Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74 results about "Chitin deacetylase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

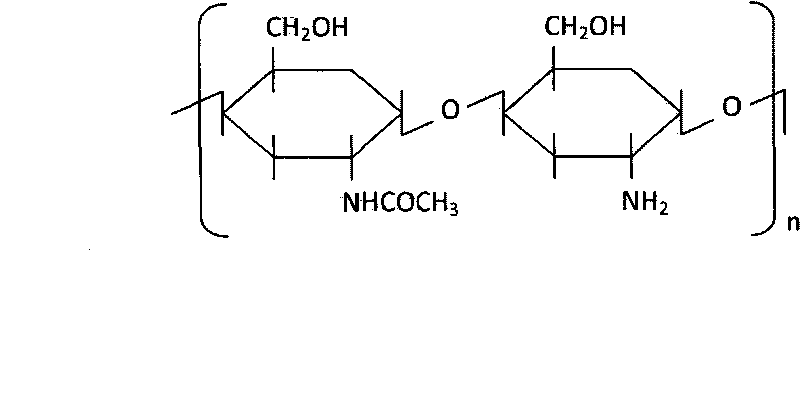

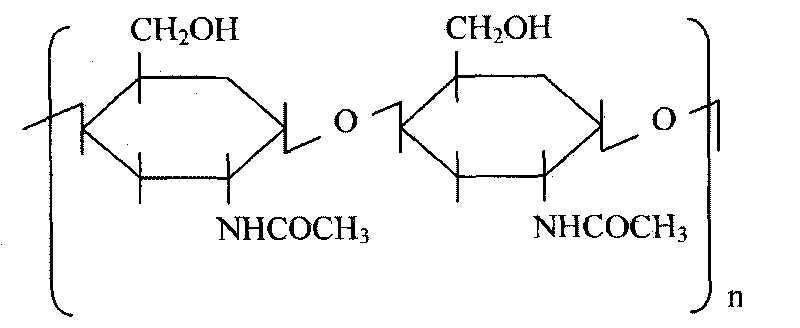

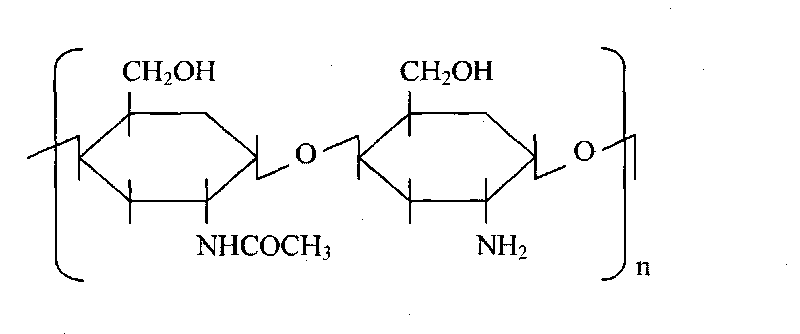

In enzymology, a chitin deacetylase (EC 3.5.1.41) is an enzyme that catalyzes the chemical reaction chitin + H₂O ⇌ chitosan + acetate Thus, the two substrates of this enzyme are chitin and H₂O, whereas its two products are chitosan and acetate. This enzyme belongs to the family of hydrolases, those acting on carbon-nitrogen bonds other than peptide bonds, specifically in linear amides. The systematic name of this enzyme class is chitin amidohydrolase.

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097ATake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

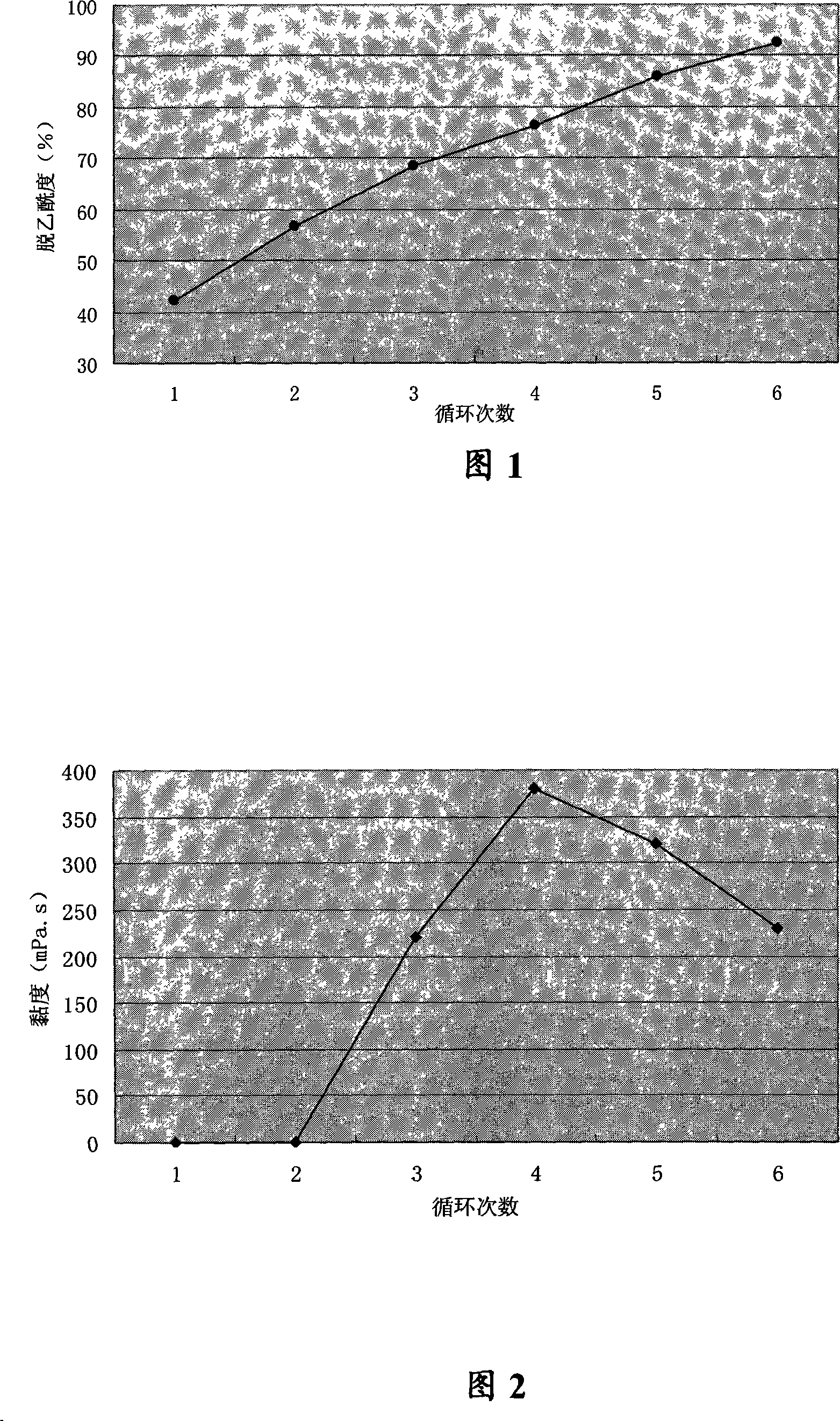

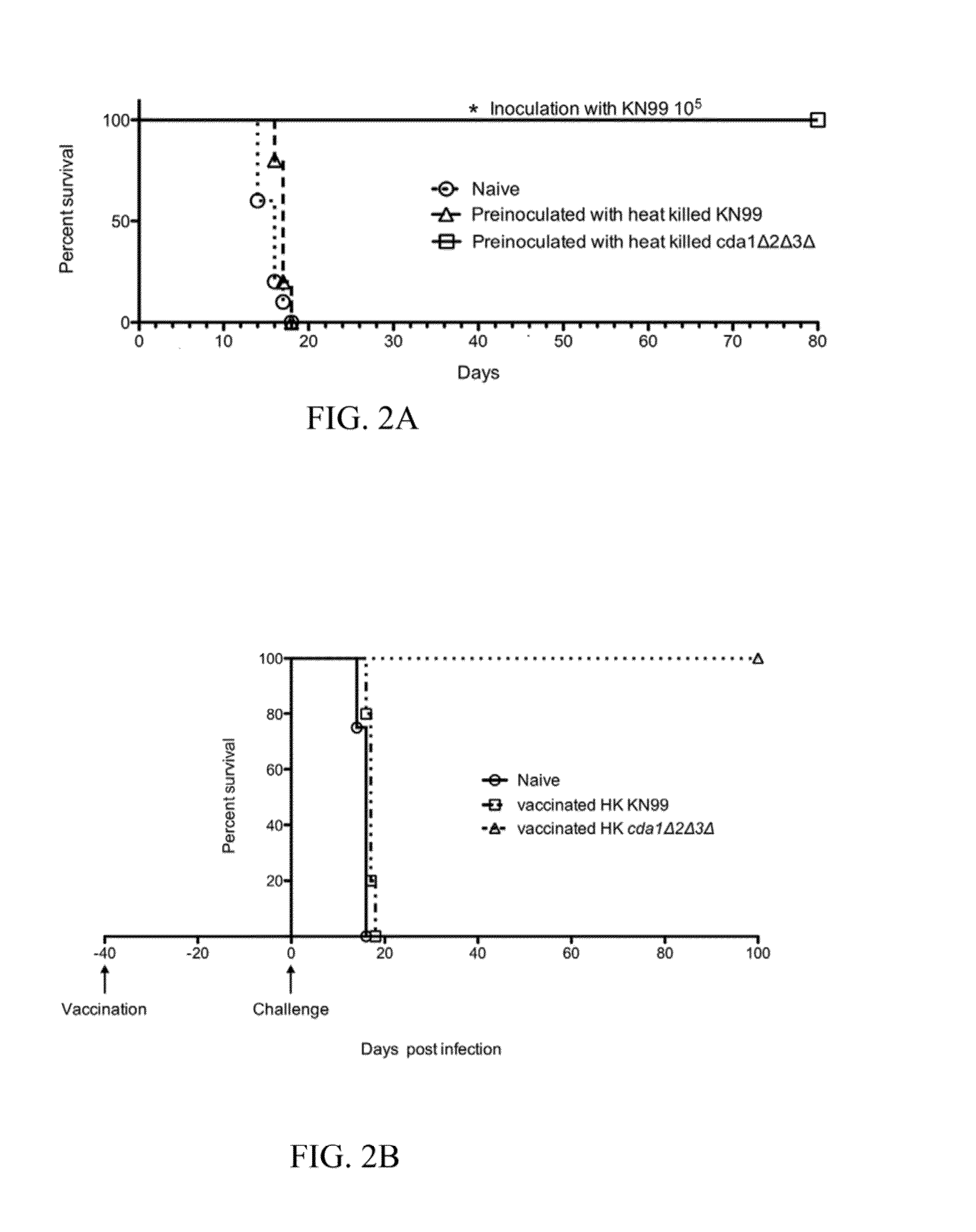

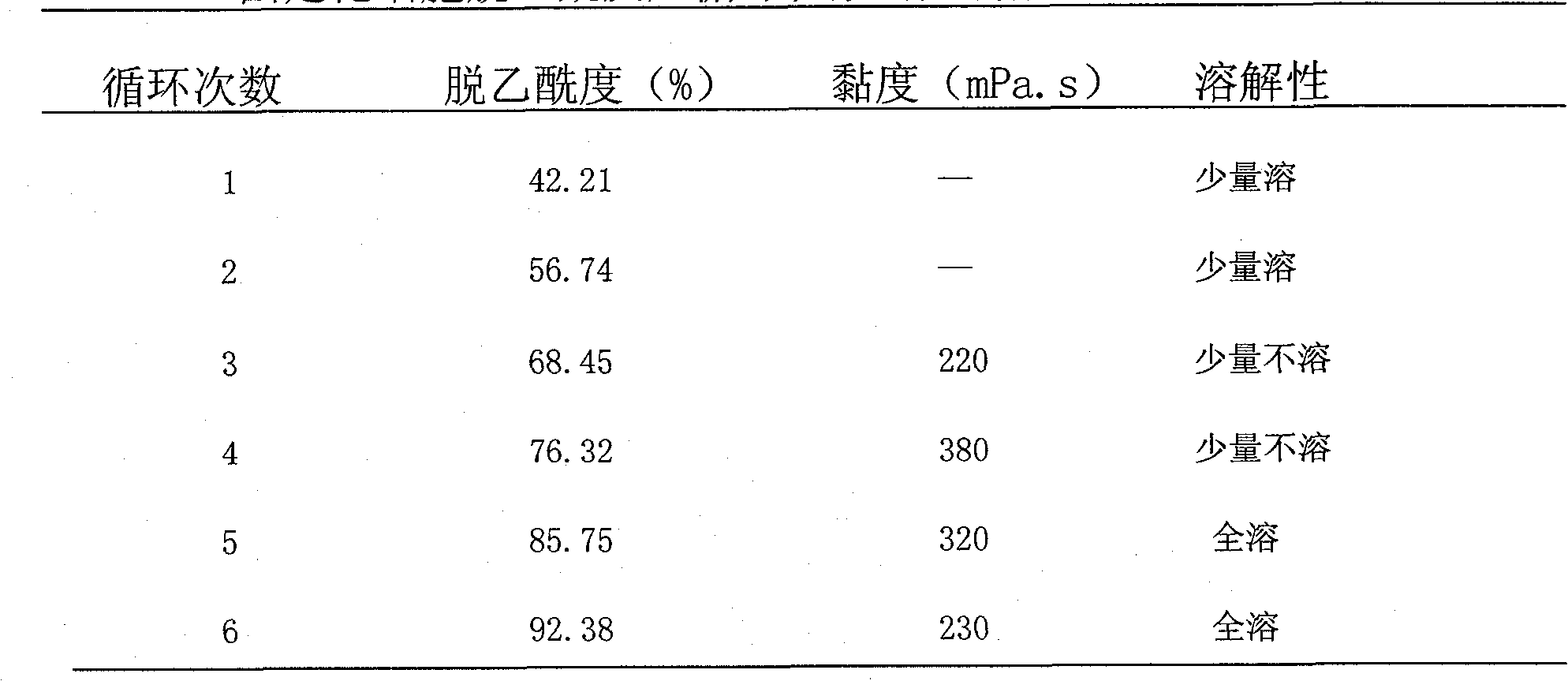

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effect is attained.

Owner:重庆百奥帝克微生态科技有限公司

Vaccination against Cryptococcus

ActiveUS20150328295A1Reduce and eliminate abilityReduce and eliminate expressionPowder deliverySpray deliveryVaccinationWild type

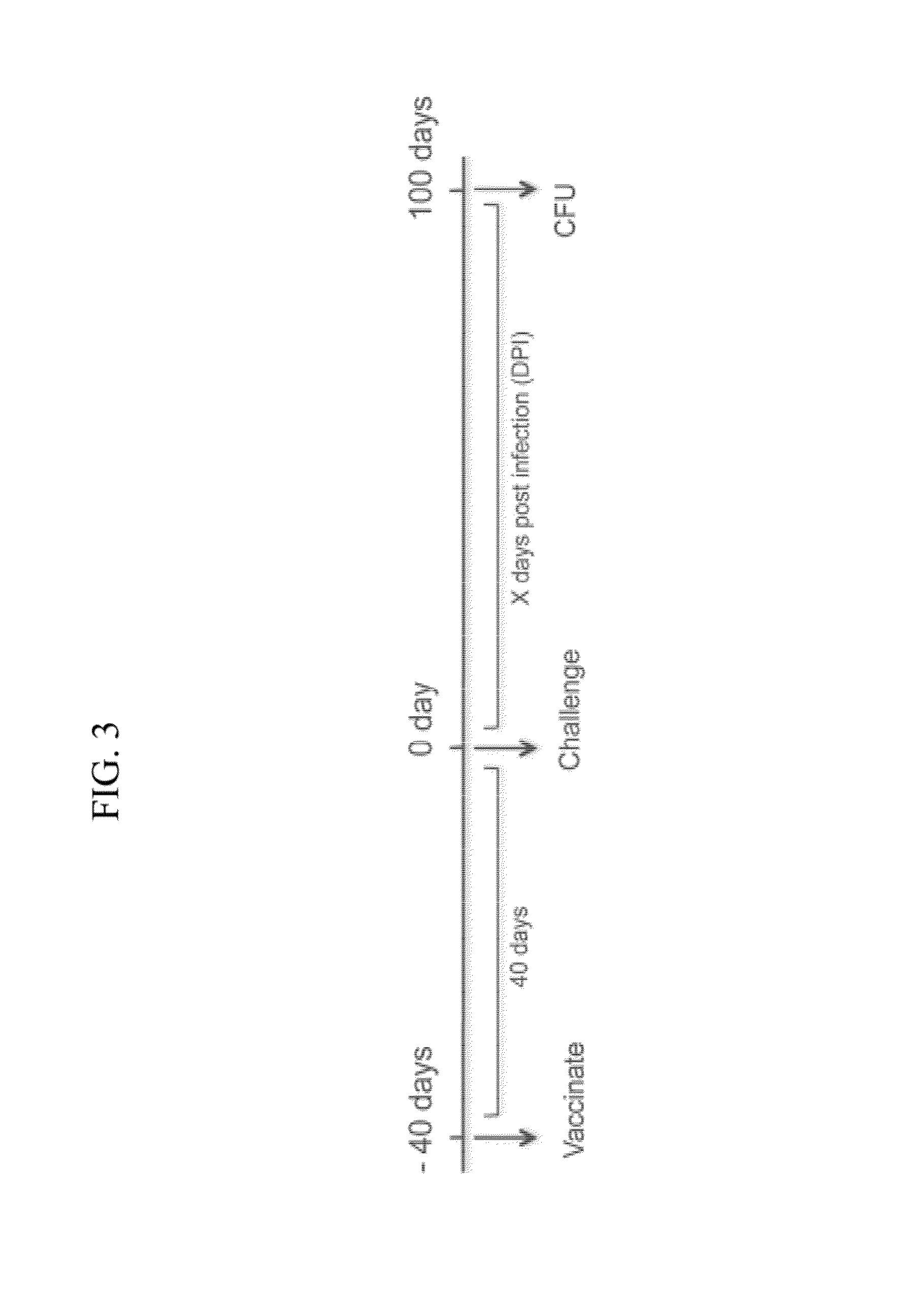

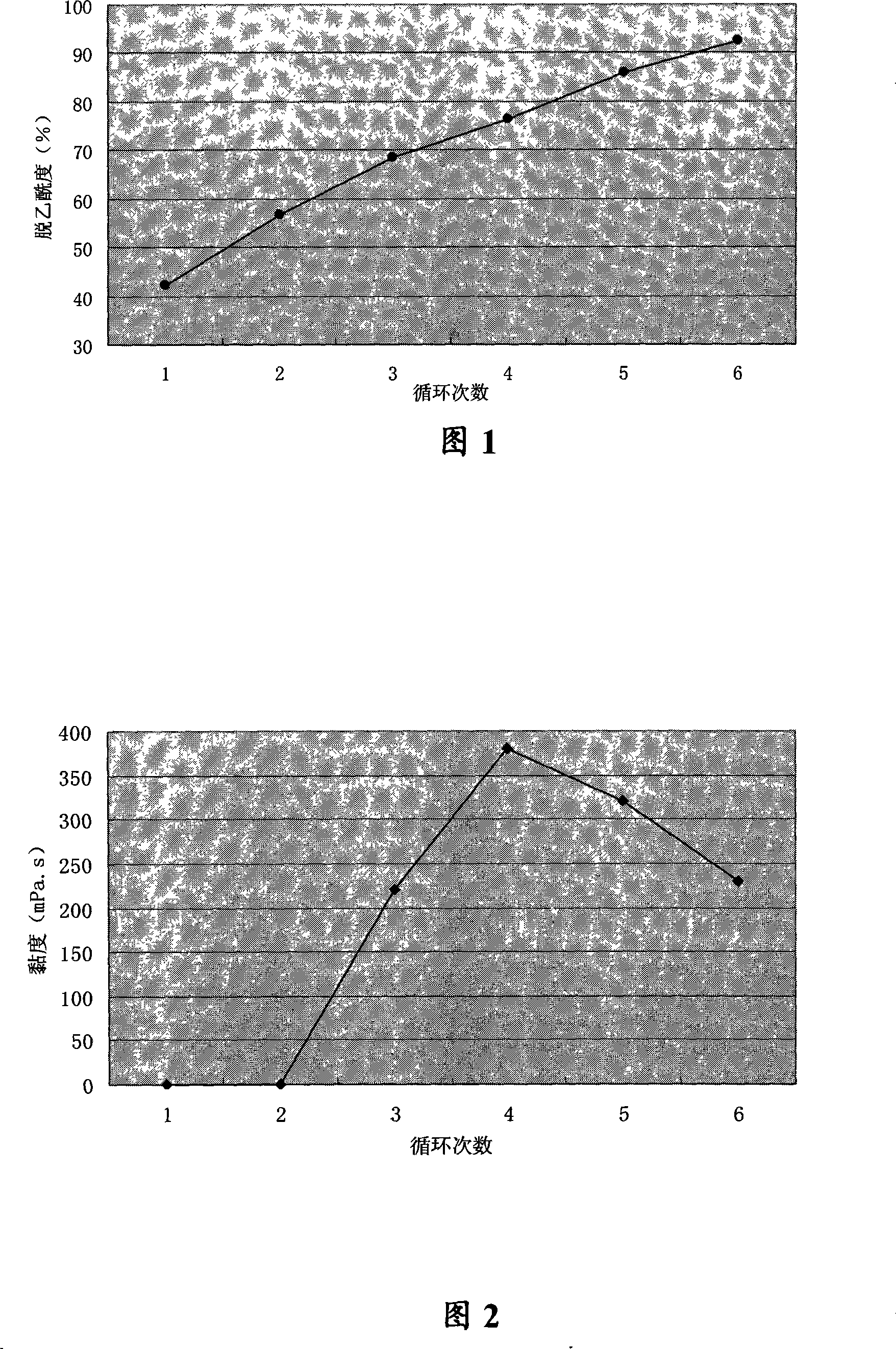

Vaccines and methods of inoculation for conferring immunity to Cryptococcus infection are disclosed. Strains of Cryptococcus fungi, including Cryptococcus neoformans and Cryptococcus gattii, can be administered to a human or animal subject via inhalation. Cryptococcus fungi that can be used to confer immunity can comprise one or more mutations in genes that contribute to chitosan production, such as genes encoding a chitin deacetylase (cda), a chitin synthase (chs) and / or a regulator of chitin synthase (csr). Inhalation administration of heat-killed Cryptococcus harboring deletions in cda1, cda2 and cda3 genes can confer immunity. In a murine model system, inhalation administration of Cryptococcus neoformans harboring deletions in cda1, cda2 and cda3 genes conferred immunity against subsequent exposure to wild type Cryptococcus neoformans in 100% of test animals. Inhalation administration of heat-killed Cryptococcus grown under conditions leading to reduced chitosan production can also confer immunity.

Owner:WASHINGTON UNIV IN SAINT LOUIS

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097BTake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effectis attained.

Owner:重庆百奥帝克微生态科技有限公司

Method for preparing chitin and chitosan through hydrothermal/two-step enzymic method from shrimp and crab shells and application of the method

InactiveCN110256603AImprove accessibilityRealize multilinkOrganic compound preparationCarboxylic acid salt preparationPollutionImpurity

The invention relates to a method for preparing chitin and chitosan by coupling shrimp and crab shells through a hydrothermal / two-step enzymic method. The method comprises the following steps: removing impurities from shrimp and crab shells, and crushing the shrimp and crab shells; adding organic acid for decalcification treatment, placing filter residues into a hydrothermal reactor, and feeding a reaction medium for hydrothermal reaction; then rapidly relieving the pressure in the reactor, collecting a hydro-thermal treatment product, carrying out solid-liquid separation, and adding protease into a solid material to carry out enzymolysis deproteinization treatment; separating the deproteinized product to obtain solid residues, drying the solid residues to obtain chitin, and adding chitin deacetylase into the chitin for enzyme treatment to prepare chitosan; and finally, treating the organic acid decalcification solution and the protein enzymatic hydrolysate to obtain organic calcium and protein peptide. According to the method, the decalcified shrimp and crab shells are modified through a hydrothermal method, the compact structure of the shrimp and crab shells is broken, the accessibility of subsequent protease and deacetylase is promoted, the enzymolysis efficiency is improved, poly-generation of organic acid calcium, protein peptide, chitin and chitosan is achieved, the production process is rapid, stable and free of pollution, and large-scale industrial application is easy to achieve.

Owner:TIANJIN UNIV OF SCI & TECH

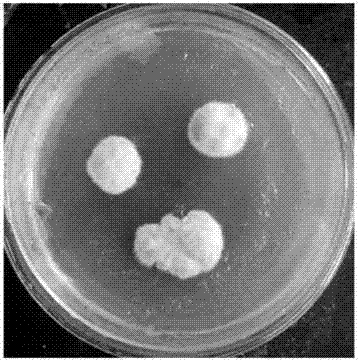

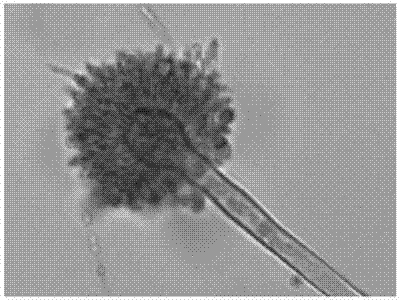

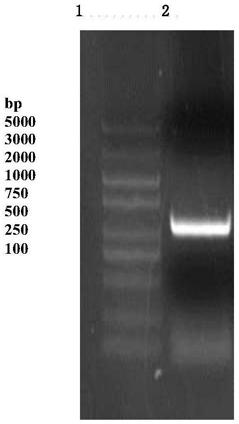

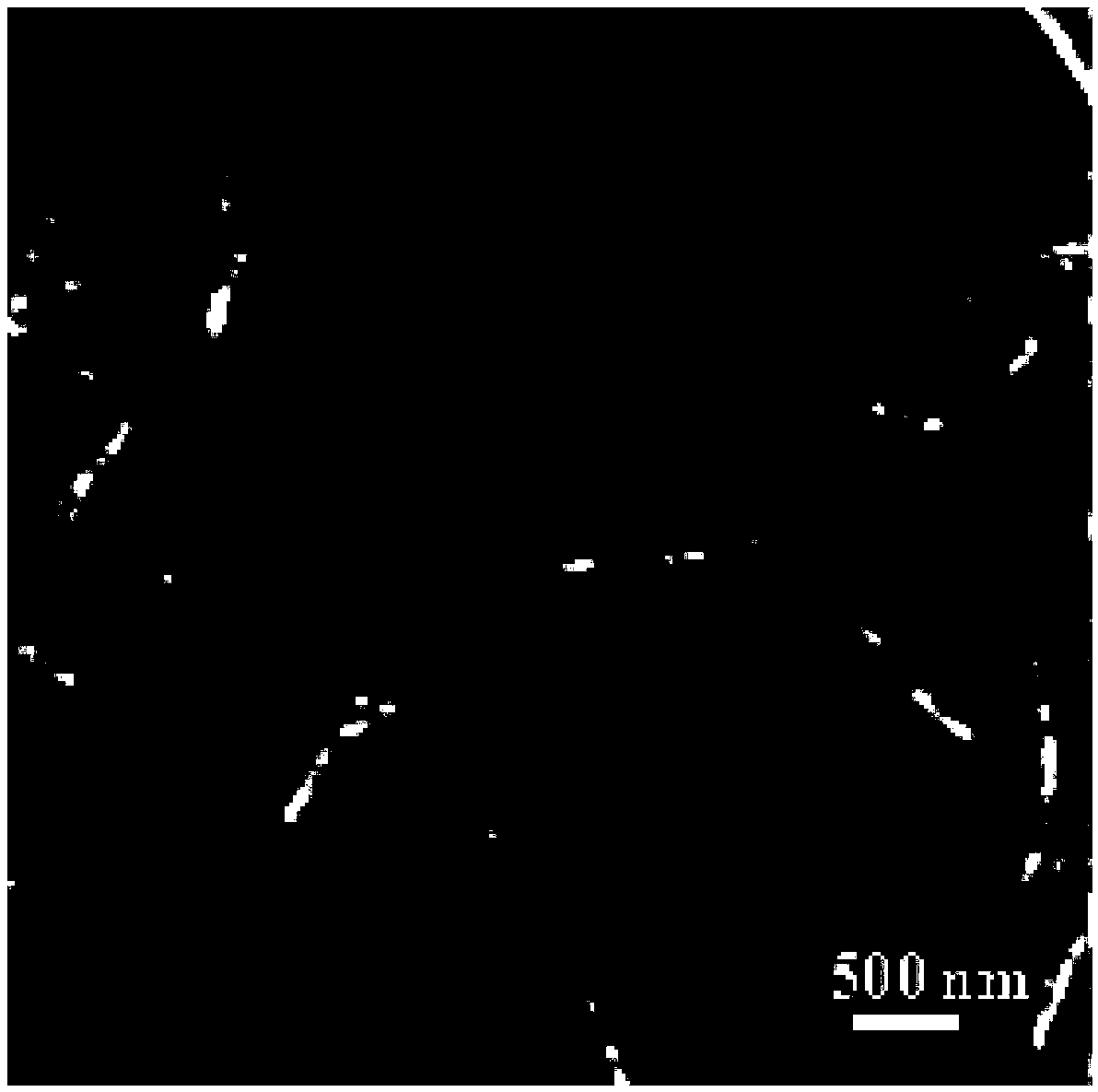

Bacterial strain capable of producing chitin deacetylase and application of bacterial strain in production of chitin deacetylase through fermentation

The invention provides a bacterial strain capable of producing chitin deacetylase and an application of bacterial strain in production of chitin deacetylase through fermentation. The bacterial strain is Aspergillus versicolor X, and is preserved at a China Center for Type Culture Collection, the preservation number is CCTCC NO.M2014459, and preservation date is 8th, Oct, 2014. The invention also provides a enzyme production method through fermentation, the enzyme activity of the prepared chitin deacetylase can reach 1.41U / mL. The application has the advantages that scope of enzyme microbe capable of producing chitin deacetylase is developed, production cost is reduced, and chitin deacetylase has wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing chitin deacetylase

ActiveCN102676485ASignificantly progressiveHigh potencyHydrolasesMicroorganism based processesHydrogenSalting out

The invention relates to a method for preparing chitin deacetylase. The method includes that Scopulariopsis brevicaulis is utilized as a producing strain of the chitin deacetylase, after an activation, the Scopulariopsis brevicaulis is inoculated to a fermentation container which contains a fermentration medium to be subjected to a fermentation for 90-100 hours on a shaking table, the potential of hydrogen (Ph) value of the shaking table is controlled between 6.5 and 7.0, the temperature of the shaking table is maintained between 27DEG C and 29 DEG C, the rotary speed of the shaking table is 200-240rpm, and a chitin deacetylase product is obtained by separating, salting out and purifying a fermentation liquor. By means of the method, the active unit of one mini liter of the fermentation liquor of the prepared chitin deacetylase can uppermost reach 36 units.

Owner:HUBEI UNIV OF TECH

Method for preparing chitin size modified by biological enzyme method

InactiveCN101736583AGood water solubilityUniform degree of deacetylationFibre treatmentMicroorganism based processesSolubilityCulture fluid

The invention belongs to the field of textile chemistry, and relates to a method for preparing chitin size modified by a biological enzyme method. The method is characterized in that the chitin size modified by the biological enzyme method is finally prepared through steps of: step 1, the preparation of a chitin deacetylase seed culture fluid; step 2, the preparation of chitin deacetylase; and step 3, the preparation of the chitin size modified by the biological enzyme method. The chitin size has better water solubility, and steady viscosity; and the size can endow fabrics with certain antibacterial property and sterilization property, so no desizing is needed after the weaving is finished, the discharge of a desizing waste liquid is avoided, the production cost is saved, the environmental pollution is reduced, and the requirement on green environmental protection is achieved.

Owner:DONGHUA UNIV

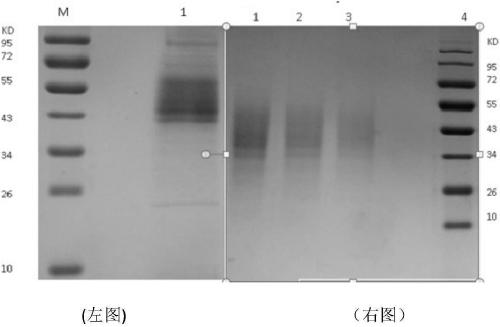

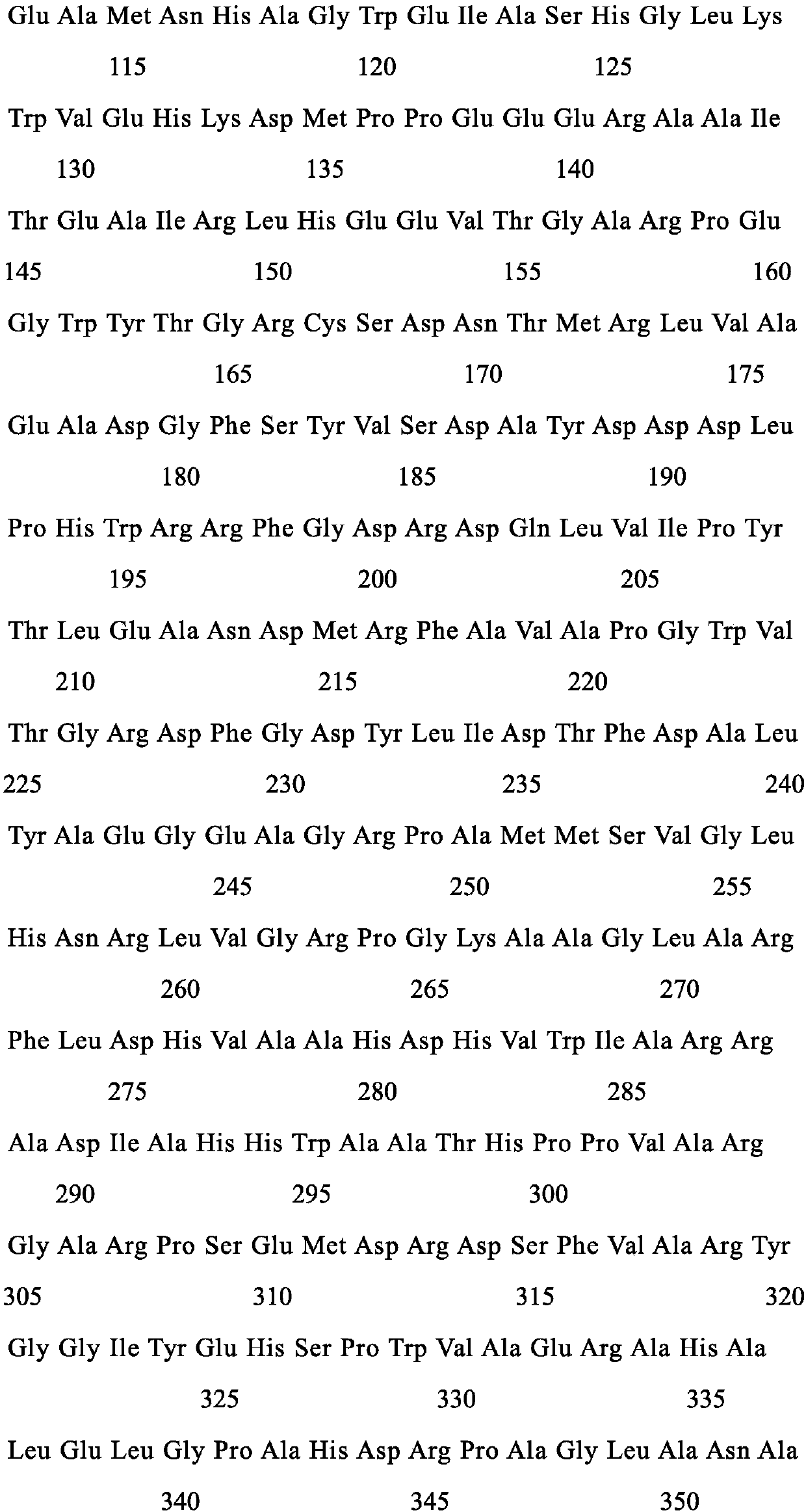

Chitin deacetylase, and construction method and application thereof

The invention relates to a chitin deacetylase, and an expression gene and an application thereof The amino acid sequence of chitin deacetylase BcCDA is represented by SEQ ID NO.2; and the nucleotide sequence of the BcCDA expression gene is represented by SEQ ID NO.1. An engineering strain constructed by using the gene can efficiently secrete and express the chitin deacetylase BcCDA. A recombinant protein with biological activity is obtained after affinity chromatography one-step purification, and the recombinant protein can degrade solid plate generated yellow green 4-nitroaniline with 4-nitroacetanilide as a substrate. Cloning of the chitin deacetylase gene and the successful preparation of the recombinant protein with biological activity are of great theoretic and practical significance to deep development and high value utilization of the chitin resource.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Biological preparation method of chitin deacetylase

InactiveCN101659960AHigh deacetylase activityShorten the production cycleHydrolasesMicroorganism based processesEscherichia coliBiotechnology

The invention discloses a biological preparation method of chitin deacetylase derived from racemomucor, which comprises the following steps: (a) preparing a recombinant expression vector of the chitindeacetylase containing a gene sequence such as SEQ ID NO.1; (b) preparing a transformant containing the recombinant expression vector in the step (a); and (c) expressing and purifying the chitin deacetylase. In the invention, a gene specificity degenerate primer is designed, a reverse transcription and polymerase chain reaction and a rapid amplification technology of cDNA segment ends are adopted, and escherichia coli strains which can generate the chitin deacetylase are obtained by combining the DNA recombination method and utilizing the known pronucleus express vector. The invention provides a reliable source for biologically preparing the chitin deacetylase and has the advantages of short production period, low extraction cost, higher product enzyme yield, higher output, and the like.

Owner:SHANGHAI OCEAN UNIV

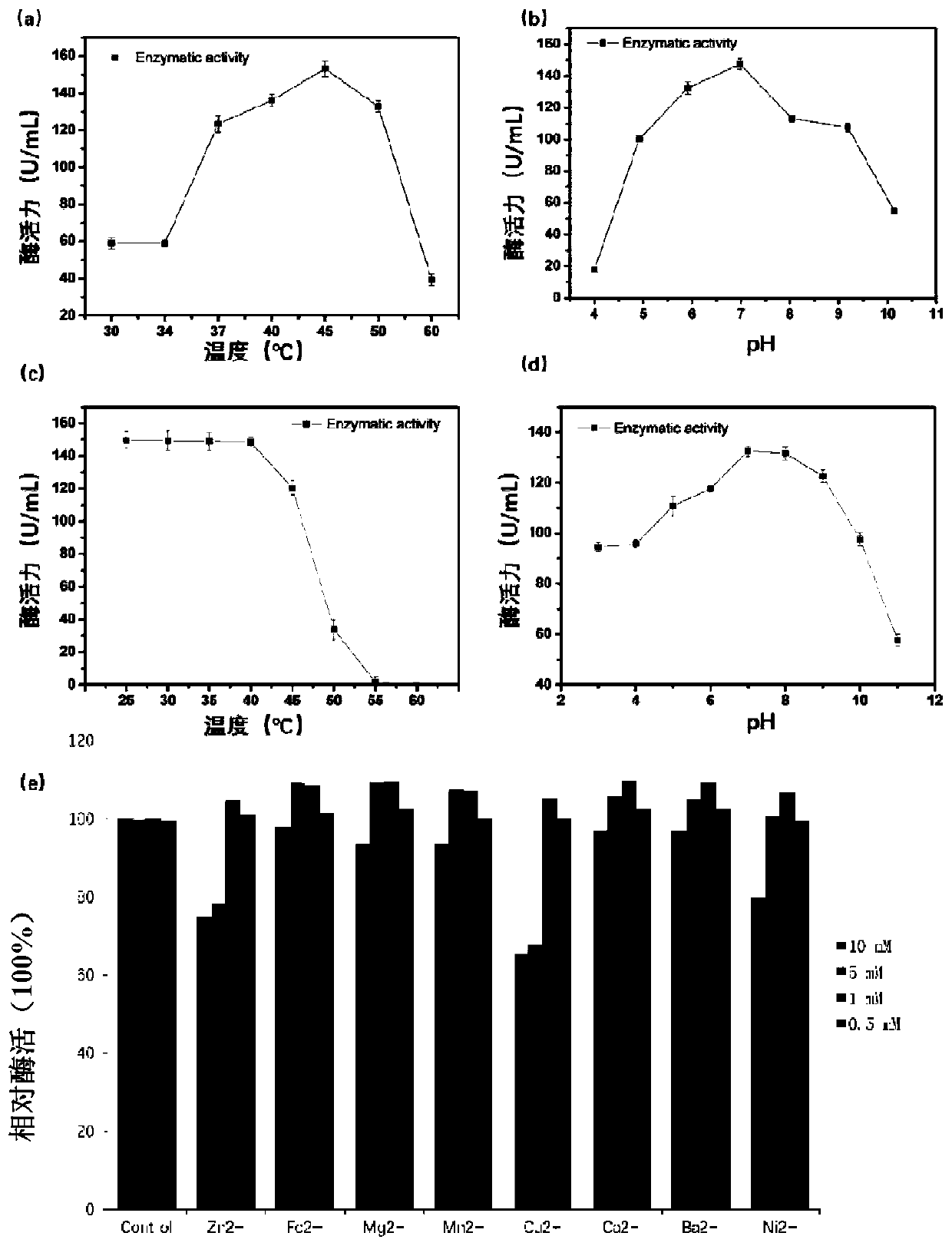

Aspergillus versicolor SD-3 and its application in preparation of chitin deacetylase

InactiveCN104109636AReduce manufacturing costIncrease vitalityFungiHydrolasesChitin formationAcetylase activity

The invention provides an Aspergillus versicolor SD-3 and its application in the preparation of chitin deacetylase. The Aspergillus versicolor SD-3 has simple nutrition requirements, has strong competitor pollution resistance, and is easy to culture; chitin deacetylase generated by the Aspergillus versicolor SD-3 is lyoenzyme, a crude chitin deacetylase liquid can be obtained after separating and removing the Aspergillus versicolor SD-3, and the crude chitin deacetylase liquid can be directly used, and is simple to prepare; the deacetylase produced by the Aspergillus versicolor SD-3 has high activity, and the vitality of the non-separated and non-purified crude deacetylase liquid reaches 142.3U / mL under optimal conditions; and a production technology of the chitin deacetylase does not use toxic harmful raw materials, so environmental protection and no pollution are realized.

Owner:ZHEJIANG SHUREN UNIV

Chitin deacetylase derived from saccharomyces cerevisiae, encoding gene and applications

InactiveCN109722429AHyperthermophilic and high temperature resistantHas a specific deacetylation modeHydrolasesGenetic engineeringHeterologousBiotechnology

The invention relates to clone expression and applications of chitin deacetylase derived from saccharomyces cerevisiae. The amino acid sequence of the saccharomyces cerevisiae chitin deacetylase is asshown in SEQ ID NO.2; and the nucleotide sequence of the saccharomyces cerevisiae chitin deacetylase is as shown in SEQ ID NO.1. The invention also provides a method for preparing the chitin deacetylase, namely cloning the gene of the chitin deacetylase onto a pichia pastoris expression vector pPICZ alpha by utilizing a genetic engineering technical method so as to obtain a pichia pastoris recombinant strain capable of expressing the chitin deacetylase in a heterologous way. The chitin deacetylase ScCDA2 prepared by the heterologous expression of the strain has wide pH adaptation range and has the characteristic of a single-minded deacetylation mode, and can be used for treating chitin and chitosan oligosaccharide of different sources such as shrimp and crab shells. The chitin deacetylaseprovided by the invention can be widely applied to the aspects of food science, biological medicines and chemical engineering materials.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

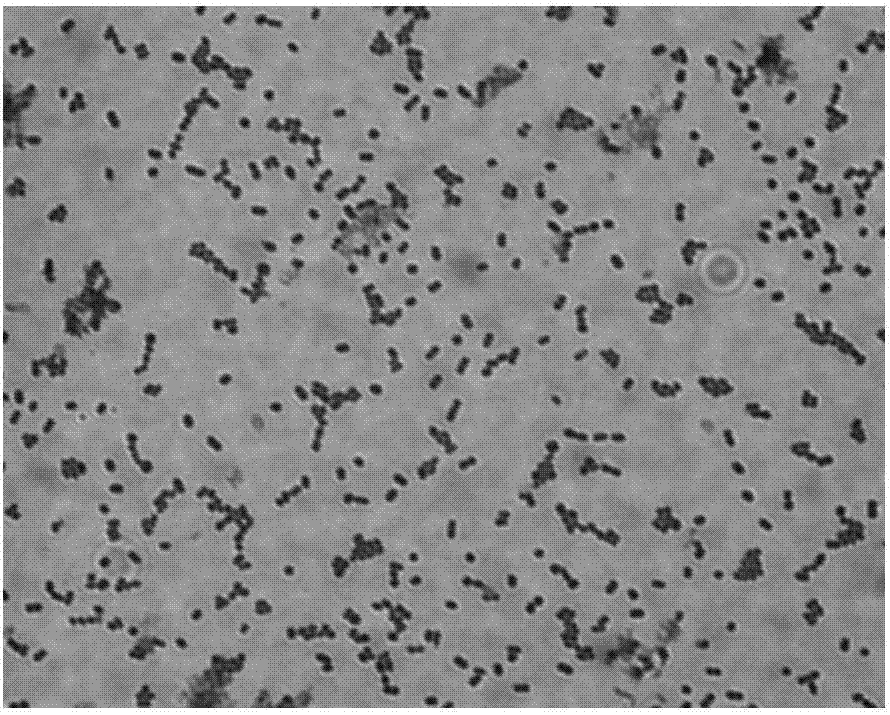

Chitin deacetylase high-yielding strain and application thereof

The invention belongs to the biological technical field, and particularly relates to a chitin deacetylase high-yielding strain and an application thereof. The chitin deacetylase high-yielding strain is particularly rhodococcus usequi F6 and has the preservation number of CGMCC No.14861. The strain has quite fast chitin deacetylase producing speed, is rhodococcus usequi capable of producing chitindeacetylase and reported for the first time at present, is also a fastest strain of all strains for fermentation production of chitin deacetylase in the prior art, and is easy to culture on a large scale.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-yield paenibacillus amyloliquefaciens csuft F14 for chitin deacetylase and its application

InactiveCN101544958ASimple cultivation conditionsBreed fastBacteriaMicroorganism based processesMicrobiologyChitin deacetylase

The present invention discloses high-yield paenibacillus amyloliquefaciens csuft F14 for chitin deacetylase and the application of the paenibacillus amyloliquefaciens csuft F14. The preservation entity of the strain is CCTCC, and the preservation number is CCTCC M 209062. The advantage of the present invention is: the strain can be cultured simply and has high enzyme activity when it is used to produce chitin deacetylase, and is favorable for development and utilization of chitin deacetylase, and has excellent application prospects.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

New preparation method for chitin deacetylase

The invention relates to a new preparation method for chitin deacetylase (chitin deacetylase, E.C.3.5.1.41, CDA), which comprises the following steps: shrimp-shell cultivated soil is taken as screened raw material; antifungal drug is used for restraining the growth of fungus; methods such as spread-plate, plate streaking and the like are used for purification; simultaneously N-paranitroacetanilide (PN)-casein plate is used for CDA activity verification; and finally bacillus cereous which can secrete CDA is obtained by separation. CDA is prepared by liquid fermentation; the CDA vitality of fermentation liquor supernatant is 0.598 to 0.912U / ml; the CDA has enzyme properties which are different from that reported in literatures. Bacillus cereous is used for secreting CDA to ectoenzyme; products are more easily obtained; and bacterium is suitable for large-scale industrial fermentation and can be applied without needing processing and transformation.

Owner:SICHUAN UNIV

Aspergillus nidulans chitin deacetylase, and preparation method and application thereof

InactiveCN109022403AHigh deacetylation activityImprove biological activityHydrolasesFermentationBiotechnologyPichia pastoris

The invention discloses an Aspergillus nidulans chitin deacetylase, and a preparation method and an application thereof. The sequence of a chitin deacetylase coding gene in Aspergillus nidulans is obtained by a whole gene synthesis technology according to the codon preference of Pichia yeast, and the optimized nucleic acid sequence is represented by SEQ ID NO.2. The optimized chitin deacetylase encoding gene is secreted and expressed by a Pichia pastoris expression system to obtain the Aspergillus nidulans chitin deacetylase, and the amino acid sequence of the Aspergillus nidulans chitin deacetylase is represented by SEQ ID NO.1. The Aspergillus nidulans chitin deacetylase obtained in the invention can remove acetyl groups in chitosan and chitosan oligosaccharides in order to obtain the chitosan or chitosan oligosaccharides with a specific structure. The modified chitosan or chitosan oligosaccharides have new or higher biological activities than unmodified chitosan or chitosan oligosaccharides. So the above enzyme and its deacelation product have good industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

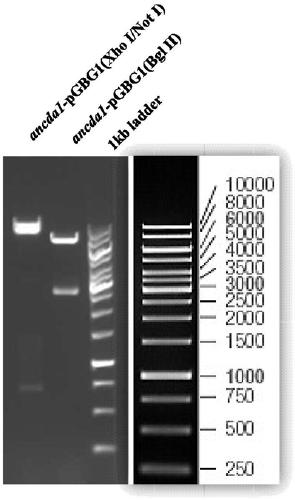

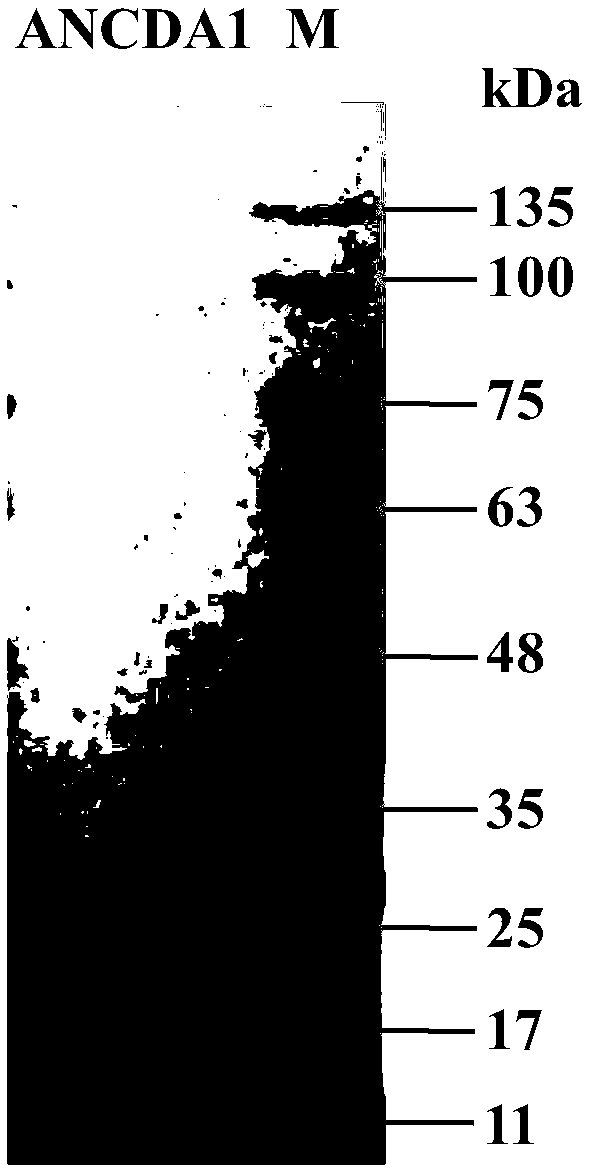

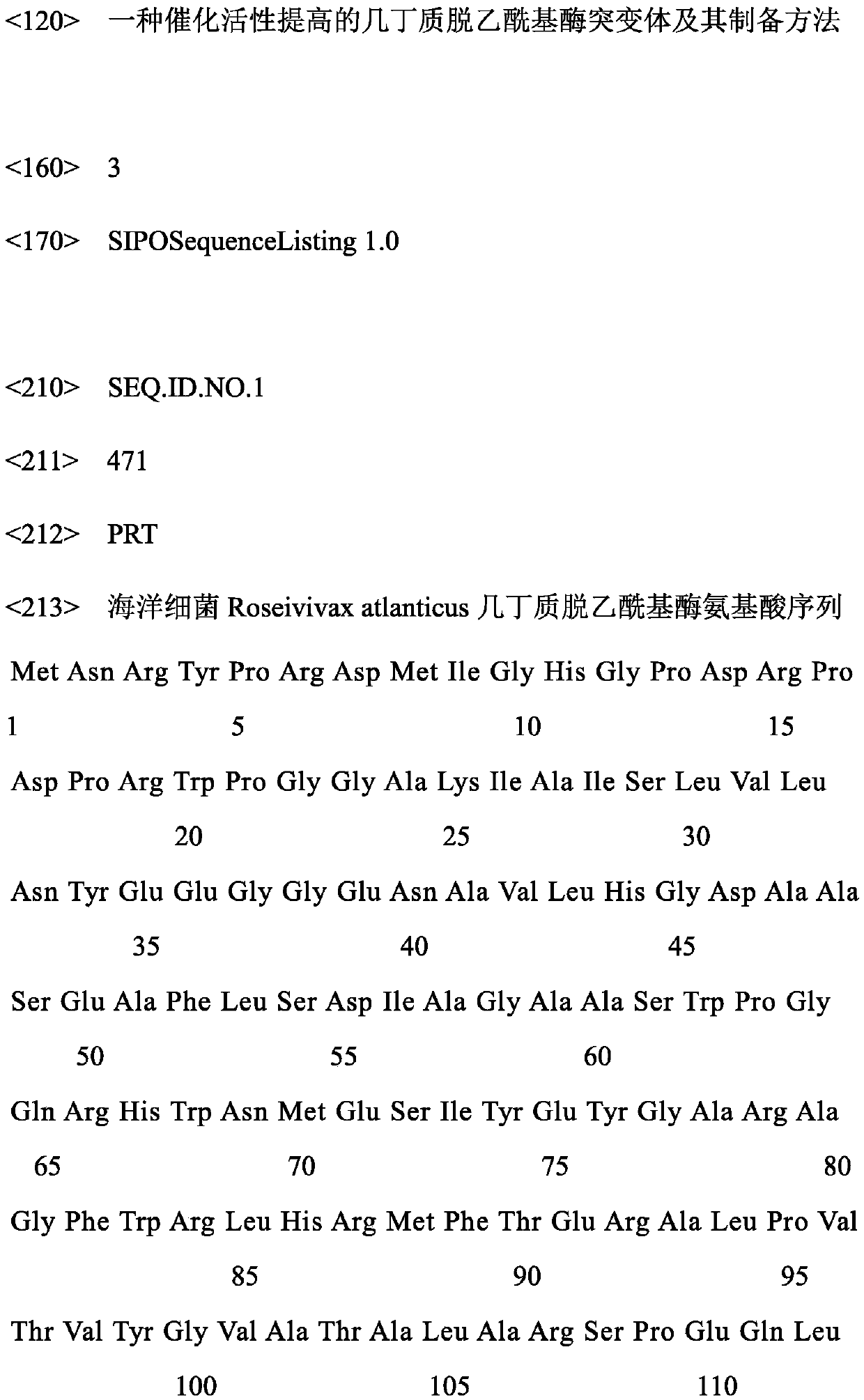

Chitin deacetylase mutant with improved catalytic activity and preparation method thereof

InactiveCN109777796AHigh catalytic activitySuitable for industrial production needsBacteriaHydrolasesBio engineeringRoseivivax atlanticus

The invention discloses a chitin deacetylase mutant with the improved catalytic activity and a preparation method thereof, and belongs to the technical field of bioengineering. Marine bacterium Roseivivax atlanticus chitin deacetylase as shown in SEQ ID NO.1 is mutated as below, 116 asparagine Q is mutated to arginine R, 179 asparagine D is mutated to glycine G, 194 histidine H is mutated to tyrosine Y, 254 valine V is mutated to leucine I, and 282 histidine H is mutated to aspartic acid. Compared with the specific activity before mutation, the specific activity of a mutant enzyme is 2.63 times that of a wild type enzyme. Accordingly, the chitin deacetylase catalytic efficiency is higher, and the mutant is more suitable for industrial production requirements.

Owner:JIANGSU AOXIN BIOTECHNOLOGY CO LTD

Method for preparing glucosamine and chitin simultaneously by using of shrimp and crab waste

InactiveCN107653294AReduce pollutionRealize comprehensive utilizationMicroorganism based processesFermentationBULK ACTIVE INGREDIENTLactobacillus acidophilus

The invention relates to the reuse of shrimp and crab waste, specifically a method for simultaneously producing shrimp and crab xanthin and chitosan by using shrimp and crab waste, using the synergistic effect of Bacillus subtilis and Gluconobacter oxydans to add glucose to ferment Shrimp and crab skin and crab head are desalinated and deproteinized, and then fermented by Streptococcus thermophilus, Lactobacillus acidophilus, and Lactobacillus bulgaricus for one week to decalcify and decolorize, use chitin deacetylase to treat chitin, and use leather Glucosamine can be obtained by processing Plasmomonas Shigella, a lambs negative bacteria. During the fermentation process, there is no need to add a large amount of acid and alkali, which reduces environmental pollution, and microbial fermentation saves costs compared with enzyme fermentation, and the content of active ingredients obtained is higher, which realizes the complete utilization of active ingredients of raw materials, and is economically feasible.

Owner:山东智宇知识产权运营中心有限公司莱州分公司

Technology for enzymatic efficient deacetylation and chitin degradation by using Thermophilic Bacillus

InactiveCN104450832ASerious pollutionHigh energy consumptionMicroorganism based processesFermentationLiquid mediumBiological property

A technology for enzymatic efficient deacetylation and chitin degradation by using Thermophilic Bacillus belongs to the fields of the food processing technology, the bio-pharmaceuticals and the chemical engineering technology. The above strain has the biological characteristic of generation of highly active extracellular chitin deacetylase and chitin degrading enzyme, and can efficiently degrade chitin. The technology mainly comprises the following steps: inoculating preserved slant strain into a double layer plate with chitin as a sole carbon source, culturing at 46DEG C for 24h, inoculating a certain amount of the above obtained substance into a liquid medium with chitin as the sole carbon source, carrying out liquid seed culturing at 46DEG C for 72h, and inoculating the obtained production strain into a fermentation medium with chitin as the sole carbon source according to a certain ratio. The technology can degrade chitin to produce chitosan, chitosan oligosaccharide with different molecular weights, glucosamine (aminoglucose), acetylglucosamine and other relevant products, and also can produce chitin deacetylase and the chitin degrading enzyme.

Owner:ZHEJIANG SHUREN UNIV

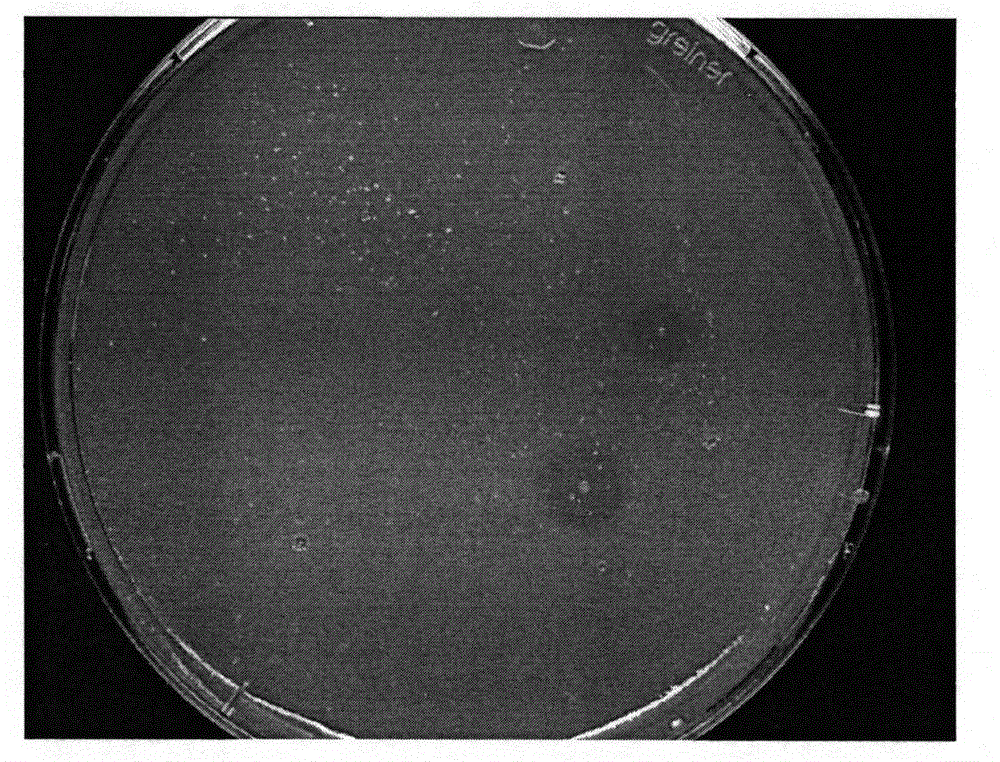

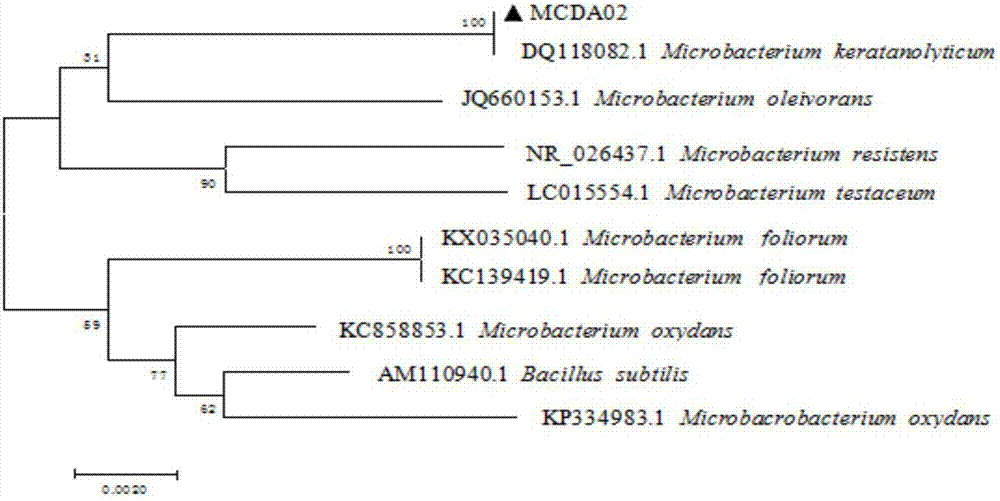

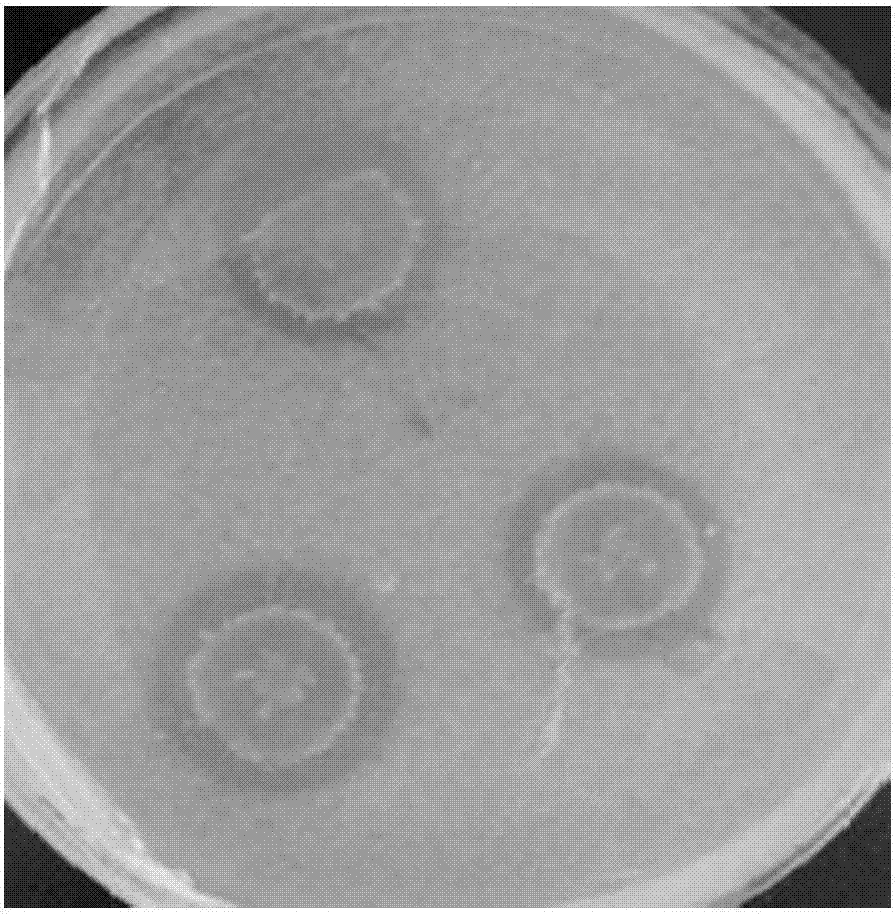

Ocean-sourced Microbacterium keratanolyticum MCDA02, method for producing enzyme from ocean-sourced Microbacterium keratanolyticum MCDA02, and product

The invention discloses ocean-sourced Microbacterium keratanolyticum MCDA02 with the collection number of CGMCC NO.13539. The strain is Gram-negative spore-free brevibacterium, and after being cultured for 48 h on a 2216E solid culture medium, the strain is yellow, translucent, smooth and moist in surface, circular, neat in edge, slightly protruding in center and easy to pick up. The strain grows slowly at 5 DEG C and 45 DEG C, and the optimal growth temperature is 30 DEG C; the growth pH range is 6.0-9.0, and the optimal growth pH is 8.0; and when the NaCl concentration is 0-10%, the strain can grow, and the optimal growth NaCl concentration is 3%. The invention further discloses a method for producing chitin deacetylase by using the strain MCDA02 and a product. For the chitin deacetylase produced by the Microbacterium keratanolyticum MCDA02 strain provided by the invention, the optimal pH is 8.0 and the optimal temperature is 30 DEG C; and at a low temperature, the chitin deacetylase has relatively high activity, so that energy can be saved and the cost can be reduced in industrial application.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG +1

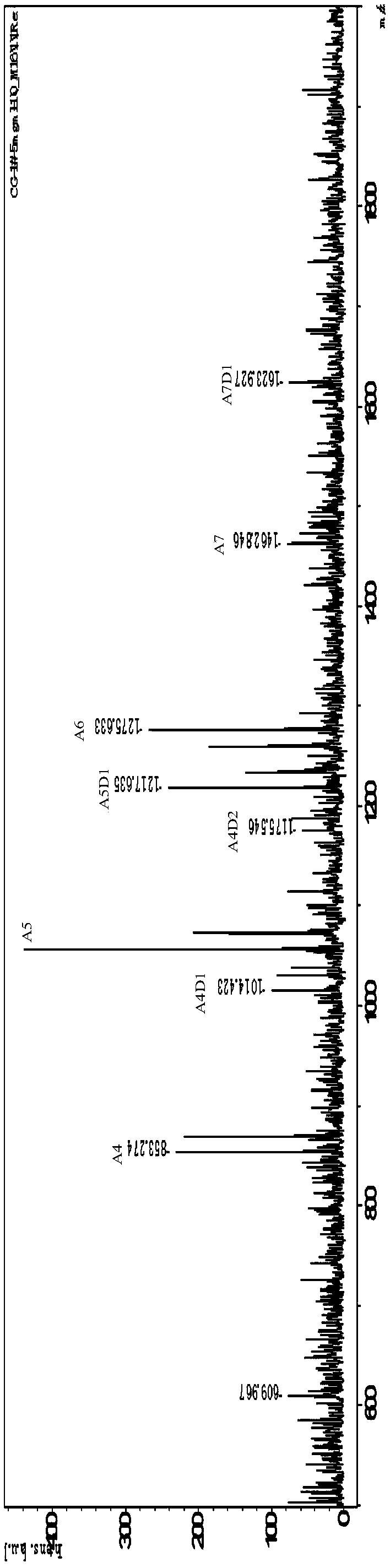

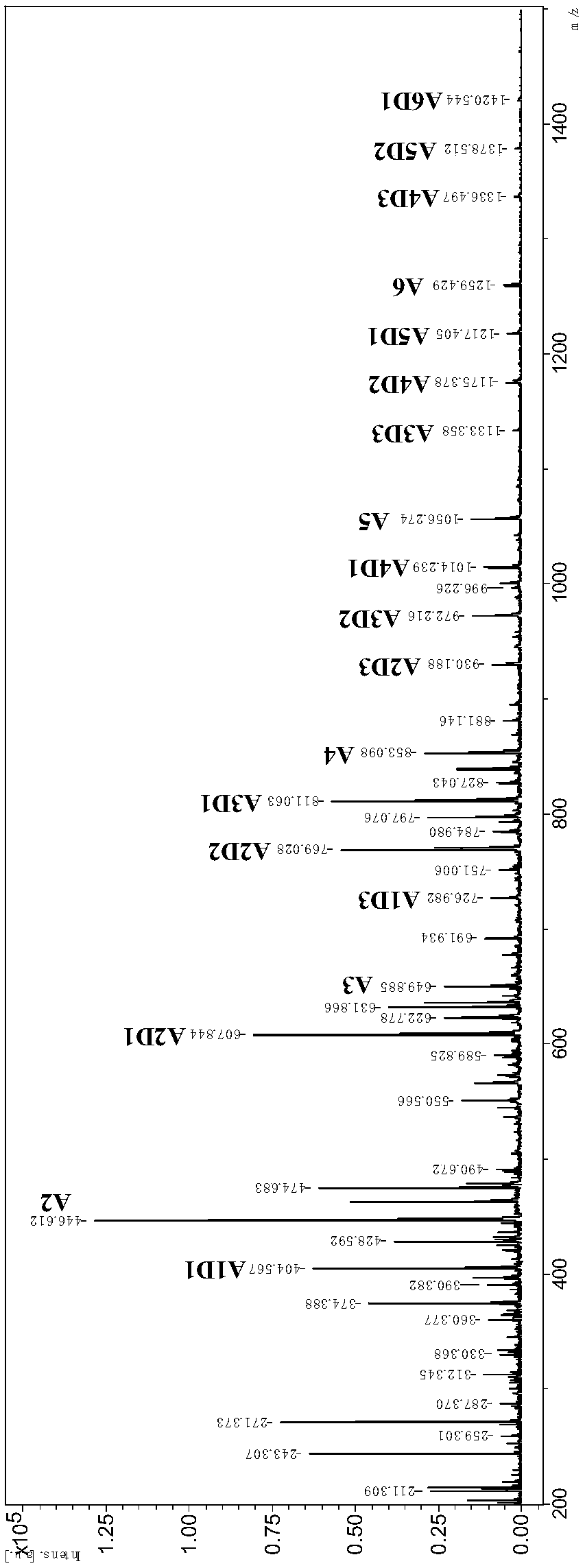

Chitin deacetylase, encoding gene and application

The invention relates to chitin deacetylase and an encoding gene, as well as preparation and application thereof. The invention further provides a method for preapring the chitin deacetylase. The method comprises the following steps: cloning a gene of the chitin deacetylase onto an escherichia coli expression vector PET-22b by utilizing a genetic engineering technical method to obtain an escherichia coli recombinant strain capable of heterogeneously expressing the enzyme. By using the chitin deacetylase PsCDA prepared by heterogeneous expression of the strain, chitin tetrasccharide (A4) can perform specific deacetylation to generate chitin oligose (A3D1) having the deacetylation degree of 75 percent and chitosan oligosaccharide (A2D2) having the deacetylation degree of 50 percent. The chitin deacetylase can act on chitin and chitin oligose from different sources, such as shrimp and crab shells and the like. The chitin deacetylase can be widely applied to the aspects of food science, biomedicine, chemical materials and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of chitosan oligosaccharide of complex structure with adjustable degree of polymerization and degree of deacetylation

InactiveCN109517090AControlling the degree of aggregation distributionControls are responsiveSugar derivativesSugar derivatives preparationChitinaseSolvent

The invention relates to the technical field of fine chemical engineering and in particular relates to a preparation method of a chitosan oligosaccharide of a complex structure with adjustable degreeof polymerization and degree of deacetylation. The preparation method comprises the following steps: dissolving or fully swelling chitin in a certain solvent, and performing uniform phase degradationunder acid catalysis so as to obtain small-molecule chitin or chitin oligose; further adjusting the degree of polymerization and degree of deacetylation of the small-molecule chitin or chitin oligoseby using chitinase, chitosanase, chitin deacetylase or a nonspecific commercial enzyme containing the previous enzyme activity, and performing spray drying, thereby obtaining the chitosan oligosaccharide of the complex structure with the adjustable degree of polymerization of 20 or less and degree of deacetylation of 20-80%. According to the preparation method disclosed by the invention, the degree of polymerization, the degree of deacetylation and other sugar chain molecular structures of the complex chitosan oligosaccharide can be adjusted, the product yield is high, the amount of by-products is small, the cost is low, and batch production is easily realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

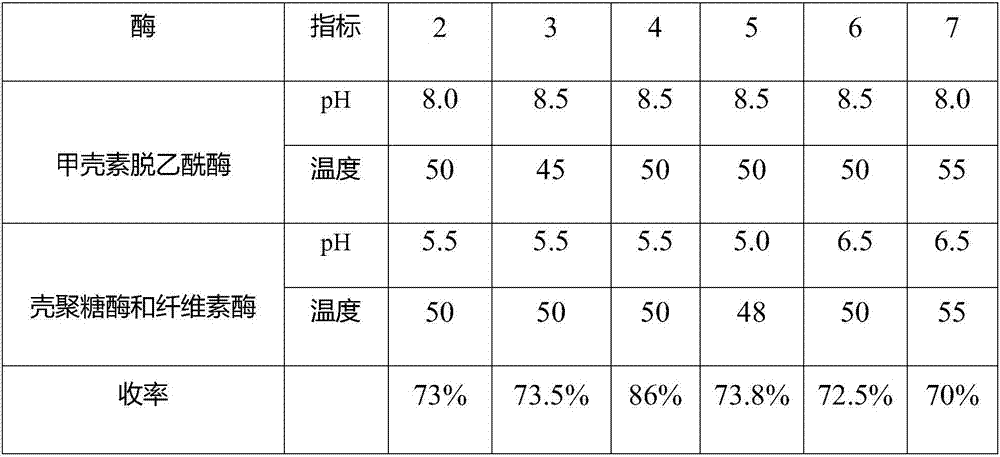

Method for preparing chitosan oligosaccharide from chitosan

InactiveCN107058420ASimple reaction conditionsFew stepsSugar derivativesDisaccharidesAlcoholCellulase

The invention discloses a method for preparing chitosan oligosaccharide from chitosan. The method comprises the following steps: 1) taking chitosan as a raw material, dissolving in water, continuously stirring, regulating pH of a sodium hydroxide solution to 8.5, adding chitin deacetylase at 50 DEG C, and reacting for 6 hours at constant temperature, thereby acquiring a chitosan solution; 2) adding hydrochloric acid for regulating pH to 5.5, adding chitosanase and cellulose, and stirring for 2 hours at the constant temperature of 50 DEG C, thereby acquiring a chitosan oligosaccharide solution; 3) regulating pH to be alkaline, thereby acquiring undegraded chitosan residues and a degraded chitosan oligosaccharide solution, filtering the undegraded chitosan residues, and returning into the next reaction; and 4) distilling and concentrating the degraded chitosan oligosaccharide solution so as to acquire a concentrated solution, adding ethyl alcohol, filtering and drying, thereby acquiring chitosan oligosaccharide. According to the preparation method, the reaction conditions are simple, and the steps are few; the efficiency is high, and the industrial large-scale production is benefited; and a relatively pure chitosan oligosaccharide product is acquired.

Owner:杭州垚信生物科技有限公司

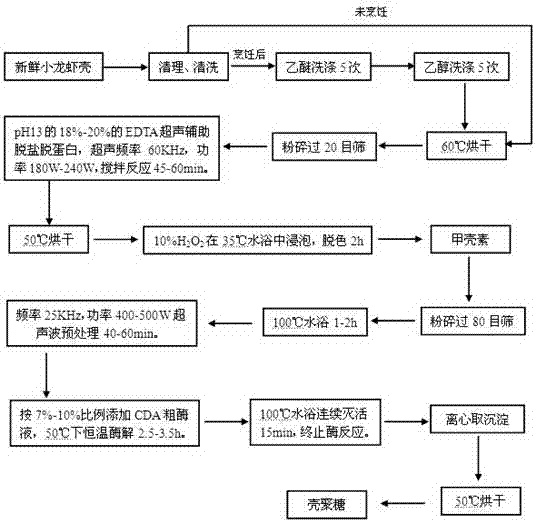

Method for preparing lobster shell chitosan through cooperation of ultrasonic wave and CDA (Chitin Deacetylase)

The invention discloses a method for preparing lobster shell chitosan through the cooperation of an ultrasonic wave and CDA (Chitin Deacetylase). The method comprises the following steps: by using lobster shells before and after cooking as raw materials, performing washing, drying and grinding pretreatment; extracting chitin from the lobster shells by adopting EDTA (Ethylene Diamine Tetraacetic Acid), and performing deacetylation through the cooperation of the ultrasonic wave and the CDA to prepare the chitosan. Compared with a conventional strong-acid and strong-base method, the method has the advantages that the process is simple; the total preparation time is as short as 8-12h; the EDTA can be completely recycled; strong acid and strong base are not used; any environmental pollution is avoided; the deacetylation degree of a product reaches 92-95 percent, and the viscosity reaches 95-105mPa.s. The prepared product is of a white powder shape, is stable in property and can be applied to the fields of food, medicine, biology, cosmetics and the like.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

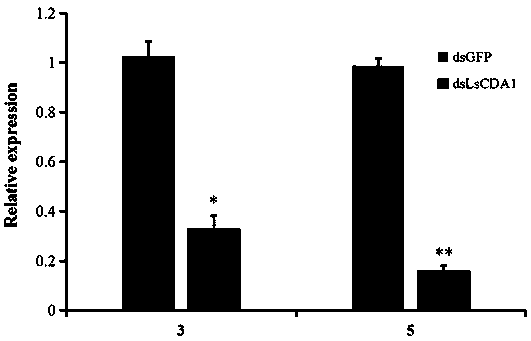

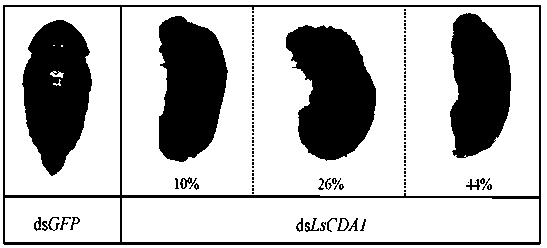

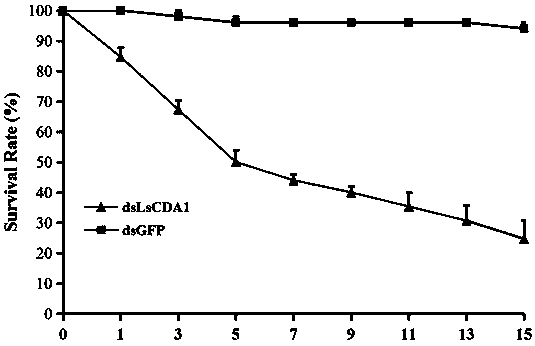

Lasioderma serricorne chitin deacetylase gene 1 and application of dsRNA thereof in pest control

The invention discloses a lasioderma serricorne chitin deacetylase gene 1 and application of dsRNA thereof in pest control, and in particular discloses a method for acquiring chitin deacetylase gene 1fragments from a lasioderma serricorne transcriptome database, performing full-length cloning on the fragments and sequencing to obtain the gene full length with a sequence shown as SEQ ID NO: 1. dsRNA of the gene is designed and synthesized based on SEQ ID NO: 1 and injected to enter a lasioderma serricorne body cavity for specifically silencing target genes, and in the growth process, the lasioderma serricorne has skin darkening, shrinking and difficult ecdysis symptoms and finally dies. Multiple experiments prove that the fatality rate reaches 76% or higher. Due to the specificity and highfatality rate, the lasioderma serricorne chitin deacetylase gene can serve as a molecular target for pest control and provides a novel pathway for effective pest control.

Owner:GUIYANG UNIV

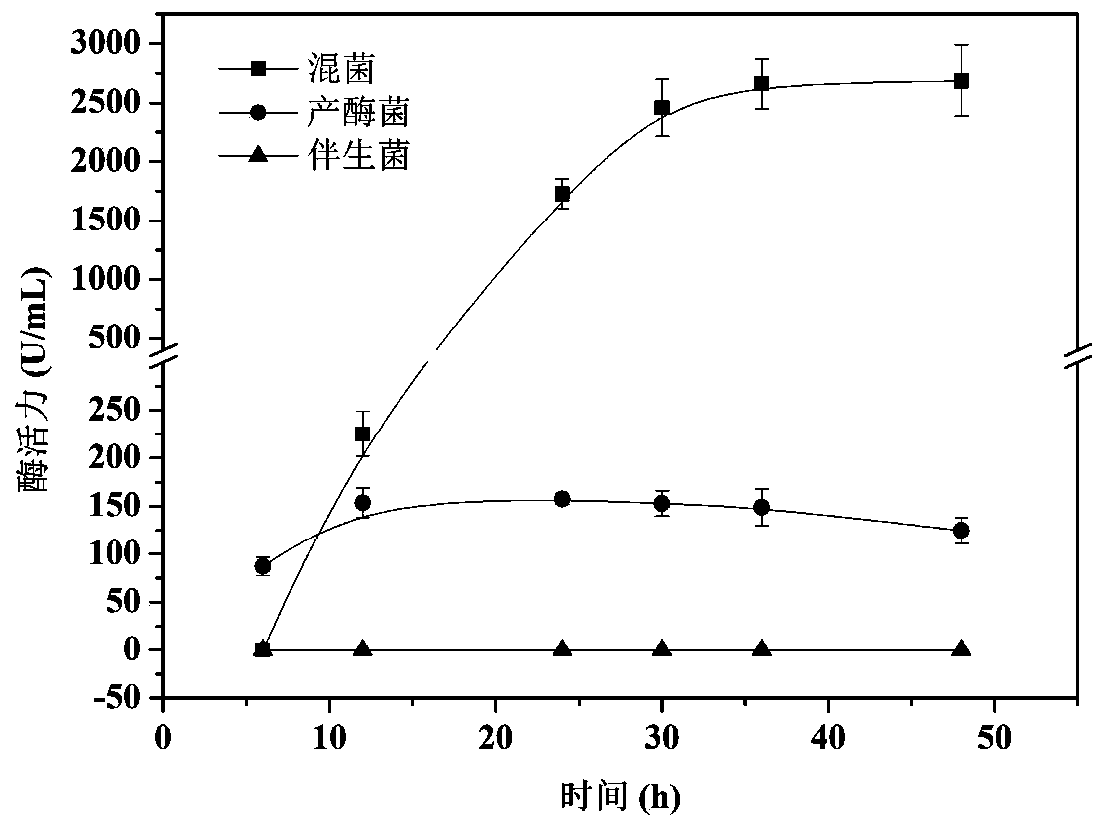

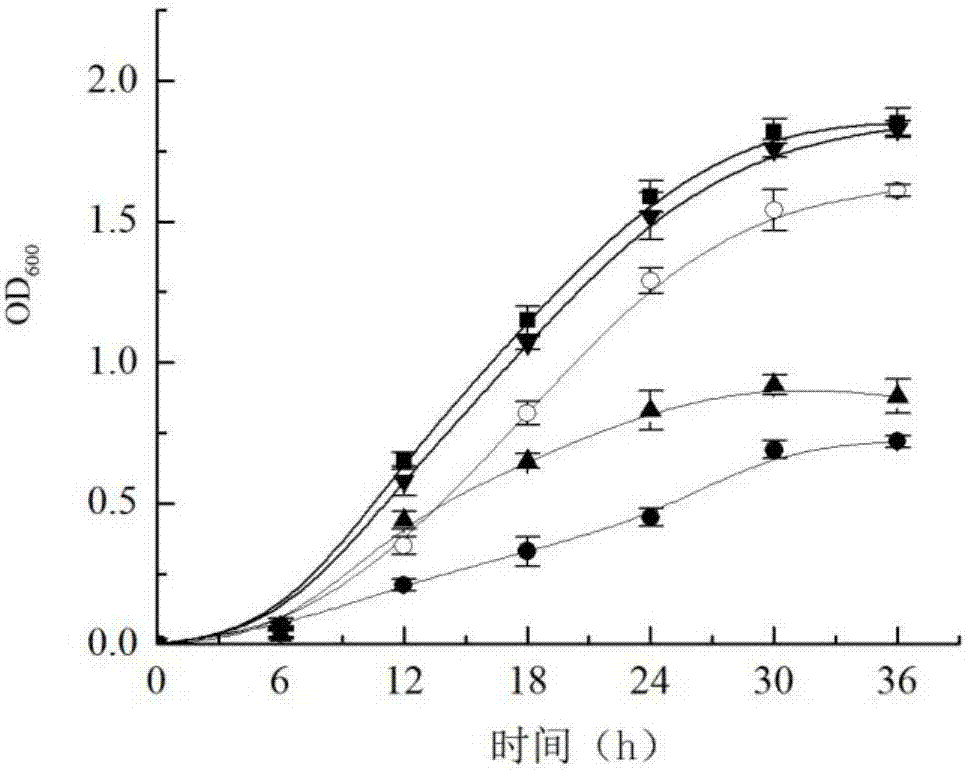

Method for increasing yield of chitin deacetylase through mixed bacterium fermentation

The invention belongs to the technical field of biologics and in particular relates to a method for increasing the yield of chitin deacetylase through mixed bacterium fermentation. The method comprises the following steps: adding staphylococcus epidermidis ATCC12228 (an accompanying strain) in the fermentation process of rhodococcus equi CGMCC No.14861 (an enzyme generation strain), and performingmixed bacterium fermentation, wherein the enzyme activity of each mL of a fermentation broth is up to 2996.2U. The enzyme yield of fermentation is increased by 20.2 times when being compared with that of single bacterium fermentation of enzyme generation strains, and compared with the prior art, the mixed bacterium fermentation process provided by the invention is capable of rapidly accumulatingchitin deacetylase, achieves a high-yield effect, and has wide industrial application prospects.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

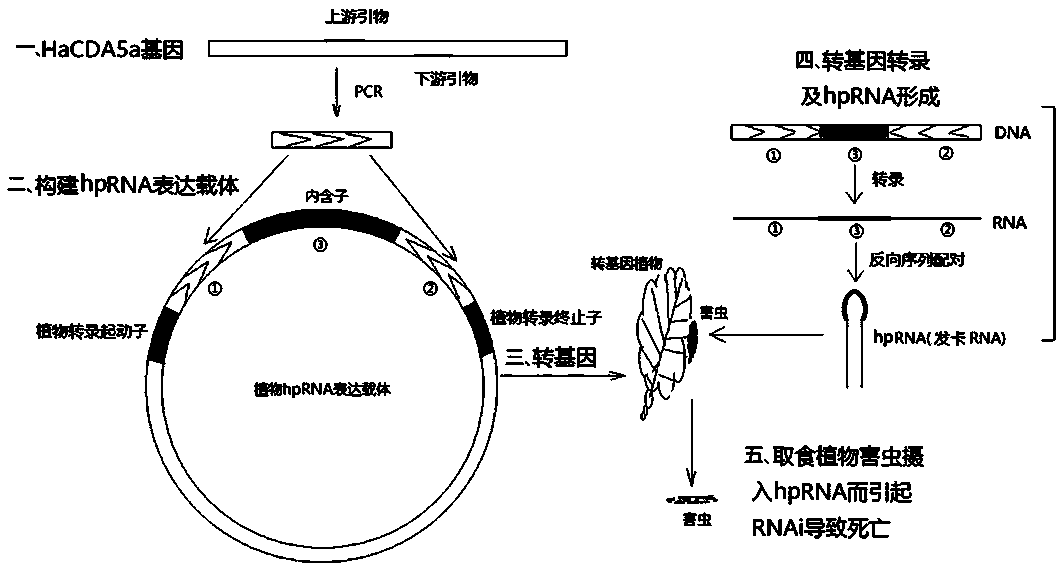

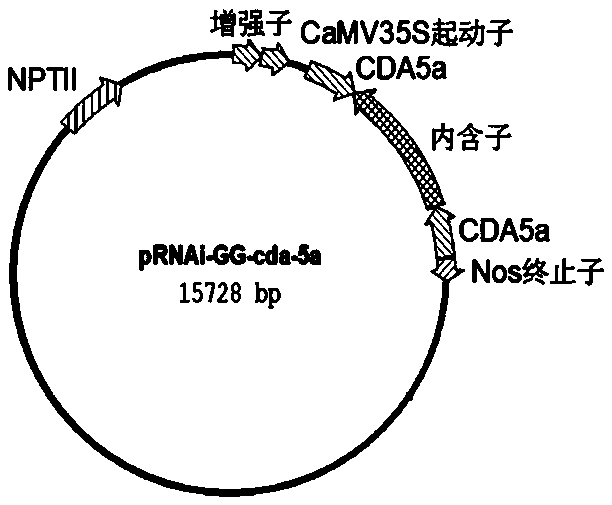

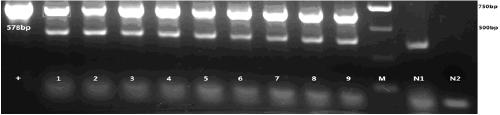

Method for improving insect resistance of plants by using RNA interference technique and special DNA fragment of method

ActiveCN109837291AReduce harmStrong food refusalFermentationVector-based foreign material introductionNicotiana tabacumWild type

The invention provides a method for improving insect resistance of plants by using an RNA interference technique and a special DNA fragment of the method. The DNA fragment is shown as formula (I), andSEQ forward -X-SEQ backward (I), wherein the SEQ forward is any one fragment at least comprising 21bp in the overall length cDNA fragment of bollworm chitin deacetylase 5a genes; SEQ backward is in backward complementary with the SEQ forward; the X is an intervening sequence between the SEQ forward and SEQ backward, and is not complementary with the SEQ forward and SEQ backward, and the overall length cDNA of the bollworm chitin deacetylase 5a gene is shown as the sequence 1 in a sequence table. For the first time, the bollworm chitin deacetylase 5a gene is used as the RNA interference targetgene, and is applied to breeding of genetically-modified plants. Insect test results prove that after switching for 2-5 days, the body weight of young bollworms is 1 / 10 smaller than that of the control group, and the mortality rate of the young insects of 5 days on genetically modified tobacco leaves achieves 68%, and the mortality rate of wild type tobacco is only 21%.

Owner:HEBEI UNIVERSITY

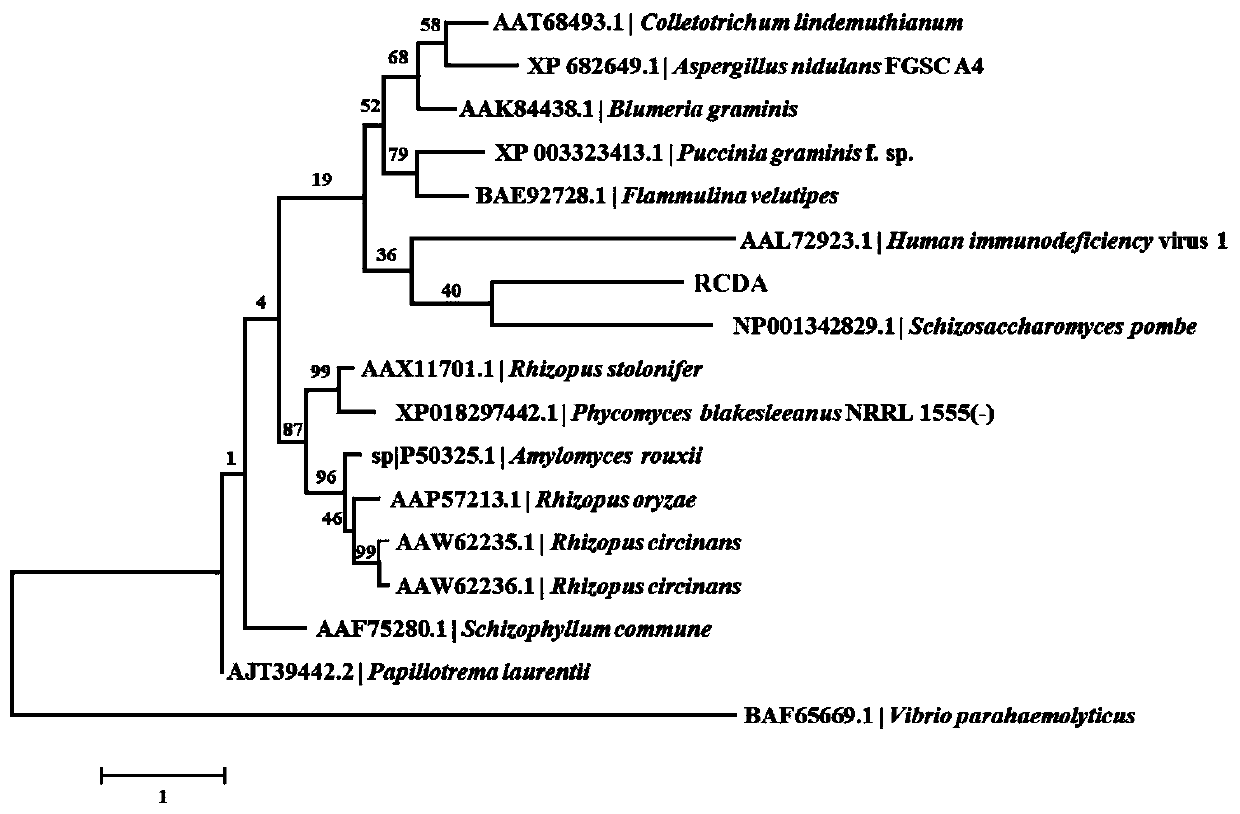

Chitin deacetylase

InactiveCN111172141ABroad substrate spectrumHigh activityHydrolasesFermentationRhodococcus equiChitin deacetylase

The invention belongs to the technical field of protease, and particularly relates to chitin deacetylase. The chitin deacetylase RCDA derives from Rhodococcus equi, has an amino acid sequence represented by SEQ ID NO.1 in a sequence table, is a novel protein sequence reported for the first time at present, has relatively low similarity with a protein sequence of the reported chitin deacetylase andhas a relatively wide substrate spectrum; and the chitin deacetylase has the characteristics that metal ion influence is low, and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

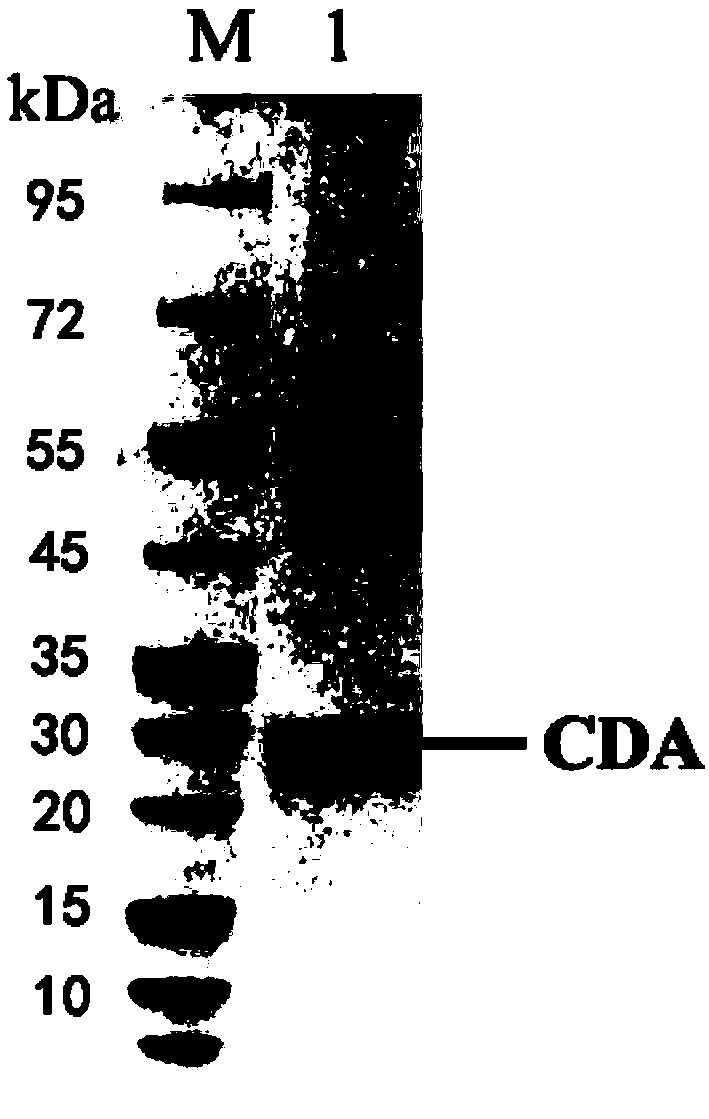

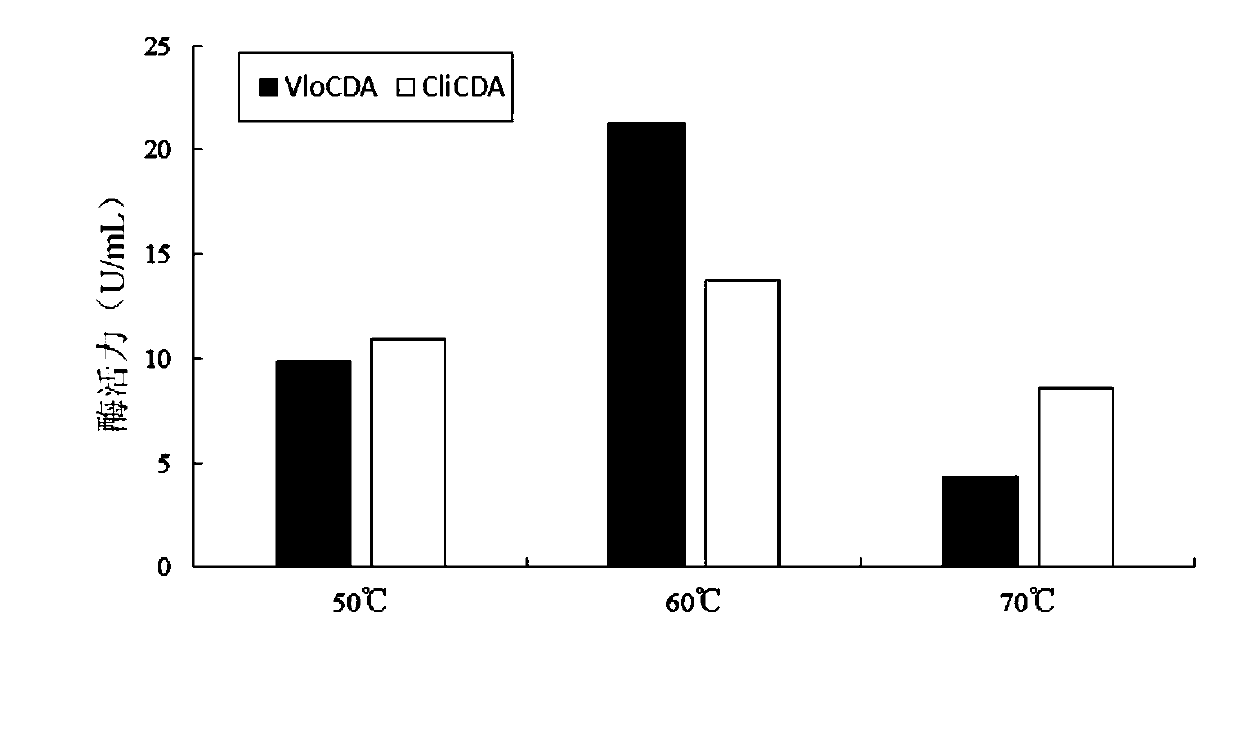

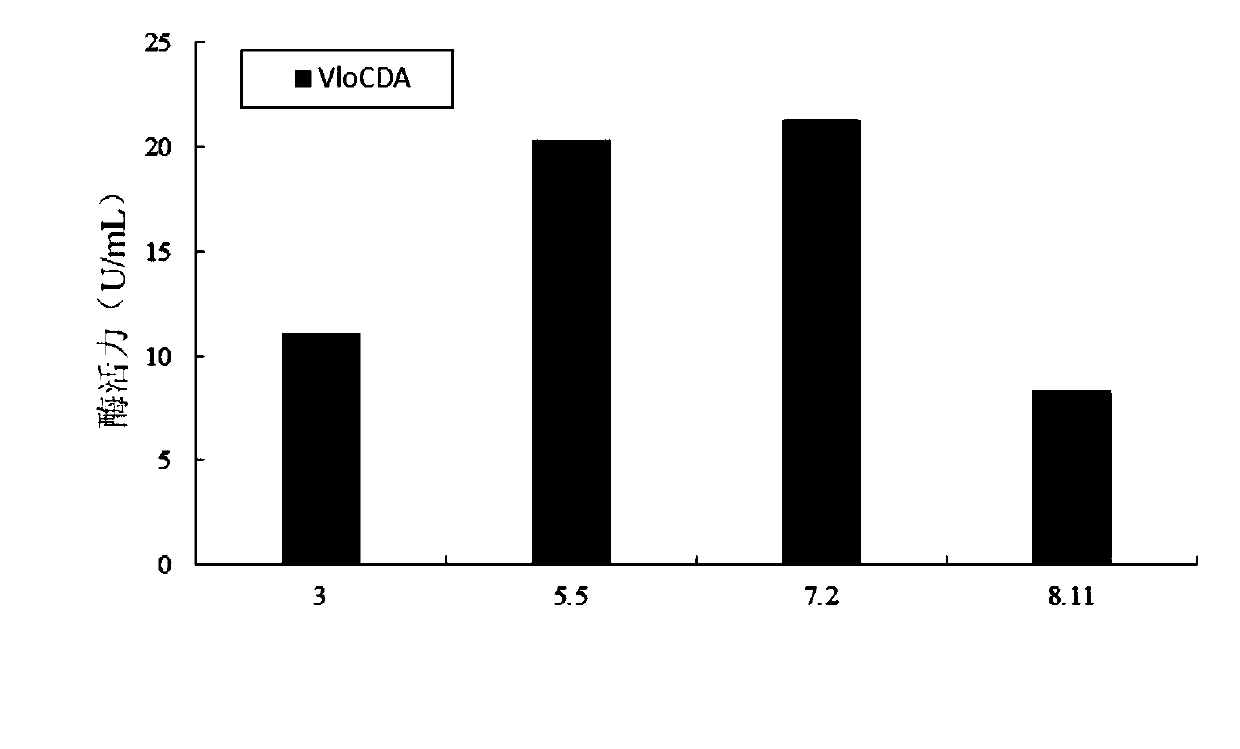

Chitin deacetylase and application thereof

ActiveCN109609485ALow requirements for production conditionsReduce pollutionBacteriaHydrolasesBiologyChitin deacetylase

By analyzing and studying different genomic sequences of different species, several unknown proteins are screened out, and chitin deacetylase with excellent deacetylase activity is further identified.More specifically, the invention relates to a chitin deacetylase derived from verticillium longisporum Vlo. Compared with the reported chitin deacetylase, the chitin deacetylase has lower requirements for production conditions, has higher biosafety, and has characteristics more suitable for industrial applications, and shows wide application potential.

Owner:JILIN COFCO BIOCHEM +2

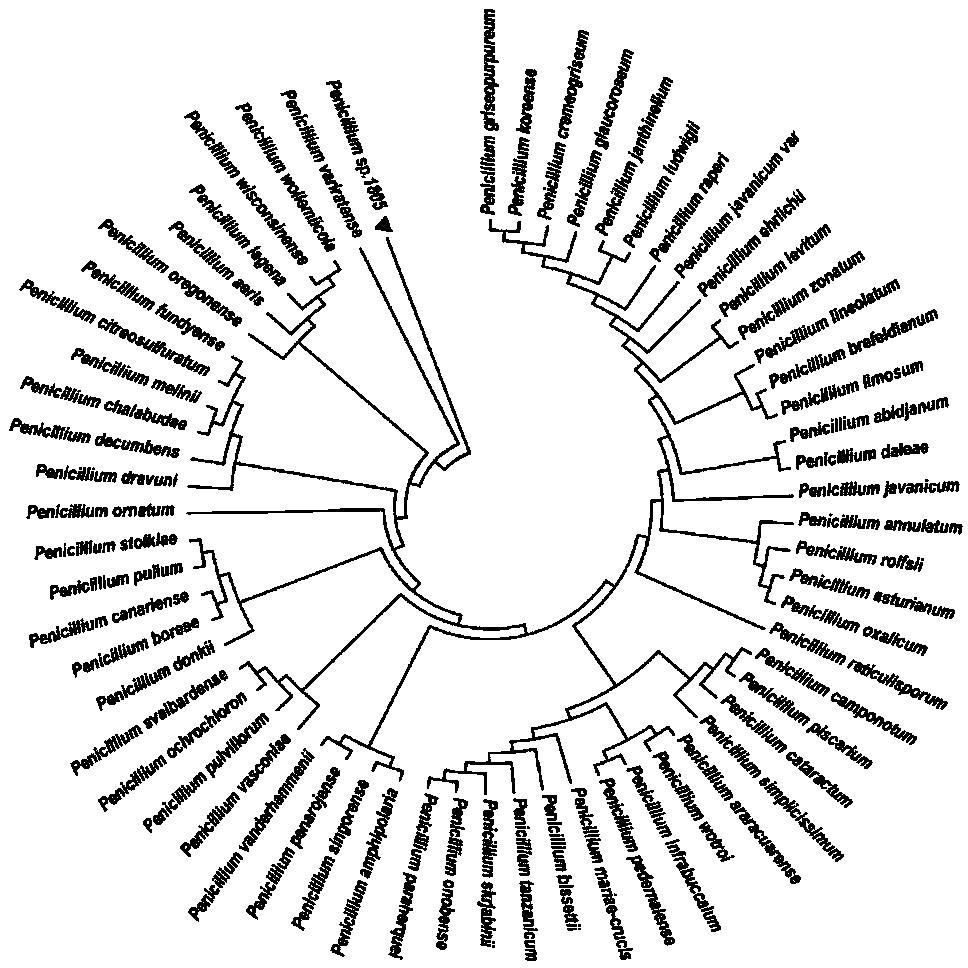

Chitin deacetylase and chitin nanofiber dispersion liquid as well as preparation method and application of chitin nanofiber dispersion liquid

The invention belongs to the technical field of preparation of chitin nanofibers and relates to chitin deacetylase and chitin nanofiber dispersion liquid as well as a preparation method and application of the chitin nanofiber dispersion liquid. The chitin deacetylase is prepared from a penicillium oxalicum 3.5705 strain through purification, wherein the collection number of the penicillium oxalicum strain is CGMCC No. 3.5705. The preparation method of the chitin nanofiber dispersion liquid comprises the following steps: Performing partial deacetylation modification on chitin by using the chitin deacetylase, to obtain partial chitosan; treating the partial chitosan under a mechanical effect, to obtain the chitin nanofiber dispersion liquid. According to the chitin deacetylase and the chitinnanofiber dispersion liquid as well as the preparation method and application of the chitin nanofiber dispersion liquid provided by the invention, the chitin is subjected to partial deacetylation modification by a novel biological enzyme process instead of traditional concentrated base pyrolysis chemical treatment, and the reaction is mild, nontoxic and pollution-free; the preparation method is green and environmentally friendly, the yield of chitin nanofiber is increased, and efficient utilization of the chitin biomass resources is realized.

Owner:NANJING FORESTRY UNIV

Acinetobacter schindleri MCDA 01 and method for preparing chitin deacetylase from Acinetobacter schindleri MCDA 01

The invention discloses Acinetobacter schindleri MCDA 01 from the sea. The Acinetobacter schindleri MCDA 01 was preserved in the China General Microbiological Culture Collection Center with the preservation number of CGMCC NO.13538. The strain is gram-negative brevibacterium, and has characteristics of no spore, white and nontransparent bacterial colony, smooth and moist surface with slight bulges and serrulateserrulated edge of bacterial colony. According to the strain, optimum growth temperature is 30 DEG C, optimum growth pH is 8.0, optimum growth NaCl concentration is 4%, and optimum fermentation pH of chitin deacetylase produced from the MCDA01 strain is 8.0 and the optimum temperature is 30 DEG C. The prepared chitin deacetylase has high activity at low temperature and helps save energy and cost in industrial application. Chitosan by utilization of enzymatic preparation has high degree of deacetylation, the biological enzyme method is green and environment-friendly, and green production of chitosan is realized. The invention has great economic benefits.

Owner:HUAIHAI INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com