Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Serious pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-lead separation flotation inhibitor and applications thereof

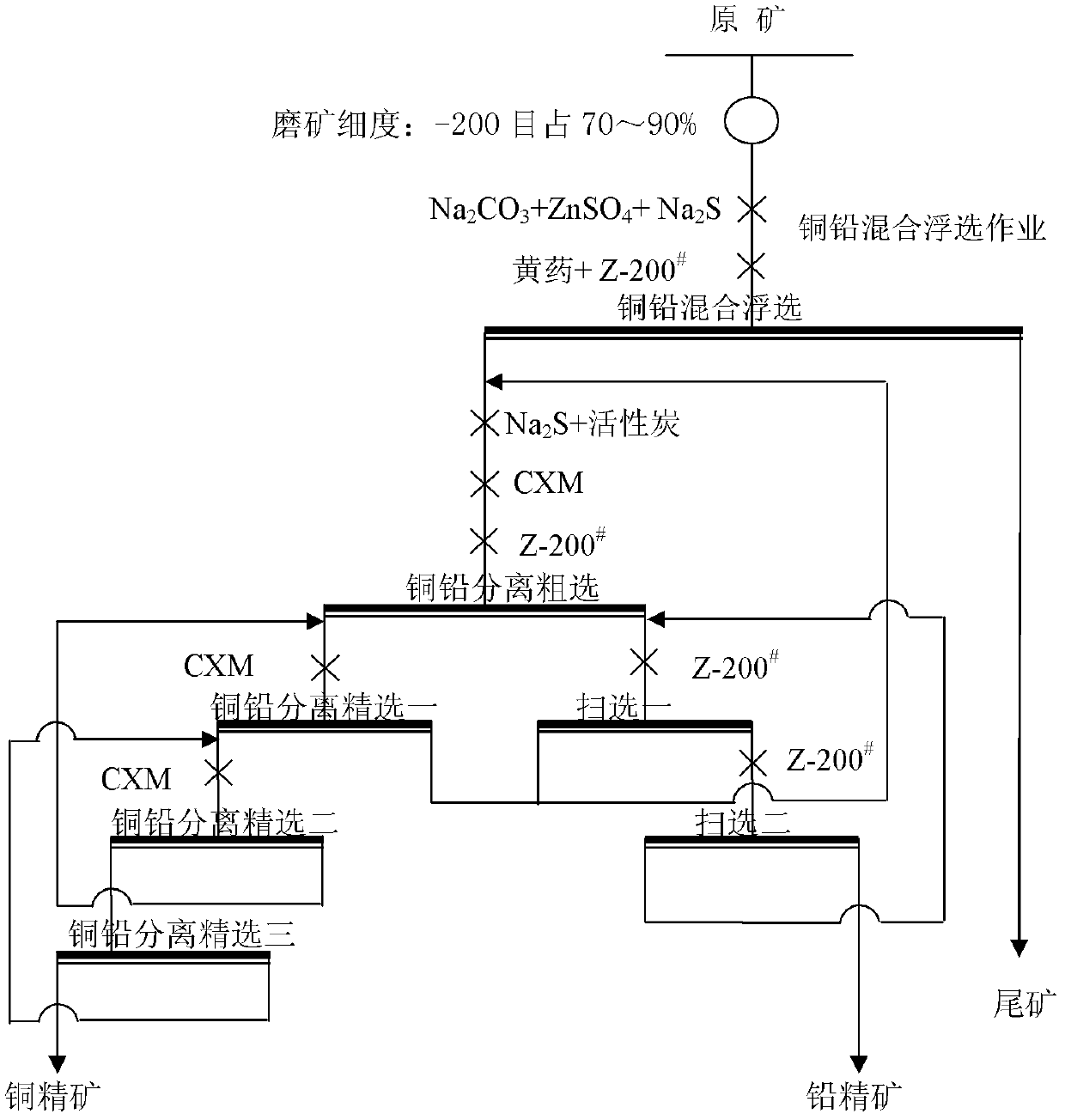

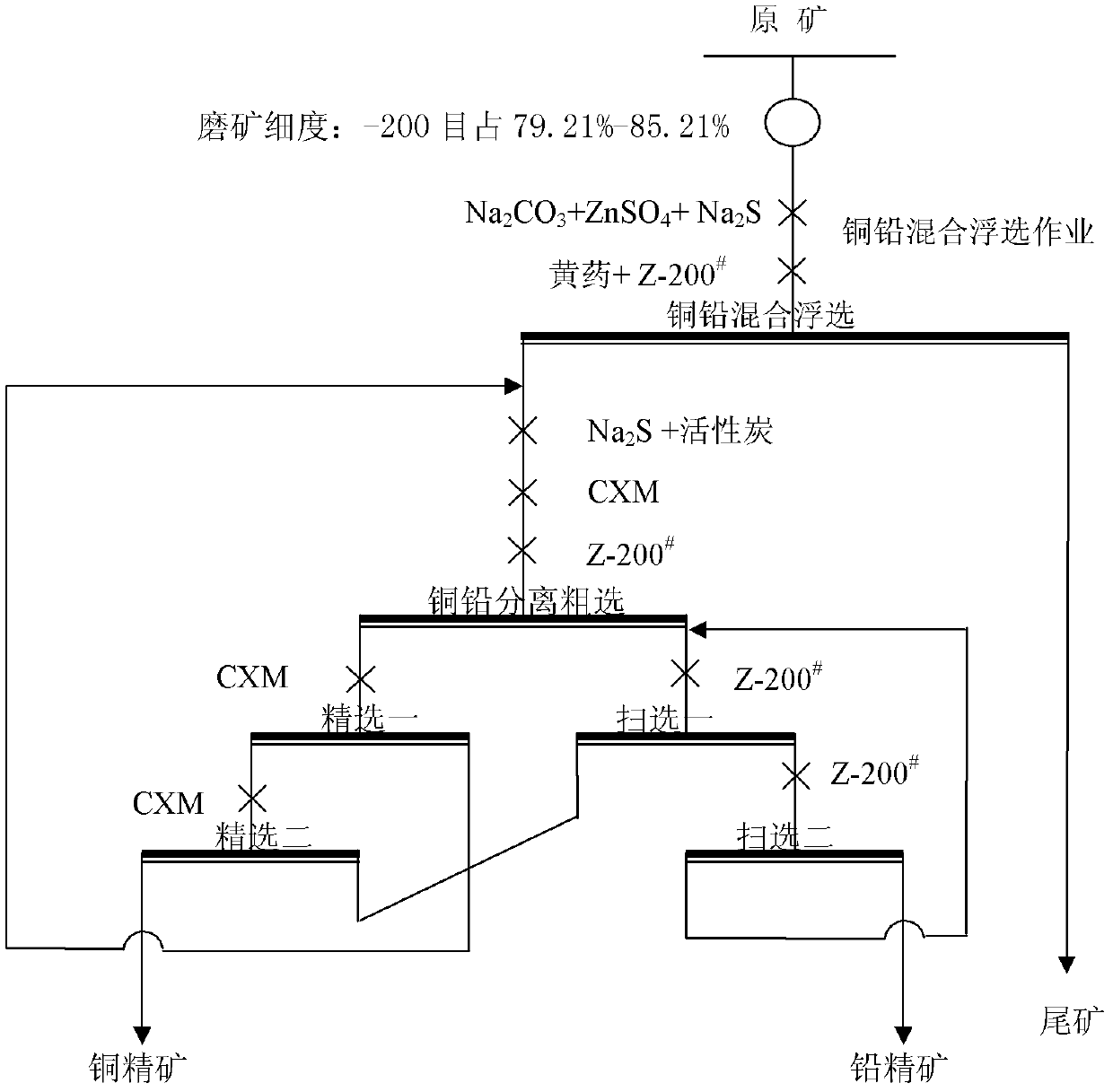

The invention belongs to the field of complicated copper-lead-zinc sulphide ore beneficiation separation and provides a copper-lead separation flotation inhibitor and applications thereof. The copper-lead separation flotation inhibitor is formed by mixing polymeric ferric sulfate solution with a mass concentration of 5.0%-6.0% and glycerin solution with a mass concentration of 0.8%-1.2%, wherein the mass ratio of the polymeric ferric sulfate solution to the glycerin solution is 1:1-4. Addition of the inhibitor in copper-lead separation operation can remarkably improve copper and lead concentrate qualities, evidently lower mutual containing of copper and lead, and improve flotation recovery rate of copper and lead minerals. The copper-lead separation flotation inhibitor and the applications thereof have the advantages that the copper-lead separation flotation inhibitor is environment-friendly, efficient in sorting, low in reagent cost, easy to operate and the like and applicable to the complicated copper-lead-zinc sulphide ore beneficiation separation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

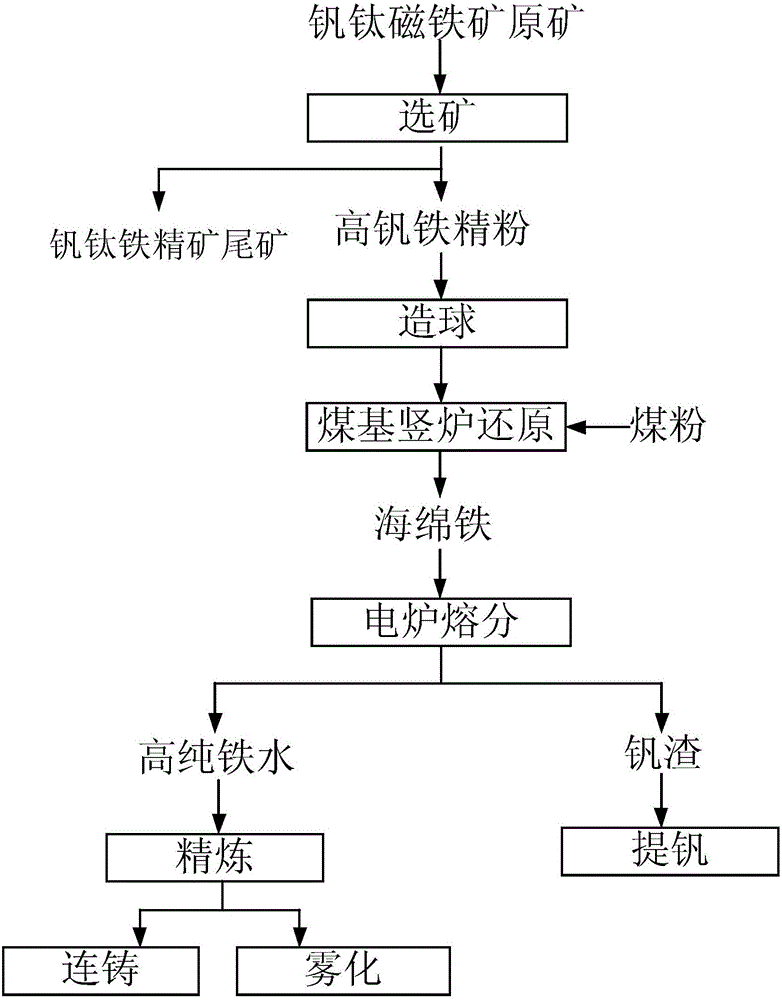

Process for comprehensively utilizing vanadium-titanium magnetite

The invention relates to a process for treating and comprehensively utilizing a vanadium-titanium magnetite. The process is characterized by comprising the following steps: (1) treating a raw vanadium-titanium magnetite by crushing, tailings discarding, fine grinding, low-intensity magnetic separating, high-intensity magnetic separating, and separating by a shaking table, so as to obtain a titanium concentrate and a high-vanadium-ferrum concentrate; (2) adding an adhesive to the high-vanadium-ferrum concentrate; uniformly mixing and pelletizing; drying; uniformly mixing with pulverized coal or coke powder; distributing; performing controlled reduction that V is not reduced through a coal based shaft furnace so as to obtain sponge iron, wherein the amount of used reducing agents such as the pulverized coal is 30 to 70% of the weight of high-vanadium-ferrum concentrate powder, and the reduction is performed for 10 to 18 hours at the temperature of 850 to 1060 DEG C; (3) heating the obtained sponge iron for 0.5 to 1.0 hour at the temperature less than 1050 DEG C through an intermediate frequency / main frequency furnace under a weak reduction atmosphere; then heating until the temperature is more than 1500 DEG C; performing melt separation to enable vanadium to enter slag, thus obtaining high-grade vanadium slag and high-purity molten iron. With the adoption of the process, a plurality of valuable elements in the vanadium-titanium magnetite can be effectively separated and utilized with high additional value.

Owner:WUHAN COSRED SCI & TECH LTD

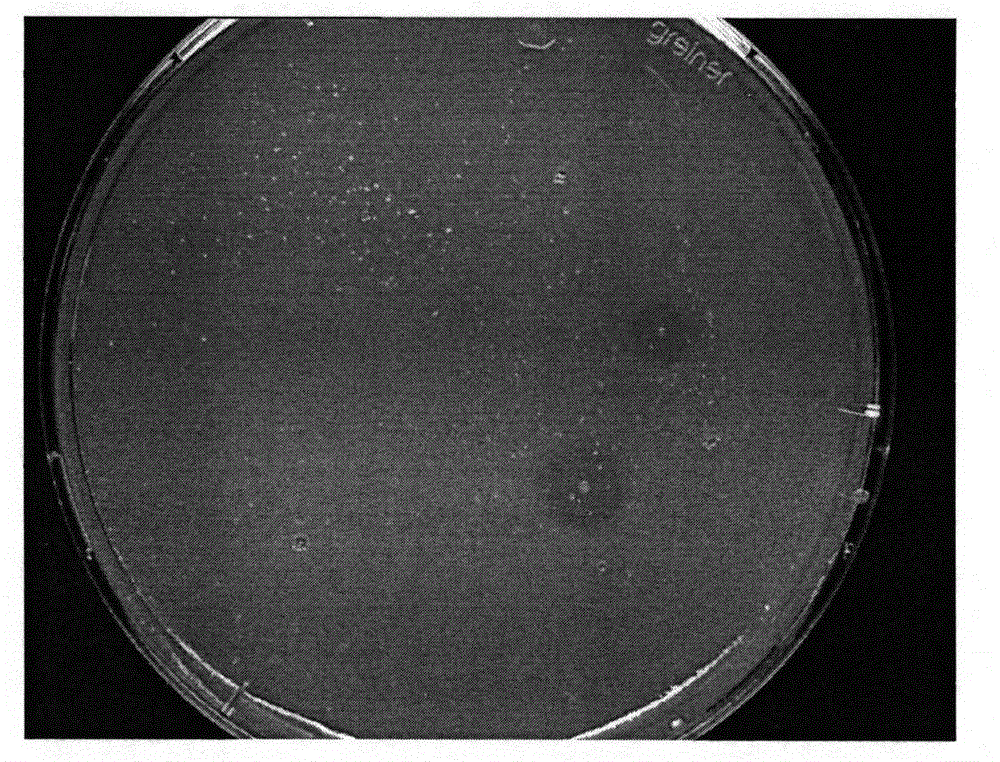

Method for extracting astaxanthin from haematococcus pluvialis

The invention belongs to the technical field of medicines, and relates to a method for extracting astaxanthin from haematococcus pluvialis. The method comprises the steps of culturing a seed stock solution in a glass apparatus with a drainage system, and carrying out later amplification culture of the haematococcus pluvialis and accumulation culture of the astaxanthin after 10-15 d; centrifuging a culture in an exponential growth period of seed culture; and inoculating cell clusters in a BBM basal medium to obtain a primary culture. The later accumulation culture of the astaxanthin is amplification culture by using a breathable plastic bag type simple device provided by the invention. In the accumulation stage, a stress culturing method is adopted to obtain a lab-scale test haematococcus pluvialis culture; and haematococcus pluvialis powder is obtained by spray drying. According to a preparation technology that extracts astaxanthin from the haematococcus pluvialis by adopting an ultrasonic cell disruption assisted mixed solvent extraction method, the haematococcus pluvialis powder is added in an organic solvent to carry out ultrasonic cell disruption, and then the astaxanthin is obtained by the steps of reflux extraction in a water bath, suction filtration, filtrate merging and concentration. Compared with a conventional direct extraction method, the method provided by the invention saves extraction time, and increases astaxanthin yield.

Owner:SHENYANG PHARMA UNIVERSITY

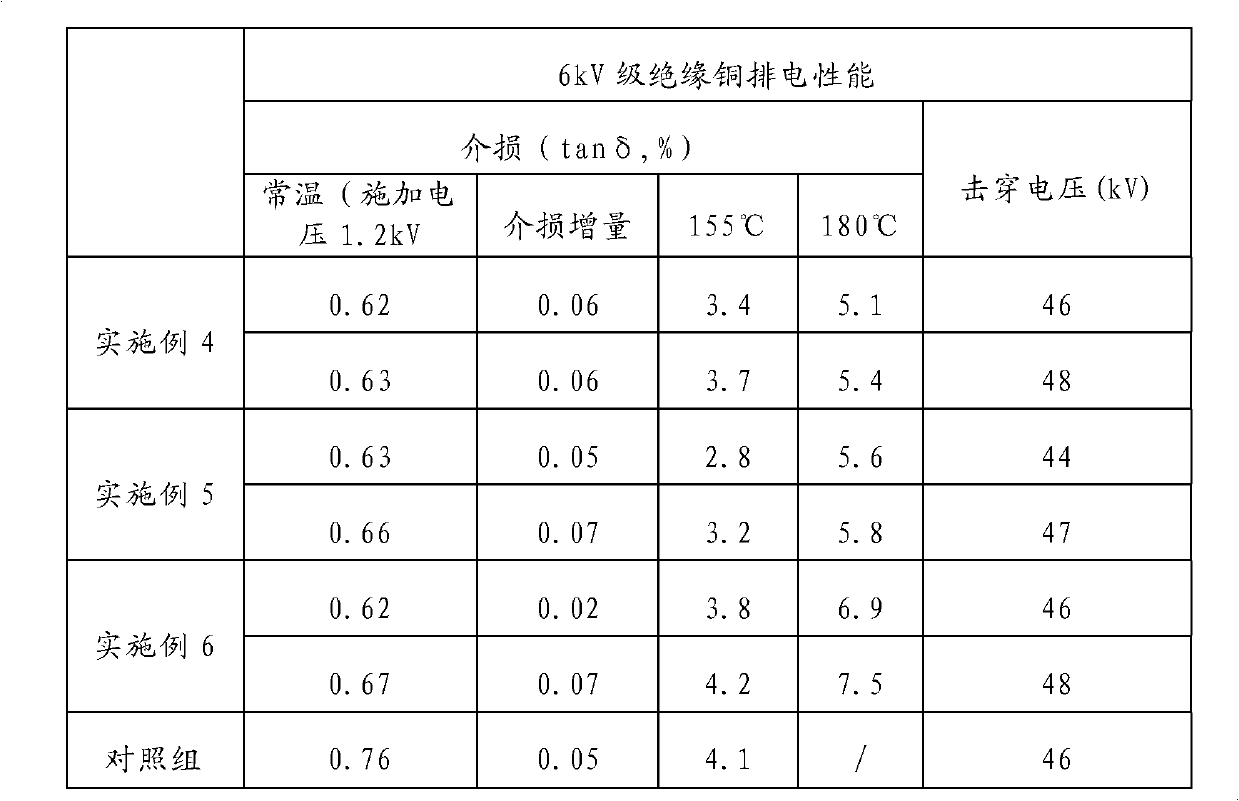

Preparation method of vacuum pressure impregnation resin

The invention relates to a preparation method of vacuum pressure impregnation resin. According to the invention, a low-smell multi-functionality low-volatilization active diluent agent is used for replacing styrene which causes severe environmental pollution. The diluent agent at least comprises two functional groups, wherein one is a double-bond functional group, and the other is a double-bond functional group or a functional group which can subject to a reaction with epoxy or a curing agent. The impregnation resin provided by the invention is advantaged in small viscosity, short gelatinizing time, excellent electrical properties, high heat-resistance, environment-friendliness, and safe application.

Owner:上海电气集团上海电机厂有限公司

Solid thermal self antipyretic steel slag treatment method in pressure

The invention relates to a remaining heat pressure self-decompression treatment method of solid thermal steel slag, which is characterized by comprising the following steps: 1) loading slag: the solid thermal steel slag is loaded in an self-decompression tank; 2) spraying water and elevating pressure: the spraying water and cooling are carried out on the slag so as to generate steams with pressure; 3) constant pressure self-decompression: self-decompression is carried out on the slag in the self-decompression tank at a constant steam pressure kept; 4) cooling: water is sprayed so as to continuously cool the steel slag; and 5) completing self-decompression: a release valve is opened to give out steam so as to finish self-decompression. The treatment method has the advantages of good product quality, high efficiency, saving lands, reducing pollution and reducing investment.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

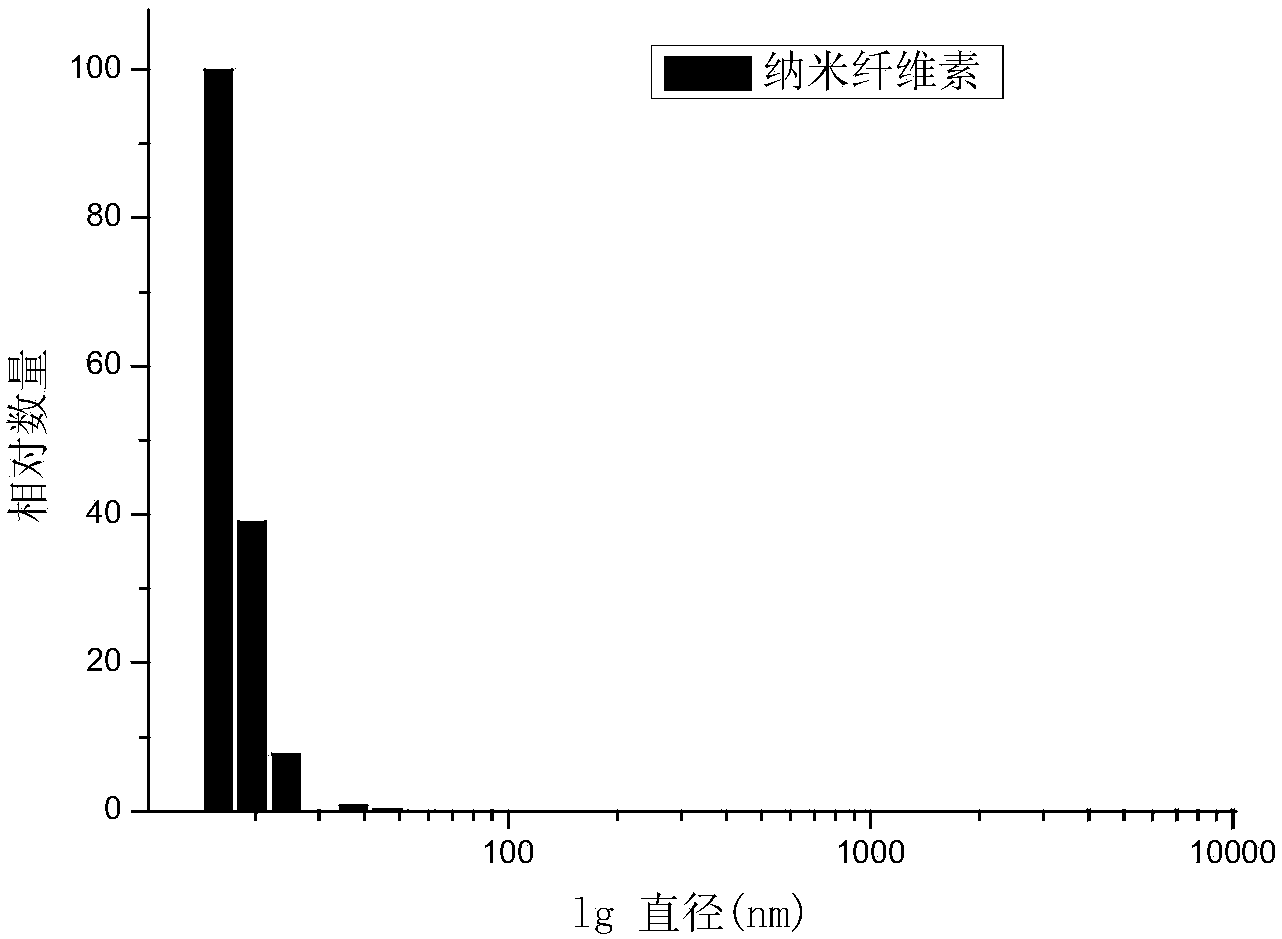

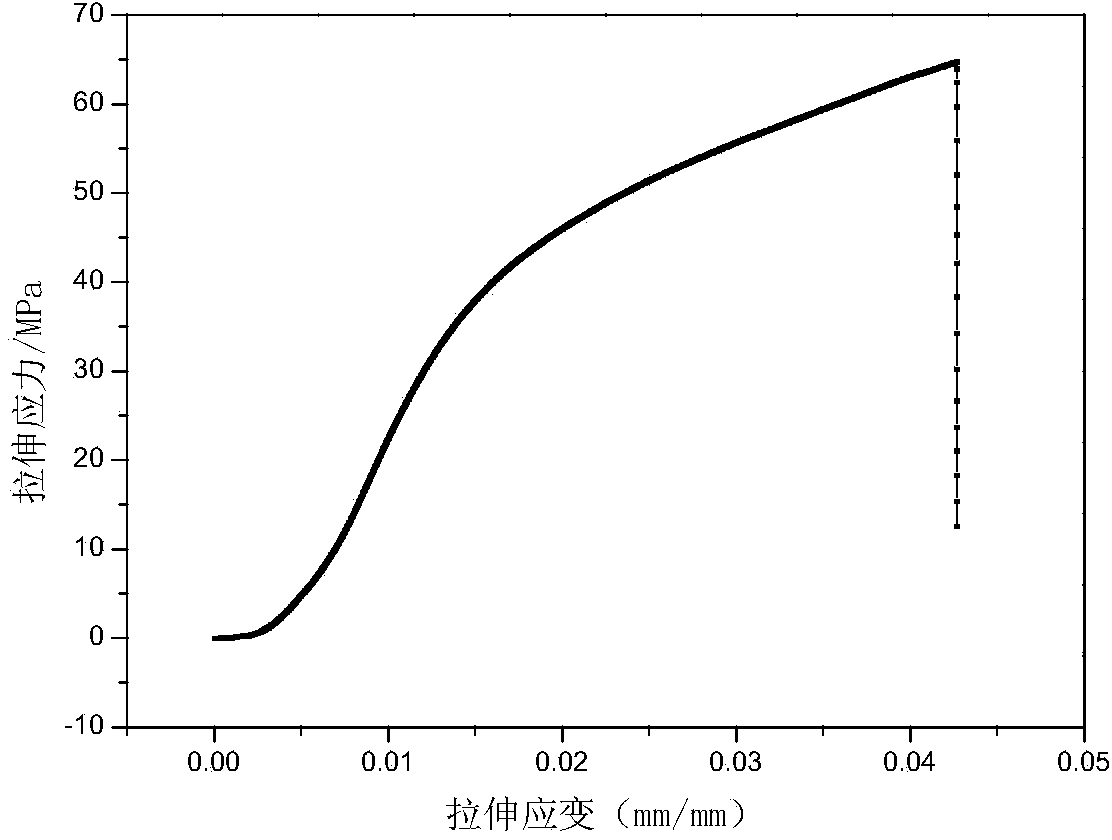

Preparation method of nanocellulose film precipitated by applying water solution

The invention discloses a preparation method of a nanocellulose film precipitated by applying a water solution. The preparation method comprises the following steps: dissolving cellulose with concentration of 10-40g / L into a mixed solution of sodium hydroxide, urea and water at minus 15-minus 8 DEG C; after heating the cellulose solution to the room temperature, dropwise adding water to the cellulose solution to precipitate cellulose to obtain nanocellulose colloid dispersion liquid; filter-pressing the nanocellulose colloid dispersion liquid to obtain the nanocellulose film, wherein the mixed solution contains 5-10% of sodium hydroxide, 10-15% of urea and the balance of water by mass percent, and the volume ratio of water to the cellulose solution is (1-3):1. The method overcomes the defects of difficulty in acid waste liquor recovery, high preparation cost, high preparation energy consumption, heavy environmental pollution and the like in the existing preparation method of nanocellulose and the film thereof, and has the advantages of simplicity and high efficiency in operation, solvent reusability, environment friendliness and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

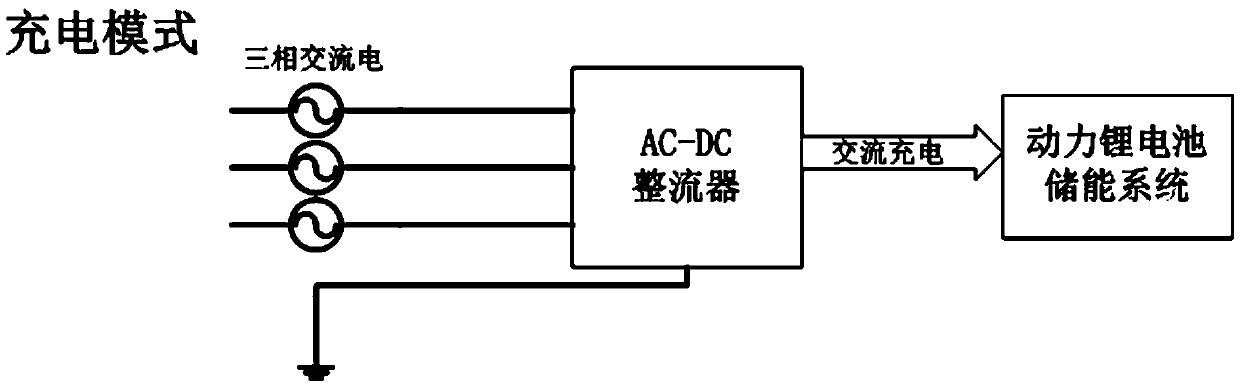

Mobile airport ground static inversion power source system

InactiveCN107565588ALoud noiseSerious pollutionFlexible AC transmissionAc network load balancingElectrical batteryCivil aviation

The invention relates to a mobile airport ground static inversion power source system mainly applied to the field of civil aviation aircrafts and used for supplying power for aircrafts landing on ground in specific working conditions. The system includes a large power rectifier, a power lithium battery power storage system and a large power inverter. The system also includes a start power system,an operation interface and a high voltage output cable. In a charging mode, after three-phase AC is connected to the rectifier, a main control system sends commands to a battery management system through CAN communication so as to close a high voltage relay of the power lithium battery power storage system. The main control system starts a charging module for charging after detecting high voltagesignals. A discharge mode includes three-phase AC on-load, power lithium battery power storage system DC on-load and AC / DC on-load. The invention can solve a problem of power supply for remote boarding gates of aircrafts and is low in noise, small in fossil fuel consumption, free of pollution and discharge and low in economic cost.

Owner:SHANGHAI AEROSPACE POWER TECH

River wastewater comprehensive treatment method

InactiveCN104370408AReduce dosageReduced settling timeWater resource protectionWater/sewage treatment bu osmosis/dialysisPurification methodsTreatment effect

Owner:TIANJIN HYDROKING SCI & TECH

Incline type double-belt diamond saw machine

InactiveCN101357489AHigh yieldSmall thickness errorStone-like material working toolsNumerical controlFrequency conversion

The sloping-type double-strip diamond saw machine is aslope arranged on a column by a large frame with enough intensity. Two pairs of light flywheels with the diameter of 1600mm-1610mm are arranged on the large frame, and two driving flywheels are connected together at the lower end of the large frame and rotate under the driving of the driving motor. Two driven flywheels at the upper end of the large frame are respectively and correspondingly arranged on the slideways with different tensioners. The thickness of boards is made by anti-slip circles with different thickness. Two welding edge of the diamond knife head is strip steel in form of wave with the width of 200mm and the thickness of 1.4mm, the strip steel is welted into a circle and arranged on the two flywheels. The knife head is welted on the wave-shaped chimb by laser. When the host machine rotates, the knife head and the saw blades do high-speed rotation movement from top to down in the eight roller-type controllers. The cooling water pipe is located at the two sides of the top end of the saw blade and sprinkles water over the incision line of the saw blade. Under the driving of the frequency conversion motor, the flat vehicle filled with crude materials facilitates the crude materials to pass through the edge of the crude materials at different speeds and the demanded thickness under the control of the numerical control stowing tool. The working form that the saw blade B is at the front and the saw blade C is at the rear is formed gradually, and the two boards after being cut fall on the transportation bracket wheel which is horizontal to the bottom of the crude materials. When the flat vehicle returns to the stop point, the two boards on the bracket wheel are rotated by a plurality of bracket wheels simultaneously in the guard to the storage point, and the numerical control stowing tool carries out a second circulation to the thickness designed by pulsion of the crude materials.

Owner:陈双英

Preparation method for instant dicyandiamide formaldehyde resin

The invention discloses a preparing method of rapid soluble typed dicyandiamide, which comprises the following steps: adding 23.16-25.85% formaldehyde, 39.30-43.38% water, 22.57-25.62% dicyandiamide and 2.59-3.73% amchlor into reacting stove sequently; heating to 70-85 Deg C; adjusting pH value at 7.5-9.5; reacting 1.5-5.5h thermostatically; moving the material into polymeric autoclave; supplementing 6.22-7.44% amchlor; controlling the temperature at 75-95Deg C with pH value at 4.0-6.8 for 1.5-5.0h; moving to opsonizing stove; controlling the temperature at 55-70 Deg C; adding 0.17-0.20% primary alcohol for 0.3-1.0h; obtaining liquid dicyandiamide formaldehyde resin; drying directly; obtaining the product.

Owner:SOUTH CHINA UNIV OF TECH

Technology for enzymatic efficient deacetylation and chitin degradation by using Thermophilic Bacillus

InactiveCN104450832ASerious pollutionHigh energy consumptionMicroorganism based processesFermentationLiquid mediumBiological property

A technology for enzymatic efficient deacetylation and chitin degradation by using Thermophilic Bacillus belongs to the fields of the food processing technology, the bio-pharmaceuticals and the chemical engineering technology. The above strain has the biological characteristic of generation of highly active extracellular chitin deacetylase and chitin degrading enzyme, and can efficiently degrade chitin. The technology mainly comprises the following steps: inoculating preserved slant strain into a double layer plate with chitin as a sole carbon source, culturing at 46DEG C for 24h, inoculating a certain amount of the above obtained substance into a liquid medium with chitin as the sole carbon source, carrying out liquid seed culturing at 46DEG C for 72h, and inoculating the obtained production strain into a fermentation medium with chitin as the sole carbon source according to a certain ratio. The technology can degrade chitin to produce chitosan, chitosan oligosaccharide with different molecular weights, glucosamine (aminoglucose), acetylglucosamine and other relevant products, and also can produce chitin deacetylase and the chitin degrading enzyme.

Owner:ZHEJIANG SHUREN UNIV

Solid thermal steel slag residual heat self-solution treatment method in pressure

The invention relates to a remaining heat pressure self-decompression treatment method of solid thermal steel slag, which is characterized by comprising the following steps: 1) loading slag: the solid thermal steel slag is loaded in an self-decompression tank; 2) spraying water and elevating pressure: the spraying water and cooling are carried out on the slag so as to generate steams with pressure; 3) constant pressure self-decompression: self-decompression is carried out on the slag in the self-decompression tank at a constant steam pressure kept; 4) cooling: water is sprayed so as to continuously cool the steel slag; and 5) completing self-decompression: a release valve is opened to give out steam so as to finish self-decompression. The treatment method has the advantages of good product quality, high efficiency, saving lands, reducing pollution and reducing investment.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Preparation method of baloxavir key intermediate and intermediate thereof

ActiveCN111808069AHarm reductionHigh yieldOrganic chemistryBulk chemical productionBenzaldehydeThio-

The invention discloses a preparation method of a baloxavir key intermediate and the intermediate thereof. The method includes subjecting 3,4-difluoro-2-methyl benzaldehyde shown as a formula (I) as araw material to a bromination reaction to obtain 3,4-difluoro-2-bromomethyl benzaldehyde shown in a formula (II), carrying out a substitution reaction to obtain 3,4-difluoro-2-(((2-bromophenyl) thio)methyl)-benzaldehyde shown in a formula (III), and finally, carrying out a nucleophilic addition reaction to synthesize a target product, namely 7,8-difluorodibenzo[b, e]thiepin-11(6H)-ol shown in aformula (IV). The specific reaction process is shown in the specification. According to the method, 2-bromothiophenol is used for replacing foul and virulent thiophenol, the reaction steps are reducedto three steps, and the preparation method is high in yield, low in cost, environmentally friendly and easy to operate.

Owner:CHINA PHARM UNIV

Method for preparing photocatalyst Cu2O based on recovering copper cutting waste

InactiveCN110240190ASerious pollutionLow costWater/sewage treatment by irradiationWater treatment compoundsOrganic dyeCopper oxide

A method for preparing photocatalyst Cu2O based on recovering copper cutting waste belongs to that technical field of molten salt solvation reaction and photocatalysis. The method fully oxidizes the copper cutting waste, removes the residual oil stains on the surface of the copper cutting waste and obtains copper oxide, melts the molten salt, adds the prepared copper oxide under argon gas atmosphere, stays at constant temperature for a period of time, drops the temperature, dissolves the molten salt with water, centrifuges, repeatedly cleans and then dries to obtain the nanometer Cu2O photocatalyst. Nano-Cu2O photocatalyst is used to degrade organic dyes. It has a good degradation effect on methyl orange or methylene blue. Cu2O photocatalyst prepared from copper cutting waste by adopting that method has the advantages of low cost, simple process flow, high efficiency and environmental friendliness, and only CO2 and O2 are produced in the process of photodegradation of organic dyes, and no pollution is caused to the environment.

Owner:NORTHEASTERN UNIV

Waste gas purification equipment for garbage incinerator

ActiveCN111617601APracticalAvoid pollutionGas treatmentTransportation and packagingExhaust fumesEnvironmental engineering

The invention discloses waste gas purification equipment for a garbage incinerator. The waste gas purification equipment comprises a purification box fixedly connected to the upper end of a water pipe; the left side wall of the purification box is connected with an air inlet pipe; the right side wall of the purification box is connected with an exhaust pipe; a first magnetic sliding plate and a second magnetic sliding plate are symmetrically and fixedly connected to the inner wall of the purification box through telescopic springs, a vertical rod is rotatably connected to the inner wall of thepurification box, the lower end of the vertical rod penetrates through the lower end of the purification box and is fixedly connected with a plurality of hydrodynamic wheels, and permanent magnet plates are symmetrically and fixedly connected to the side wall, located in the purification box, of the vertical rod. According to the invention, the two permanent magnet plates are driven by the hydrodynamic wheels to rotate ceaselessly; and then the first magnetic sliding plate and the second magnetic sliding plate are continuously close to and away from each other under the action of the elasticforce of a telescopic spring and the repulsive force of the permanent magnet plates, so that the purifying box continuously sucks waste gas to be in full contact with a purifying agent, a harmful gasin the waste gas is absorbed, and serious atmospheric pollution caused by exhaust of the waste gas into air is avoided.

Owner:JIANGSU XINGXIN SEPARATION EQUIP MFR

Application of eutrophic water to resistance regulation of lawn plants

InactiveCN101574035AStrong stress resistanceSerious pollutionClimate change adaptationSewage/sludge fertilisersEutrophic waterLawn

The invention discloses an application of eutrophic water to resistance regulation of lawn plants, wherein the eutrophic water is the eutrophic water with 25 percent-75 percent of the original concentration; the eutrophic water has TN of 9.7mg / L-13.1mg / L, TP of 0.6mg / L-0.9mg / L and pH value of 8.12-8.99; and the evaluation indicator of the resistance refers to the change in contents of proline, soluble sugar and malonaldehyde. Results show that the diluted eutrophic water is applied to irrigation to improve the resistance of the lawn plants to adverse growing environment and achieve the purpose of resource conservation and environmental protection.

Owner:TIANJIN NORMAL UNIVERSITY

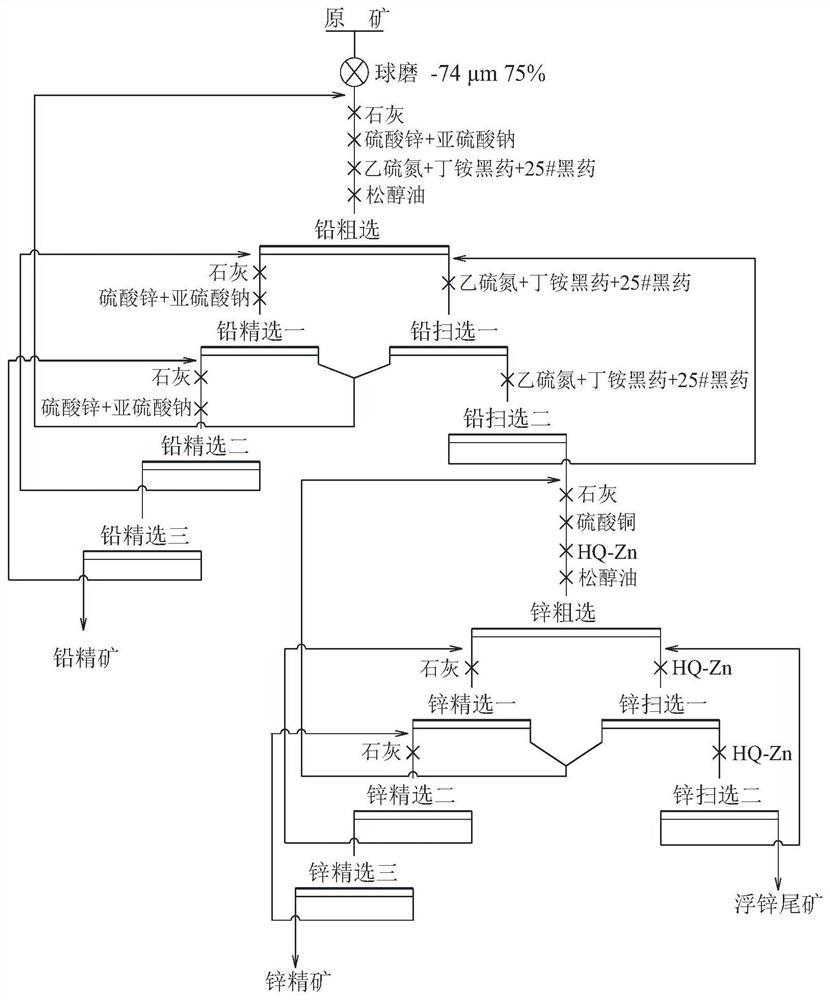

Efficient flotation collecting agent for zinc sulfide and application of agent

The invention discloses an efficient flotation collecting agent for zinc sulfide and application of the efficient flotation collecting agent, and the efficient flotation collecting agent is composed of the following components in percentage by mass: 92%-98% of 2-hydroxyethyl dibutylcarbamodithioate, 1.5%-5% of 2-hydroxy-1-mercaptomercaptan and 0.5%-3% of octanol. According to the synergistic effect of the medicament, the 2-hydroxyethyl dibutylcarbamodithioate, the 2-hydroxy-1-mercaptomercaptan and a non-ionic collecting agent octanol are used as the zinc combined collecting agent. The combinedcollecting agent has good collecting performance on zinc sulfide minerals, the collecting performance on pyrite is weak, and the purpose of efficiently recycling zinc can be achieved. According to the zinc combined collecting agent HQ-Zn, when a higher zinc recovery rate is obtained, the dosage of copper sulfate is 1 / 5-1 / 2 of that of copper sulfate in a sodium butyl xanthate system, and the dosage of HQ-Zn is 1 / 4-3 / 5 of that of sodium butyl xanthate. After the agent and the method are adopted, raw ore containing 0.3%-5% of lead, 0.3%-7% of zinc and 1%-25% of sulfur is treated, the zinc gradein the zinc concentrate can be larger than 50%, and the zinc operation recovery rate is larger than 88%.

Owner:CENT SOUTH UNIV

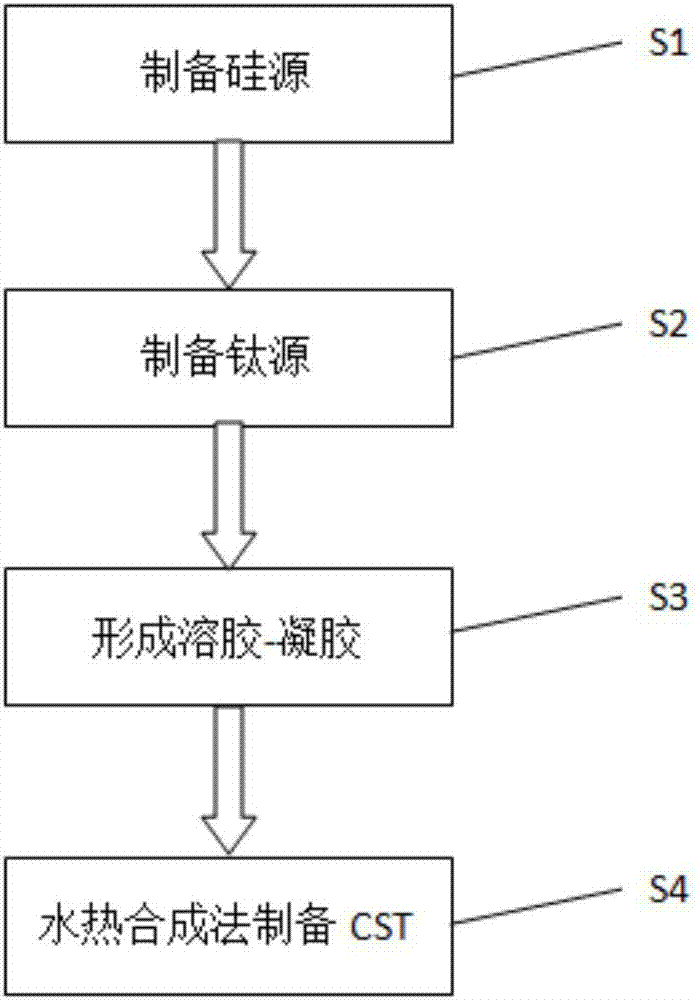

Method for synthesizing nano hydrated crystalline sodium silicon titanate by utilizing inorganic raw material

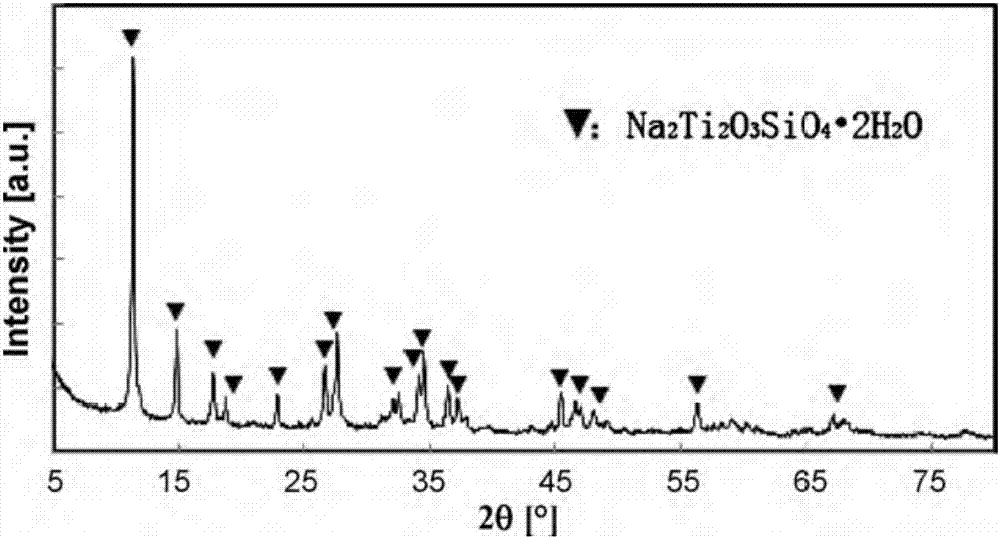

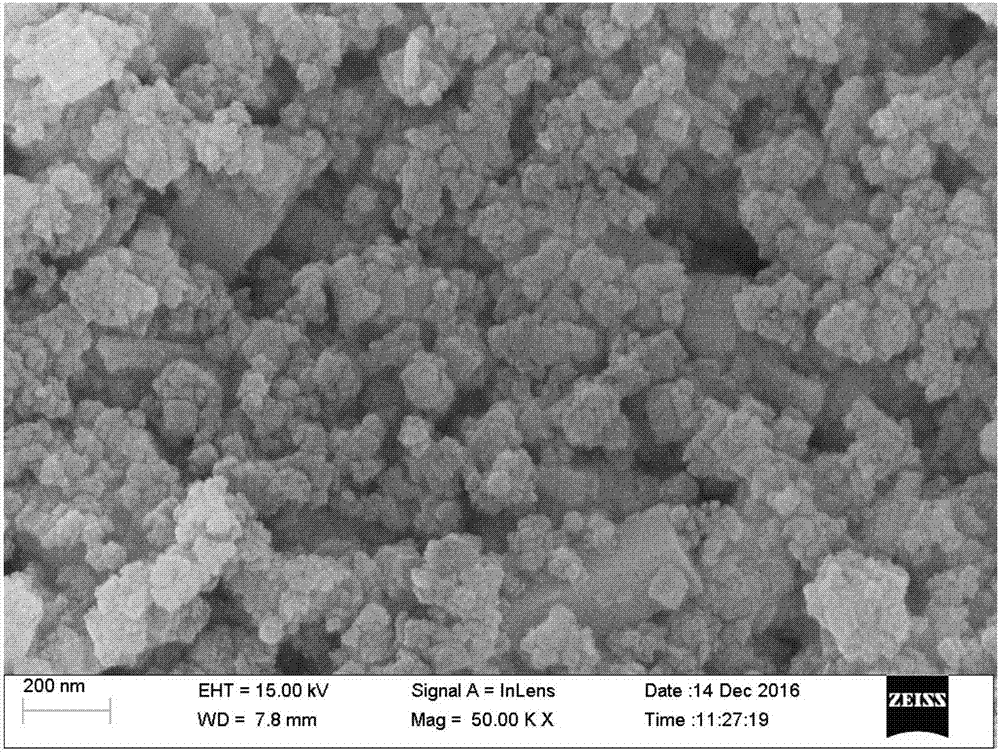

InactiveCN106882813AStrong chemical stabilityIncrease costMaterial nanotechnologySilicon compoundsSol-gelHydrothermal synthesis

The invention discloses a method for synthesizing nano hydrated crystalline sodium silicon titanate by utilizing an inorganic raw material. According to the method, Na2Si2O3.9H2O and NaOH are used as silicon sources and an ethanol solution of TiCl4 is used as a titanium source; a nano CST (Crystalline Silicotitanate) crystal without an impure phase is successfully prepared by adopting a sol gel-hydrothermal synthesis method; the difficulty that the prepared CST contains the impure phase is solved; the method is low in operation cost and simple in preparation process.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Gasification slag magnesium-nickel alloy hydrogen storage composite material and preparation method thereof

The invention provides a preparation method of a gasification slag magnesium-nickel alloy hydrogen storage composite material. The method is characterized in that after magnesium powder, nickel powderand gasification slag are mixed, by means of a porous structure of the gasification slag, pore channels of the gasification slag are filled with the magnesium powder and the nickel powder through ball milling, ultrasonic vibration and other modes, and a mixture is uniformly mixed; and then through pressing, sintering and cooling, the gasification slag magnesium-nickel alloy hydrogen storage composite material is prepared. When the composite material is used for hydrogen storage, the porous gasification slag serving as a catalyst is distributed in a magnesium-nickel alloy matrix, so that alloyhydrogenation and hydride dehydrogenation can be promoted, alloy hydrogen collection and hydrogen desorption speed can be increased, and the activation energy of a hydrogen storage system can be reduced; and fine magnesium-nickel alloy particles are distributed in the gasification slag pore channels, so that the growth, caused by heating in a hydrogen desorption process, of the magnesium-nickel alloy particles can be effectively inhibited, and then the hydrogen storage cycle stability of the composite material is maintained. The preparation method is low in cost and wide in raw material source, has the effects of solid waste gasification slag treatment, and reclamation and higher value application of the gasification slag at the same time, and is remarkable in advantage and suitable for popularization.

Owner:YULIN UNIV

Method for recycling lead paste in spent lead-acid battery

ActiveUS20190305388A1Zero emissionReduce environmental loadLead-acid accumulatorsLead monoxideLead chloridePollution

The disclosure discloses a method for recycling lead paste in a spent lead-acid battery, comprising: (1) pretreating lead paste in a spent lead-acid battery as a raw material under vacuum; mixing the pretreated lead paste with a chlorination reagent to obtain reactants; and heating the reactants under vacuum to carry out a chlorination volatilization reaction, so that lead element in the pretreated lead paste is combined with chlorine element in the chlorination reagent to form lead chloride, which is then volatilized, and after the reaction is completed, chlorination residue and a crude lead chloride product are obtained by condensation and crystallization after volatilization; (2) purifying the crude lead chloride product obtained in the step (1) under vacuum to obtain a refined lead chloride product. The disclosure improves the overall process flow of the recycling method as well as parameter conditions of the respective steps thereof, and can effectively solve the problem of serious pollution in lead paste recycling in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

Lithium ion battery anode coating technology

InactiveCN103943815ASerious pollutionMeet the requirementsElectrolyte layer coatingOrganic solventCombustion

The invention discloses a lithium ion battery anode coating technology, which comprises the following steps: mixing and stirring butadiene styrene rubber and carboxymethylcellulose sodium for 20-40 minutes, adding a cathode material for stirring for 20-40 minutes, then adding acetylene black for stirring for 2 hours, standing for 10 minutes to form a paste, uniformly coating the paste on a coating matrix, and drying at the temperature of 80 DEG C. The anode coating employs aqueous binders of butadiene styrene rubber and carboxymethylcellulose sodium, and has the advantages of no solvent release, environment requirement conformity, low cost, non combustion and safe usage. Compared with the organic solvent type binder, the electrode performance by employing the aqueous binder for coating is excellent, and the lithium ion battery anode coating technology has the economic and environmental protection characteristic as well as wide development prospect.

Owner:傅汝毅

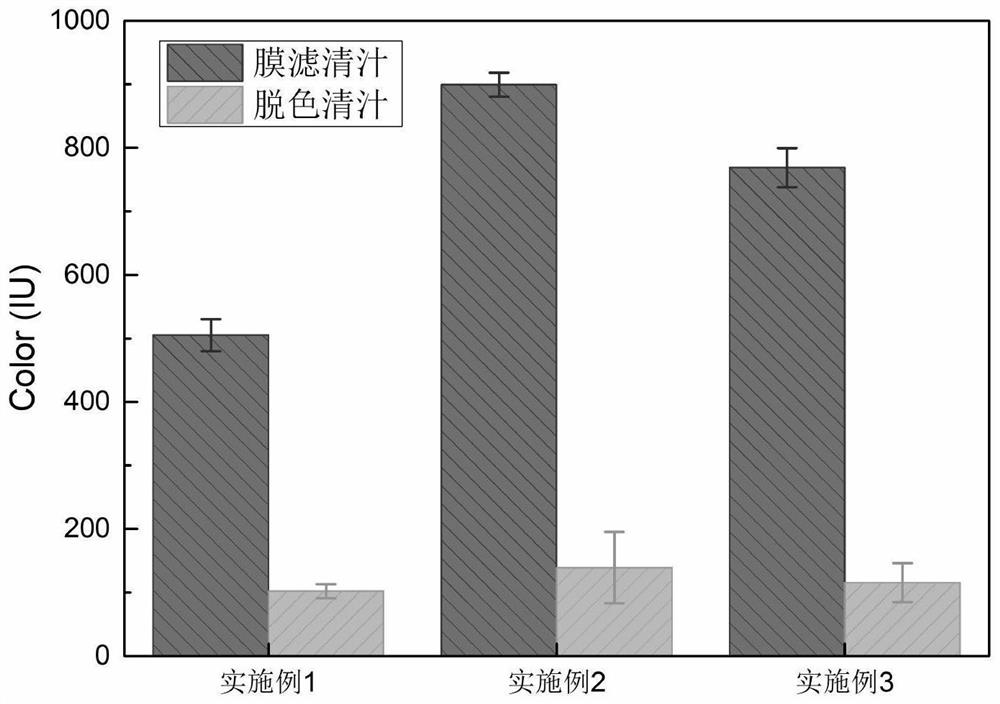

Decoloring method of redissolved syrup

PendingCN114736992APromote degradationGreen and non-toxicPurification using adsorption agentsSeparation technologyOxide composite

The invention discloses a decoloring method of remelt syrup, which comprises the following steps: mixing quaternary ammonium functionalized chitosan / graphene oxide composite aerogel with remelt syrup, and adsorbing pigment of the remelt syrup. The quaternary ammonium functionalized chitosan / graphene oxide composite aerogel is prepared by taking chitosan and graphene oxide as raw materials and 25% glutaraldehyde as a cross-linking agent and stripping the graphene oxide through a cross-linking polymerization method, and then amino on a chitosan molecular chain is subjected to graft modification and grafted with quaternary ammonium groups with positive charges. According to the invention, chitosan is used as a raw material to prepare the decolorizing agent for sugar, and graphene oxide solves the problem that pores are easy to collapse after quaternization of chitosan, so that the chitosan-based aerogel decolorizing agent has a rich pore structure and is coupled with a membrane-method green sugar production process; the problem that the color value of finished white granulated sugar is high due to the fact that small molecular pigments cannot be intercepted when remelt syrup is treated through a membrane separation technology is solved, the greening of the sugar manufacturing process is achieved, and meanwhile the quaternary ammonium functionalized chitosan / graphene oxide composite aerogel can be recycled after being subjected to decoloration treatment.

Owner:GUANGXI UNIV +1

Preparation method and application of shark chondroitin sulfate chelated zinc salt

PendingCN113880964AMild production conditionsQuality controllableOrganic active ingredientsAntipyreticSulphate chondroitinHealth food

The invention relates to a preparation method of shark chondroitin sulfate chelated zinc salt. The method comprises the following steps: pretreating shark cartilage to obtain shark cartilage powder, and preparing shark chondroitin sulfate by utilizing an enzyme extraction and centrifugal machine separating synergistic nanofiltrating membrane purification linkage technology. The shark chondroitin sulfate zinc salt crude product is prepared by taking the shark chondroitin sulfate as a raw material and utilizing an ultrasonic cavitation and shark chondroitin sulfate zinc chelation technology. And a shark chondroitin sulfate zinc salt powder finished product is prepared by utilizing a centrifugal separating electrodialysis purification and spray drying integrated technology. The method is mild in reaction condition, controllable in quality and suitable for large-scale production. The shark chondroitin sulfate zinc salt prepared by the preparation method disclosed by the invention is concentrated in average relative molecular mass, good in solubility, high in bioavailability, high in safety and free from toxic and side effects, and can be applied to the fields of antiinflammatory health foods and medicines.

Owner:THIRD INST OF OCEANOGRAPHY MINIST OF NATURAL RESOURCES

One-component type multi-functional fracturing fluid additive and process for preparing the same

ActiveUS11384282B1Reduced functionalityImprove performanceDrilling compositionBorehole/well accessoriesOctanolGlycol synthesis

The present disclosure discloses a one-component type multi-functional fracturing fluid additive and a process for preparing the same. The process the following steps: mixing ethylene glycol, isopropanol, 1-butanol, 1-hexanol and 1-octanol, and heating to uniformly disperse the mixture to obtain an aqueous dispersant; adding a high molecular polymer thickener and an auxiliary agent to the aqueous dispersant, and stirring the mixture at a high speed to obtain a suspension, wherein the auxiliary agent is one or more selected from clay stabilizers, drainage aids, drag reducers, emulsion inhibitors, filtrate reducers, corrosion inhibitors and fungicides; and slowly stirring the suspension at a low speed, and cooling the suspension to room temperature to collect a sample of suspension. This auxiliary agent has good characteristics such as temperature resistance, shear resistance, salt resistance, and sand suspension.

Owner:SHAANXI UNIV OF SCI & TECH

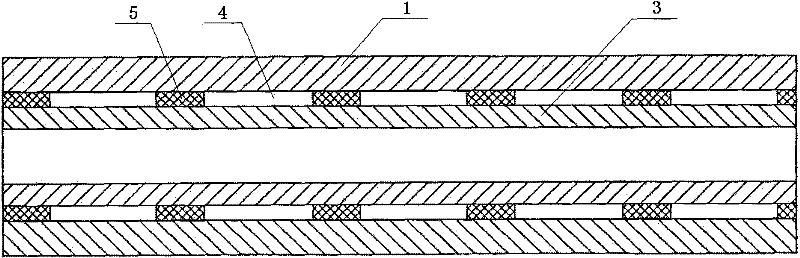

medical infusion tube

InactiveCN102266640AImprove bending resistanceGood chemical resistanceInfusion devicesOther medical devicesChemical compatibilityBiomedical engineering

The invention discloses a medical infusion tube, which comprises an inner layer, an outer layer and an intermediate layer bonding the inner layer and the outer layer, and the intermediate layer is composed of a hollow cavity and a hollow cylindrical fence alternately. The medical infusion tube saves a lot of raw materials, has low production cost, also has excellent bending resistance, is more conducive to the normal activities of patients during treatment, has good compatibility with human skin and medicinal liquid, and meets environmental protection requirements.

Owner:李广英

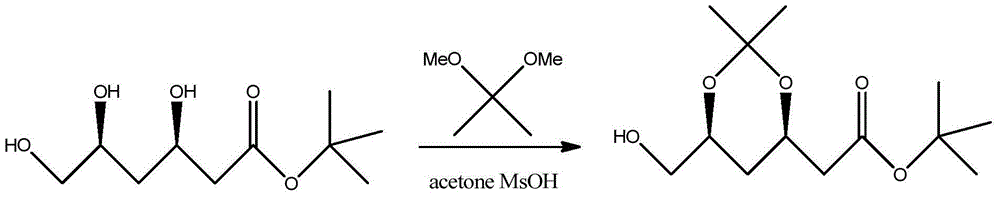

Biocatalytic hydrogenation composition and method for synthesis of Rosuvastatin chiral intermediate

InactiveCN105713884ASimple and fast operationHigh yieldMicroorganism based processesOxidoreductasesTert butylGlucose dehydrogenase

A selective biocatalytic hydrogenation composition comprises glucose dehydrogenase, ketoreductase and coenzyme. The present invention also provides a preparation method of tert-butyl (3R, 5S) 3,5,6-trihydroxy hexanoate, and the tert-butyl (3R, 5S) 3,5,6-trihydroxy hexanoate is prepared by mixing tert-butyl (S)-5,6-dihydroxy-3-oxo-hexanoate with the glucose dehydrogenase, the ketoreductase and the coenzyme for reaction. The present invention also provides a method for synthesis of a Rosuvastatin intermediate, and the Rosuvastatin intermediate is mainly prepared from the selective biocatalytic hydrogenation composition. Compared with the prior art, the method has the advantages of being mild in reaction conditions, safe, environmentally-friendly, low in cost, high in product stereoselectivity, and the like.

Owner:ANGELYEAST CO LTD

A high-efficiency flotation collector of zinc sulfide and its application

The invention discloses a high-efficiency flotation collector of zinc sulfide and its application. According to the mass percentage, it consists of the following components: 92%-98% of 2-hydroxyethyl dibutyl dithiocarbamate, 2‑Hydroxy‑1‑mercaptothiol 1.5% to 5%, octanol 0.5% to 3%. According to the synergistic effect of medicaments, 2-hydroxyethyl dibutyl dithiocarbamate, 2-hydroxy-1-mercaptothiol and non-ionic collector octanol are used as zinc combined collector. The combined collector has a good collection performance on zinc sulfide minerals, but a weak collection performance on pyrite, and can achieve the purpose of efficiently recovering zinc. The combined zinc collector HQ-Zn of the present invention, when obtaining a higher zinc recovery rate, the amount of copper sulfate is 1 / 5 to 1 / 2 of the copper sulfate in the butyl xanthate system, and the amount of HQ-Zn is 1 / 5 to 1 / 2 of the butyl xanthate system. 1 / 4~3 / 5 of that. After the present invention adopts the medicament and method, the raw ore containing 0.3% to 5% of lead, 0.3% to 7% of zinc and 1% to 25% of sulfur can be treated to obtain zinc grade > 50% in the zinc concentrate. Zinc recovery rate> 88%.

Owner:CENT SOUTH UNIV

Preparation method of vacuum pressure impregnation resin

The invention relates to a preparation method of vacuum pressure impregnation resin. According to the invention, a low-smell multi-functionality low-volatilization active diluent agent is used for replacing styrene which causes severe environmental pollution. The diluent agent at least comprises two functional groups, wherein one is a double-bond functional group, and the other is a double-bond functional group or a functional group which can subject to a reaction with epoxy or a curing agent. The impregnation resin provided by the invention is advantaged in small viscosity, short gelatinizing time, excellent electrical properties, high heat-resistance, environment-friendliness, and safe application.

Owner:上海电气集团上海电机厂有限公司

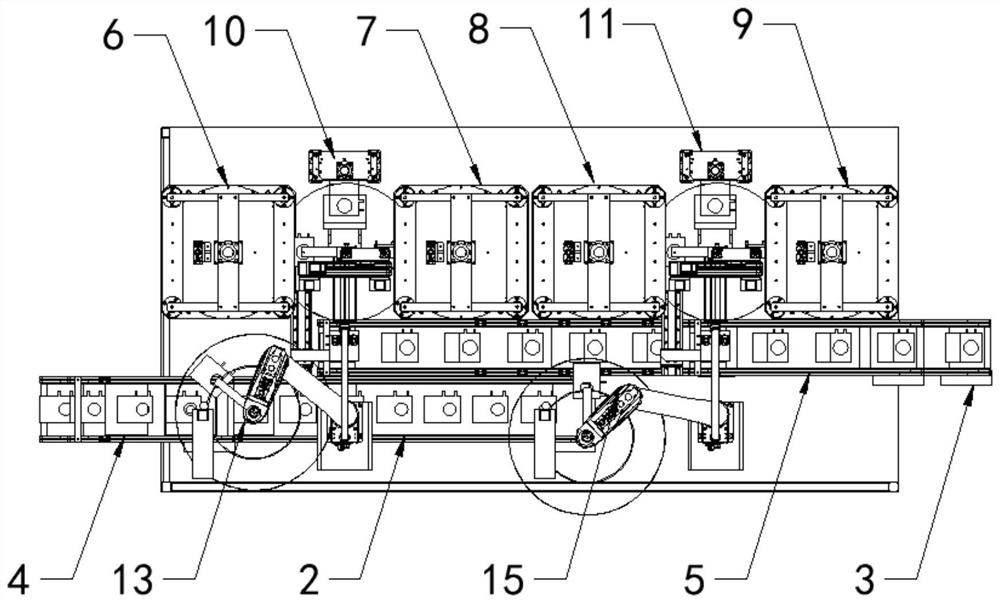

Linear centrifugal secondary sealing machine

PendingCN112952205AScientific and reasonable design spaceLarge maintenance spaceAssembling battery machinesFinal product manufactureEngineeringMachine

The invention discloses a linear centrifugal secondary sealing machine, which comprises a rack, wherein a second feeding pull belt and a first discharging pull belt are fixedly arranged in the center of the top of the rack, a first feeding pull belt is fixedly arranged at one end of the top of the second feeding pull belt, a second discharging pull belt is fixedly arranged at one end of the top of the first discharging pull belt, a centrifugal cavity A, a centrifugal cavity B, a centrifugal cavity C and a centrifugal cavity D are sequentially and fixedly arranged on one side of the top of the rack from left to right, a first edge cutting mechanism is fixedly arranged between the centrifugal cavity A and the centrifugal cavity B, and a second edge cutting mechanism is fixedly arranged between the centrifugal cavity C and the centrifugal cavity D. According to the linear centrifugal secondary sealing machine, linear layout is adopted, operation is convenient during maintenance, the productivity is high, all the cavities work independently and do not influence one another, and the space and the cost can be greatly saved due to the fact that the cavities share the same mechanism.

Owner:东莞市冠逸自动化科技有限公司

Copper-lead separation flotation inhibitor and applications thereof

The invention belongs to the field of complicated copper-lead-zinc sulphide ore beneficiation separation and provides a copper-lead separation flotation inhibitor and applications thereof. The copper-lead separation flotation inhibitor is formed by mixing polymeric ferric sulfate solution with a mass concentration of 5.0%-6.0% and glycerin solution with a mass concentration of 0.8%-1.2%, wherein the mass ratio of the polymeric ferric sulfate solution to the glycerin solution is 1:1-4. Addition of the inhibitor in copper-lead separation operation can remarkably improve copper and lead concentrate qualities, evidently lower mutual containing of copper and lead, and improve flotation recovery rate of copper and lead minerals. The copper-lead separation flotation inhibitor and the applications thereof have the advantages that the copper-lead separation flotation inhibitor is environment-friendly, efficient in sorting, low in reagent cost, easy to operate and the like and applicable to the complicated copper-lead-zinc sulphide ore beneficiation separation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com