One-touch popping device of memory module test socket

A storage module and ejection device technology, which is applied to measurement devices, coupling devices, static storage devices, etc., can solve the problem of damage to the operator's hand, the complicated insertion and extraction of storage modules 5, and the inability to ensure constant force to complete insertion and extraction. and other problems to achieve the effect of preventing damage to the contact part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

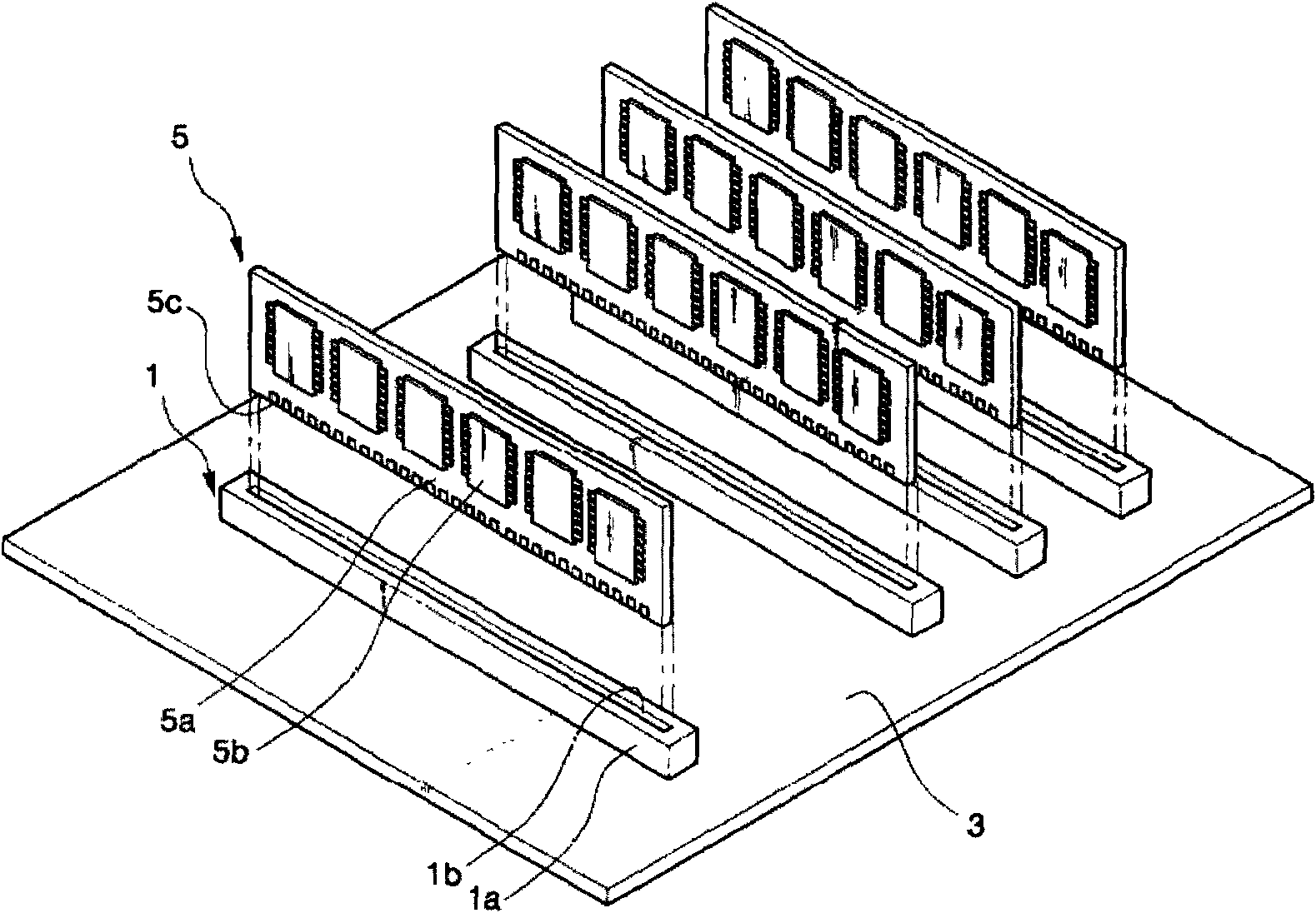

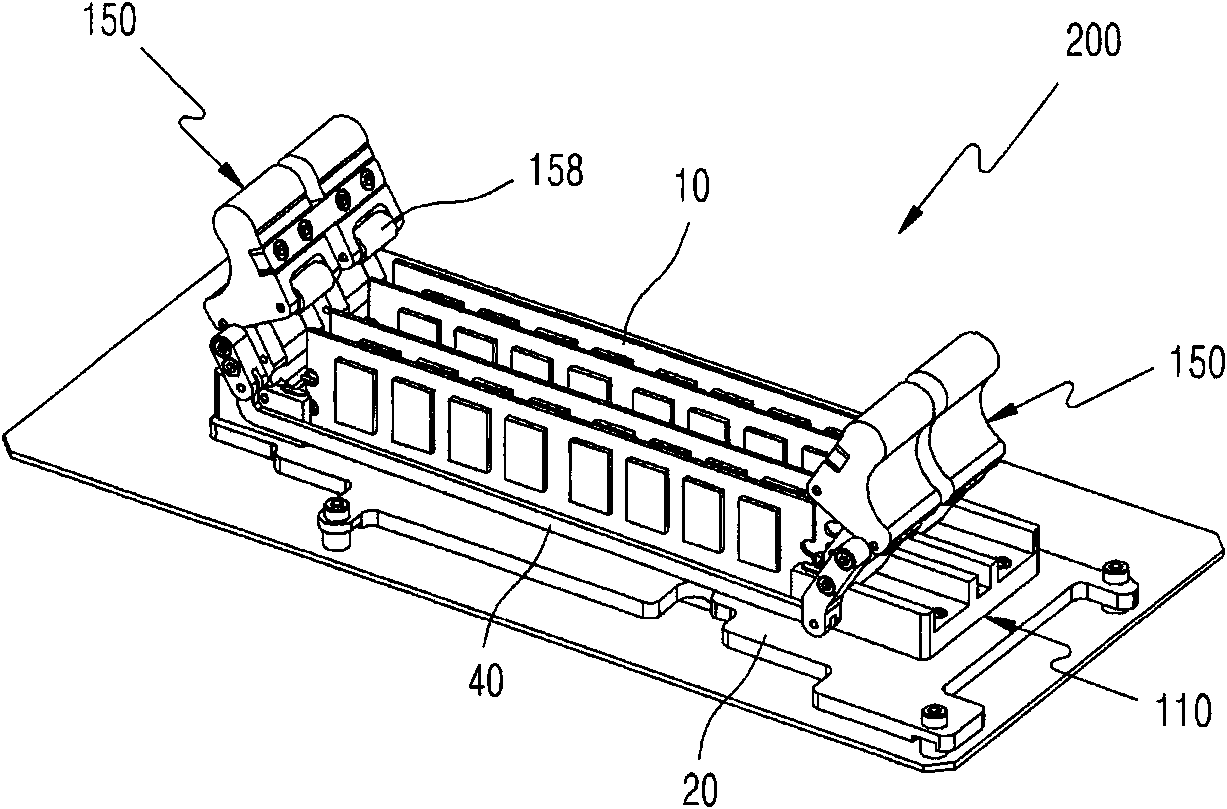

[0054] In order to achieve the above object, the present invention provides a single-press pop-up device for a memory module test socket, which is characterized in that it consists of the following:

[0055] The guide block is symmetrically arranged on both sides of the fixture body, one side is formed with a shaft hole, and the front side is formed with several vertical grooves as internal spaces;

[0056] The guide lifter is formed on the inner side of the above-mentioned guide block, vertically inserted into the vertical grooves facing each other on the fixture body, directly built into both sides of the storage module, and used for guiding insertion and separation;

[0057] The control body is symmetrically arranged on both sides of the fixture body, and is connected to the shaft hole at the upper end of the guide lifting member through the bolt so that it can rotate left and right;

[0058] The locking piece is housed inside the above-mentioned control body, the lower end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com