Anti-fingerprint stain-resistant PMMA resin and preparation method thereof

An anti-fingerprint and anti-fouling technology, which is applied in the field of anti-fingerprint and anti-fouling PMMA resin and its preparation, can solve the problems of poor anti-fingerprint and anti-fouling properties, improve anti-fingerprint performance and anti-fouling performance, good oil solvent resistance, low temperature good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

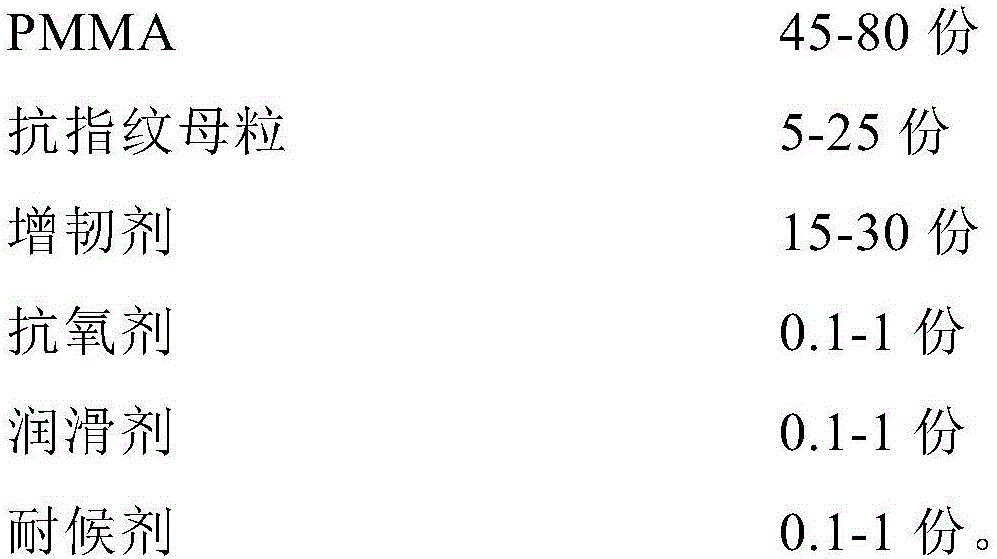

Method used

Image

Examples

Embodiment 7-9

[0045] Embodiment 7-9 formula is as shown in table 3,4, and used raw material is as follows:

[0046] PMMA: Chi Mei CM211

[0047] Fluorosiloxane: Polytrifluoropropylmethylsiloxane (PTFPMS)

[0048] Compatibilizer: Ethylene-Butyl Acrylate-Maleic Anhydride

[0049] Toughener: LG Chem EM600 (acrylate core-shell toughener)

[0050] Antioxidant: Ciba TG-1076 (hindered phenolic compound)

[0051] Lubricant: silicone oil

[0052] Weather resistance agent: commercially available UVP and 770, the ratio is 1:1.

[0053] Table 3 Anti-fingerprint masterbatch formula (unit: kg)

[0054] components Anti-fingerprint masterbatch 4 Anti-fingerprint masterbatch 5 Anti-fingerprint masterbatch 6 Fluorosiloxane 5 15 20 PMMA 93 90 75 Compatibilizer 2 4.5 5 antioxidant 0.1 0.5 1

[0055] Table 4 embodiment 7-9PMMA resin formula (unit: kg)

[0056] components Example 7 Example 8 Example 9 PMMA 45 55 80 Anti-fingerpri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com