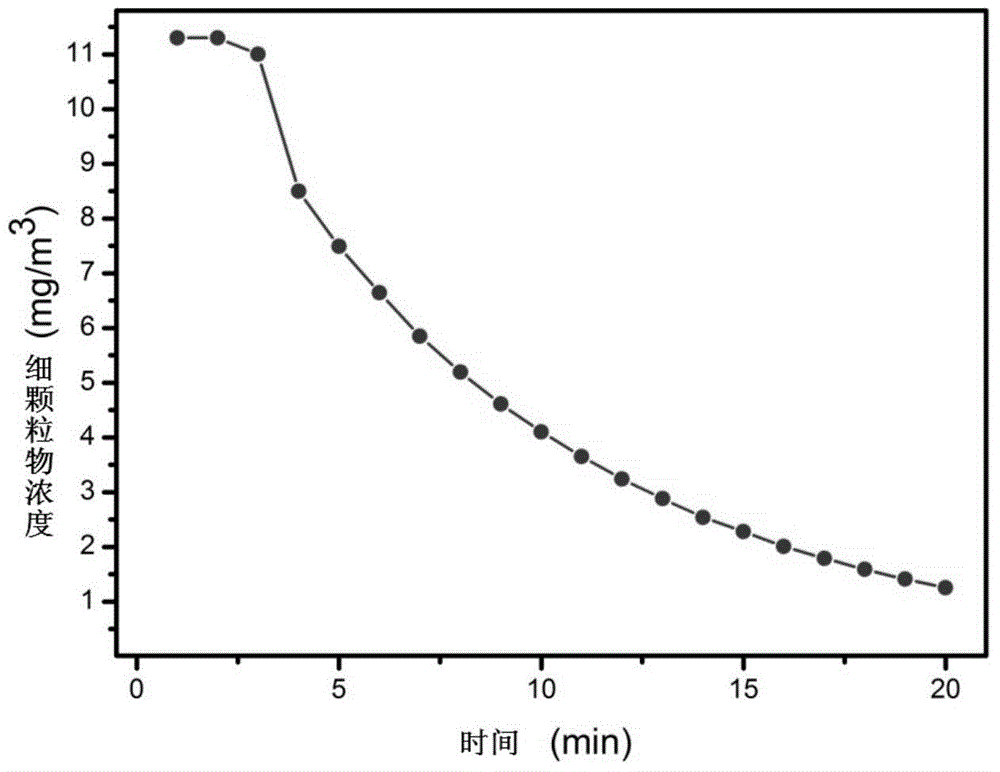

A polyimide, filter membrane technology, applied in separation methods, chemical instruments and methods, membrane technology and other directions, can solve the problems of high retention rate of fine particle pollutants, small pore size, fiber shedding, etc., and achieve smooth material surface, The effect of dense structure and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Correspondingly, the embodiment of the present invention also provides a method for preparing a polyimide filter membrane, comprising the following steps:

[0034] S01. Compound B and Compound C shown in the following chemical structural formulas (II) and (III) are provided respectively:

[0035]

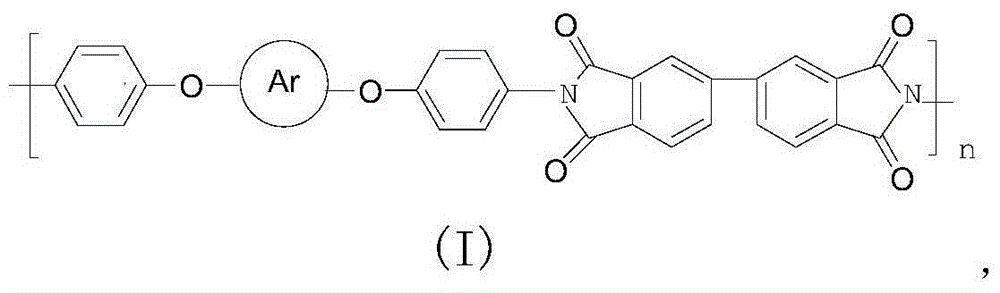

[0036] S02. Under an inert environment, the compound B and the compound C are heated and polymerized in an organic solvent to obtain a compound A polyimide, and the number average molecular weight of the compound A is 80000-100000, and the reaction formula is as follows:

[0037]

[0038] S03. Prepare a polyimide filter membrane from the polyimide by electrospinning,

[0039] Among them, the for One of the structural formulas.

[0040] Specifically, in the above step S01, the compound B and compound C can be obtained by self-preparation or commercial purchase. Preferably, the compound B is obtained by self-preparation. Specifically, the compound B is prepared by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com