Technology for enzymatic efficient deacetylation and chitin degradation by using Thermophilic Bacillus

A thermophilic bacillus, deacetylation technology, applied in the fields of biopharmaceutical technology, chemical engineering, and food processing technology, can solve the problems of difficult product purification, easy pollution of the environment, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

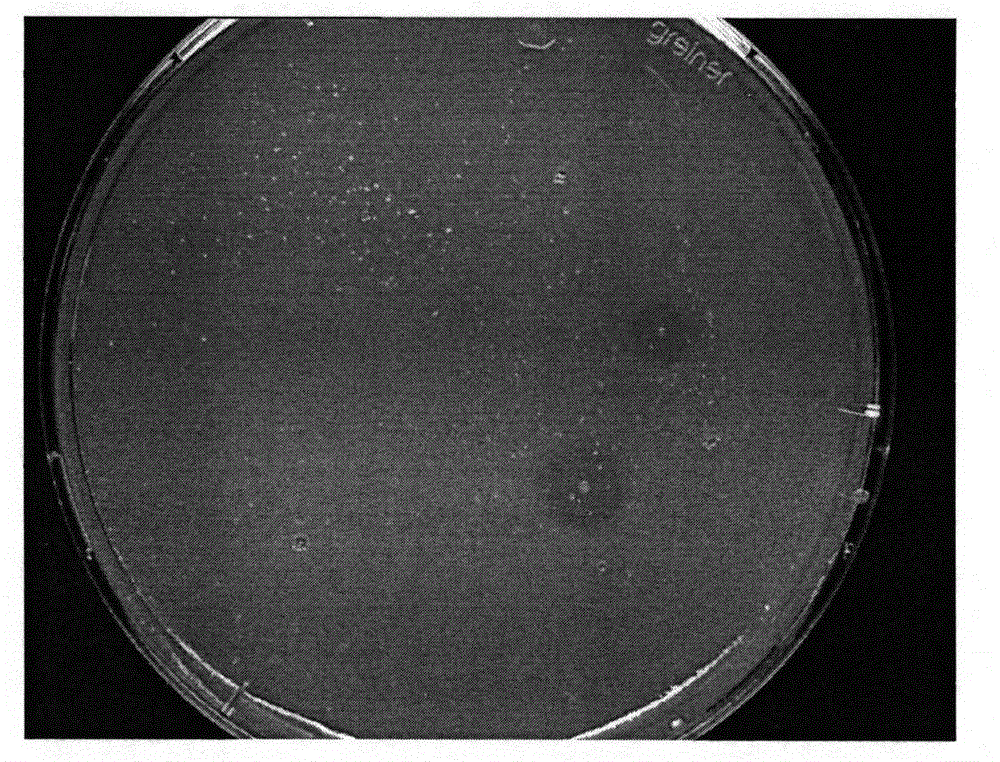

Image

Examples

Embodiment Construction

[0010] A technology for efficient deacetylation of chitin by using Thermophilic Bacillus enzyme

[0011] 1. Preparation of strains

[0012] 1) Plate culture: Bacillus thermophilus C8-3-2a, ctn C8-1, ctn C8-1`, ctn x10, ctn x5-3 were cultured on a double-layer plate with chitin as the sole carbon source, respectively. Streak inoculation on the base, culture at 45-46°C for 24 hours, and put it in the refrigerator for later use; 2) Liquid culture: Use an inoculation loop to pick out the cultured plates of Bacillus thermophilus C8-3-2a, ctnC8- 1. Inoculate ctn C8-1`, ctn x10, ctn x5-3 strains into 100 mL of liquid medium with chitin as the only carbon source, culture at 45-46 °C for 72 hours, and store it in a refrigerator for later use;

[0013] 3) Raw material treatment: The chitin used to prepare the plate medium should be ground first, and then passed through a 30-mesh sieve. Chitin for fermentative production is cut into small pieces or small particles.

[0014] 2. Ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com