Biocatalytic hydrogenation composition and method for synthesis of Rosuvastatin chiral intermediate

A biocatalysis and composition technology, applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve the problems of poor product stereoselectivity, unsuitable for large-scale production, unfavorable large-scale production, etc., and achieve product stereoselectivity. The effect of poor selectivity, high product stereoselectivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a kind of preparation method of rosuvastatin intermediate, comprises the steps:

[0052] (1) In the tetrahydrofuran solution, according to the ratio of the amount of substances (S)-3-hydroxybutyrolactone: tert-butyl acetate = 1:2 feeding, under the protection of argon, under low temperature conditions, through diisopropylamino Lithium-catalyzed Claisen condensation reaction to generate (S)-5,6-dihydroxy-3-oxohexanoic acid tert-butyl ester;

[0053] (2) Mix (S)-5,6-dihydroxy-3-oxohexanoic acid tert-butyl ester with glucose dehydrogenase, ketoreductase and coenzyme to prepare (3R,5S)-3,5 , tert-butyl 6-trihydroxyhexanoate;

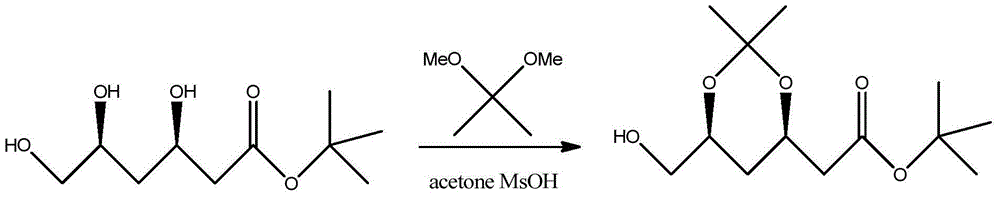

[0054] (3) tert-butyl (3R,5S)-3,5,6-trihydroxyhexanoate obtained in step (2) is reacted with 2,2-methoxypropane under the catalysis of methanesulfonic acid to obtain acetonylidene Protected tert-butyl (3R,5S)-3,5,6-trihydroxyhexanoate. In the preparation method, in step (2), (S)-5,6-dihydroxy-3-oxohexanoic acid t...

Embodiment 1

[0108] Preparation and activity detection of embodiment 1 ketoreductase and glucose dehydrogenase

[0109] 1. Preparation and Activity Detection of Ketoreductase

[0110] 1.1 Preparation of Ketoreductase

[0111] (1) Shake flask fermentation culture of ketoreductase

[0112] Inoculate the recombinant Escherichia coli from the slant medium into 30mL liquid LB medium containing 20uL ampicillin, and then complete the primary culture process for 18 hours at 25°C and 240rpm. Then, the primary culture seeds were inoculated into 1 L of liquid LB medium containing 5-10 mL of arabinose inducer, and cultured at the same temperature and rotation frequency for 20 hours to complete the secondary culture process. After the culture solution was centrifuged at 4000rpm for 12 minutes, the bacteria were collected, and the wet weight of the bacteria was weighed, and then the mass volume ratio was m bacteria: v buffer = 1:10 concentration ultrasonic / high pressure disruption. After complete cru...

Embodiment 2

[0142] Preparation and activity detection of embodiment 2 ketoreductase and glucose dehydrogenase

[0143] 1. Preparation and Activity Detection of Ketoreductase

[0144] 1.1 Preparation of Ketoreductase

[0145] (1) Shake flask fermentation culture of ketoreductase

[0146] Inoculate the recombinant Escherichia coli from the slant medium into 30mL liquid LB medium containing 25uL ampicillin, and then complete the primary culture process for 19 hours at 30°C and 240rpm. Then, the primary culture seeds were inoculated into 1 L of liquid LB medium containing 8 mL of arabinose inducer, and cultured at the same temperature and rotation frequency for 22 hours to complete the secondary culture process. After the culture solution was centrifuged at 4000rpm for 12 minutes, the bacteria were collected, and the wet weight of the bacteria was weighed, and then the mass volume ratio was m bacteria: v buffer = 1:8 concentration ultrasonic / high pressure disruption. After complete crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com