Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Silky touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

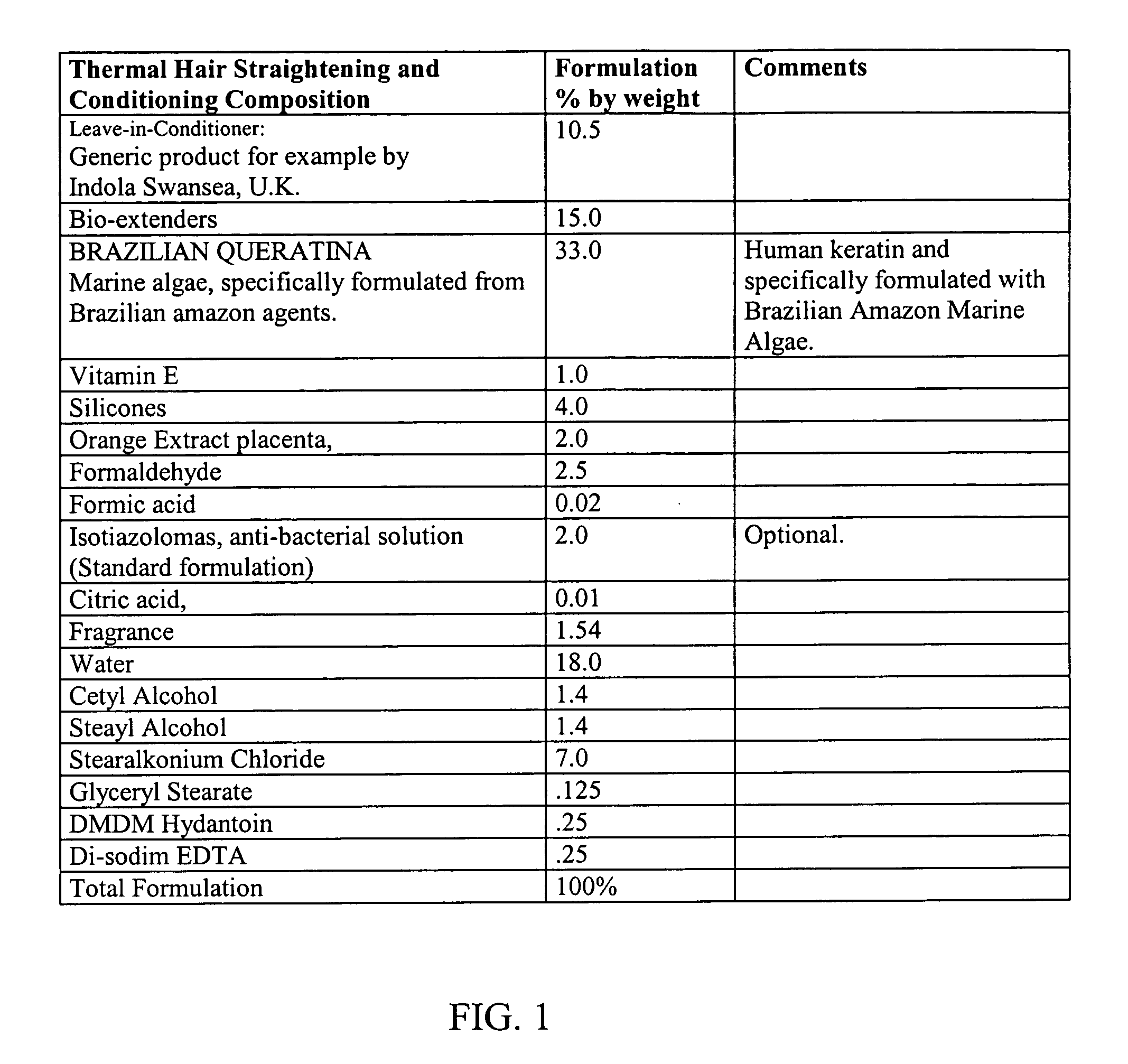

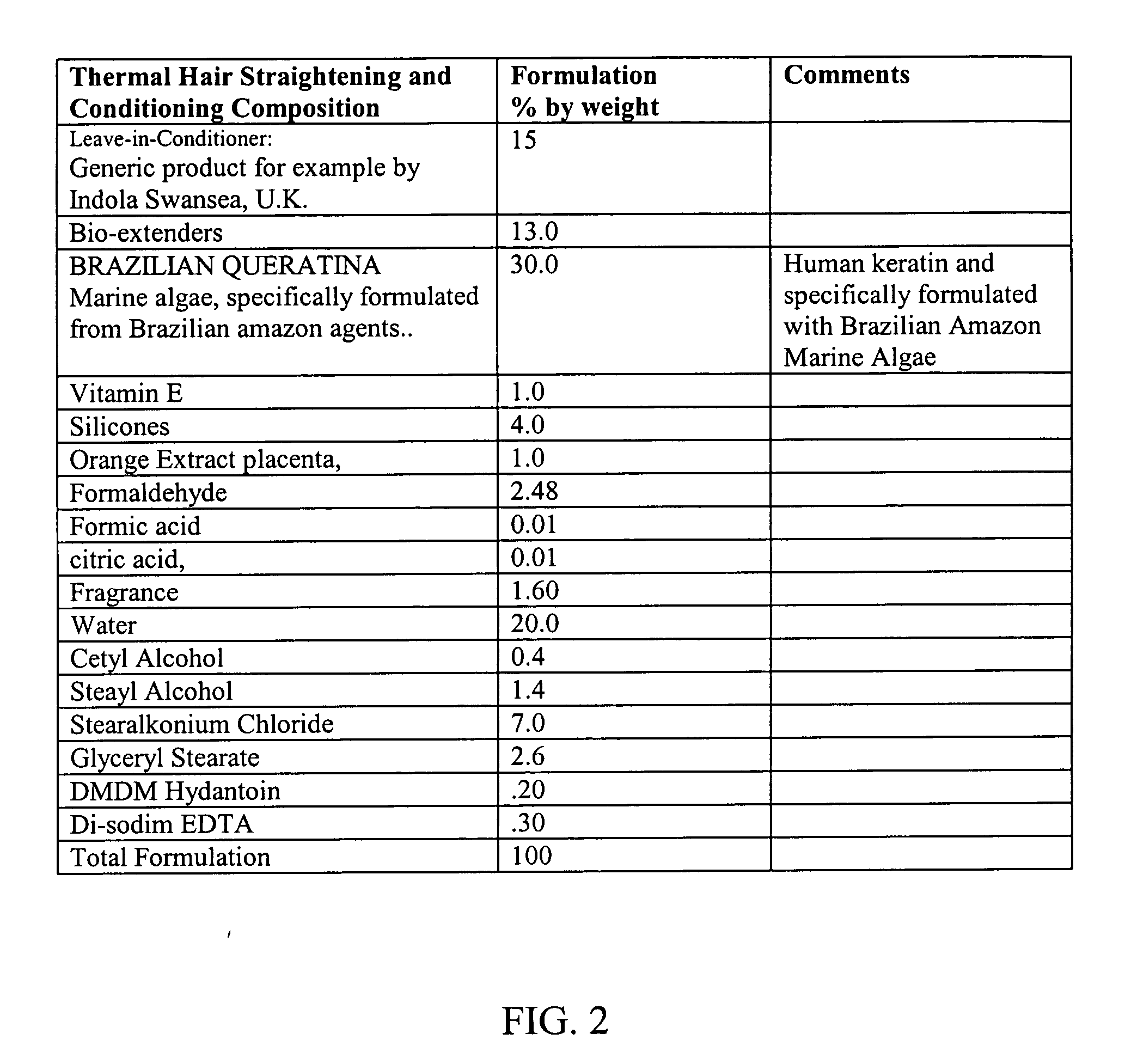

Thermal hair straightening and conditioning composition

InactiveUS20060104928A1Minimize static chargeMinimize tanglingCosmetic preparationsHair cosmeticsHair straighteningAmino acid

A thermal hair straightening and conditioning composition and method for rendering hair more manageable, minimizing static charge, tangling, and scattering of the hair is disclosed. A gelatinous aqueous thermal hair straightening and conditioning composition is provided that imparts a firm and silky look and feel to hair and inhibits wind and motion induced hair scattering during use. The composition comprises amino acids of human hair keratin, bio-extenders, oligo elements of marine algae, vitamin-E, silicones with orange extract placenta, formaldehyde, water, formic acid, isotiazolomas, citric acid, and fragrance. The hair straightener and conditioner composition of the invention preferably is used during hot iron and after hot iron straightening of curly hair, to impart a smooth and silky feel to the hair.

Owner:FURTADO LUCIMAR

Refreshing and moistening cream

InactiveCN107582478ARefreshing textureSilky touchCosmetic preparationsToilet preparationsCholesterolIsononyl Isononanoate

The invention provides a refreshing and moistening cream having refreshing texture and soft and smooth touch sense and making skin younger and brighter. The refreshing and moistening cream comprises the following components: cyclopentasiloxane; glycerol; isononyl isononanoate; propylene glycol; 1,2-pentanediol; ethanol; betaine; an ammonium acryloyldimethyltaurate / VP copolymer; a mixture of components of ceramide 3, ceramide 6 II, ceramide 1, phytosphingosine, cholesterol, sodium lauroyl lactylate, carbomer and xanthan gum; octyl polymethyl siloxane; hydroxyethyl urea; polydimethylsiloxane; sodium hyaluronate; hydrolytic sodium hyaluronate; glyceryl stearate citrate; nicotinamide; cyclopentasiloxane or dimethiconol; tocopherol acetate; methyl hydroxybenzoate; an acrylic acid (acrylate) / C10-30 alkanol acrylate cross-linked polymer; aminomethyl propanol; a mixture of glycerol stearate and PEG-100 stearate; a daily chemical fragrance compound and the like.

Owner:蝶柔化妆品(浙江)有限公司

Odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and preparation method thereof

The invention belongs to the field of coatings and particularly relates to an odorless and wear-resisting smooth UV (ultraviolet) matt finish paint coating and a preparation method thereof. The odorless and wear-resisting smooth UV matt finish paint coating comprises components in percentage by weight as follows: 25%-50% of hexa-functional polyurethane acrylate prepolymers, 15%-50% of trifunctional modified polyurethane acrylate prepolymers, 15%-50% of acrylate monomers, 1%-10% of a photoinitiator, 0.2%-2% of a wetting dispersant, 0.2%-1% of a leveling agent, 0.2%-0.5% of a defoaming agent and 1%-15% of a matting agent. According to the odorless and wear-resisting smooth UV matt finish paint coating, the technical problems that a pungent smell is left, wetting of the matting agent is difficult, matting is difficult, a paint film is prone to floating and the like after curing of a conventional UV matt finish paint coating are solved, and meanwhile, the defect of crispness of the paint film caused by improvement of the wear resistance of the conventional UV matt finish paint coating is overcome.

Owner:AODA KOALA PAINT HUIZHOU

Ultraviolet light solidified wear resistant lacquer in use for coating layer on surface of dense board plastes

InactiveCN1696225AImprove performanceSoft matte finishPolyurea/polyurethane coatingsMethacrylateHigh density

An ultraviolet solidified antiwear paint for the surface of high-density board with hot-pressed surficial paper layer contains proportionally acrylate (or methylacrylate) modified amino resin, polyurethane acrylate or polyurethane methylacrylate, epoxy acrylate or epoxy methyl acrylate, acrylate or methylacrylate, optical trigger, antiwear inorganic powder and dulling powder.

Owner:湖南亚大新材料科技股份有限公司

High skin-attaching-performance crystal facial mask spunlaced non-woven fabric and processing method thereof

InactiveCN104762750AImprove water absorptionGood moisture absorption and release functionNon-woven fabricsFiberPunching

The invention discloses high skin-attaching-performance crystal facial mask spunlaced non-woven fabric and a processing method thereof. Copper ammonia fibers and silk serve as raw materials, and the non-woven fabric is formed by pre-mixing and entangling the copper ammonia fibers and the silk in a disorder mode through a cotton mixing machine according to the mass ratio of 9:1. The method includes the following steps that firstly, the copper ammonia fibers and the silk are weighed according to the mass ratio of 9:1; secondly, the copper ammonia fibers and the silk are mixed; thirdly, the mixed raw materials are opened, carded, lapped in a crossed mode and drafted to form an even net face; fourthly, pre-wetting is adopted, strengthening is conducted on platform spunlace, and the non-woven fabric is formed through punching; fifthly, the non-woven fabric enters a drying machine after being dehydrated, and winding, splitting and packaging are conducted. The manufactured spunlaced non-woven fabric product is soft, smooth and silky in touch and has the features of tenacity and fresh, a cross lapping spunlace technology is adopted so that the lengthwise and transverse strength ratio of the manufactured product reaches 1.3:1, deformation is avoided, softness and the high attachment degree are achieved, normal movement is achieved, displacement is avoided, and therefore the manufactured product has the advantages that lightness, thinness and transparency are achieved, and a crystal is invisible.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

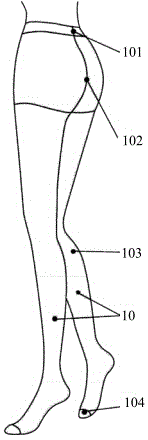

Composite snagging-resisting wear-resisting stretch yarn and silk stockings utilizing same

ActiveCN104532430AIncrease usage intensityImprove wear resistancePanty-hoseHosieryYarnPHENOLSULFONIC ACID

The invention discloses a composite snagging-resisting wear-resisting stretch yarn. The composite snagging-resisting wear-resisting stretch yarn comprises a plurality of high stretch yarns and a plurality of traction fibers, which are arranged in a quantity ratio of 5: (3-14), and a silk beam is coated with a film formed by drying sizing agent; the high stretch yarn is polyurethane high stretch yarn and comprises 5 to 15 percent by weight of phenolsulfonic acid and 5 to 25 percent of dyhydroxy phenyl sulfone. The composite stretch yarn is prepared by mixing a plurality of materials, so that the wear resistance is good; the external friction or snagging is resisted by utilizing Dacron low stretch yarn or polypropylene fiber low stretch yarn, the thorough fracturing difficultly occurs, the durability is good, and the prepared silk stockings are elastic and resistant to electrostatic, long in service life, high in cost performance, capable of giving different tightness to legs and capable of alleviating the fatigue of the legs and preventing varicosity; different sizes of the silk stockings can be provided according to different body forms, and the fitness of the silk stockings is maximized; the breathability is good, perspiration can volatize smoothly, and comfort in wearing can be realized; moreover, the silk stockings are smooth in surface, no silk end is exposed, and stocking toes, stocking heels and rip tops of the stockings are smooth.

Owner:浙江宝娜斯袜业有限公司

Film forming agent for leather garment

InactiveCN105400336ASilky touchExcellent frost resistance and bending resistanceWax coatingsPolyurea/polyurethane coatingsAfter treatmentEmulsion

The invention relates to a film forming agent for a leather garment. The film forming agent is applicable to real clothing leather and belongs to the field of leather finishing agents. The film forming agent comprises, by weight, 90 to 120 parts of coloring cream, 115 to 160 parts of acrylic resin, 30 to 50 parts of aliphatic bonding polyurethane, 80 to 125 parts of waterborne polyurethane resin, 50 to 75 parts of modified casein, 50 to 75 parts of waterborne wax emulsion, 5 to 10 parts of a feeling agent and 440 to 520 parts of distilled water. After treatment with the film forming agent for the leather garment, real clothing leather is not viscous at a high temperature, does not crack at a low temperature, has excellent resistance to freezing and flex, can withstand a low temperature of -20 DEG C, shows good elasticity, feels smooth on the surface and presents the sensation of real leather; the film forming agent is nontoxic, pollution-free, labor-saving, material-saving, cost-saving and easily-operable; and the raw materials of the film forming agent cooperate with each other, various performances of the raw materials are comprehensively combined, and optimal compounding effect is obtained.

Owner:GUANGZHOU DIFU KALE IMPORT & EXPORT TRADE CO LTD

Moisture-transfer and fast-drying wool knitted fabric and its making method

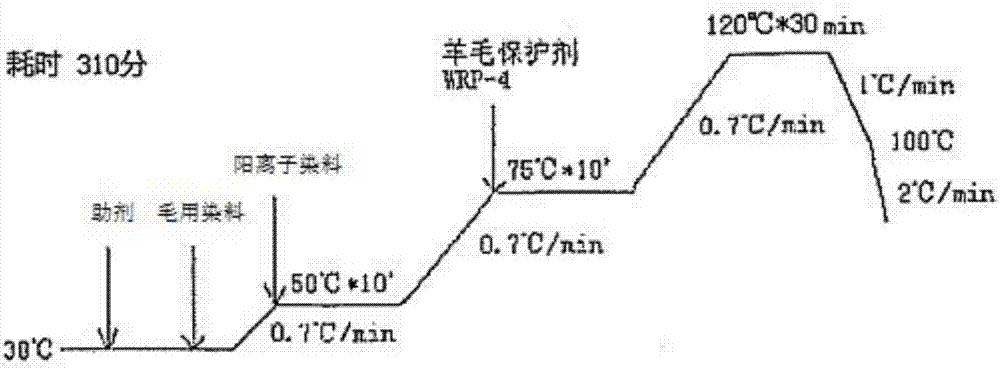

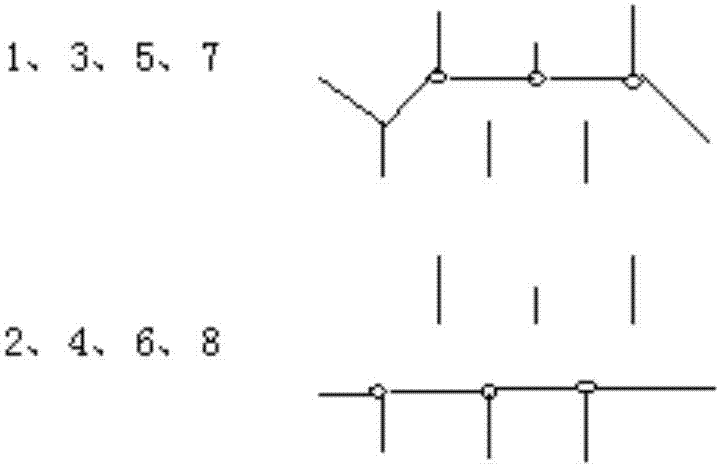

InactiveCN107574544ALarge specific surface areaHelp exportWeft knittingHeating/cooling textile fabricsYarnFiber

The invention relates to a moisture-transfer and fast-drying wool knitted fabric and its making method. The fabric is a double-side knitted fabric and includes a next-to-the-skin surface and a front surface; yarn used by the next-to-the-skin surface is fine-denier cation modified polyester fibers, and yarn used by the front surface is high-count wool and cation modified polyester fibers. The yarnis woven to obtain the fabric; water is injected in a dye vat, the fabric is soaked in water with the bath ratio of 1:20, an auxiliary agent and dye used for wool are then added, after the temperatureis kept for 10 min, the temperature is increased to 50 DEG C, cationic dye is added, the temperature is kept for 5-10 min and then increased to 75 DEG C, after a wool protection agent is added, the temperature is kept for 5-10 min and then increased to 120 DEG C, after the temperature is kept at 120 DEG C for 20-30 min, cooling is conducted, finally, a hydrophilic finishing agent is added, the temperature is increased to 40 DEG C for 10-20 min, and a dyed fabric is obtained; the dyed fabric is subjected to setting to obtain the moisture-transfer and fast-drying wool knitted fabric. The fabricis thin, delicate, smooth in hand feeling and comfortable to wear and has the moisture-transfer and fast-drying functions.

Owner:SHANGHAI CHALLENGE TEXTILE

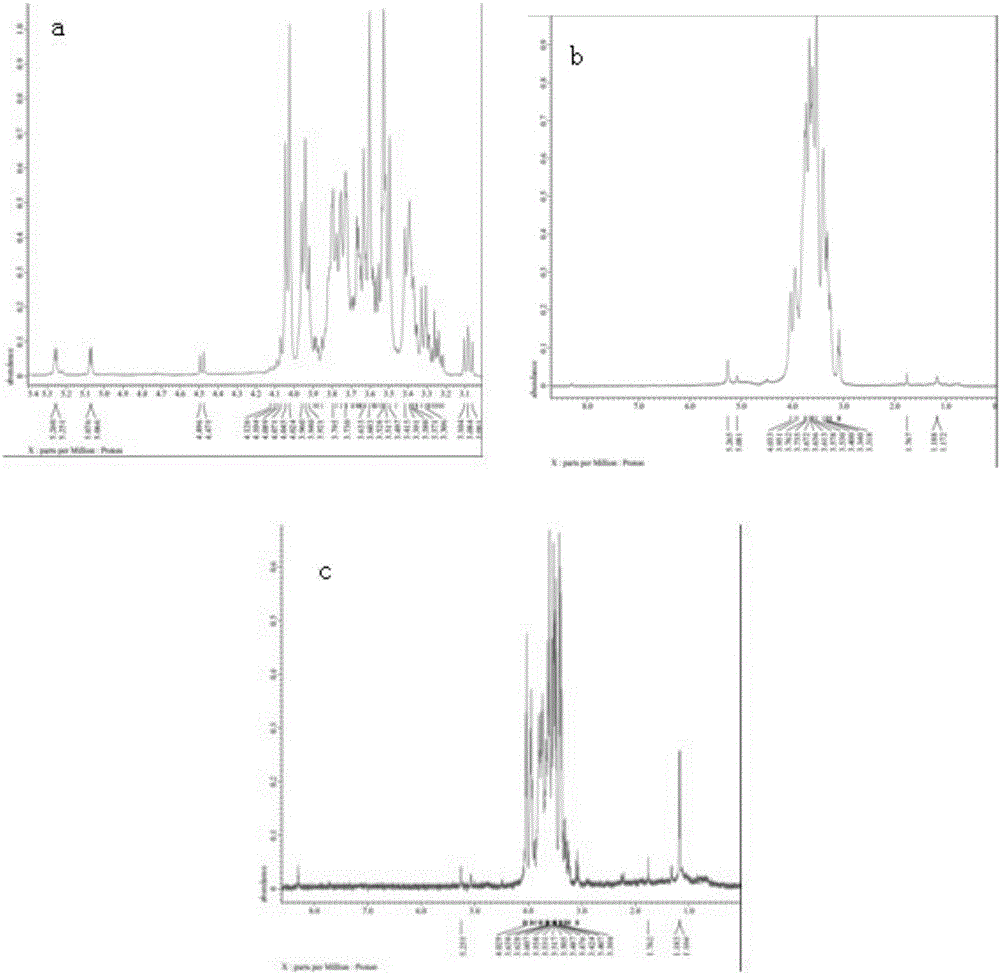

Bacillus amyloliquefaciens and preparation method of exopolysaccharides thereof

ActiveCN106520641ANon-irritatingAntigenicBacteriaMicroorganism based processesChromatographic separationBacillus amyloliquefaciens

The invention provides bacillus amyloliquefaciens EZ99. The bacillus amyloliquefaciens is gram positive bacteria, exists in plant rhizosphere soil, has no pathogenicity for people and plants, is collected from an orchard county, in the west of a Qilihe district in the Lanzhou city of the Gansu province, and has been identified, registered and preserved in the China common microorganism strain preservation center, and the preservation number is CGMCC No.13267. Component analysis is performed on bacterial colonies formed by the bacillus amyloliquefaciens on a PMA and MS culture medium, and it is found that the bacillus amyloliquefaciens has the characteristic of synthesizing and secreting exopolysaccharides. Optimal culture medium formulas and fermentation optimal conditions based on fermentation production of the exopolysaccharides of the strains are built, a fermentation solution is subjected to centrifuging, alcohol precipitation, dialysis and chromatographic separation, four purification polysaccharide components are obtained, and four-polysaccharide-component monosaccharide composition and monomer molecular weight are determined. The exopolysaccharides obtained through the strain and the method have the various applications of medicines, cosmetics, food additives, biological film raw materials and the like.

Owner:甘肃尚农生物科技有限公司

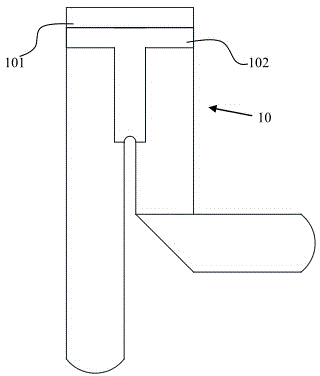

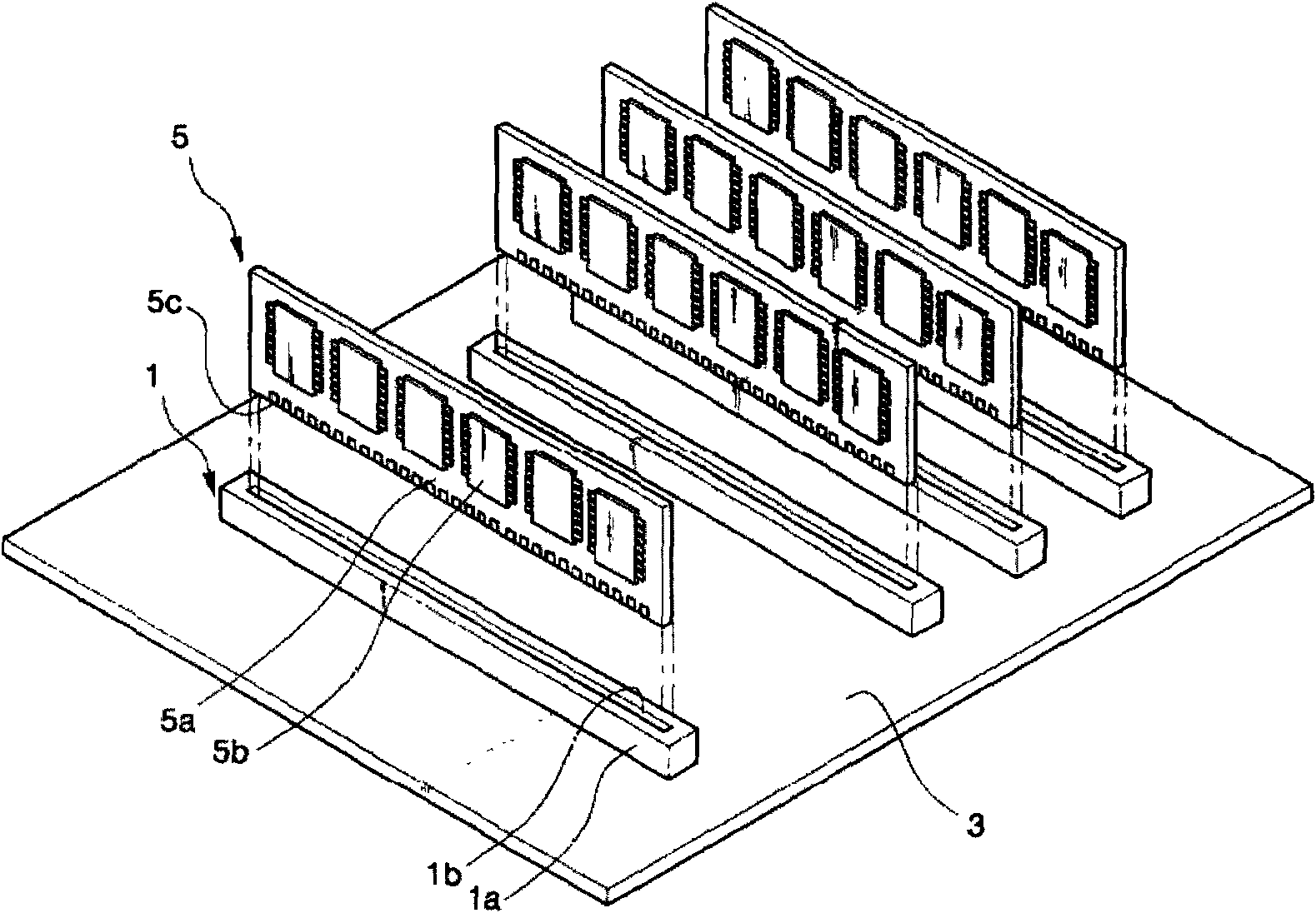

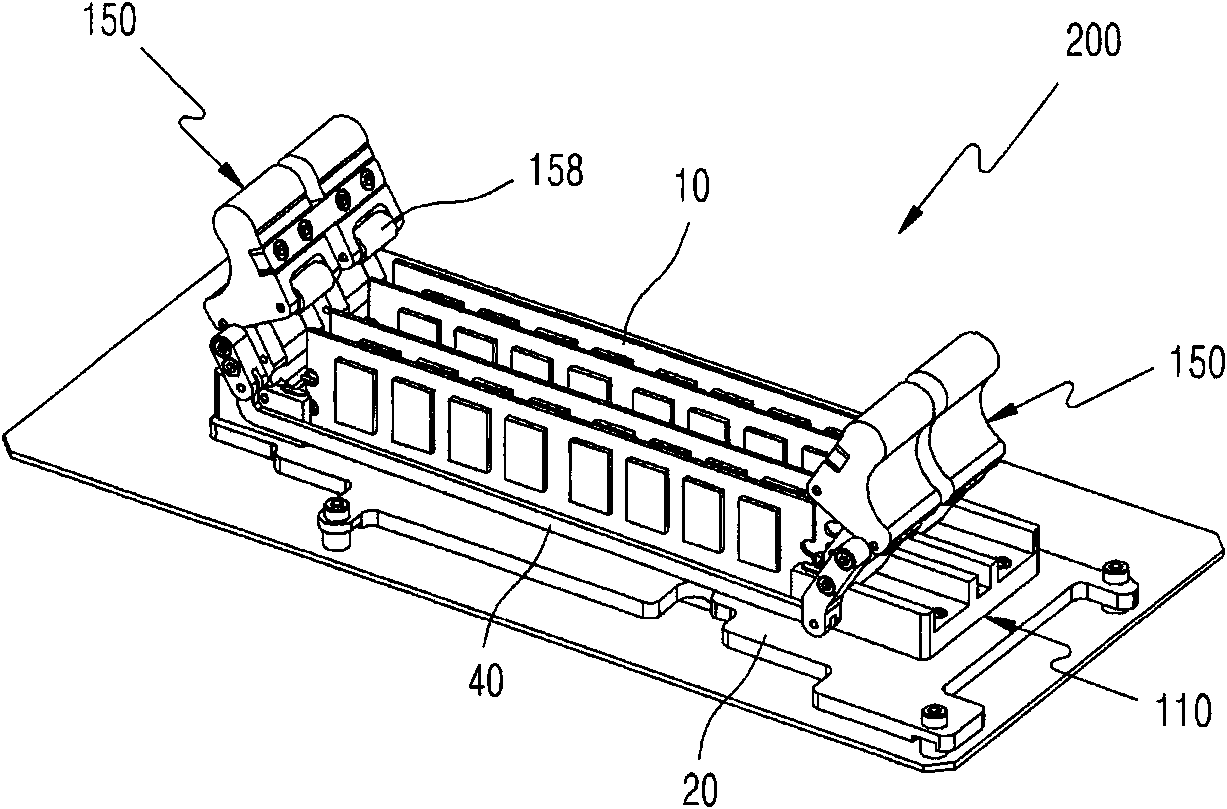

One-touch popping device of memory module test socket

ActiveCN101924299APrevent contact damageAvoid breakingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsEngineeringMemory module

The invention relates to a popping device which enables to insert or pull out a memory module from a clamp body made of a main board used for testing, so as to test the memory module and to install various memory modules with height difference in the computer assembling environment. Provided is a one-touch popping device which is provided with a memory module test socket at the upper end so as to avoid the interference among the components during the arrangement of the memory module on the clamp body and to successfully insert and pull out the memory module. In order to prevent the damage to the part which contacts with the memory module, the structure is improved, thereby enhancing the performance in inserting and pulling out the memory module and further enhancing the test yield as a result. In addition, the movement of inserting the memory module in and pulling the memory module out of the clamp body is completed by a physical force, so as to guarantee that the force applied each time is constant, thereby preventing the damage to the memory module.

Owner:MICRO CONTACT SOLUTION

Freckle-removing whitening VACE essence

InactiveCN108210362ATo promote metabolismPromote regenerationCosmetic preparationsToilet preparationsChemistrySkin complexion

The invention discloses a technical formula of a freckle-removing whitening VACE essence. The freckle-removing whitening VACE essence is mainly characterized in that 1) the main ingredients comprise retinyl palmitate (VA), ascorbyl tetraisopalmitate (VC), tocopheryl acetate (VE), canola oil, organosilicone, polydimethylsiloxane and other auxiliary ingredients; 2) the main ingredients are as follows in parts by weight: 0.1-10 parts of retinyl palmitate, 12-30 parts of ascorbyl tetraisopalmitate, 8-22 parts of tocopheryl acetate, 5-25 parts of canola oil, 1-20 parts of organosilicone, 1-20 partsof polydimethylsiloxane and 0.1-10 parts of other auxiliary ingredients. The freckle-removing whitening VACE essence has the advantages that the fat soluble ingredient VC and VA and VE essences whichare in high affinity with the skin are particularly adopted; on the basis that spots are faded, the allergy is prevented, the inflammation is eliminated and the dark matte skin is improved, the pollution of the external environment is deeply isolated, and the complexion is brightened. The organosilicone material is used as the auxiliary material, so that the essence is smooth and fresh, is good in spreadability, and is suitable for any skins, particularly the dry dark matte skin.

Owner:天津强微特生物科技有限公司

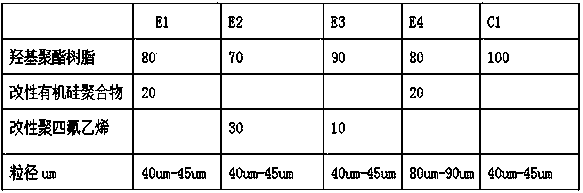

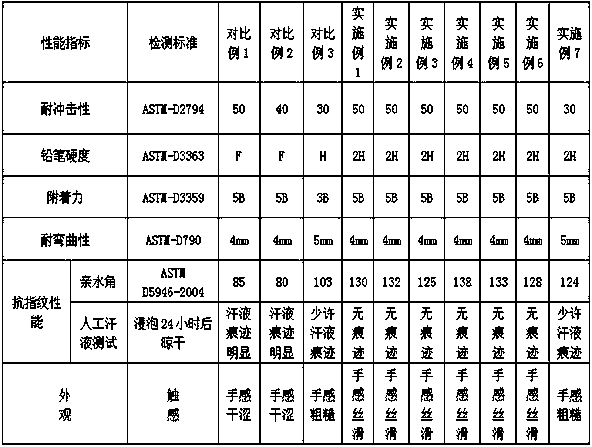

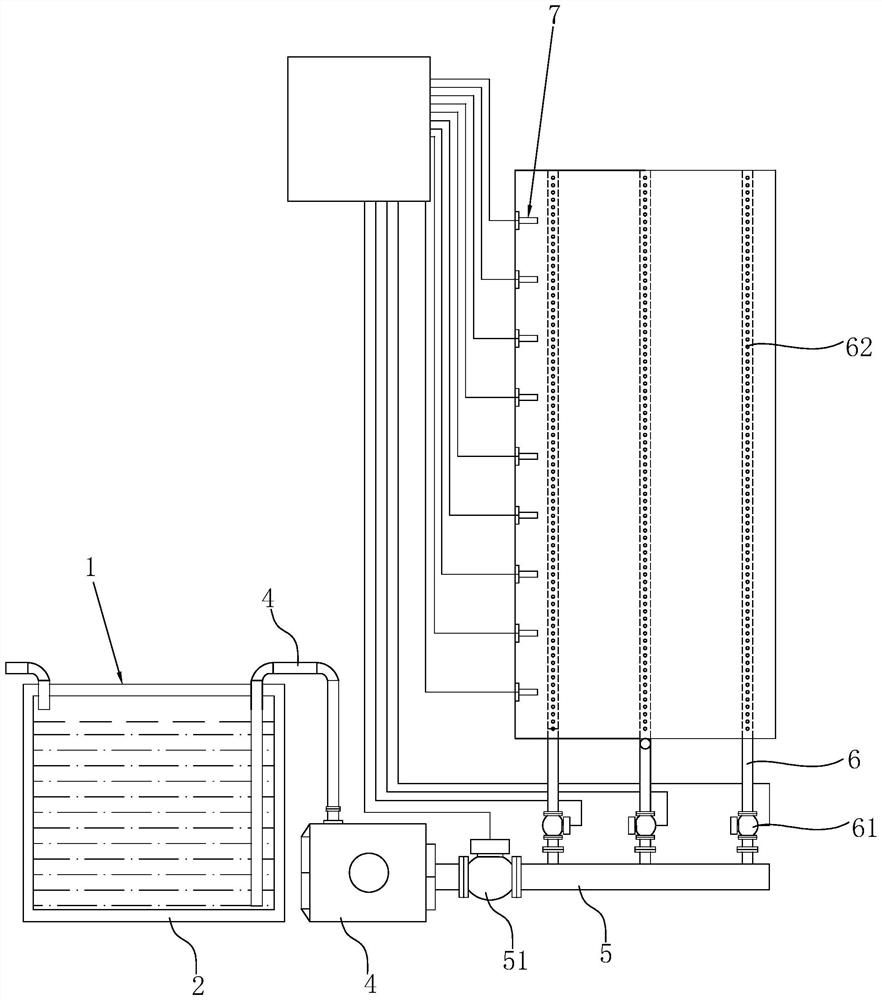

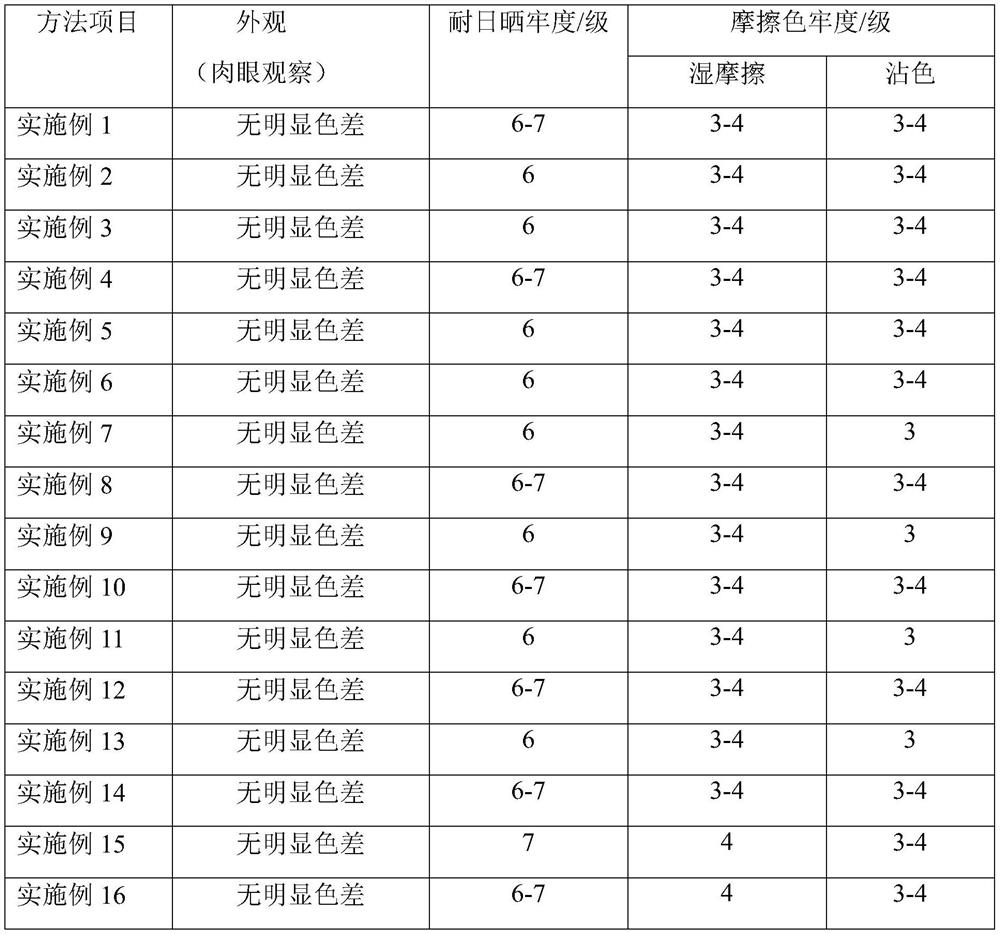

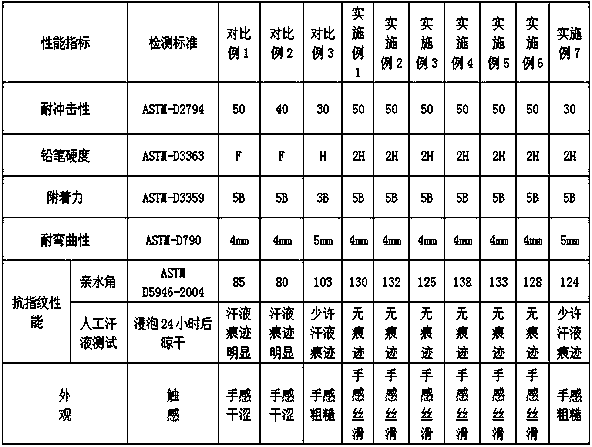

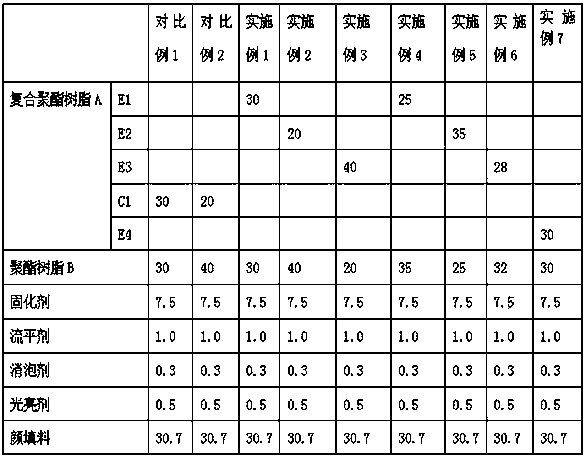

Anti-fingerprint powder coating and preparation method and application thereof

ActiveCN109082210AImprove anti-fingerprint performanceSilky feel goodPowdery paintsPolyester coatingsElectronic communicationPolyester resin

The invention discloses anti-fingerprint powder coating and a preparation method and application thereof. The anti-fingerprint powder coating is prepared from, by weight, 20-40 parts of composite polyester resin A, 30-50 parts of polyester resin B and 0-30 parts of other auxiliary agents. The preparation method includes: well mixing hydroxyl polyester resin and a composite material, subjecting tomelt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and crushing to obtain the composite polyester resin A; adding the composite polyester resin A, the polyesterresin B and other auxiliary agents into a premixing tank, well mixing, subjecting to melt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and finally crushing andgrading through a high-speed crusher to obtain powder in particle size of 33-38micron. By synergistic effects of the composite polyester resin A and the polyester resin B, a formed coating is easy toclean and remarkable in anti-fingerprint performance, automatic fingerprint clearing is realized, and the powder coating is silky and smooth to touch and especially suitable for terminal products including furniture, door and window accessories, decorative lamps, electronic communication equipment and the like and manifests high end and elegance of products.

Owner:广东歌丽斯化学有限公司

Anti-pilling finishing agent for wool fabrics

InactiveCN105839412ASoft touchSilky touchGrip property fibresAbrasion resistant fibresPolyethylene glycolMoisture absorption

The invention discloses an anti-pilling finishing agent for wool fabric, which is composed of the following raw materials in parts by weight: 3-6 parts of pure sodium lauryl sulfate, 2-6 parts of starch ether, 12-16 parts of natural saponin, polyoxyethylene 20‑24 parts of diamine, 6‑8 parts of glutamine, 2‑7 parts of borax, 5‑8 parts of fatty alcohol polyoxyethylene ether, 2‑6 parts of dispersant, 3‑6 parts of emulsifier, alkyl aryl 4‑8 parts of sodium sulfonate, 11‑14 parts of linolenic acid, 6‑8 parts of allyl glycidyl ether, 4‑9 parts of sophorolipids, 5‑8 parts of defoamer, 5‑8 parts of ethoxylated lauramide 12 parts, 20‑30 parts of deionized water. The cashmere sweater obtained by the wool fabric anti-pilling finishing agent of the present invention not only feels softer, but also has good anti-pilling effect, strong deodorizing ability and washable. Moreover, the woolen fabric prepared by the invention has a softer, silky, delicate hand feel and stronger moisture absorption capacity.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

Production method of eyebrow pencil refill

ActiveCN111000736ASilky touchOvercoming powdery foundationCosmetic preparationsMake-upProcess engineeringCaking

The invention belongs to the field of beauty, and particularly relates to a production method of an eyebrow pencil refill. The production method comprises the following steps: heating and mixing, grinding, baking, extruding, baking and freezing. The eyebrow pencil refill produced through the production method solves the technical problems of unnatural caking, poor oil resistance and poor water resistance of existing products in the using process. The maximum powder content of the refill can reach 70%, the refill is smooth, fin and skin-friendly in the using process, caking is avoided, and themakeup time on eyebrows is greatly prolonged.

Owner:苏州工业园区黛宜菲化妆品有限公司

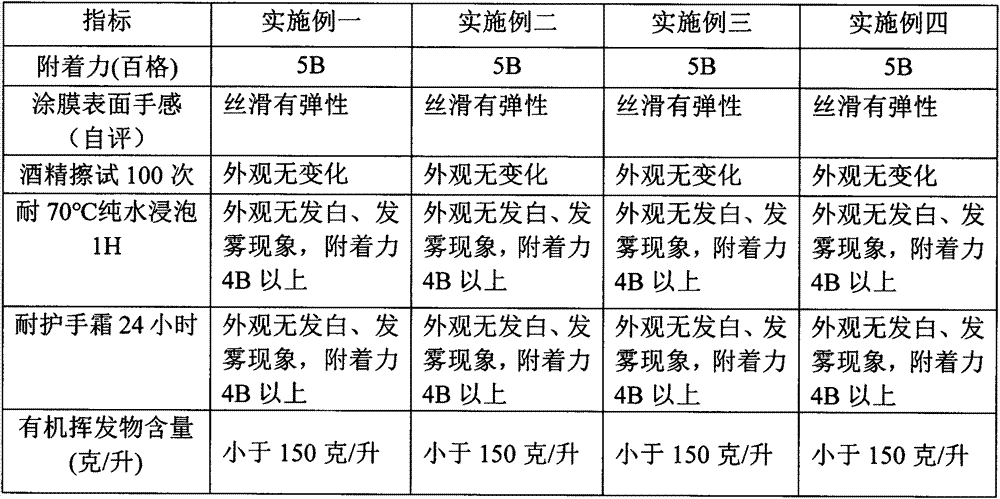

Water-based PU elastic coating and preparation method thereof

ActiveCN107502174AEmission reductionIncrease elasticityPolyurea/polyurethane coatingsEmulsion paintsWater basedWater dispersible

The invention discloses water-based PU elastic coating and a preparation method thereof. The water-based PU elastic coating comprises the following component substances: water-based polyester resin, water dispersible polycarbonate diol, a dispersing agent, extinction powder, a wetting agent, a leveling agent, an organic cosolvent, an anti-settling agent, polyurethane particles, an ammonium neutralizing agent and water dispersible isocyanate. The water-based PU elastic coating disclosed by the invention overcomes the defects of the prior art, VOC content of the water-based PU elastic coating is lower than 150g / L and is 60-70% lower than that of the traditional solvent PU elastic coating, pollutant discharge of an enterprise is reduced, after the water-based PU elastic coating is dried, surface of a film is smooth in handfeel, elasticity is better, the film has excellent water resistance, alcohol resistance and physical and chemical properties, and related detection standards of cosmetic coating are met.

Owner:东周化学工业(昆山)有限公司

Beautifying facial cream

InactiveCN109125238AFits without floating powderIncrease elasticityCosmetic preparationsToilet preparationsSkin complexionDimethyl siloxane

The invention discloses beautifying facial cream. The beautifying facial cream is characterized by being prepared from water, 1,3-propylene glycol, glycerin, cyclopentasiloxane, polydimethylsiloxane,nicotinamide, titanium dioxide, 1,2-hexanediol, 1,2-pentanediol, hydrogenated methyl abietate, sodium polyacryloyldimethyl taurate, polydimethylsiloxane / vinyl polydimethylsiloxane crosslinked polymerand the like. The beautifying facial cream has the cream texture, light herbal fragrance, can spread after one beat and touches soft and smooth; water moistures in the diamond cream can form water films on skin surfaces to be quickly absorbed; the cream can eliminate yellow complexion after being applied to the face, make the skin healthy and white, hide skin pores instantly, has light soft lightunder sunlight and increase the good complexion; the cream is fine and moist in texture, can avoid makeup dropping and powder blockage and create breathable fresh foundation, and skin becomes white after use and is natural and glossy like skin without makeup.

Owner:杭州王氏广告有限公司

Wedding dress fabric

The invention discloses a wedding dress fabric which comprises a chiffon fabric. The chiffon fabric comprises warps and wefts, the warps are made of plant fibers, the wefts are made of organza, the diameter of each plant fiber is 6.75 micrometers, the size of each plant fiber is 150dtex, the diameter of the organza is 14.65 micrometers, the size of the organza is 187dtex, the density of the warps is 12 yarns / cm, and the density of the warps is 14 yarns / cm. The made wedding dress fabric has the advantages of easiness in modeling, silky and elegant hand feeling and light texture.

Owner:常熟市碧溪新区吴市卓艺家纺厂

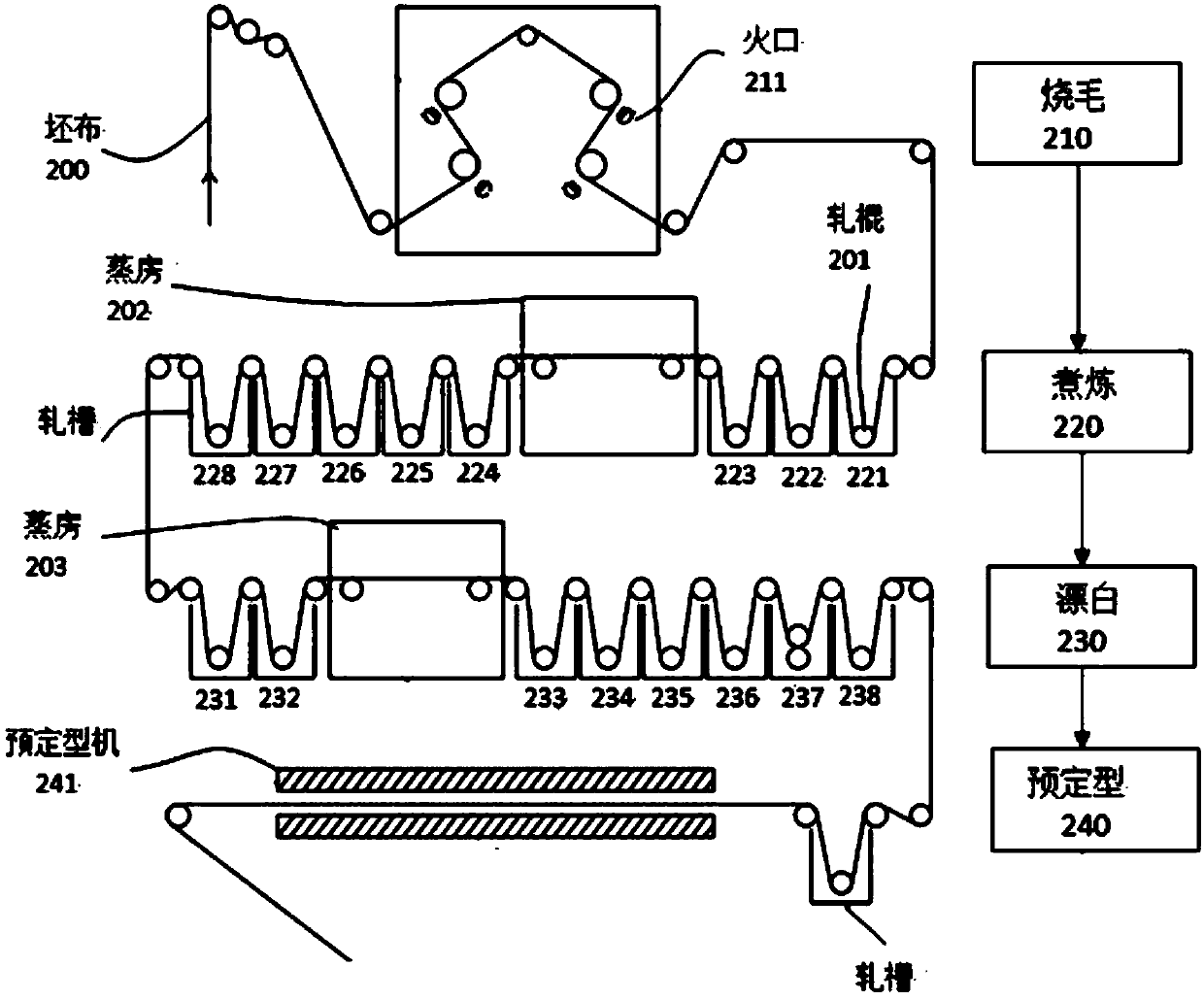

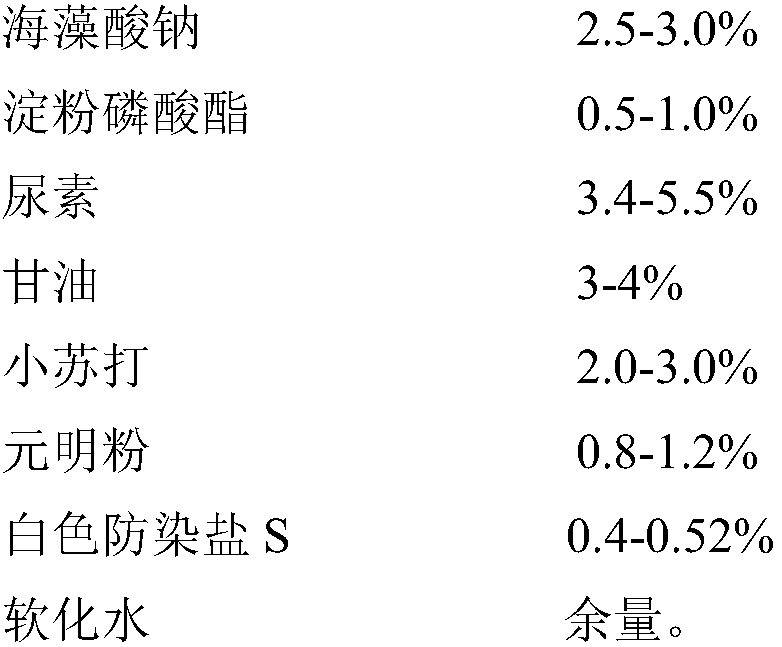

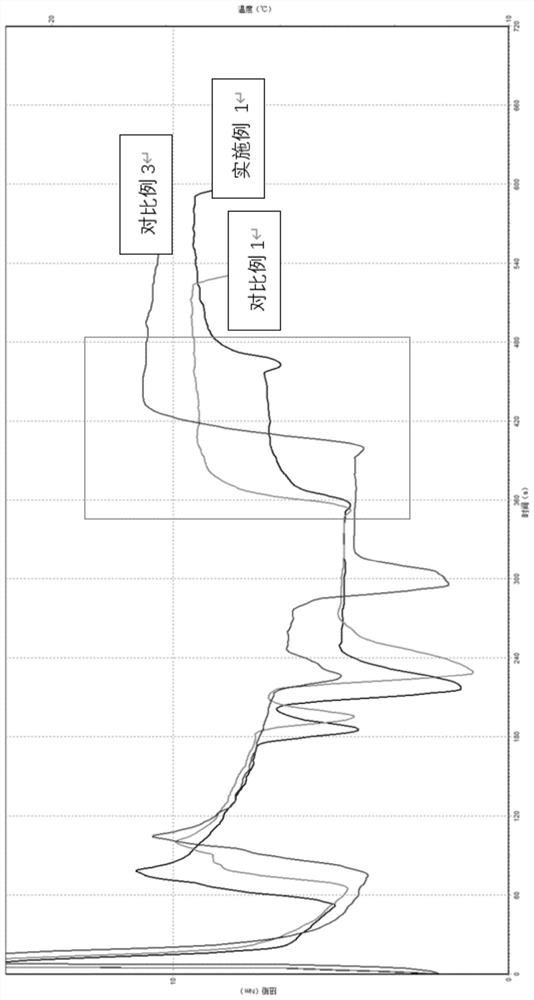

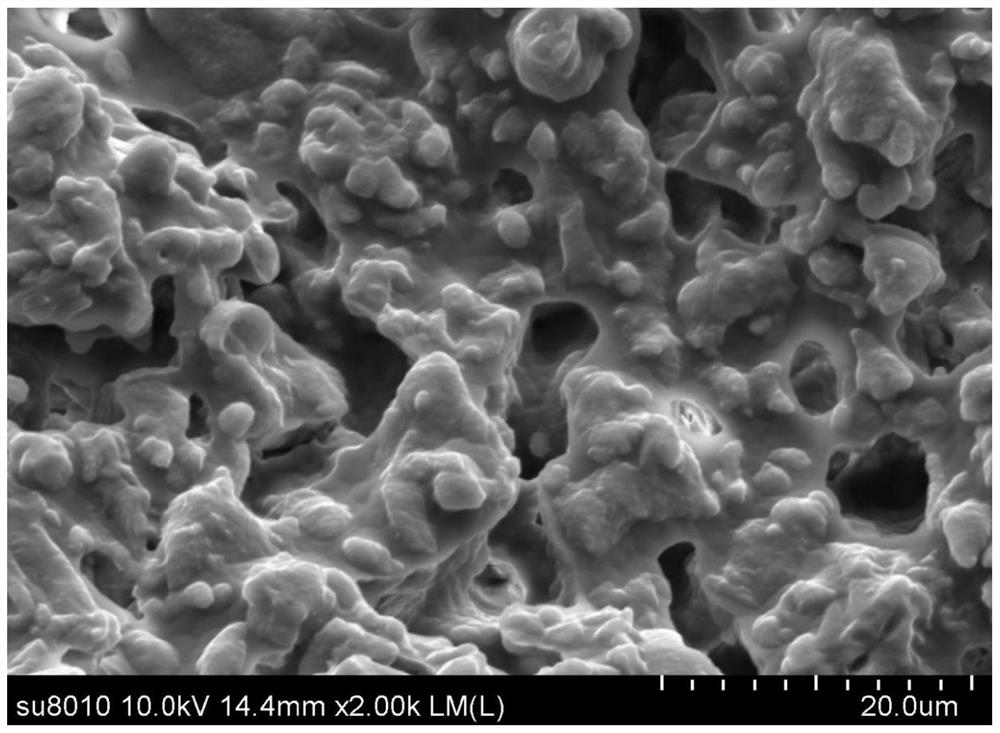

Pretreatment technology before digital printing of high-count cotton fabric

InactiveCN107761411AGood alkali resistanceAdapt to alkaline treatmentMercerising of indefinite length fabricsPhysical treatmentSlurryEngineering

The invention relates to a pretreatment technology before digital printing of high-count cotton fabric. Before digital printing, processes of singeing, ultrasonic boiling and bleaching, mercerizing, process of padding a slurry and preshaping are sequentially performed on gray fabric, and through formula optimization and technological optimization during boiling and bleaching as well as slurry padding, the fabric has a relatively good printing state before digital printing; the high-count cotton fabric treated by the pretreatment technology provided by the invention not only keeps smooth and soft surface properties of the high-count cotton and the like, but also is endowed with relatively high cleanliness, whiteness, dye affinity and the like, so that a guarantee is provided for high-precision digital printing, and the printed fabric is exquisite in pattern and high in color and luster.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

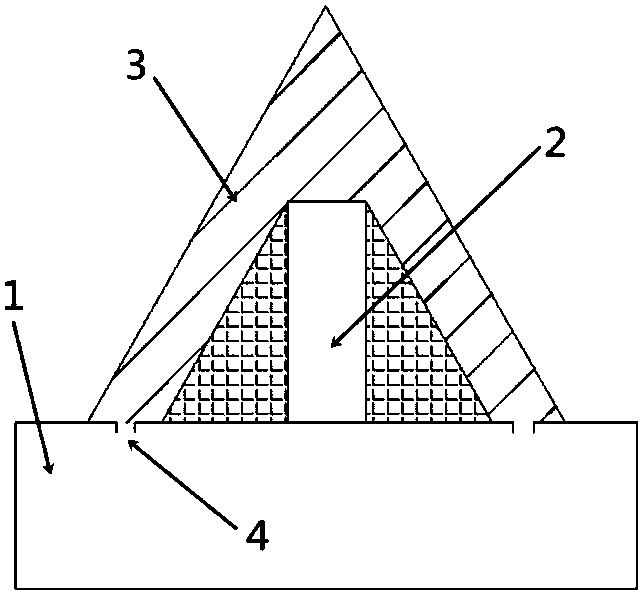

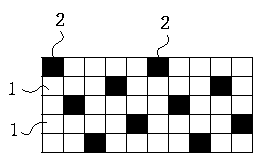

Smooth and high-hone-finished PVC decorative film capable of resisting scratch and smudginess, and preparation method of decorative film

InactiveCN104960299ASilky touchImprove scratch resistanceSynthetic resin layered productsLaminationEngineeringCoating

The invention relates to the technical field of decorative films and preparation methods thereof and in particular relates to a smooth and high-hone-finished PVC decorative film capable of resisting scratch and smudginess, and a preparation method of the decorative film. The decorative film comprises a touching coating (2), a base material (1), a rubber layer (3) and a PVC printing film (4) which are composited in sequence from top to bottom. The preparation method comprises the following steps: firstly, forming the touching coating (2) on the front surface of the base material (1), and stoving the touching coating (2) so as to enable the touching coating (2) to be cured at certain temperature; secondly, applying glue on the back surface of the base material (1) or the printing surface of the PVC printing film (4), so as to form a glue layer (3); and finally, fitting the back surface of the base material (1) with the printing surface of the PVC printing film (4). Compared with the prior art, the decorative film is smooth in handfeeling, is good in scratch resisting and smudginess resisting effects and has the high-hone-finished and soft visual effect.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

High-resilience polyurethane/organic silicon thermoplastic elastomer and preparation method thereof

ActiveCN113004682AReduce vulcanization rateProlong vulcanization timePlastic recyclingThermoplasticOrganosilicon

The invention relates to the technical field of dynamically vulcanized thermoplastic elastomers, and discloses a high-resilience polyurethane / organic silicon thermoplastic elastomer and a preparation method thereof.The preparation method comprises the steps that blending thermoplastic polyurethane, vinyl silicone rubber, a compatilizer and reinforcing filler, placing a product in an internal mixer to be premixed, adding a cross-linking agent, uniform mixing continuesly to obtain rubber and plastic blend; adding the rubber and plastic blend into a twin-screw extruder, adding a prepolymerization catalyst, and carrying out prevulcanization and shear dispersion treatment; when a pre-vulcanized cross-linked product passes through the screw middle section of the double-screw extruder, adding a dynamic vulcanization catalyst, and carrying out shearing dispersion treatment to obtain the polyurethane / organic silicon thermoplastic elastomer; wherein the prepolymerization catalyst and the dynamic vulcanization catalyst are both rubber compounds formed by mixing a catalyst and vinyl silicone rubber. The catalyst is added in batches, so that the silicon rubber can be dispersed in the polyurethane, and the vulcanization rate can be reduced; by adopting the catalyst masterbatch, the uniform particle size of the silicon rubber can be ensured, so that the prepared TPSiV is silky in hand feeling.

Owner:CHENGDU SILIKE TECH

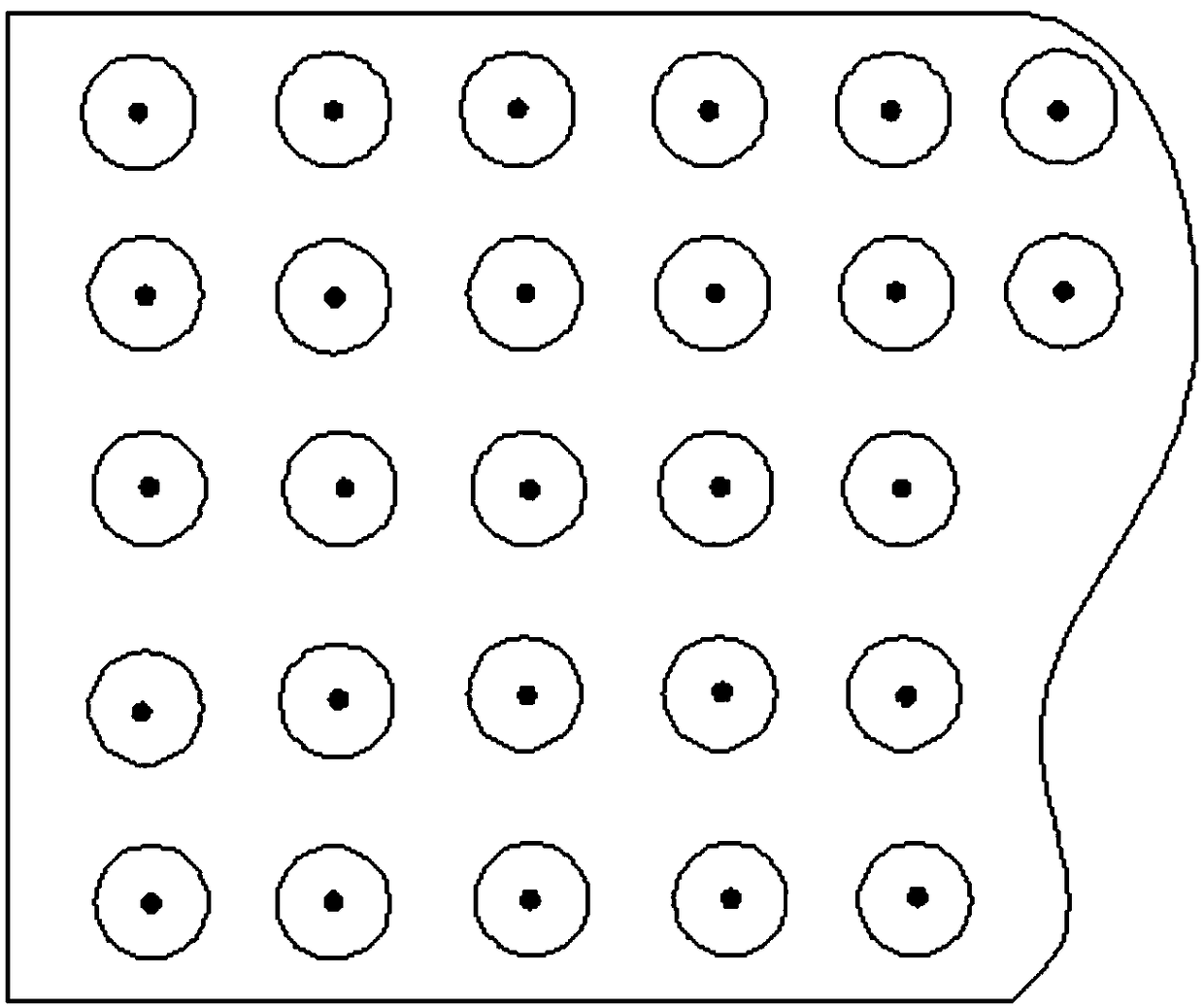

Nutritional soluble microneedle and microneedle slide

PendingCN108325068AEliminate wrinklesSkin glowMicroneedlesPharmaceutical delivery mechanismAdditive ingredientStratum corneum

The invention provides a nutritional soluble microneedle and a microneedle slide. The nutritional soluable microneedle comprising a substrate and a microneedle fixed on the substrate is characterizedin that the microneedle is peripherally provided with a nutritional needle sleeve which can be dissolved on the skin and directly acts on the skin; two or more nutritive soluble microneedles are connected to form a nutritional soluble microneedle slide. The nutritional soluble microneedle has the advantages of being a revolution in existing microneedles, being directly dissolved in the skin, allowing the skin to absorb directly, and allowing the cosmetic liquid to penetrate directly into the skin with the arrangement of the needle sleeve containing hyaluronic acid or silk fibroin material or other nutritional ingredients, only puncturing stratum corneum of the skin during use with being painless, non-invasive and no bleeding, and being soft, silky to touch, close to the skin, and breathable and refreshing.

Owner:陈彦彪

Preparation method of whitening pearl additive for cosmetics

InactiveCN107737096APromote absorptionSilky touchCosmetic preparationsToilet preparationsUltrasonic assistedMicrowave

The invention discloses a preparation method of whitening pearl additive for cosmetics and relates to the technical field of beauty and cosmetics. The preparation method disclosed by the invention comprises the following steps: controlling a pearl powder particle size to be 100nm or less by adopting a nano pulverization technology, and extracting and purifying pomegranate bark to obtain polyphenol-enriched extract by adopting a microwave-ultrasound assisted low eutectic reagent extraction technology and a two aqueous phase extraction and CO2 counter-current extraction technology, and finally,uniformly mixing pearl powder, glycerin and polyphenol extract by adopting an emulsifying mixing technology, thereby obtaining the whitening pearl additive. According to the whitening pearl additive prepared by the method disclosed by the invention, the pearl powder is small in particle size, adsorption of skin on active ingredients is promoted, the cosmetic has a smooth hand feeling, and the antioxidant effect of the cosmetic is effectively enhanced. In addition, the whitening pearl additive is non-irritating and excellent in skin affinity and can be widely applied to cosmetics such as liquidfoundation, cream, sun cream, essence lotion and the like.

Owner:林燕

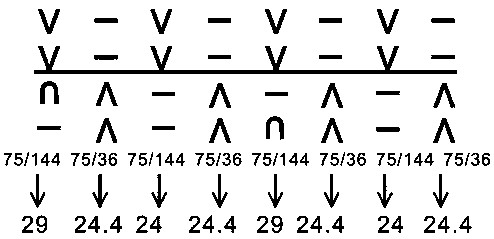

Ultra-soft wearproof velveteen-like fabric and preparation process thereof

ActiveCN104047094ASilky touchBreak through the phenomenon that is easy to fall offHeating/cooling textile fabricsWoven fabricsYarnPolyester

The invention discloses an ultra-soft wearproof velveteen-like fabric and a preparation process thereof. The ultra-soft wearproof velveteen-like fabric is interweaved by warps and wefts; the wefts comprise ground wefts and pile wefts; the warps are 50D / 72F ultrafine polyester yarns, and the ground wefts are 75D / 24*12F polyester-nylon high-shrinkage yarns; the pile wefts are five-heddle satin. According to the ultra-soft wearproof velveteen-like fabric and the preparation process thereof, 50D / 72F ultrafine polyester yarns are utilized radially, imported 75D / 24*12F polyester-nylon high-shrinkage yarns are utilized in a weft direction, and the tissue is five-heddle satin; by utilizing the high shrinkage percentage of high-shrinkage yarns, the floating furs of the five-heddle satin is shrunk into looped piles, so that the style and hand feeling like the velveteen are provided; the fabric is full and soft and has the silk hand feeling, and the situation that the traditional velveteen is likely to remove furs is broken through; the fur hand feeling is lasting, the furs are difficult to remove, and the fabric has the functions of moisture absorption and sweat releasing.

Owner:YANGZHOU JIYUAN TEXTILE

Dyeing and finishing process of cellulose acetate fiber and protein fiber silk fabric

ActiveCN113373705AUniform colorNot prone to chromatic aberrationDyeing processDisperse dyeColour fastness

The invention relates to the technical field of dyeing and finishing, in particular to a dyeing and finishing process of cellulose acetate fiber and protein fiber silk fabric. The dyeing and finishing process of the cellulose acetate fiber and protein fiber silk fabric comprises the following steps that S1, pretreatment is carried out; S2, a two-bath dyeing method is adopted for dyeing, the two-bath dyeing method is divided into two steps, the first step is that the protein fibers are dyed with reactive dye, and the second step is that the cellulose acetate fibers are dyed with disperse dye; S3, softening treatment is carried out; S4, drying treatment is carried out; and S5, shaping treatment is carried out. The cellulose acetate fiber and protein fiber silk fabric obtained through dyeing and finishing is not prone to generating color difference, uniform in color and luster, high in color fastness, not prone to decoloring, soft in hand feeling and comparable with real silk.

Owner:HAIYAN JIAYUAN PRINTING & DYEING

A kind of anti-fingerprint powder coating and its preparation method and application

ActiveCN109082210BImprove anti-fingerprint performanceSilky feel goodPowdery paintsPolyester coatingsPolymer scienceElectronic communication

The invention discloses anti-fingerprint powder coating and a preparation method and application thereof. The anti-fingerprint powder coating is prepared from, by weight, 20-40 parts of composite polyester resin A, 30-50 parts of polyester resin B and 0-30 parts of other auxiliary agents. The preparation method includes: well mixing hydroxyl polyester resin and a composite material, subjecting tomelt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and crushing to obtain the composite polyester resin A; adding the composite polyester resin A, the polyesterresin B and other auxiliary agents into a premixing tank, well mixing, subjecting to melt extrusion through a double-screw extruder, cooling sheets to the normal temperature, and finally crushing andgrading through a high-speed crusher to obtain powder in particle size of 33-38micron. By synergistic effects of the composite polyester resin A and the polyester resin B, a formed coating is easy toclean and remarkable in anti-fingerprint performance, automatic fingerprint clearing is realized, and the powder coating is silky and smooth to touch and especially suitable for terminal products including furniture, door and window accessories, decorative lamps, electronic communication equipment and the like and manifests high end and elegance of products.

Owner:广东歌丽斯化学有限公司

COLOUR ISTGURU glamor gloss lipstick and production method thereof

InactiveCN109908012ASilky touchUniform coloringCosmetic preparationsMake-upOCTYLDODECANOLShea butter

The invention relates to COLOUR ISTGURU glamor gloss lipstick, prepared from, by weight, a component A, a component B and a component C, a component D and a component E, wherein the component A includes 2-6 parts of dibutyl lauroyl glutamide, 2-6 parts of dibutyl ethylhexanoyl glutamide, 10-22 parts of tridecyl trimellitate, 4-10 parts of diisostearyl malate, 10-20 parts of isooctyl palmitate, 5-20 parts of hydrogenated C6-C20 polyolefin, and 5-12 parts of octyldodecanol; the component B includes 20-40 parts of alkyl benzoate and 0.05-0.15 part of variable color powder; the component C includes 0.5-4.5 parts of hydrogenated castor oil; the component D includes 0.05-0.15 part of hydrogenated shea butter, 0.05-0.15 part of olive oil, and 0.05-0.15 part of meadowfoam seed oil; the component Eincludes 1-1.5 parts of a pigment. The invention also discloses a production method of the COLOUR ISTGURU glamor gloss lipstick. The COLOUR ISTGURU glamor gloss lipstick is made with unique color combination according to the principle of human body PH-responding color variation, has black appearance but displays red after being applied, and provides lasting full coat; with the shea butter, oliveoil and meadowfoam seed oil, the COLOUR ISTGURU glamor gloss lipstick enables the lips to be nourished and protected for long time.

Owner:广州尚庄化妆品有限公司

Hand soap

InactiveCN106265380AGood decontamination and cleaningGood moisturizing effectCosmetic preparationsToilet preparationsHand sanitizerPolyphenol

The invention discloses hand soap. The hand soap is prepared from the following raw materials in parts by weight: 1-3 parts of water-soluble macadamia oil, 2-5 parts of water-soluble olive oil, 5-10 parts of tea saponin, 1-2 parts of anda-assu oil, 3-6 parts of licorice root extract, 0.1-0.4 part of tea polyphenol and 50-80 parts of water. The hand soap is prepared from natural plant raw materials, does not contain chemical substance, is mild and non-irritant, and has good capabilities of removing stains, cleaning, moisturizing and nourishing skin.

Owner:LIUZHOU LIJIE TECH

Pearl protein fiber rich in amino acid protein and preparation method of pearl protein fiber

InactiveCN111764000ASilky touchMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceBiology

The invention belongs to the technical field of textiles, and particularly relates to pearl protein fiber rich in amino acid protein and a preparation method of the pearl protein fiber. The inventionprovides the pearl protein fiber rich in the amino acid protein, a preparation raw material comprises the following components of, in parts by weight, 20 parts of viscose fiber spinning solution, 1-5parts of pearl powder and 5.5-13.5 parts of auxiliaries. According to the pearl protein fiber rich in the amino acid protein and the preparation method of the pearl protein fiber, the technical solution that the pearl powder is dispersed in the viscose fiber by utilizing various amino acids and proteins of a pearl, and the characteristics of whitening skin, maintaining beauty and keeping young ofthe pearl can be given to a fiber material, so that the fiber material has the effects of being soft, fine and smooth in touch, and the effect is more obvious along with the increase of the pearl powder content in the viscose fiber.

Owner:深圳千维生态纺织有限公司

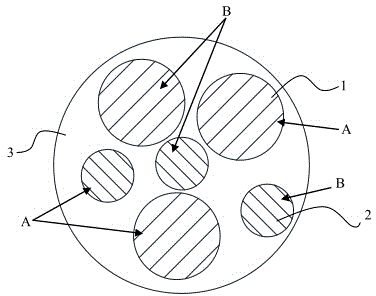

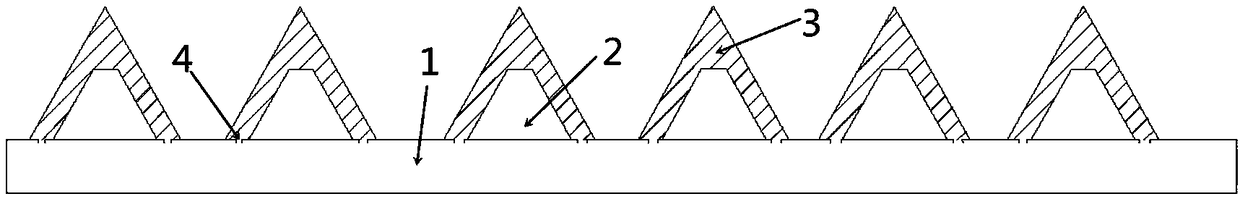

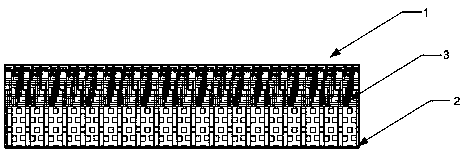

Quick-dry cloth with dry single face for wet conduction

InactiveCN111549438AKeep dryThe preparation method is simple and easyWeft knittingWarp knittingPolyesterPolymer science

The invention relates to quick-dry cloth with a dry single face for wet conduction. The quick-dry cloth with the dry single face for wet conduction comprises a cloth body 1; the cloth body comprises an inner layer 2 and an outer layer 3; the inner layer 2 is super-fineness polyester filaments, and a denier (DPF) of a single fiber is smaller than 0.7; and the outer layer 3 is common fineness polyester filaments, and a denier (DPF) of a single fiber is larger than 2. By adopting the structure, the quick-dry cloth with the dry single face for wet conduction has the advantages that a melting pointof polyester is high, and the requirements of extreme process processing such as high-temperature press ironing, bonding and the like of a garment can be thoroughly met. When the cloth is used for awearing function, fibers of the face against skin are soft, smooth and skin-friendly to touch, have a very excellent wicking (wet conduction) function and can conduct water vapor through capillaries in a fabric, and the water vapor is conducted to another cloth face layer with a large denier of the fibers. That is, when the cloth is manufactured into the garment for wearing, sweat of the skin is conducted to the cloth face at the outer layer through the superfine fibers of the face contacting the skin, so that the skin is kept dry, not hot and damp, air permeable and comfortable.

Owner:金田岭纺织科技(惠州)有限公司

Blister packaging box

InactiveCN110202895AExcellent formabilityLower surface energySynthetic resin layered productsBoxesSurface layerEngineering

The invention discloses a blister packaging box. The packaging box is of a structure with three layers which are a PET bottom layer, a pearlescent middle layer and a PET surface layer in order. The three layers are combined by hot pressing, and the packaging box with a required shaped is prepared by using a blister process. The invention provides the packaging box material with good processing formability, soft high glossiness, low surface energy and easy degradation. The packaging box made of the packaging box material by blister process is exquisite and high-grade in appearance and smooth intouch and meets the needs of high-grade packaging materials.

Owner:深圳市星迪尔实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com