Decoloring method of redissolved syrup

A syrup and solution technology, which is applied in the decolorization field of resolvable syrup, can solve the problems of inability to retain small molecular pigments of resolvable syrup, and high color value of finished white sugar, so as to improve its own properties, improve the adsorption effect, and improve the collapse of pore structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

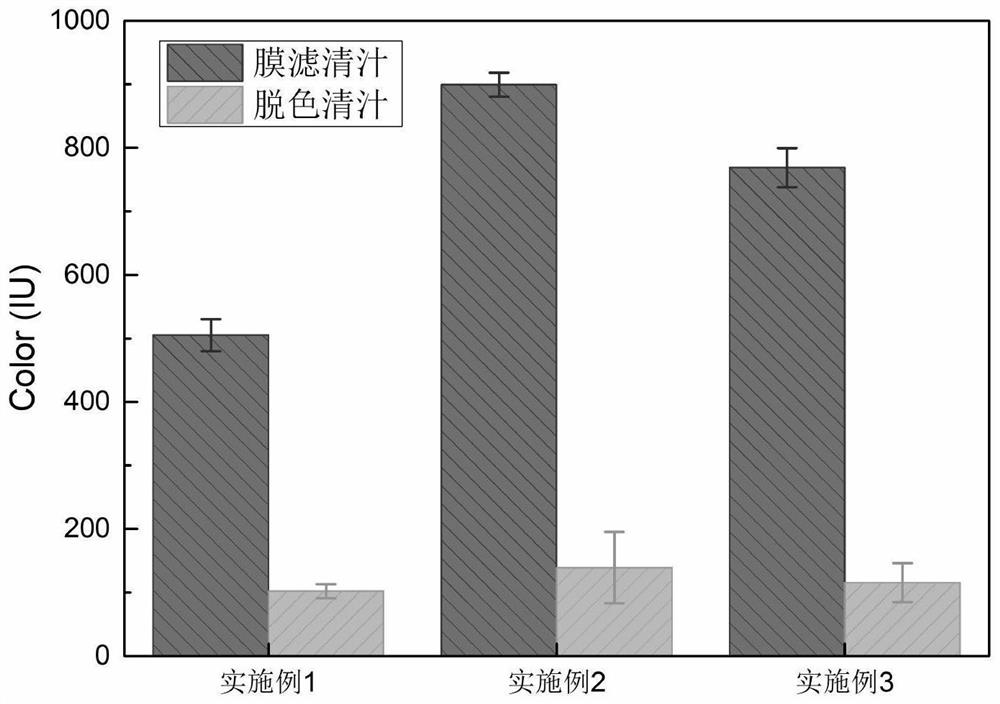

Embodiment 1

[0032] The preparation of quaternary ammonium functionalized chitosan / graphene oxide composite aerogel, the specific steps are as follows:

[0033] (1) Mix chitosan, sodium hydroxide aqueous solution with a concentration of 30% and analytically pure isopropanol solution in a mass ratio of 1.0:2:12, and heat it to 40°C in a water bath to make chitosan generate Swelling reaction, the mixture was stirred and swollen in a constant temperature magnetic stirrer for 200min;

[0034] (2) 60% of (3-chloro-2-hydroxypropyl) trimethylammonium chloride was added dropwise to the mixture, wherein (3-chloro-2-hydroxypropyl) trimethylammonium chloride was the same as the step (1) The mass ratio of the mixture is 0.1:1, and the temperature of the water bath of the mixture is increased to 60°C, stirred in a constant temperature magnetic stirrer, and the stirring condition is 60°C for 6 hours;

[0035] (3) adjust the pH of the reaction mixture with 5% dilute HCl solution to keep the pH neutral; ...

Embodiment 2

[0052] The preparation of quaternary ammonium functionalized chitosan / graphene oxide composite aerogel, the specific steps are as follows:

[0053] (1) Mix chitosan, sodium hydroxide aqueous solution with a concentration of 50% and isopropanol solution in a ratio of 1.5:5:20 by mass, and heat it to 60°C in a water bath to make chitosan undergo a swelling reaction, The mixture was swollen in a constant temperature magnetic stirrer for 300 min;

[0054] (2) 60% of (3-chloro-2-hydroxypropyl) trimethylammonium chloride was added dropwise to the mixture, wherein (3-chloro-2-hydroxypropyl) trimethylammonium chloride was the same as the step (1) The mass ratio of the mixture is 1.0:1, and the temperature of the water bath of the mixture is increased to 80°C, stirred in a constant temperature magnetic stirrer, and the stirring condition is 80°C for 8h;

[0055] (3) adjust the pH of the reaction mixture with 15% dilute HCl solution to keep the pH neutral;

[0056] (4) Collect the rea...

Embodiment 3

[0072] The preparation of quaternary ammonium functionalized chitosan / graphene oxide composite aerogel, the specific steps are as follows:

[0073] (1) Mix chitosan, sodium hydroxide aqueous solution with a concentration of 40% and isopropanol solution in a mass ratio of 1.3:3:15, and heat it to 50°C in a water bath to make the chitosan undergo a swelling reaction, The mixture was swollen in a constant temperature magnetic stirrer for 250 min;

[0074] (2) 60% of (3-chloro-2-hydroxypropyl) trimethylammonium chloride was added dropwise to the mixture, wherein (3-chloro-2-hydroxypropyl) trimethylammonium chloride was the same as the step (1) The mass ratio of the mixture is 0.5:1, and the temperature of the water bath of the mixture is increased to 70°C, stirred in a constant temperature magnetic stirrer, and the stirring condition is 70°C for 7 hours;

[0075] (3) adjust the pH of the reaction mixture with 10% dilute HCl solution to keep the pH neutral;

[0076] (4) Collect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com