Method for preparing chitin and its chitosan and chitosan oligosaccharide

A technology of chitin and chitosan, applied in the biological field, can solve the problems of difficult extraction, pollute the environment and water environment, huge energy consumption, etc., and achieve the effects of improving comprehensive economic benefits, fully utilizing resources and improving production conditions.

Inactive Publication Date: 2010-12-01

重庆百奥帝克微生态科技有限公司

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although chitin is recognized as an excellent natural organic raw material of extraordinary value, it is not easy to extract from its original material as a structural component of various animals, microorganisms and certain plants

In recent decades, the mainstream process for extracting chitin / chitosan and preparing its derivatives at the actual production level is the chemical method. At present, it has been found that there are a series of disadvantages as follows: 1) Excessive use of strong acids, strong Alkali and harmful chemical reagents produce a large amount of waste water and waste, which seriously pollutes the environment, especially the water environment; 2) The high-frequency, long-term high-temperature treatment process produces huge energy consumption; 3) The preparation process requires corrosion-resistant and high-temperature-resistant equipment , increase production costs; 4) non-specific catalytic action of chemical catalysts, so that different chemical structure components can not be clearly and effectively dissociated and / or synthesized, affecting the yield and purity of the target product; 5) strong acid, strong base and other extraction The severe chemical reaction conditions of the solvent obviously restrict the stability and quality control of the target chemical composition; 6) The frequent washing and purification procedures in the process and the difficulty in the recovery and treatment of dilute acid and dilute alkali lead to a large amount of precious clean fresh water being consumed and wasted ; 7) The chemical characteristics of strong acid, strong alkali and other extraction solvents such as corrosiveness and explosiveness pose a safety threat to the working environment and human health

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

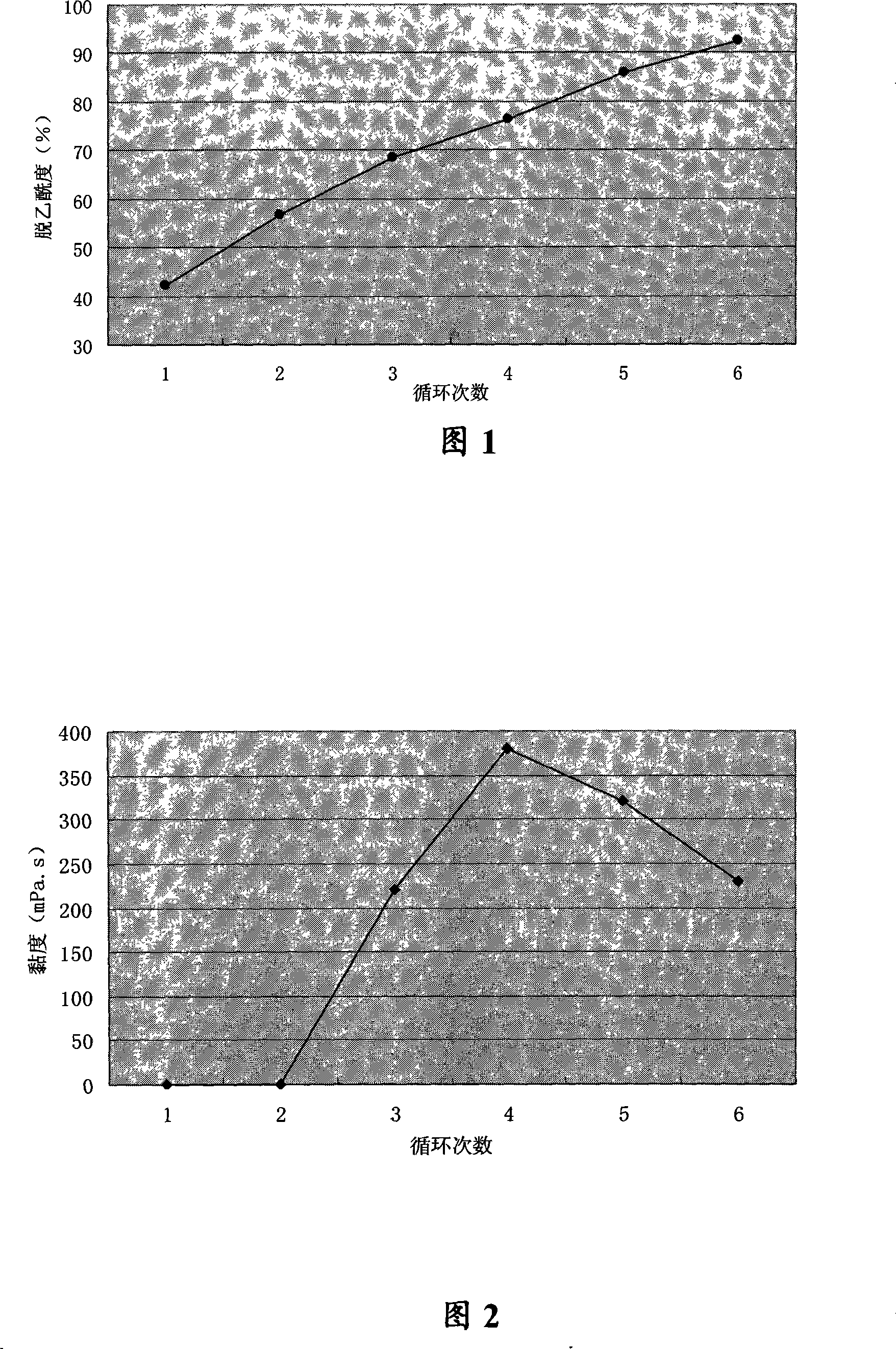

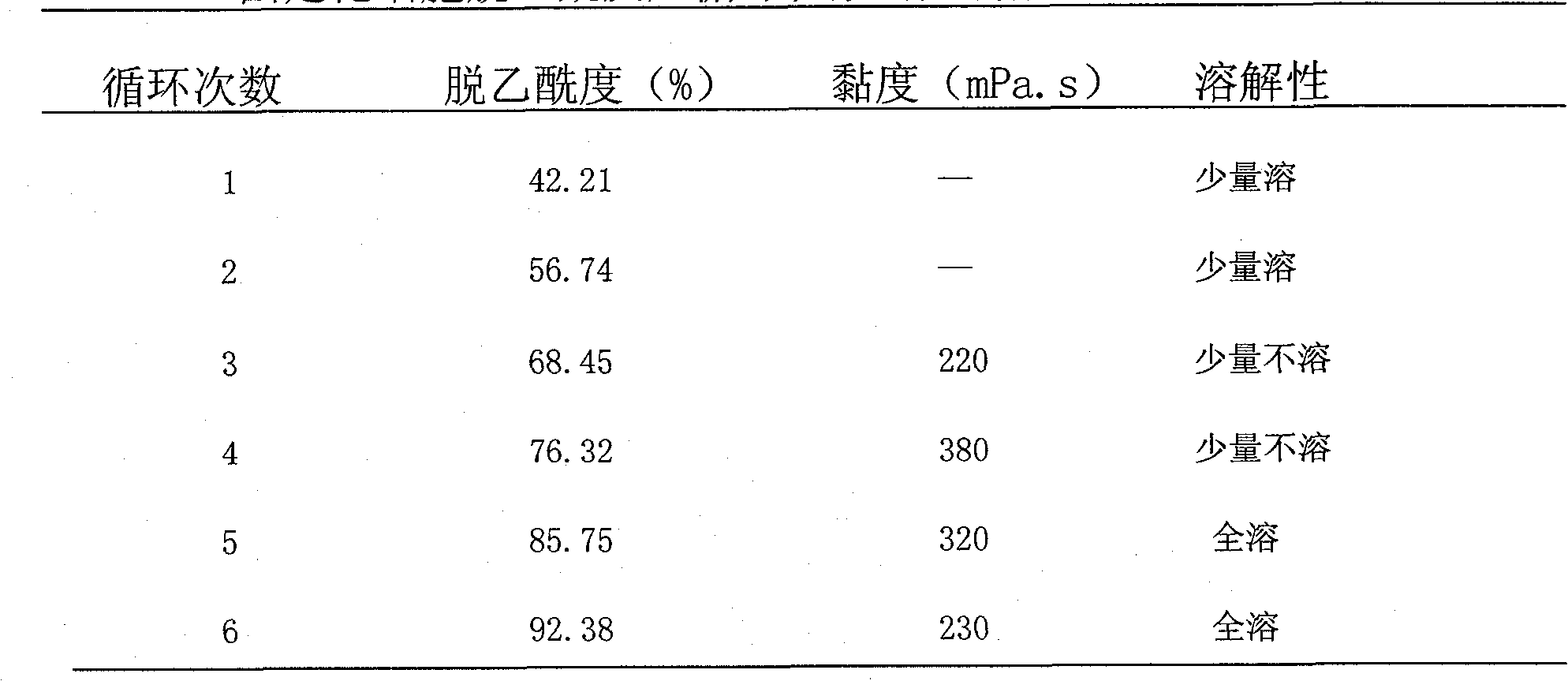

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effectis attained.

Description

A kind of method for preparing chitin and its chitosan and chitosan oligosaccharide technical field The invention belongs to the field of biotechnology, relates to a new process for producing chemical products and new materials, in particular to a method for preparing chitin, chitosan and chitosan oligosaccharide from various raw materials. Background technique As we all know, chitin (chitin, chitin) is one of the most widely existing natural organic compounds on the earth, ranking second only to cellulose in quantity, with an annual biosynthesis amount of nearly 10 billion tons; chitin is also The largest amount of nitrogen-containing natural organic compounds on the earth except protein; these two points alone are enough to explain the important position of chitin in nature and human life. Studies in recent decades have shown that chitin and its deacetylated product chitosan, as well as various derivatives of the two, as new chemical materials and organic products, have ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12P19/04C12R1/01C12R1/645C12R1/725C12R1/845

Inventor 吴力克

Owner 重庆百奥帝克微生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com