Pearl protein fiber rich in amino acid protein and preparation method of pearl protein fiber

A pearl protein fiber and amino acid technology, applied in the textile field, can solve problems such as blockage, increase difficulty and cost, and achieve a silky touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

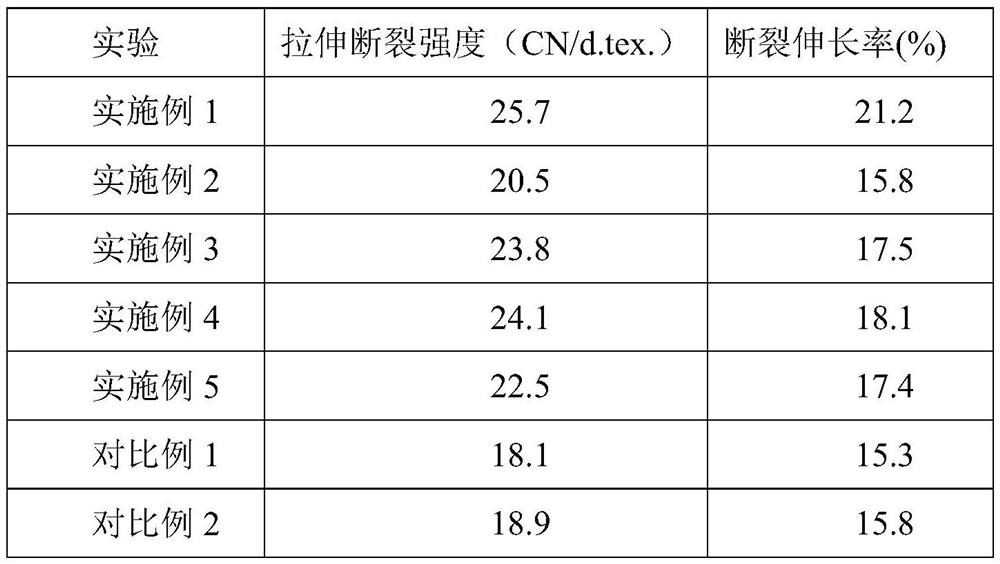

Examples

preparation example Construction

[0033]Preferably, the preparation method of described viscose spinning solution comprises the following steps: (1) taking natural cellulose as raw material, carrying out alkalization treatment in a sodium hydroxide solution with a pH of 8-12, and stirring with an electric mixer 5-20 minutes; (2) Add carbon disulfide to the basified cellulose, and sulfonate it in a sulfonation box for 1-5 hours to obtain a sulfonate solution; (3) The obtained sulfonate solution is viscose spinning silk liquid.

[0034] Further preferably, the natural cellulose raw material is selected from pulp, purchased from Baoding Baigou Xincheng Jinnian Special Fiber Manufacturing Co., Ltd.;

[0035] Further preferably, the pH value of the sodium hydroxide solution is adjusted to 10 to alkalinize the pulp;

[0036] Further preferably, the electric stirring time is 10 minutes;

[0037] Further preferably, the consumption of carbon disulfide is 10 milliliters;

[0038] Further preferably, the sulfonation ...

Embodiment 1

[0053] A pearl protein fiber rich in amino acid protein, the preparation raw materials include: viscose fiber spinning liquid, pearl powder and auxiliary agents. Wherein, by weight, 20 parts of viscose spinning solution, 3 parts of pearl powder, 5.5 parts of isopropyl tris (dioctyl phosphate acyloxy) phthalate, and 8 parts of surfactant.

[0054] The surfactant is sodium salt of secondary alkylsulfonic acid and monoglyceride laurate, and its weight ratio is 2.3:1.

[0055] Pearl powder, product number ZZF-290, purchased from Shaanxi Guben Biotechnology Co., Ltd.; isopropyl tris(dioctyl phosphate acyloxy) phthalate, product number KR-01204, purchased from Guangzhou Welina Chemical Co., Ltd. ; Secondary alkyl sulfonic acid sodium salt, model SAS60, purchased from Guangzhou Yisheng Trading Co., Ltd.; monoglyceride laurate, item number 205-526-6, purchased from Hubei Yuying Biotechnology Co., Ltd.; natural cellulose purchased from Baoding Baigou Xincheng Jinnian Special Fiber Man...

Embodiment 2

[0060] A pearl protein fiber rich in amino acid protein, the preparation raw materials include: viscose fiber spinning liquid, pearl powder and auxiliary agents. Wherein, by weight, 20 parts of viscose fiber spinning solution, 1 part of pearl powder, 5.5 parts of isopropyl tris (dioctyl phosphate acyloxy) phthalate, and 8 parts of surfactant.

[0061] The surfactant is sodium salt of secondary alkylsulfonic acid and monoglyceride laurate, and its weight ratio is 2.3:1.

[0062] Pearl powder, product number ZZF-290, purchased from Shaanxi Guben Biotechnology Co., Ltd.; isopropyl tris (dioctyl phosphate acyloxy) phthalate, product number KR-01204, purchased from Guangzhou Welina Chemical Co., Ltd.; Secondary alkylsulfonic acid sodium salt, model SAS60, was purchased from Guangzhou Yisheng Trading Co., Ltd.; monolauric acid ester, product number 205-526-6, was purchased from Hubei Yuying Biotechnology Co., Ltd.; natural cellulose was purchased from Baoding Bai Ditch Xincheng Jin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com