Method for preparing chitin size modified by biological enzyme method

A biological enzymatic method and chitin technology, applied in the field of textile chemistry, can solve problems such as environmental pollution, chitin macromolecular chains reduce molecular weight, etc., achieve good water solubility, uniform deacetylation degree, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

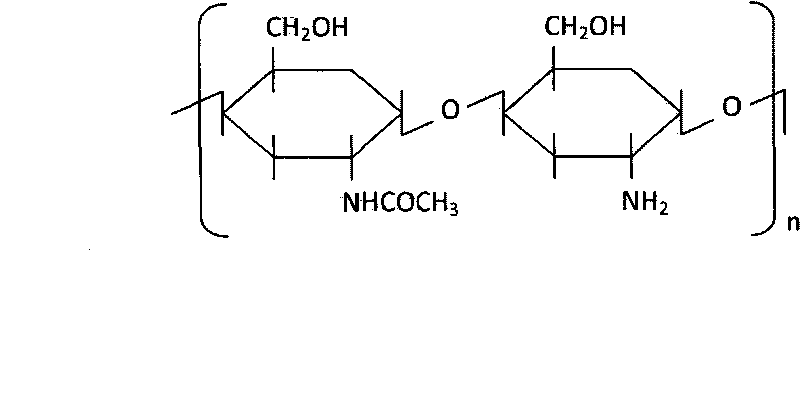

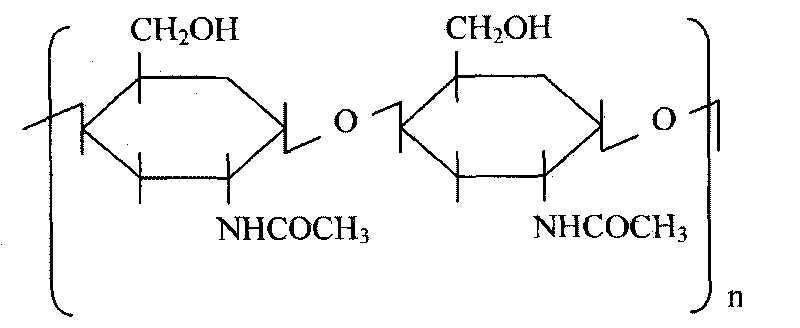

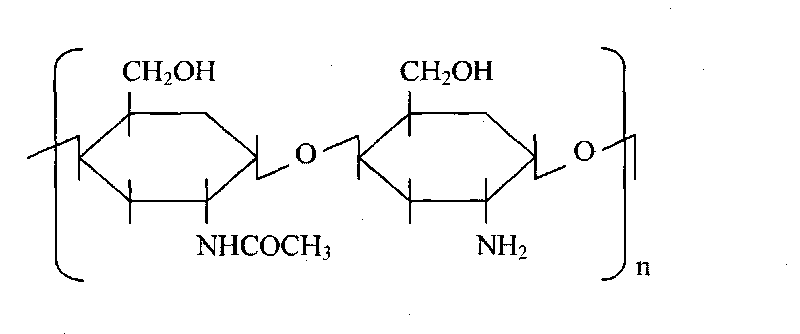

Image

Examples

Embodiment 1

[0046] Step 1: Preparation of Chitin Deacetylase Seed Culture Solution

[0047] ① According to the formula of chitin deacetylase seed culture solution, weigh the percentage by weight of each component: 30% sucrose, 2% sodium nitrate, 1% potassium hydrogen phosphate, 0.01% ferrous sulfate, 0.5% anhydrous magnesium sulfate, 0.5% potassium chloride , the remaining amount of water, put it into the beaker, and heat it to dissolve at a temperature of 50°C;

[0048] ②Use 0.1mol / L NaOH solution to adjust the pH value of the solution obtained in ① above to 7.0, then put it in a 250mL Erlenmeyer flask and wrap the mouth of the bottle with eight layers of degreasing gauze and eight layers of paper;

[0049] ③Put the above-mentioned conical flask in a vertical pressure steam sterilizer, and sterilize it by moist heat for 20 minutes at a temperature of 121°C and a pressure of 0.1MPa. After sterilization, place it on a sterile workbench. Irradiate with UV light for 20min;

[0050] ④ Open ...

Embodiment 2

[0062] Step 1: Preparation of Chitin Deacetylase Seed Culture Solution

[0063] ① According to the formula of chitin deacetylase seed culture solution, weigh the percentage by weight of each component: sucrose 20, sodium nitrate 3.5, dipotassium hydrogen phosphate 1, ferrous sulfate 0.01, anhydrous magnesium sulfate 0.5, potassium chloride 0.5 , the remaining amount of water, put it into the beaker, and heat it to dissolve at a temperature of 50°C;

[0064] ②Use 0.1mol / L NaOH solution to adjust the pH value of the solution obtained in ① above to 7.1, then put it in a 250mL Erlenmeyer flask and wrap the mouth of the bottle with eight layers of degreasing gauze and eight layers of paper;

[0065] ③Put the above-mentioned conical flask in a vertical pressure steam sterilizer, and sterilize it by moist heat for 20 minutes at a temperature of 121°C and a pressure of 0.1MPa. After sterilization, place it on a sterile workbench. Irradiate with UV light for 20min;

[0066] ④ Open th...

Embodiment 3

[0077] Step 1: Preparation of Chitin Deacetylase Seed Culture Solution

[0078] ① According to the formula of chitin deacetylase seed culture solution, weigh the percentage by weight of each component: sucrose 40, sodium nitrate 5, dipotassium hydrogen phosphate 1, ferrous sulfate 0.01, anhydrous magnesium sulfate 0.5, potassium chloride 0.5 , the remaining amount of water, put it into the beaker, and heat it to dissolve at a temperature of 50°C;

[0079] ②Use 0.1mol / L NaOH solution to adjust the pH value of the solution obtained in ① above to 7.2, then put it in a 250mL Erlenmeyer flask and wrap the mouth of the bottle with eight layers of degreasing gauze and eight layers of paper successively;

[0080] ③Put the above-mentioned conical flask in a vertical pressure steam sterilizer, and sterilize it by moist heat for 20 minutes at a temperature of 121°C and a pressure of 0.1MPa. After sterilization, place it on a sterile workbench. Irradiate with UV light for 20min;

[0081...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com