Anti-fingerprint powder coating and preparation method and application thereof

A powder coating and anti-fingerprint technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of less anti-fingerprint and silky feel, and achieve good anti-fingerprint, simple preparation method, and good anti-fingerprint performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

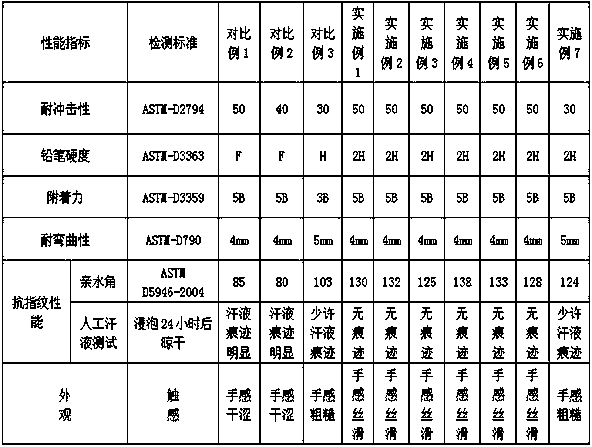

Embodiment 1-6 and comparative example 1-2

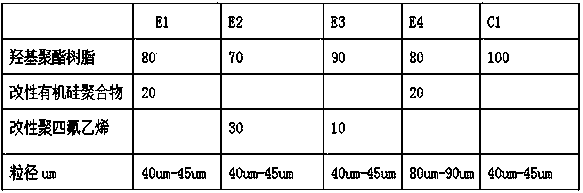

[0048] a. According to the ratio in Table 1, mix the hydroxyl polyester resin and the composite material evenly, and then melt and extrude it through a twin-screw extruder. Composite polyester resin A with a diameter of 40um-45um;

[0049] b. Put composite polyester resin A, polyester resin B, curing agent, leveling agent, defoamer, brightener, and pigments and fillers into the pre-mixing tank according to the ratio in Table 2, and then extrude through twin-screw after mixing evenly Machine melt extrusion, twin-screw extruder melt extrusion temperature is 100 ℃, cooling tablet to room temperature, and finally crushed and classified by high-speed pulverizer to make powder with a particle size of 33um-38um.

Embodiment 7

[0051] Crushed to obtain particle diameter is the composite polyester resin A of 80um-90um, all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com