Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Satisfy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar fireproof monitoring and prewarning system for gridding forestry

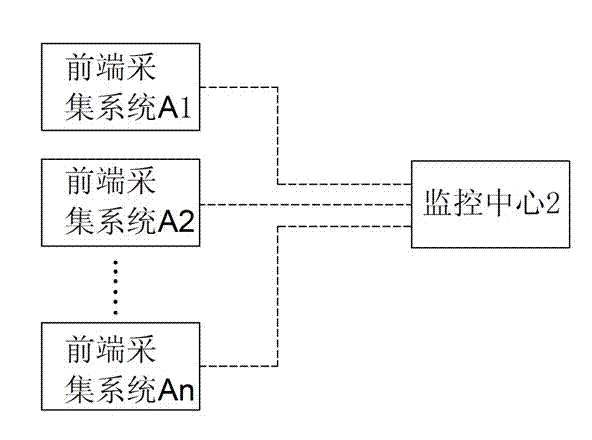

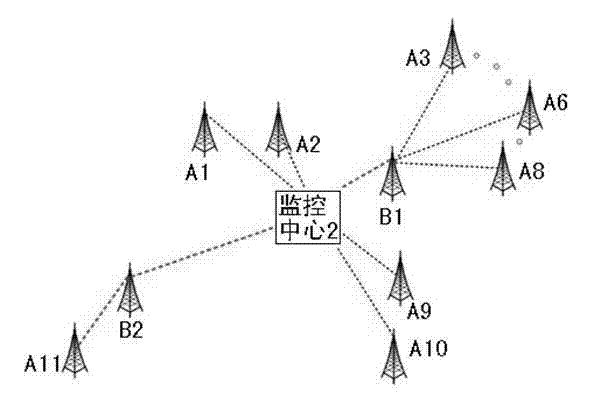

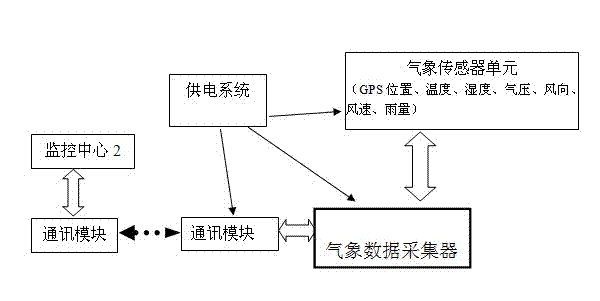

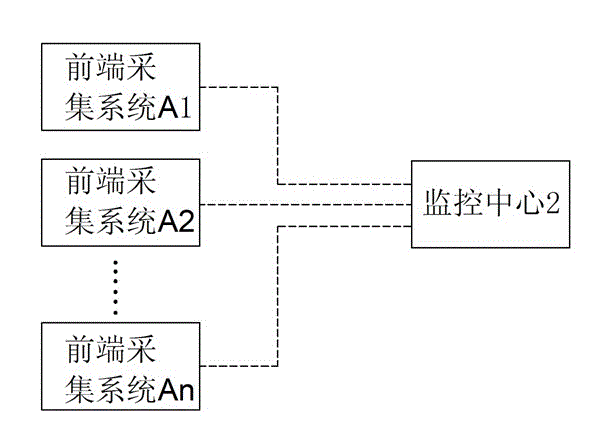

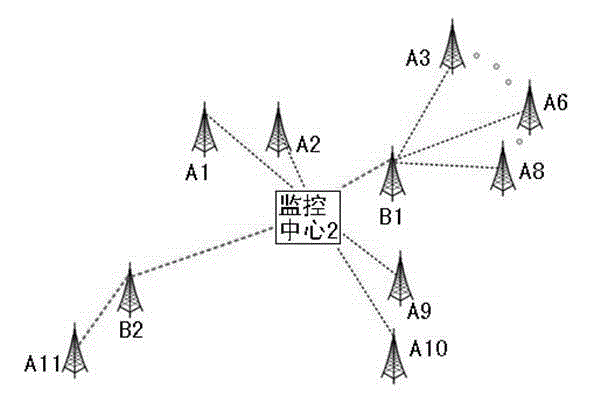

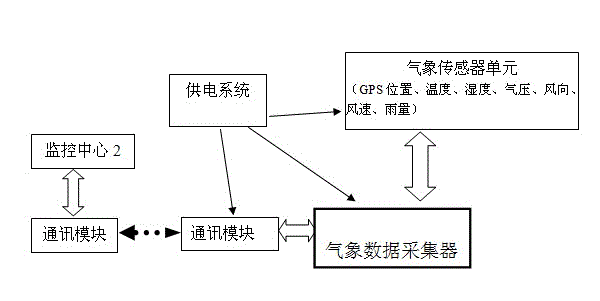

The invention relates to a solar fireproof monitoring and prewarning system for gridding forestry. The solar fireproof monitoring and prewarning system is characterized by comprising front-end acquisition systems and a monitoring center, wherein the plurality of front-end acquisition systems transmit acquired fire information to the monitoring center in a wired or wireless manner; and the fire information comprises video, smoke and / or temperature information. The solar fireproof monitoring and prewarning system has the advantages of avoiding the limitation of the traditional manual fire overseeing and observing method, realizing digitalization and scientization of forestry management, greatly reducing the charge against revenue and the management cost of a forestry department and enhancing the effect of a forestry enterprise.

Owner:WINCHANCE TECH

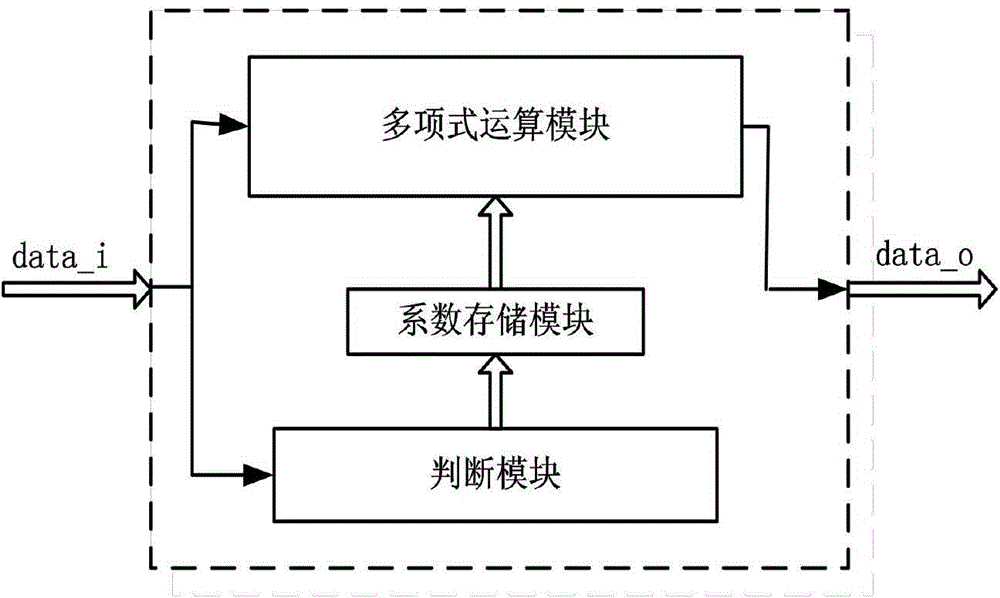

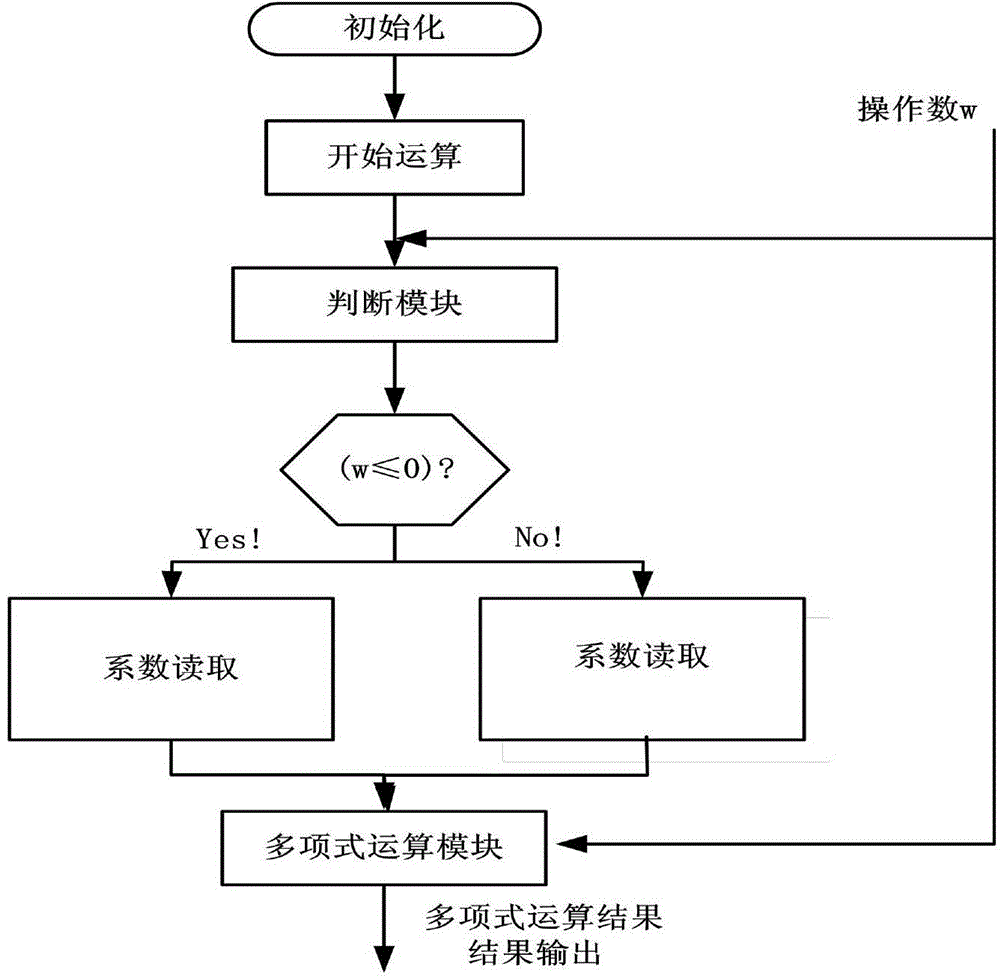

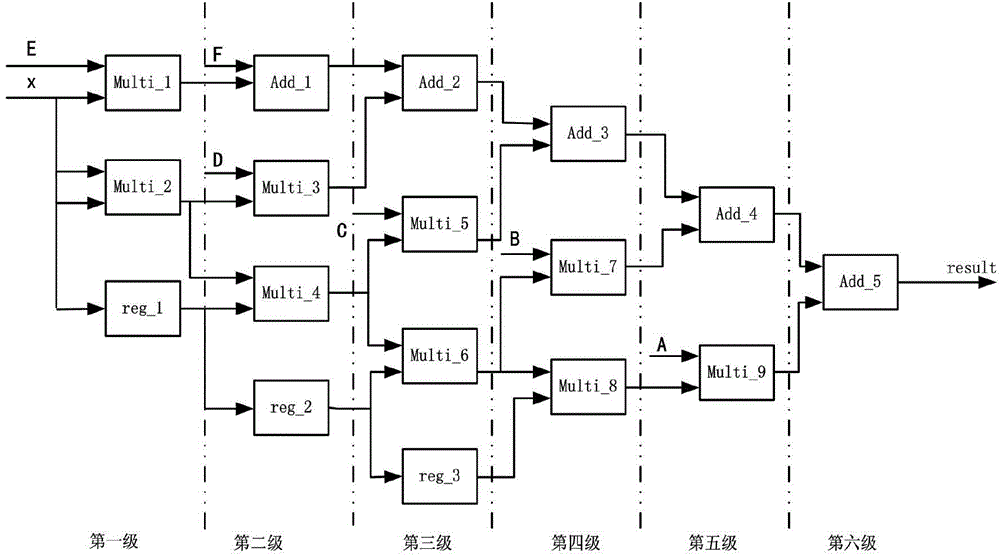

Sigmoid function fitting hardware circuit based on Remez approximating algorithm

ActiveCN104484703ASatisfy consumptionIncrease the number ofPhysical realisationResource consumptionSigmoid function

The invention discloses a sigmoid function fitting hardware circuit based on a Remez approximating algorithm. A sigmoid function fitting method is characterized by including the following steps that (1), the order of a fitting polynomial is determined; (2), a fitting interval of a sigmoid function is obtained; (3), a piecewise interval is obtained; (4), the fitting polynomial is obtained; (5), a coefficient storing module is designed; (6), a polynomial calculation module is designed; (7), a judgment module is designed; (8), the fitting hardware circuit is obtained; (9), a fitting execution interval where operands are located is judged; (10), a coefficient of the fitting polynomial is read; (11), fitting calculation is carried out in the polynomial calculation module. On the basis of reducing hardware resource consumption, the calculation accuracy is improved, the calculation speed is increased, and the flexibility of a calculation structure is promoted.

Owner:黄山市开发投资集团有限公司

Direct-drinking ginger tea beverage and preparation method thereof

InactiveCN103549071ASolve the ineffective extractionSolving activityTea substituesVitamin CActive component

The invention provides a direct-drinking ginger tea beverage. The beverage comprises the following materials by mass: 1 to 15 parts of ginger, 1 to 2 parts of red date, 1 to 2 parts of longan pulp, 0.5 to 1.5 parts of wolfberry, 7 to 10 parts of brown sugar, 0.5 to 0.8 part of honey, 0.1 to 1 part of vitamin C and 96 to 102 parts of water. A preparation method for the direct-drinking ginger tea beverage comprises the following steps: cleaning and pretreating the raw materials; subjecting ginger to wet ultrafine grinding; soaking red date without pit, longan pulp and wolfberry, carrying out extraction with hot water, then carrying out filtering and adding brown sugar; and adding honey and vitamin C after mixing of material liquid and carrying out dissolving, filtering, sterilization, canning and secondary sterilization to prepare the tasty beverage with health care functions like cold dispelling, dampness elimination, stomach strengthening, vomiting prevention, blood enriching and appetite promotion. The method employs wet ultrafine grinding technology and has the characteristics of rapidness, convenience, a low heat value during production, a fast dissolution speed of active components, a high recovery rate and high bioavailability.

Owner:三沙大海蓝生态农业科技有限公司

Method for producing large thickness and high intensity steel plate for boiler drum

InactiveCN101451213AImprove mechanical propertiesImprove performance qualityMolten metal pouring equipmentsRoll mill control devicesSteam drumAustenite

The invention discloses a production method for a high tensile steel plate used for a high thickness boiler drum. The production method comprises the following steps: (1) smelting: smelting molten steel in an electric furnace, the refining the molten steel in an LF finer, adding 300 to 500 meters of Al thread, and carrying out vacuum treatment in a bale VD furnace when the temperature of the bale is more than or equal to 1600 DEG C; (2) casting: keeping the temperature between 1,545 and 1,555 DEG C after damaging the vacuum; (3) heating: realizing the sending, clearing and filling of a steel ingot at a moderate temperature, cooling down the furnace for over 30 minutes before steel filling, and stewing the steel for one hour; (4) rolling: adopting II type rolling control technology, and setting a first stage as an austenite recrystallization stage and a second stage as an austenite non-recrystallization stage; (5) water cooling: cooling down the rolled steel plate on line, and keeping the red temperature between 700 and 750 DEG C; (6) heat treatment: carrying out the normalizing plus tempering treatment of the steel plate; and (7) shot blasting: carrying out shot blasting before storing the steel plate in a warehouse so as to completely remove the iron sheet produced during heating. The method shortens the steel rolling and heating time, reduces the consumption of production energy, and meets the requirements of a plurality of heat cycles during the boiler manufacturing process. The steel plate has good welding performance.

Owner:WUYANG IRON & STEEL

Educational toy capable of improving children's reaction speed

InactiveCN109260724AReduce power consumptionPromote thinking divergenceMusical toysMovement coordination devicesEngineeringReaction speed

The invention discloses an educational toy capable of improving the reaction speed of children. The educational toy comprises a first box body, a transparent glass made of resin is embedded in the front surface of the first box body, a switch is embedded and installed at the upper left corner position on the front surface of the first box body, a labyrinth lattice is fixedly arranged on the innerside of the first box body, and a small ball outlet is arranged at the tail end position of the labyrinth lattice on the inner bottom end of the first box body. The invention is novel in design, the labyrinth is made up of a number of crisscrossing strips and a wheel that changes the direction of the ball, at each junction there are two and several exit, however, there is only one route to connectcorrectly. Once the ball deviates from the correct path, it will need to be reoperated to make the ball return to the correct path, which will affect the overall passing speed. This method can trainchildren's hand-eye-brain coordination ability and overall reaction speed, and promote children's divergence of thinking.

Owner:苏州颗粒智能玩具有限公司

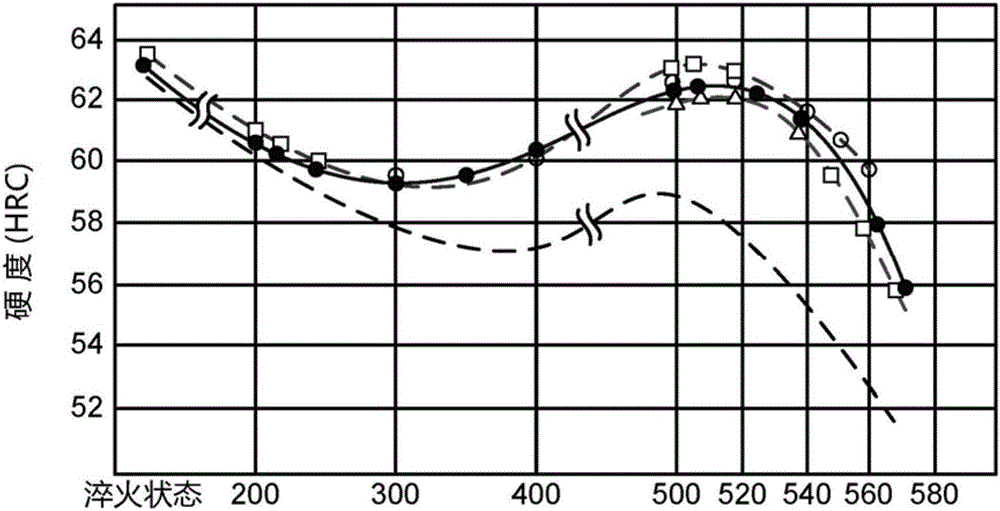

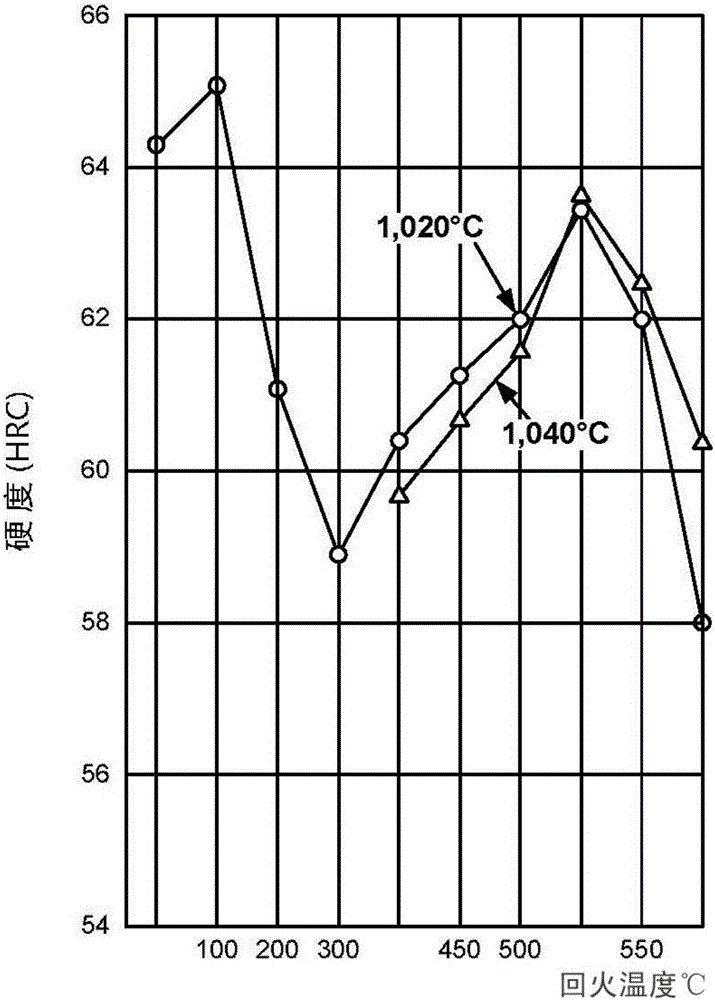

High-performance and high-speed-stamping cold work die steel and preparation method thereof

The invention relates to high-speed-stamping cold work die steel and a preparation method thereof. The high-speed-stamping cold work die steel is characterized by primarily comprising, by mass, 0.85%-0.95% of C, 0.80%-1.20% of Si, 0.30%-0.60% of Mn, 0.025% or less of P, 0.015% or less of S, 7.90%-8.40% of Cr, 1.40%-1.70% of Mo, 1.90%-2.20% of W, 2.20%-2.50% of V, 0.90%-1.20% of Al, 0.20% or less of Cu, 0.25% or less of Ni, and the balance Fe. By adding the alloy element, namely Al, the hardness, red hardness and the surface hardness and heat stability after nitriding of the steel are further improved; through addition of Mo, the hardenability, heat resistance, temper embrittlement resistance and temper softening resistance of the steel can be improved; and the high-speed-stamping cold work die steel has the remarkable beneficial effects of having high hardness, heat hardness and heat stability, meeting the development demand of modern industry, reducing consumption and increasing social benefits.

Owner:GUANGDONG STRONG METAL TECH

Continuous production method of cotton fiber heat-insulating material by using molten yellow phosphorus slag

The invention relates to a production method of cotton fiber, comprising the following steps: 1. conveying molten phosphorus slag; 2. adjusting components of the phosphorus slag: selecting the following additives based on the weight percentage of the phosphorus slag: 1%-10% of borax, 0.1%-0.5% of albite, 0.01%-0.03% of sodium carbonate and 10%-30% of glass, evenly mixing the additives, placing in a storage container, heating and melting the additives by tail gas of a phosphorus furnace to form a molten mass, and directly adding the molten mass to the molten phosphorus slag; 3. making the phosphorus slag into cotton: transferring the phosphorus slag obtained in step 2 into a four-roll high-speed centrifugal cotton making machine, and adding a secondary adjuvant to positive-pressure airflow needed for cotton making to participate in the cotton-making procedure, wherein, the secondary adjuvant is mixed liquid composed of the following components in percentage by weight: 60%-80% of kerosene and 20%-40% of paraffin, and the secondary adjuvant accounts for 0.5%-1% of the weight of the phosphorus slag; and 4. collecting, curing and forming the cotton fiber.

Owner:YUNNAN WANFUYUAN IND & TRADE

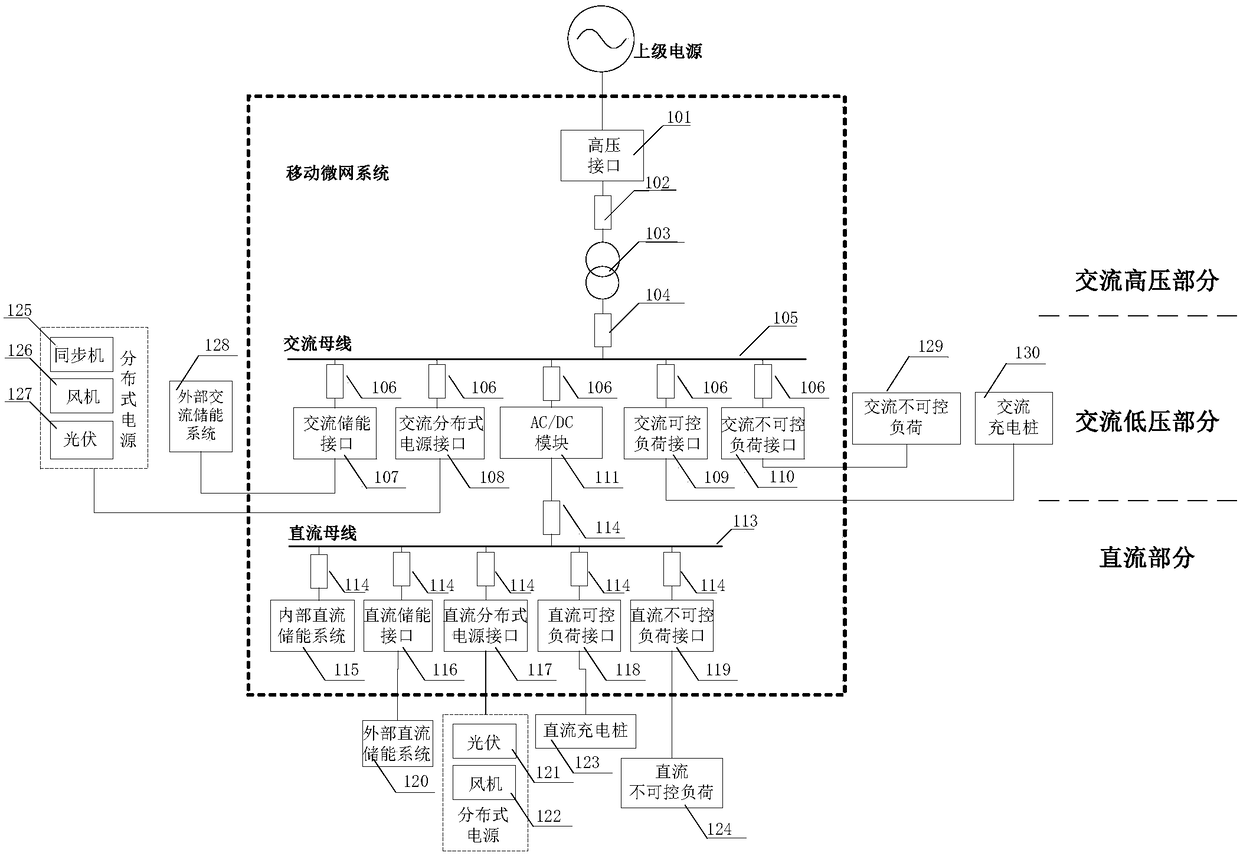

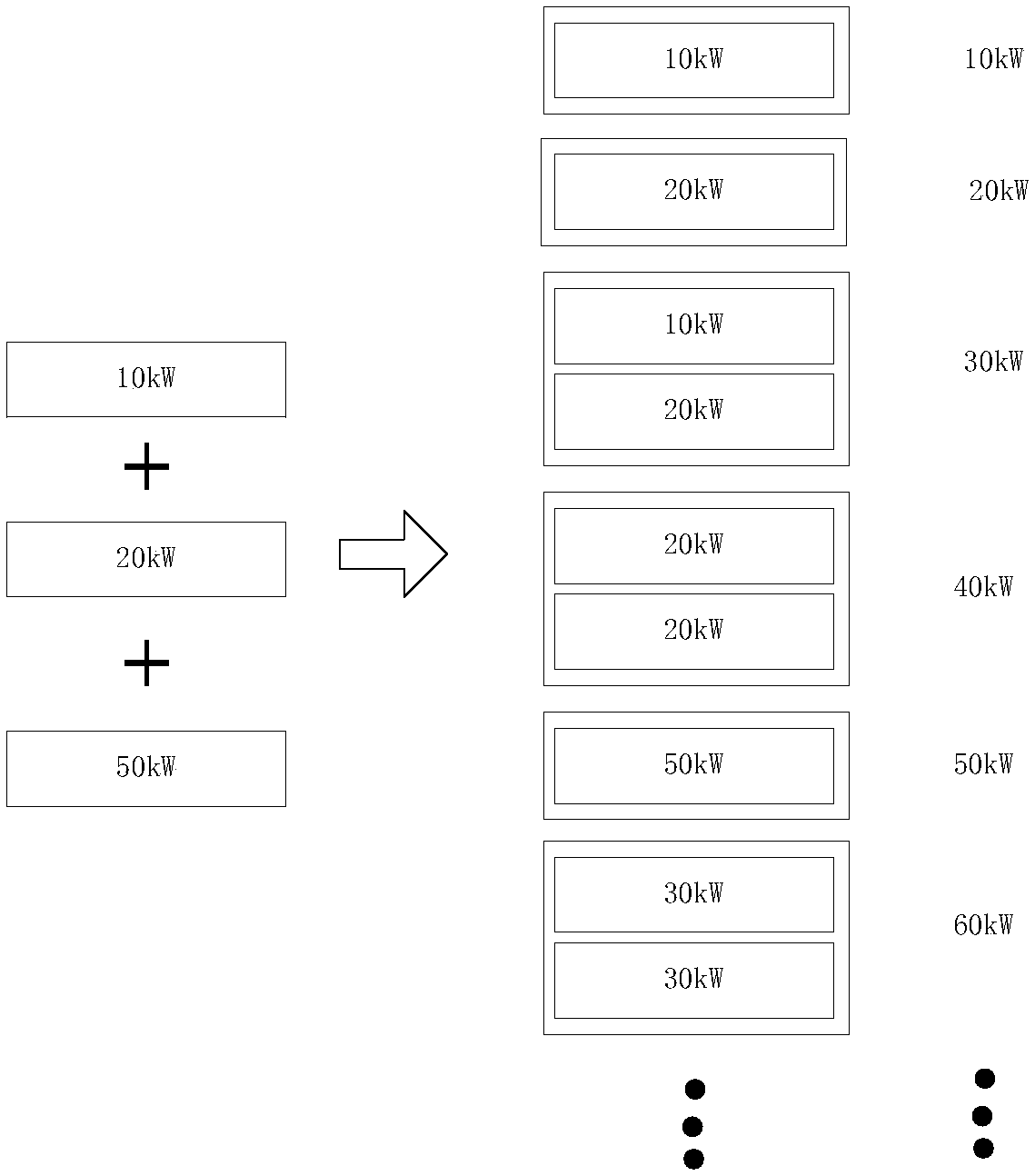

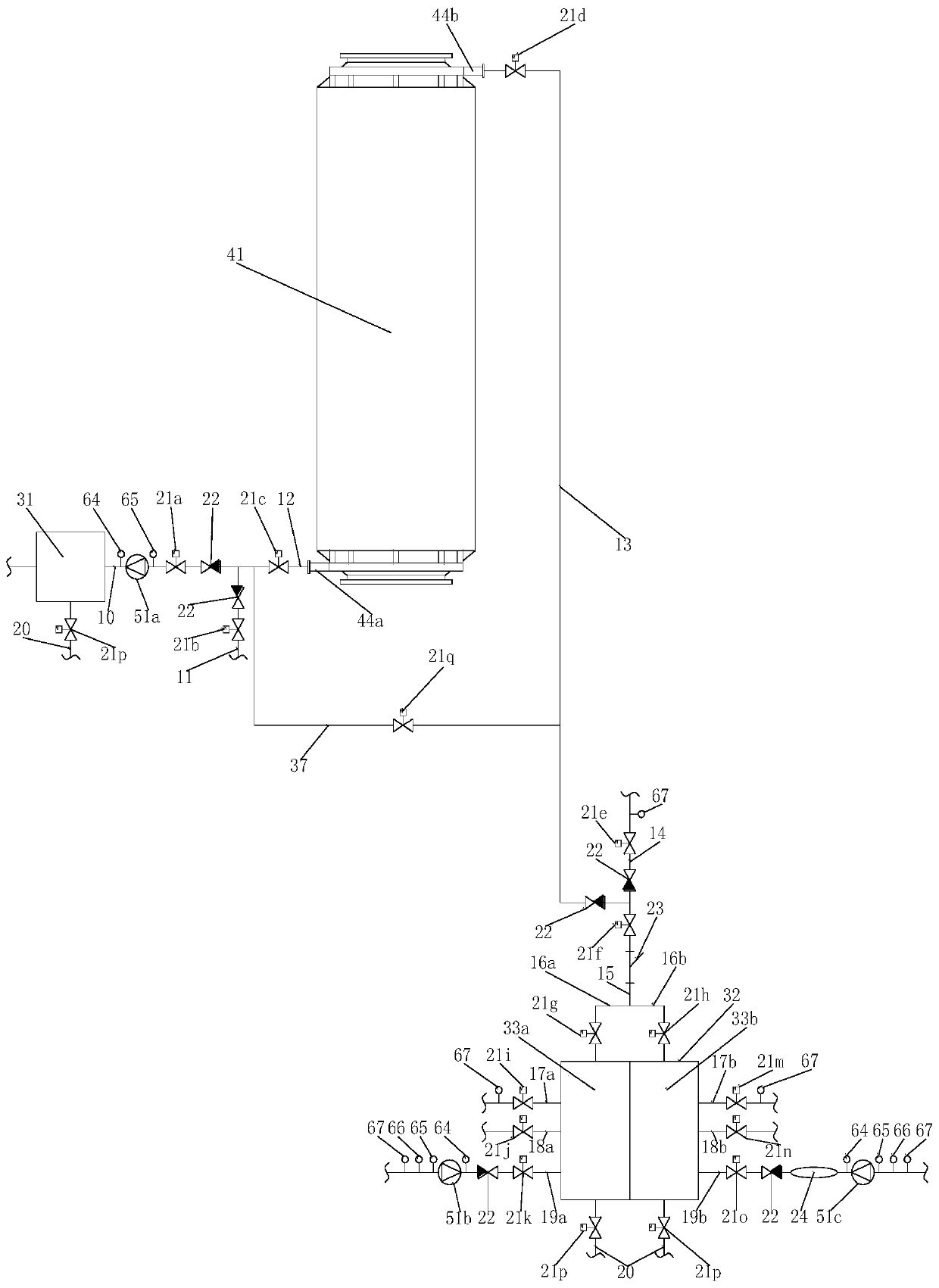

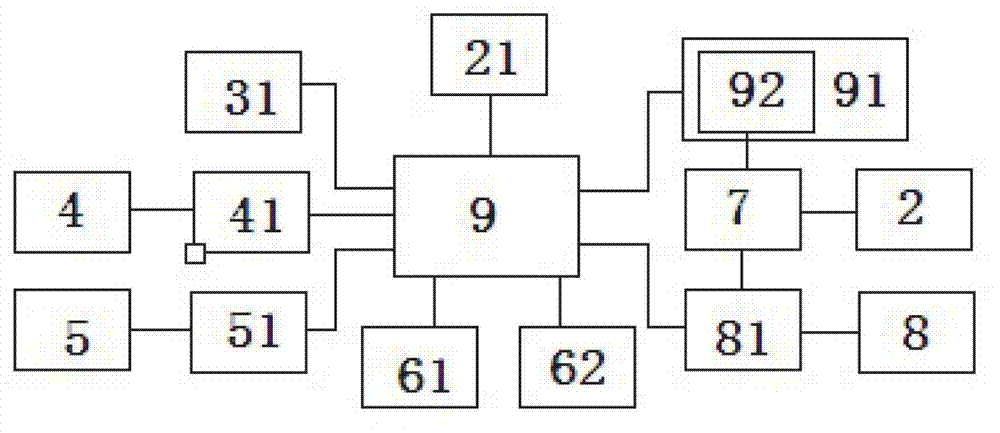

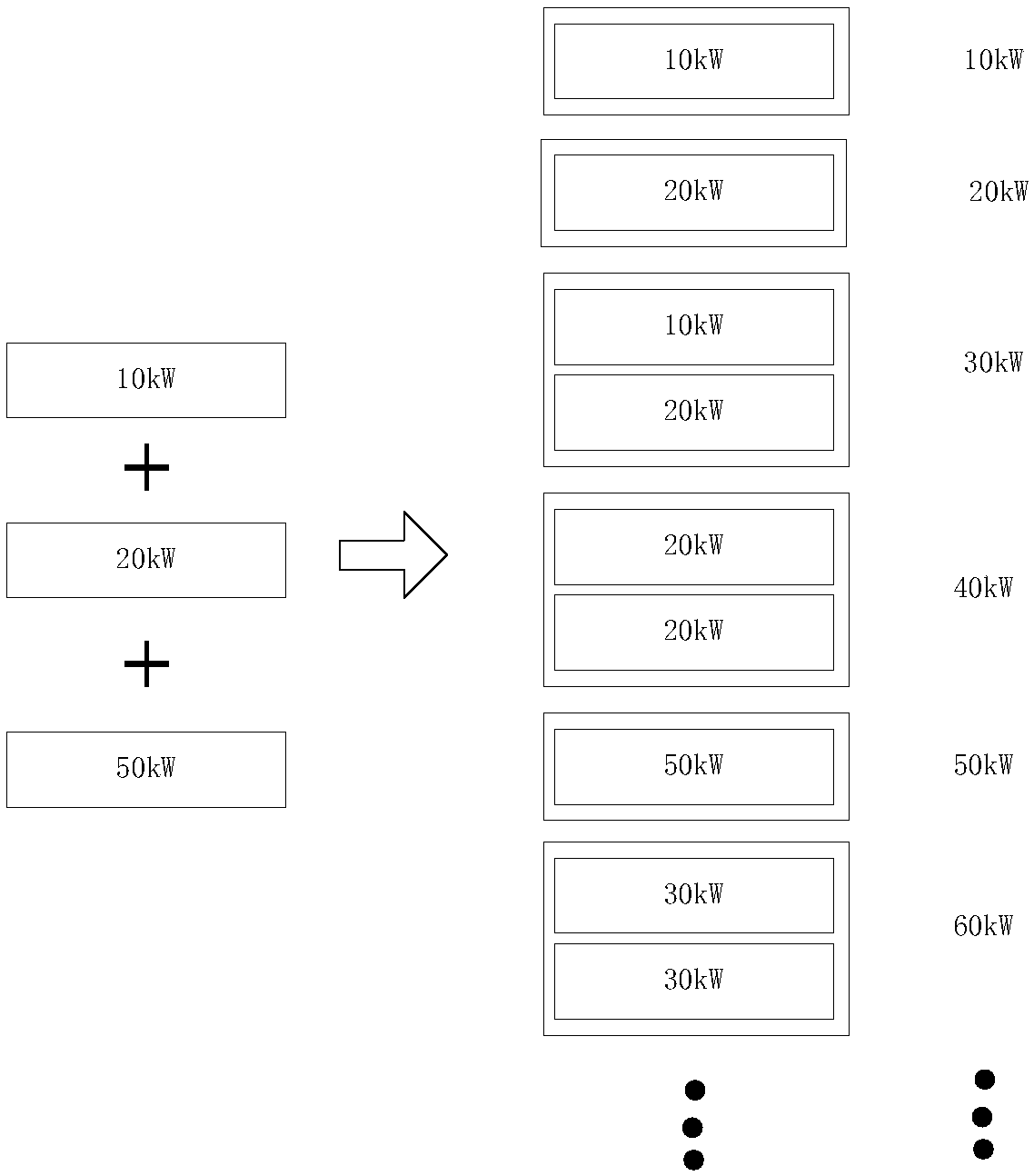

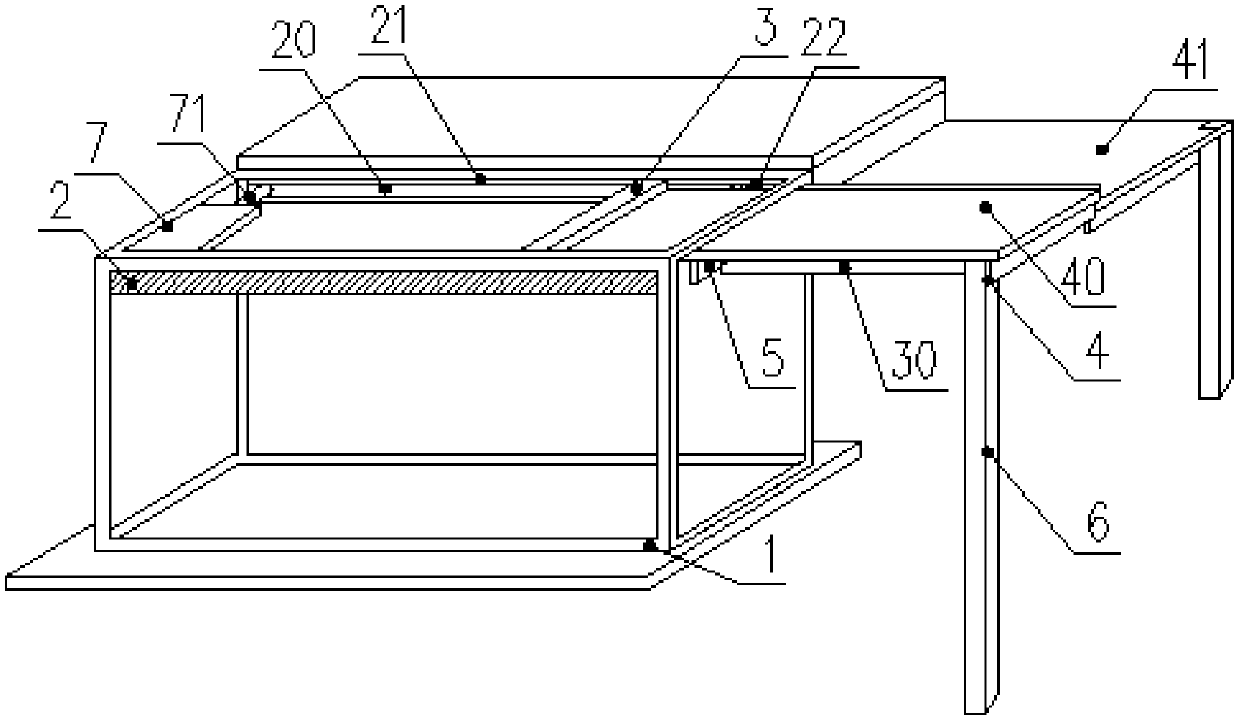

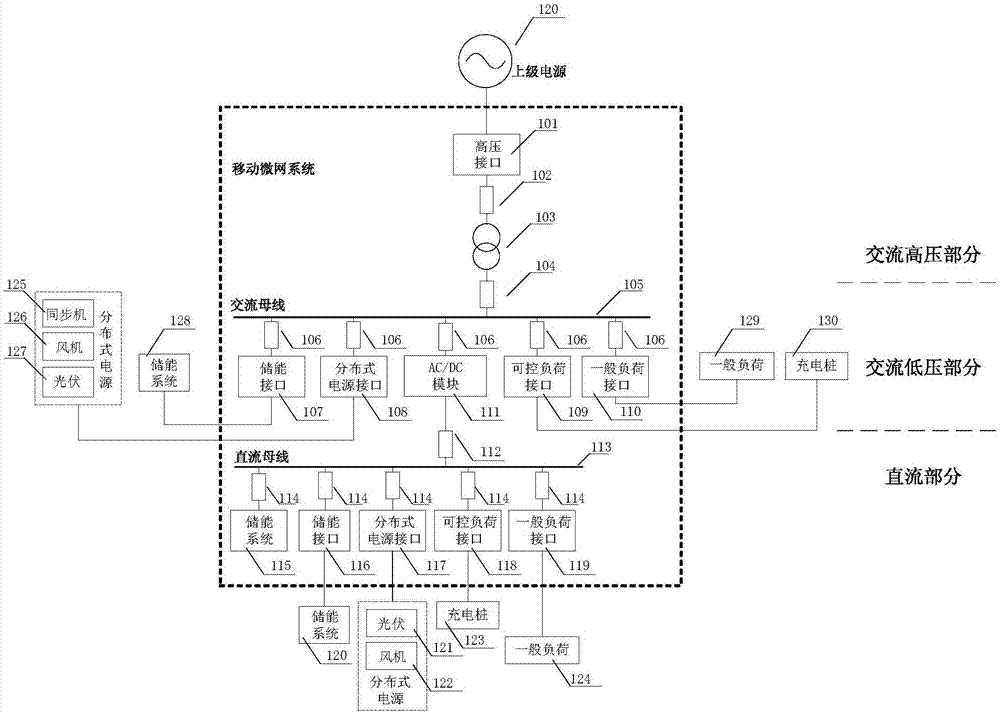

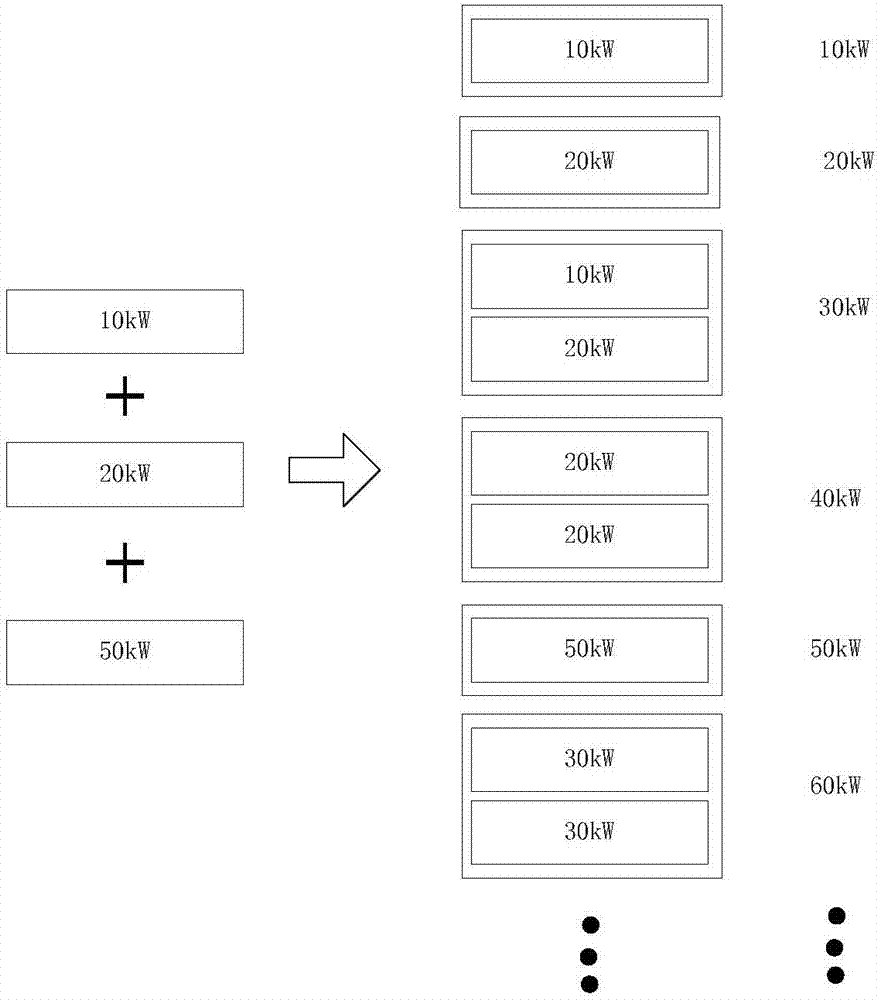

Mobile micro-grid system

InactiveCN108075489ARealize factoryRealize standardized processing and productionSingle network parallel feeding arrangementsSystems intergating technologiesPower qualityTransformer

The invention discloses a mobile micro-grid system, which comprises a movable carrier, a transformer arranged on the movable carrier, a prefabricated cabin arranged on the movable carrier, an interface circuit arranged in the prefabricated cabin and a control system for monitoring control of the interface circuit. The interface circuit comprises an AC bus, a DC bus, a distributed resource AC interface electrically connected with the AC bus and a distributed resource DC interface electrically connected with the DC bus. The high-voltage side of the transformer is electrically with an external superior power supply, and the low-voltage side thereof is electrically with the AC bus. The AC bus is electrically connected with the DC bus through an AC / DC module. The system can realize local area power supply, and small-area power balance and energy optimization under the condition where a main network frame is damaged, and meanwhile, meet high power customization requirements of users, such asdistributed resource consumption, uninterrupted power supply and reactive power and power quality compensation and the like.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

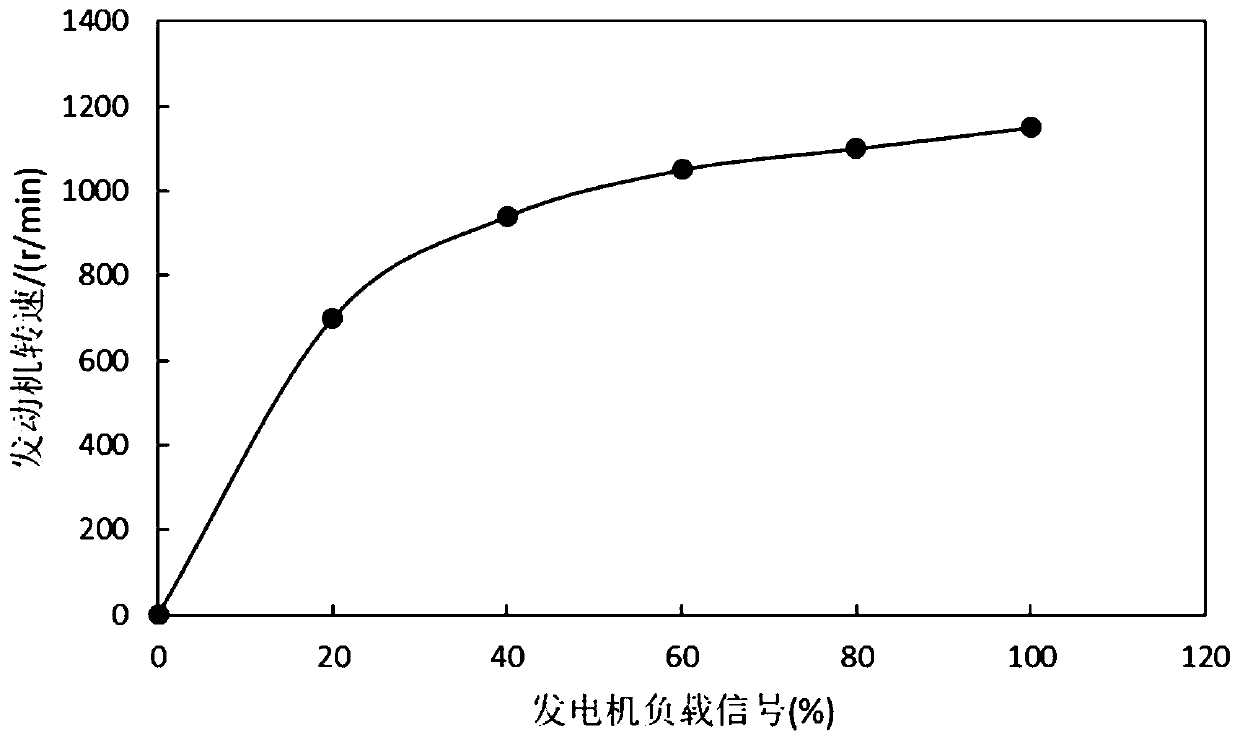

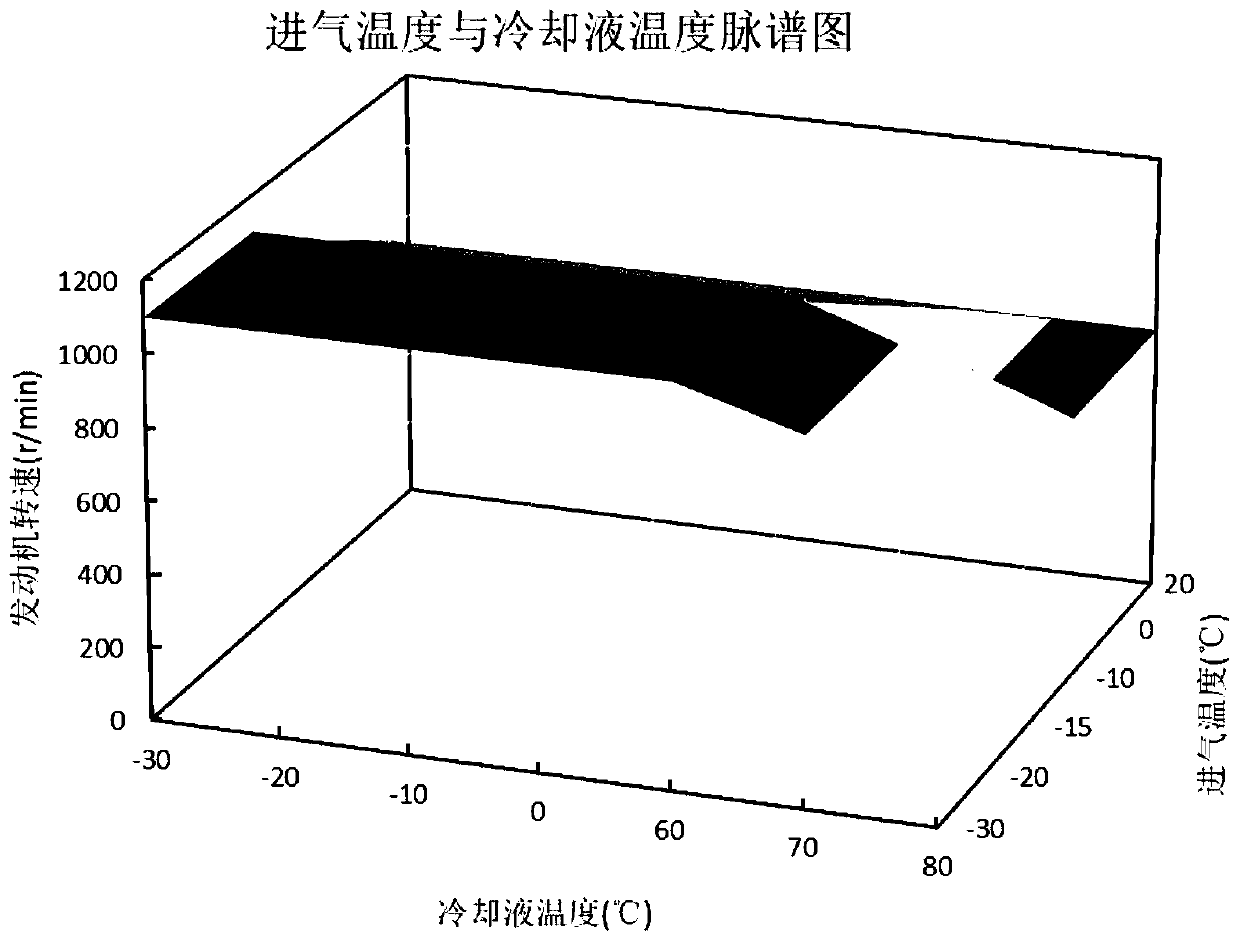

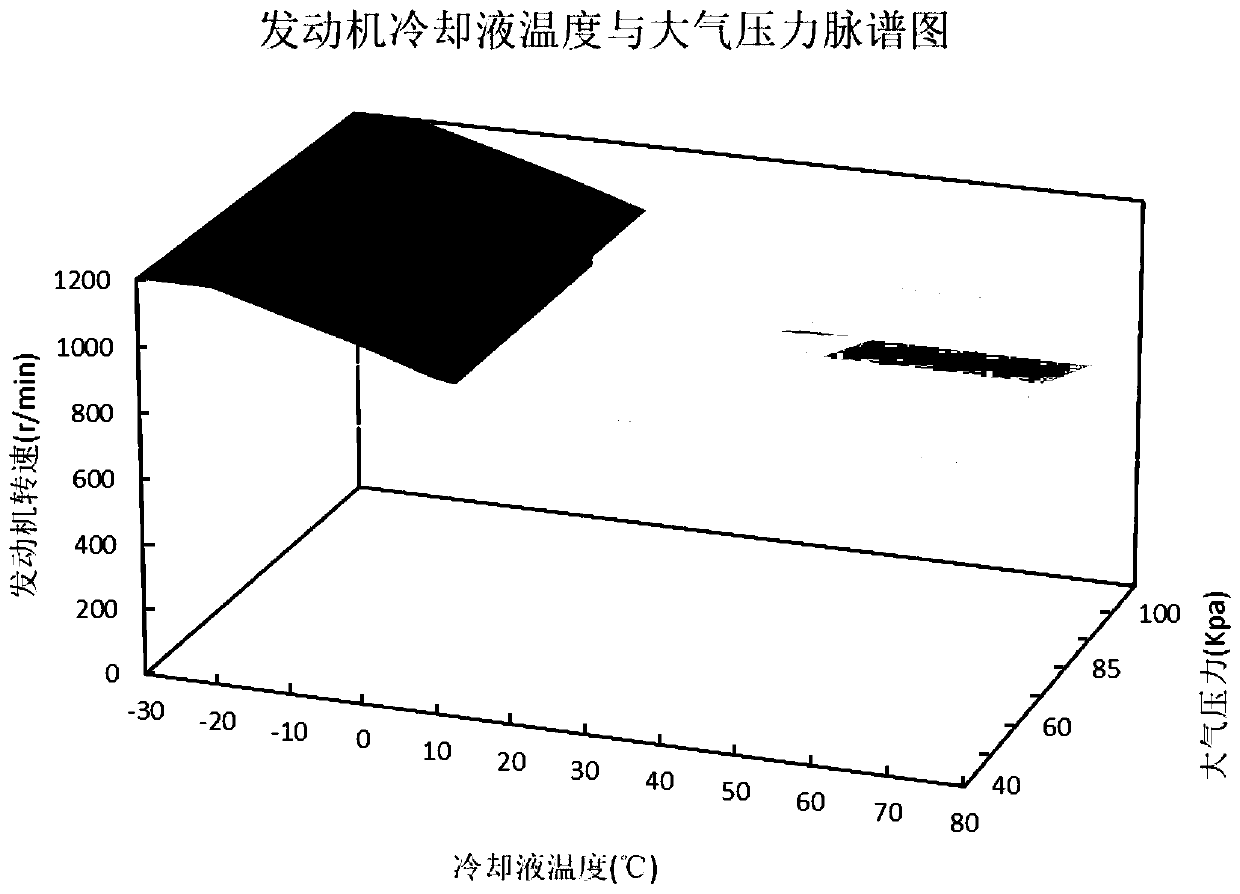

Idling target rotating speed control method

ActiveCN111365135AImprove load resistanceImproved speed stabilityElectrical controlSpeed sensing governorsSignal onCoolant temperature

The invention relates to the technical field of automobile control, in particular to an idling target rotating speed control method. The idling target rotating speed control method includes the stepsthat operating information of a vehicle is acquired, data of the engine load, the atmosphere pressure, the air inflow temperature and the cooling liquid temperature of the vehicle is acquired, an idling target rotating speed K1 is determined based on an engine load signal of the vehicle, then the idling target rotating speed K1 based on the engine load signal is corrected through the atmosphere pressure, the air inflow temperature and the cooling liquid temperature, and a current engine idling target rotating speed L is obtained. The influences of the engine load signal on the engine idling target rotating speed are fully considered, in combination with the atmosphere pressure, the air inflow temperature and the cooling liquid temperature, the idling target rotating speed best conforming to the operating condition of an engine is obtained, the stability of the engine during idling operation can be improved advantageously, and great promotional value is achieved.

Owner:DONGFENG MOTOR CORP HUBEI

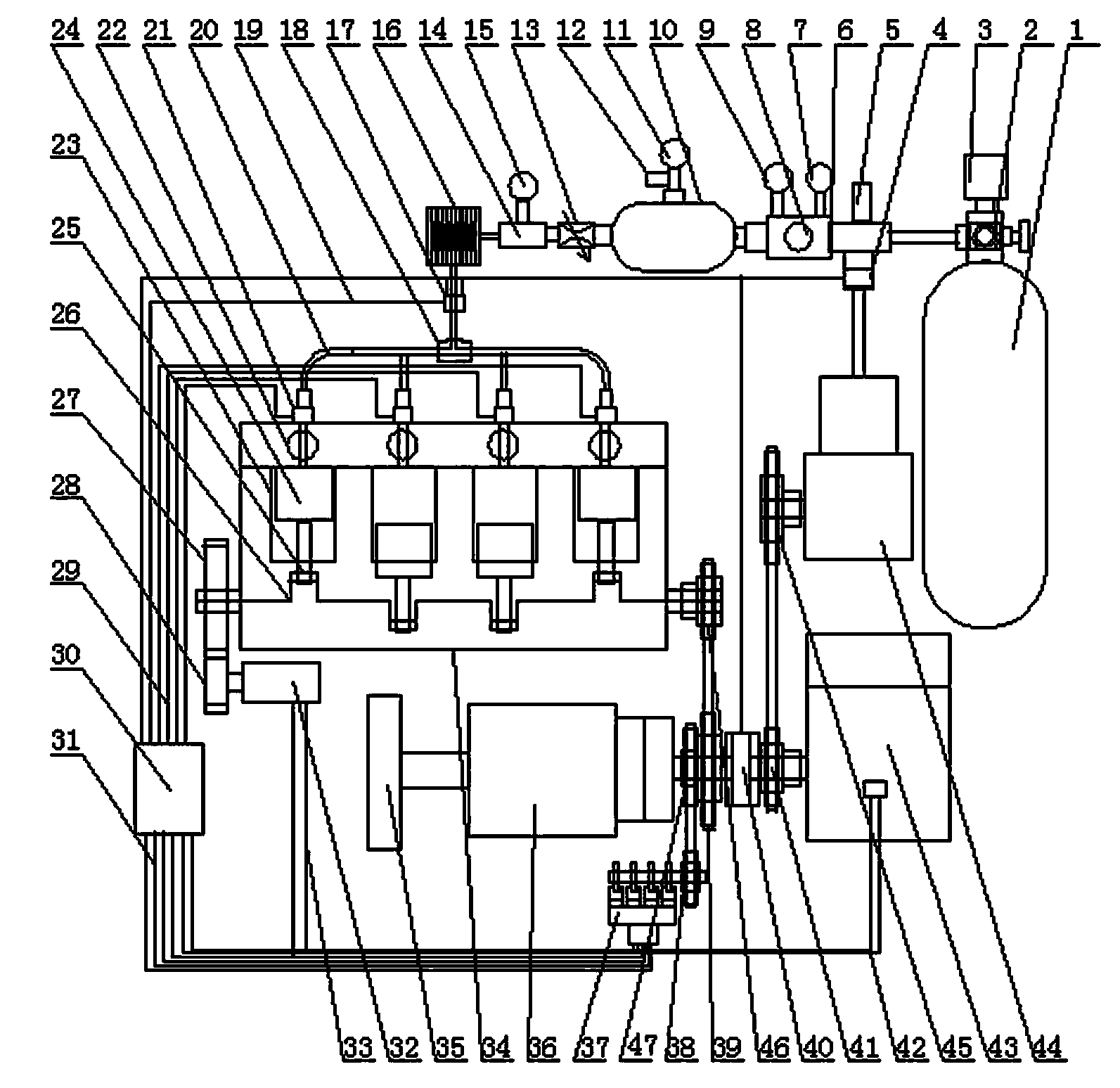

Air energy fuel oil hybrid engine

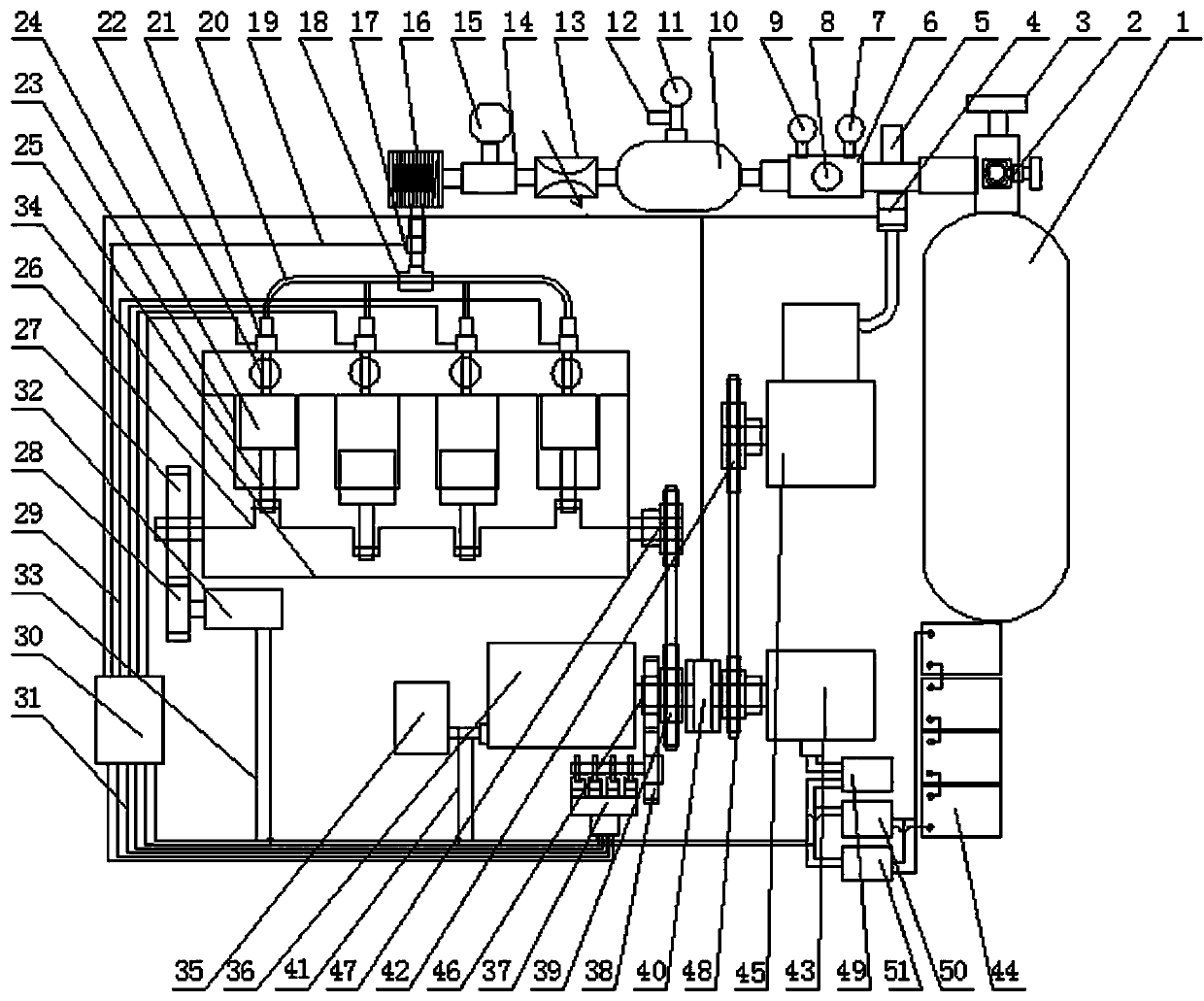

InactiveCN103352726ASolve battery lifeReduce volumeHybrid vehiclesReciprocating combination enginesHybrid typeCycle control

The invention discloses an air energy fuel oil hybrid engine which comprises an air energy storage device, an engine air supply control device, a solenoid valve gas control system, an air energy fuel oil hybrid engine, an engine starting device, a fuel oil engine transmission device, an air supply cycle control device and a various clutch transmission output device. The invention provides an air energy fuel oil hybrid engine, and by utilizing an engine consisting of an air medium and a fuel oil engine, a compressor is driven to operate for supplying an air source by employing a fuel oil engine; and meanwhile, a load is driven to operate to form an air energy fuel oil hybrid engine, external auxiliary gas station equipment is not required to refuel, the air storage tank is small in size, the air energy fuel oil hybrid engine completely depends on a self-help power control system, the compressor is driven to cyclically supply air to the air energy engine in a reciprocating mode through the fuel oil engine, the problems of low cruising ability of the air energy fuel oil hybrid engine, low fuel oil consumption and slight environmental pollution, and the air energy fuel oil hybrid engine has wide application field in the future, can be applicable to various motor vehicles and replaces the conventional fuel oil engine with energy consumption and pollution.

Owner:SHENZHEN PINCHUAN ENERGY ELECTRIC CO LTD

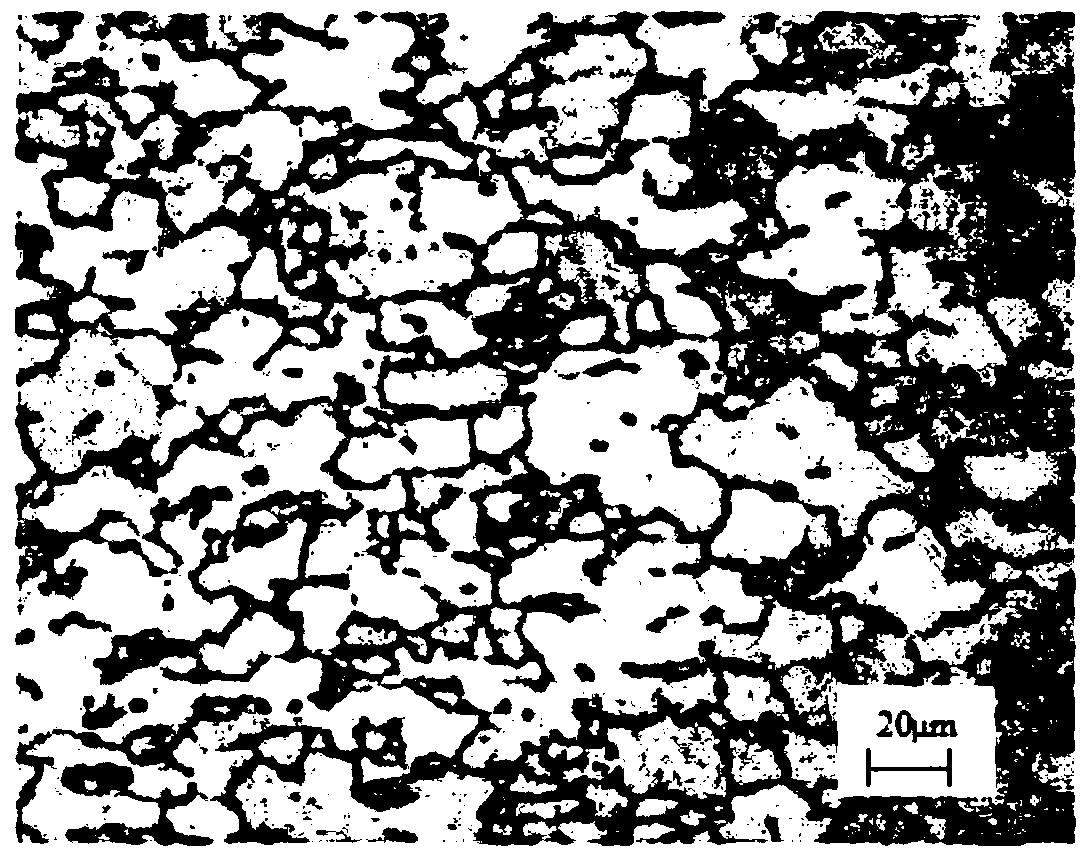

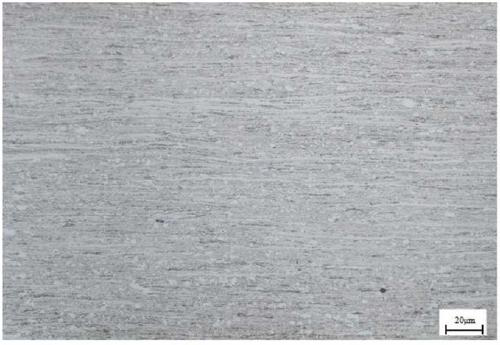

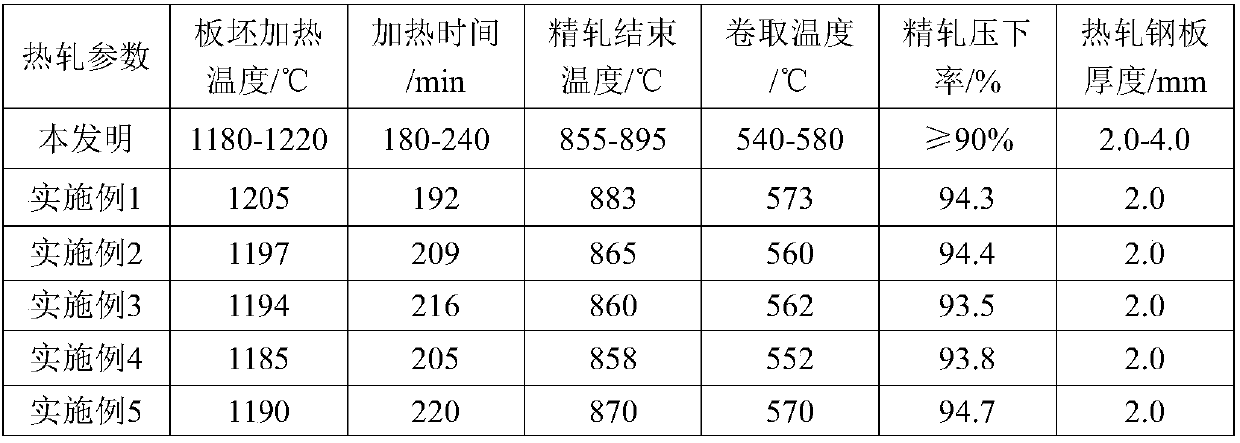

Cold-rolled steel sheet for automobile silencer and production method of cold-rolled steel sheet

InactiveCN111041166AOptimize the reduction rateHigh strength requirementsFurnace typesHeat treatment furnacesMetallurgyUltimate tensile strength

The invention discloses a cold-rolled steel sheet for an automobile silencer and a production method of the cold-rolled steel sheet. The technical problems that an existing cold-rolled steel sheet forthe automobile silencer is high in manufacturing cost and not stable in material performance are mainly solved. The cold-rolled steel sheet for the automobile silencer is prepared from chemical components in percent by weight including 0.05%-0.07% of C, smaller than or equal to 0.034% of Si, 0.2%-0.3% of Mn, smaller than or equal to 0.018% of P, smaller than or equal to 0.0164% of S, 0.01%-0.04%of Al and the balance Fe and inevitable impurity elements. The yield strength RP0.2 of the cold-rolled steel sheet is 580 MPa-740 MPa, the Vicker's hardness HV1 is 185-230, the wave height within 2 min the rolling direction of the cold-rolled steel sheet is smaller than or equal to 2.5 mm, and the surface roughness Ra of the cold-rolled steel sheet is 0.45 micrometer-0.60 micrometer. The cold-rolled steel sheet is used for the automobile silencer component, and the production cost is reduced by 50-100 yuan / ton of steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for producing mixed braided wire used for trawlnet fishing gear or aquaculture net cage

The invention relates to a method for producing a mixed braided wire used for a trawlnet fishing gear or an aquaculture net cage. The method comprises the following steps of: obtaining a polyethylene fishing fibre yarn bobbin used for processing a mixed braided wire face; obtaining a polyethylene fishing filament core bobbin used for processing a mixed braided wire core; determining the central parts of the mixed braided wire face used for the trawlnet fishing gear or the aquaculture net cage and a mixed braided wire used for the trawlnet fishing gear or the aquaculture net cage; and weaving to obtain the mixed braided wire used for the trawlnet fishing gear or the aquaculture net cage. According to the mixed braided wire used for the trawlnet fishing gear or the aquaculture net cage produced by the invention, a fishing material structure in China can be adjusted, a high performance material can be provided, the water resistance of the trawlnet fishing gear or the aquaculture net cage can be reduced, the energy consumption and raw material consumption of the trawlnet fishing gear or the aquaculture net cage can be reduced, and the cost of trawlnet finery industry or aquaculture net cage industry can be reduced.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

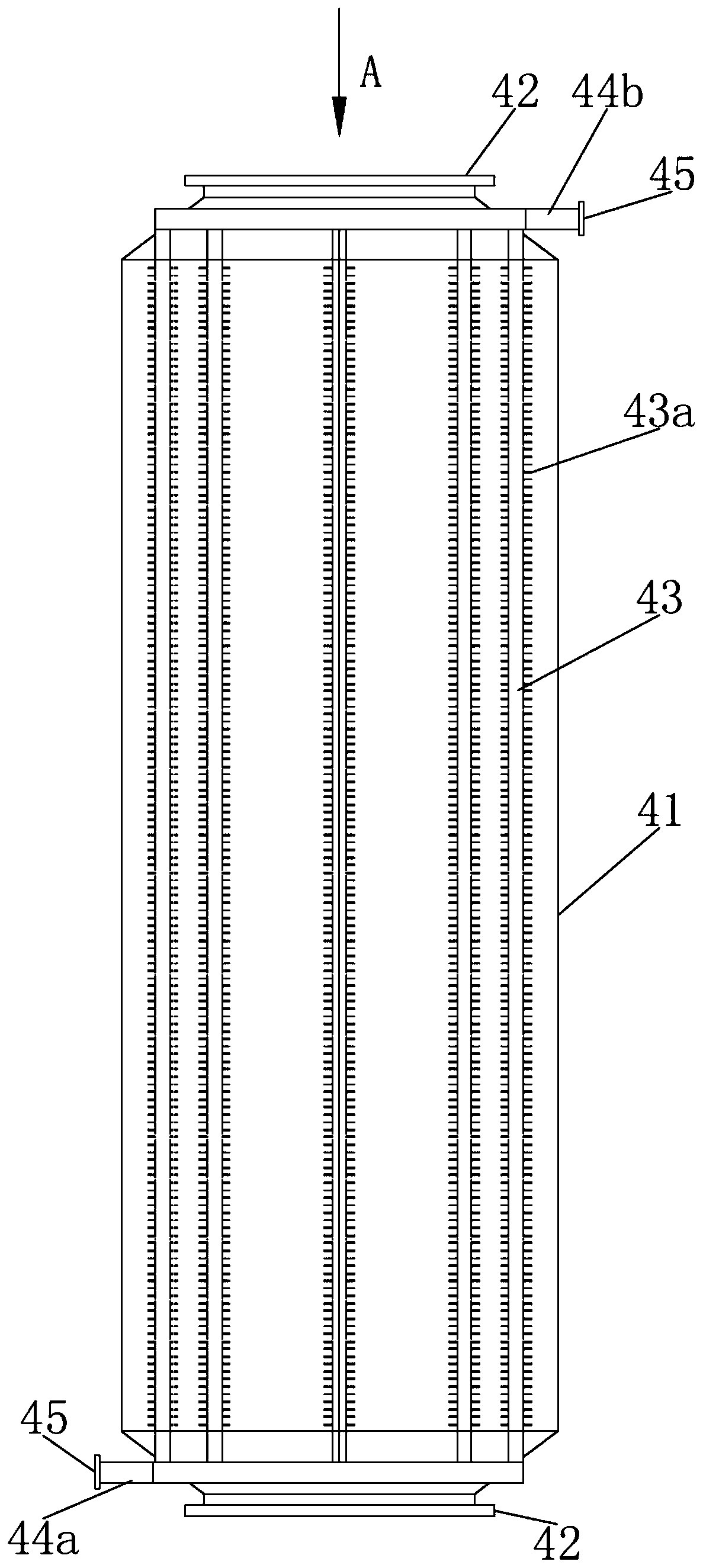

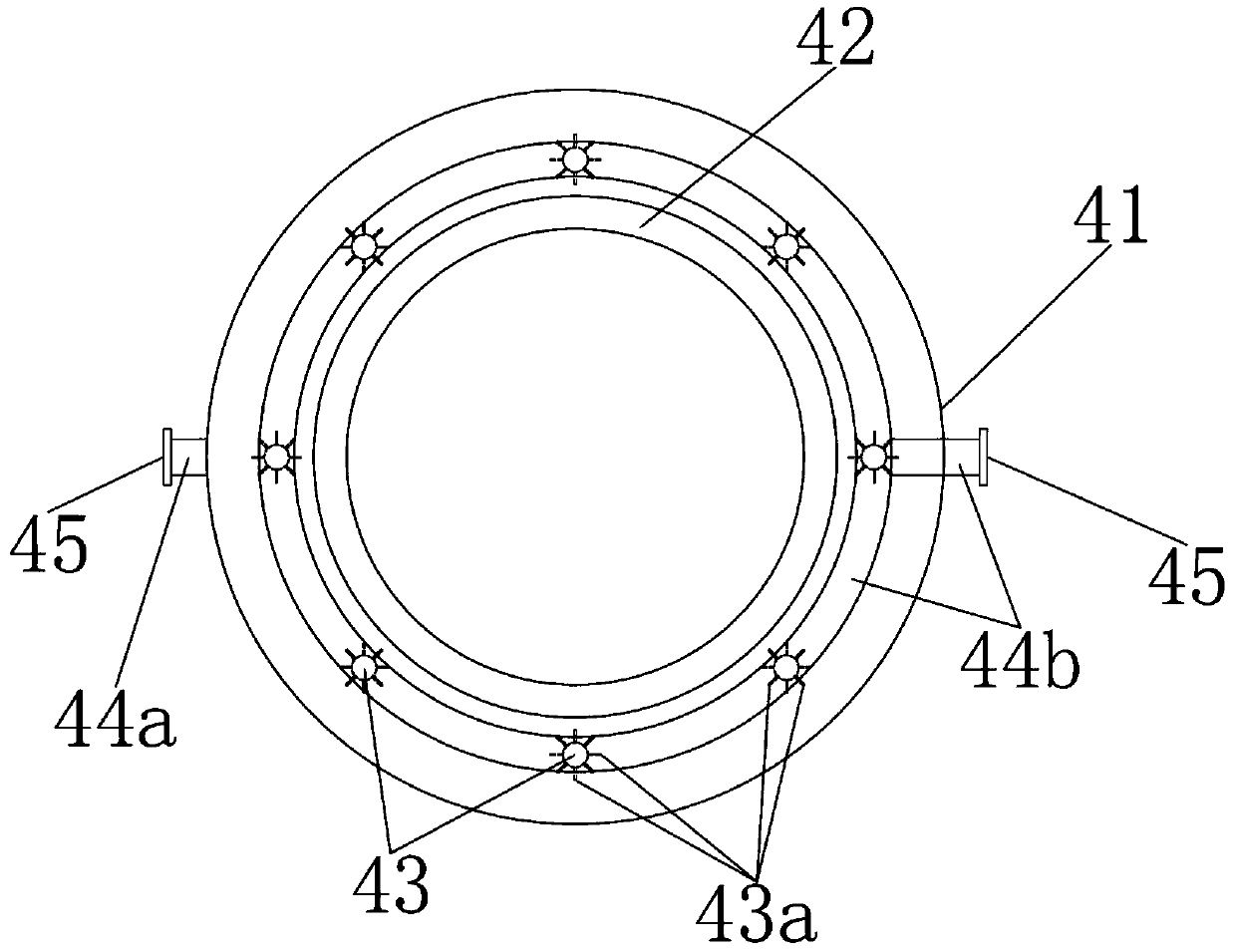

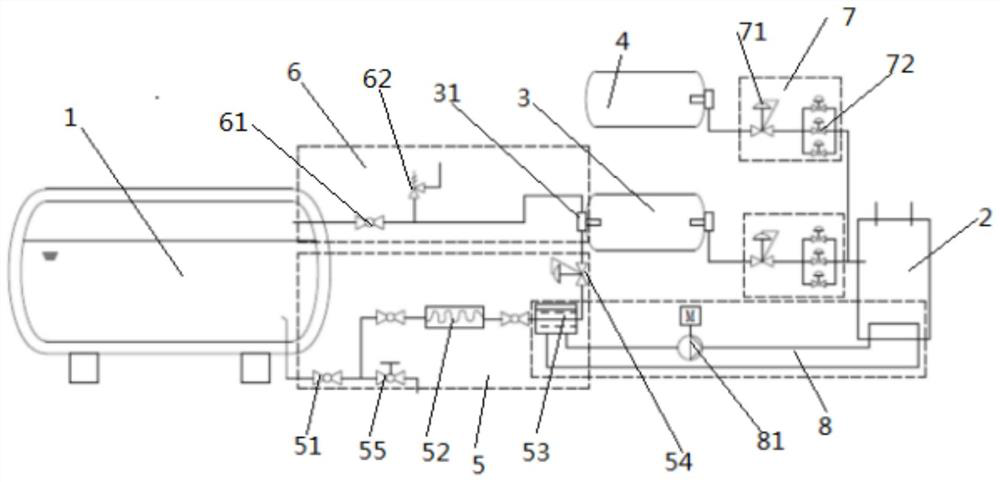

Ship condensate water and waste heat recycling device and using method thereof

ActiveCN111547219AReduce wasteReduce energy consumptionInternal combustion piston enginesAuxillariesWater pipePower unit

The invention provides a ship condensate water and waste heat recycling device. The device comprises an exhaust funnel communicated with an exhaust port of a power unit, a distribution pipe and a liquid collecting pipe are arranged at the two ends of the exhaust funnel respectively, a plurality of vertical heat exchange pipes are installed in the exhaust funnel, the two ends of each heat exchangepipe are communicated with the distribution pipe and the liquid collecting pipe respectively, and a plurality of protrusions are evenly distributed on the outer wall of each heat exchange pipe; a water inlet is formed in the distribution pipe, the water inlet is communicated with an air conditioner condensate water tank through an air conditioner condensate water pipe, and an air conditioner condensate water booster pump is arranged on the air conditioner condensate water pipe; the liquid collecting pipe is provided with a water outlet, the water outlet is communicated with user equipment through a water outlet pipe, and the air conditioner condensate booster pump is electrically connected with the control panel. Air conditioner condensate water is collected through the air conditioner condensate water tank, heated through exhaust waste heat and then supplied to user equipment, normal life of crews is guaranteed, secondary utilization of the air conditioner condensate water and the exhaust waste heat is achieved, energy consumption is reduced, and infrared radiation is restrained.

Owner:JIANGNAN SHIPYARD GRP CO LTD

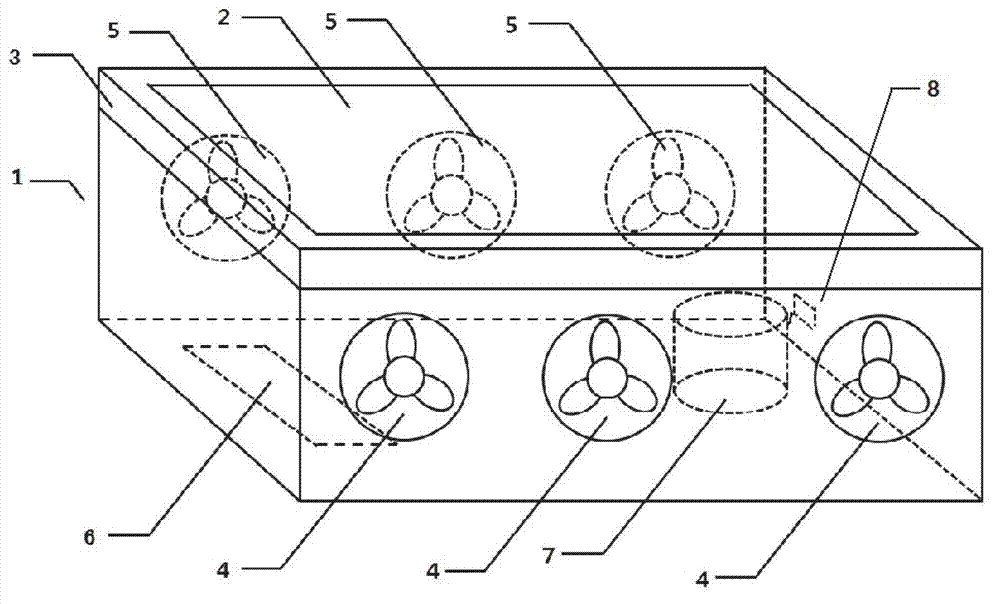

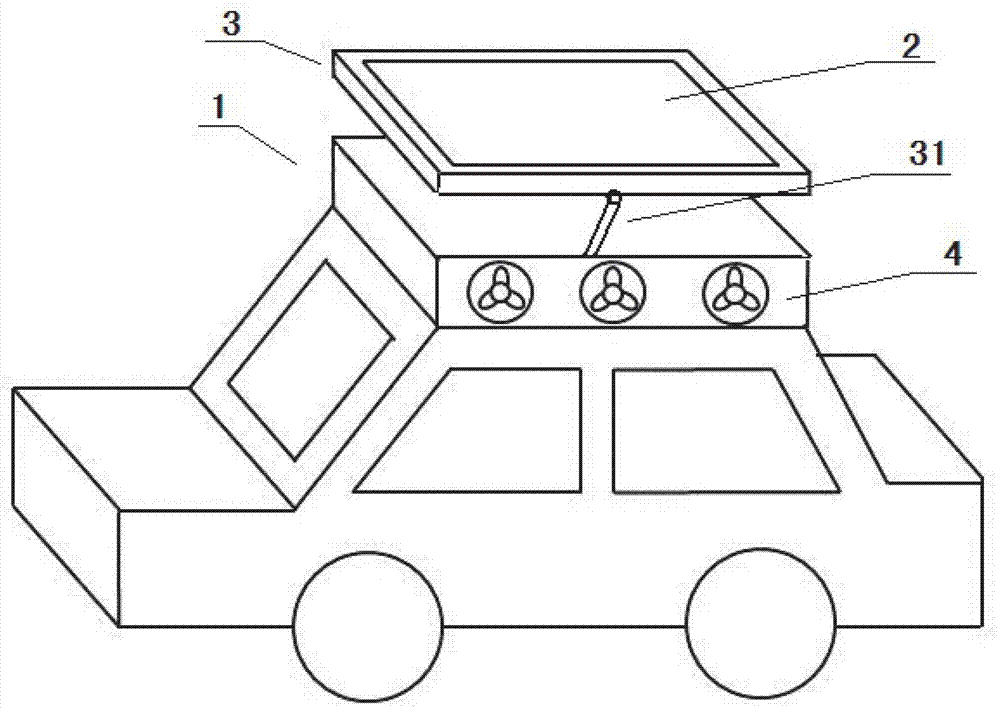

Automotive ventilation system based on solar power supply

ActiveCN102897001AReduce fuel consumptionAvoid emissionsAir-treating devicesVehicle heating/cooling devicesAutomotive fuelSolar power

The invention relates to the field of automotive devices, in particular to a solar ventilation system. A automotive ventilation system based on solar power supply comprises a shell, an automotive ventilation system and a solar power storage system, wherein the solar power storage system is connected with a power supply end of the automotive ventilation system. By adopting the technical scheme, the automotive ventilation system, provided by the invention, has the advantages of environmental friendliness, energy saving, simple structure, low manufacturing cost and excellent cooling and ventilation effects, and when the automotive fuel is insufficient, the necessary energy is provided.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

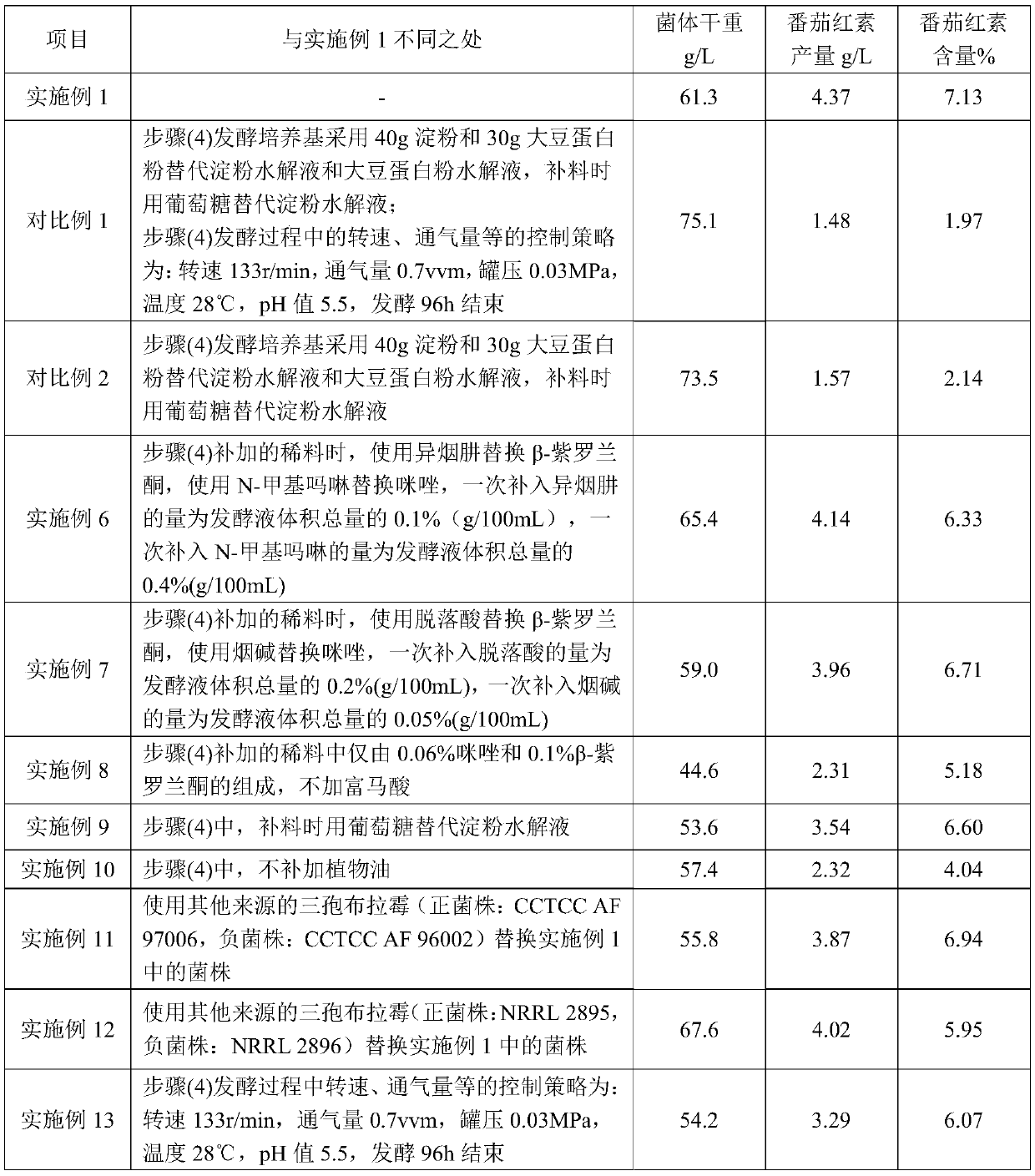

Fermentation medium, application thereof and method for preparing lycopene through fermentation of Blakeslea trispora

ActiveCN110283854AIncrease productionSatisfy consumptionMicroorganism based processesFermentationVegetable oilHydrolysate

The invention belongs to the field of production of lycopene and discloses a fermentation medium, the application thereof and a method for preparing lycopene through fermentation of Blakeslea trispora. The fermentation medium comprises the following ingredients: a starch component, a bean flour component, fish meal, vegetable oil, copper sulfate, magnesium sulfate, monopotassium phosphate, vitamin E and an emulsifying agent, wherein the starch component comprises starch and / or starch hydrolysate; the bean flour component comprises bean flour and / or bean flour hydrolysate; and at least one of the starch component and the bean flour component is the hydrolysate of the starch or bean flour. With the adoption of the fermentation medium provided by the invention, the concentration of dissolved oxygen can be improved, and the dissolved oxygen can be reasonably and efficiently utilized. Therefore, the yield of lycopene is improved.

Owner:KINGDOMWAY BIOTECH (JIANGSU) CO LTD +2

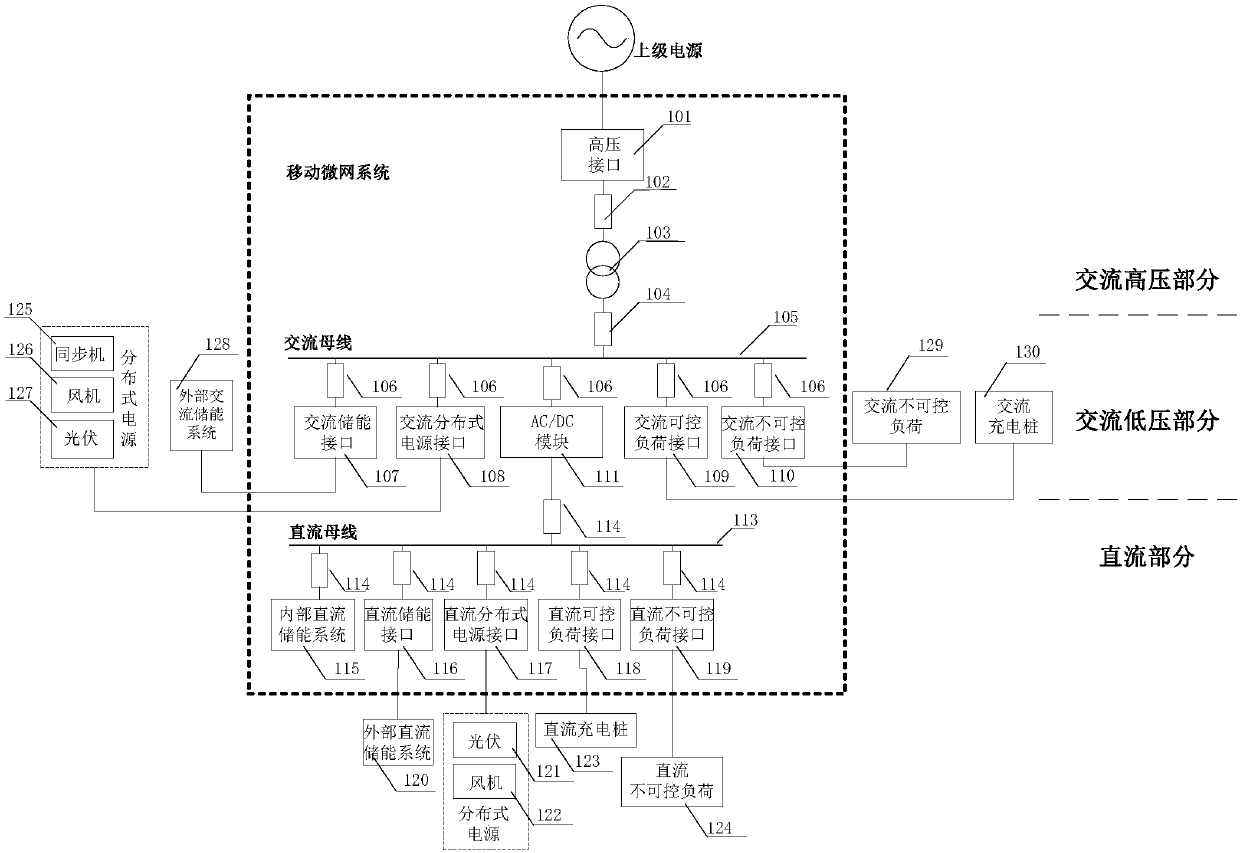

Interface circuit of mobile microgrid system

PendingCN107947168ARealize factoryRealize standardized processing and productionSubstation/switching arrangement cooling/ventilationPolyphase network asymmetry elimination/reductionPower qualityMicrogrid

The invention discloses an interface circuit of a mobile microgrid system. The interface circuit comprises a transformer, an AC bus and a DC bus, wherein a high-voltage side of the transformer is connected with an external upper power supply via a high-voltage interface, a low-voltage side of the transformer is electrically connected with the AC bus, the AC bus is electrically connected with the DC bus via an AC / DC module, various distributed resource AC interfaces are connected to the AC bus, and various distributed resource AC interfaces are connected to the DC bus. By the interface circuit,local regional power supply, small-regional power balancing and energy optimization under the condition of damage to a main network frame can be achieved; and meanwhile, the high power customizationdemands such as distributed resource absorption, uninterruptible power supply, reactive power and electric energy quality compensation of a user are satisfied.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

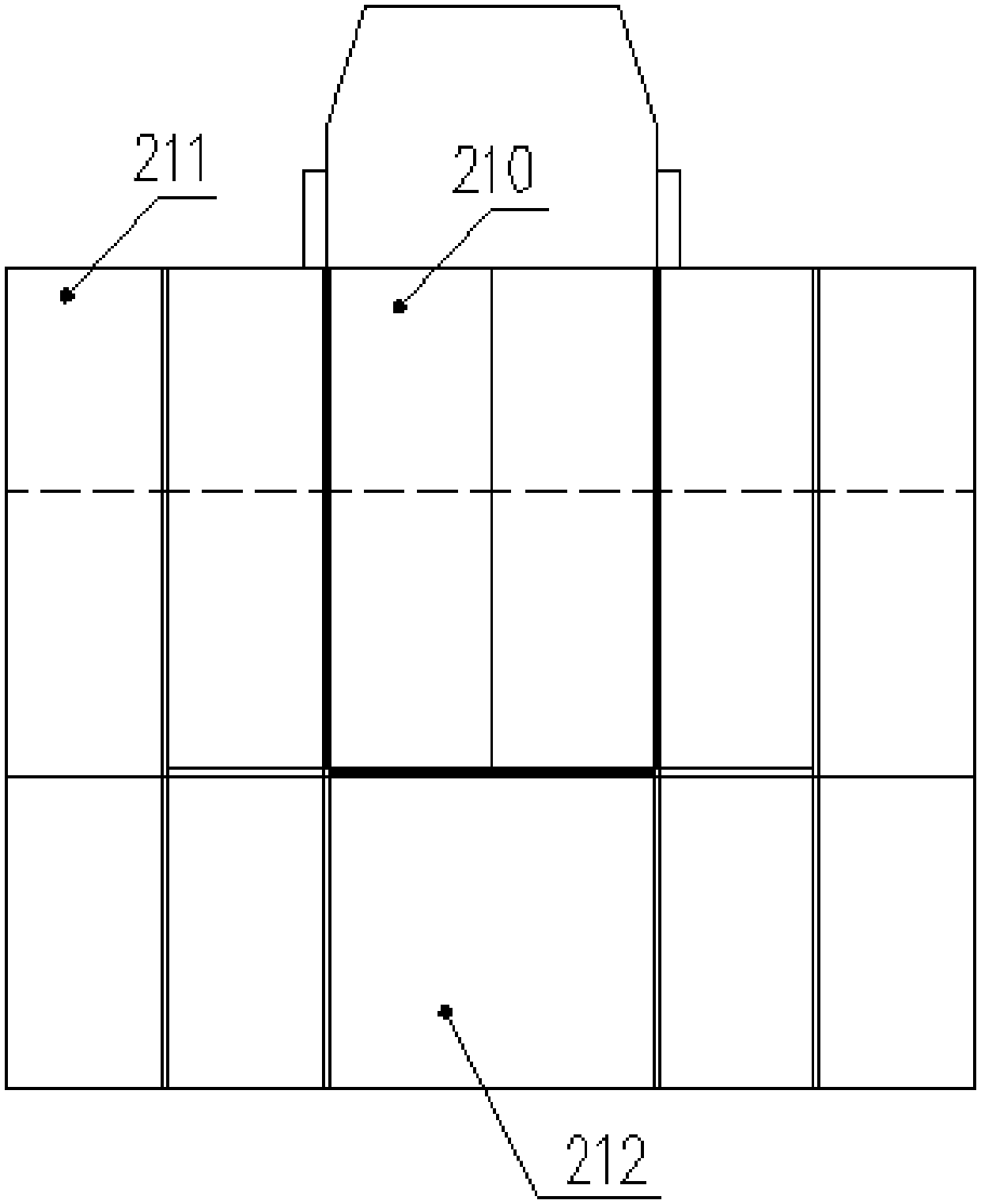

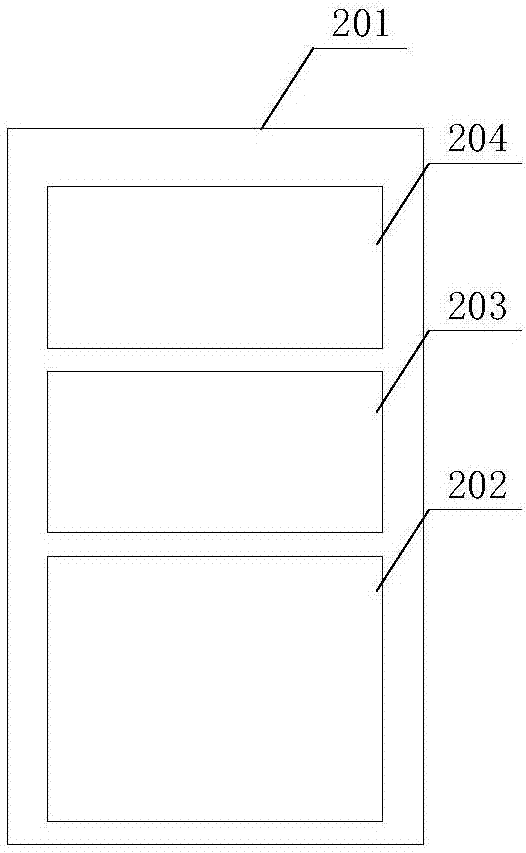

Multilayer stack-up storage panel structure applied to extendable carriage and extending method thereof

PendingCN107696948AMaximum spreadLarge personalized event spaceVehicle with living accommodationEngineeringSuperstructure

The invention relates to a multi-layer laminated storage panel structure and a spreading method applied to an expanded carriage, which is arranged and applied in a carriage composed of support frames, and includes guide rail components arranged symmetrically on each support frame, the guide rails The components include guide rails, transmission chains and pulleys attached to the guide rails. A detachable beam is horizontally installed between the two corresponding guide rail components. The beam moves along the extension direction of the guide rail components through the application of the transmission chain and pulleys; The first support plane composed of the corresponding two guide rail members and the crossbeam is equipped with a multi-layer laminated and stored panel group; by applying the multi-layer laminated structure of the panel group, the panel can be realized in the limited application area of the carriage. The spread is maximized, and different forms of guide rail components are further set to realize different ways of panel spread, effectively providing larger and more spacious personalized activity spaces for traveling users.

Owner:SHENZHEN WOHAISEN TECH CO LTD

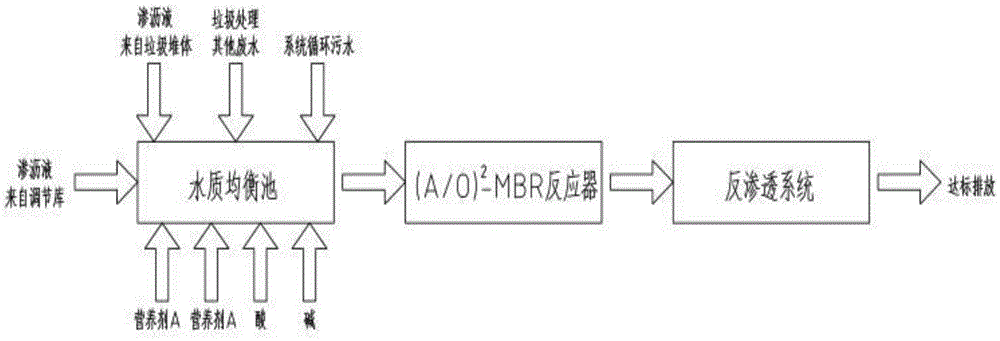

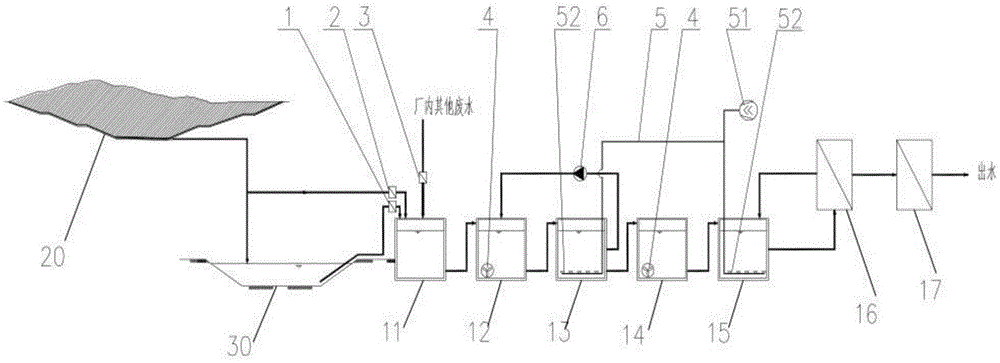

Municipal domestic waste leachate (A/O)2 combined membrane biochemical reaction-reverse osmosis membrane treatment process

InactiveCN105621807ALow investment costLow running costWater treatment compoundsTreatment involving filtrationUltrafiltrationWater quality

The invention discloses a municipal domestic waste leachate (A / O)2 combined membrane biochemical reaction-reverse osmosis membrane treatment process. A core process comprises an (A / O)2 combined membrane biochemical reaction system and a reverse osmosis membrane system. The (A / O)2 combined membrane biochemical reaction system is a membrane bio-reactor adopting a low-circulation multistage denitrification process and combines links like separate-stage nitrification, denitrification, multi-source water quality adjustment and ultrafiltration / microfiltration membrane outgoing membrane separation. In the reverse osmosis membrane system, compact membrane characteristics of a reverse osmosis membrane are utilized, most of ions and all of suspended matters are intercepted, and organic matters and other small-molecule substances degraded by a biochemical treatment method are further separated. The process has the advantages of high water quality adaptability, high treatment load, high treatment efficiency, small facility occupation area, low comprehensive energy consumption and stable quality of outgoing water, and is suitable for wastewater treatment with high organic matter concentration, high ammonia nitrogen and total nitrogen concentration and strict requirements on outgoing water.

Owner:广东省环境保护工程研究设计院有限公司

Mobile microgrid system

PendingCN107453414ARealize factoryRealize standardized processing and productionElectrical apparatusPower qualityMicrogrid

The invention discloses a mobile microgrid system including an AC high voltage part, an AC low voltage part and a DC part. The AC high voltage part includes a high voltage interface, a transformer high-voltage switch and a transformer. The AC low voltage part includes a transformer low voltage switch, an AC bus, a plug-and-play AC interface-side low voltage AC switch, different-type distributed resource plug-and-play AC interfaces and an AC / DC module. The DC part includes an AC / DC module DC-side DC switch, a DC bus, a plug-and-play DC interface-side DC switch, an intra-system energy storage system and different-type distributed resource plug-and-play DC interfaces. According to the invention, the microgrid system is constructed when a main grid gets damaged, so that local area power supply is realized and small area power balance and energy optimization are achieved. At the same time, high electric power customized demands of users for absorption of distributive resource, uninterrupted power supply and reactive and electric power mass compensation and the like are met.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

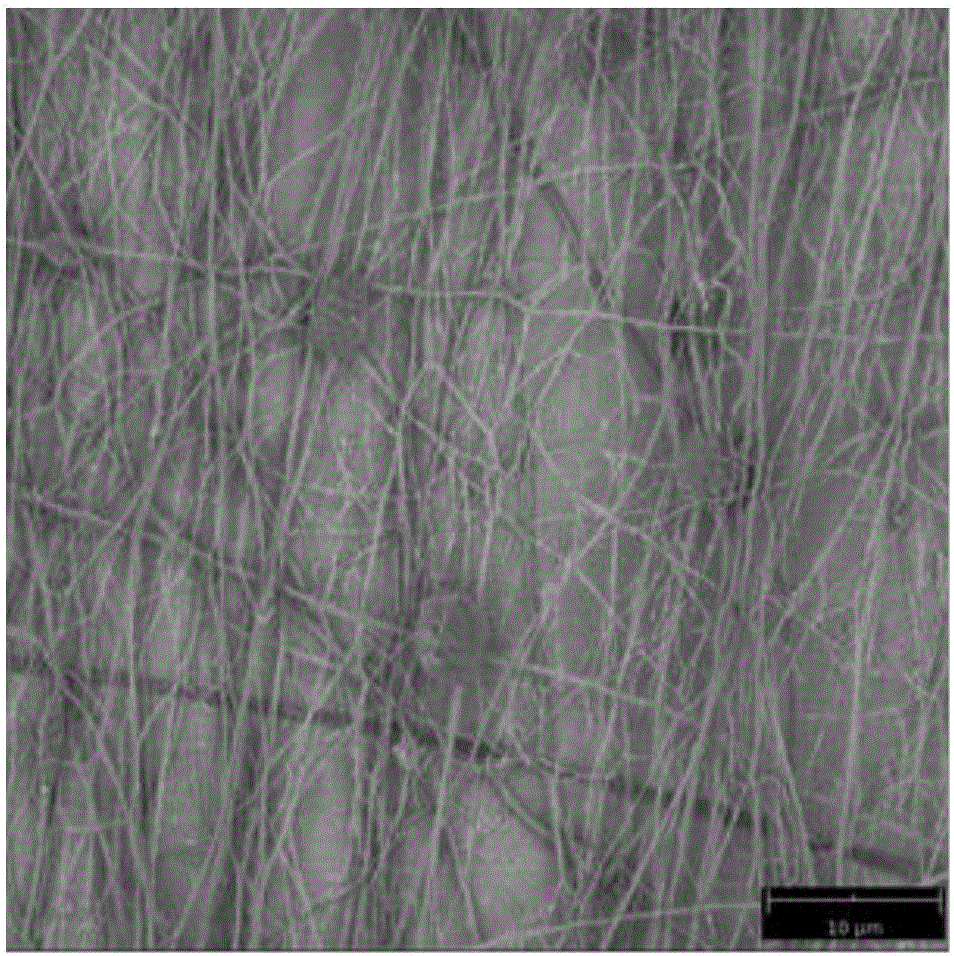

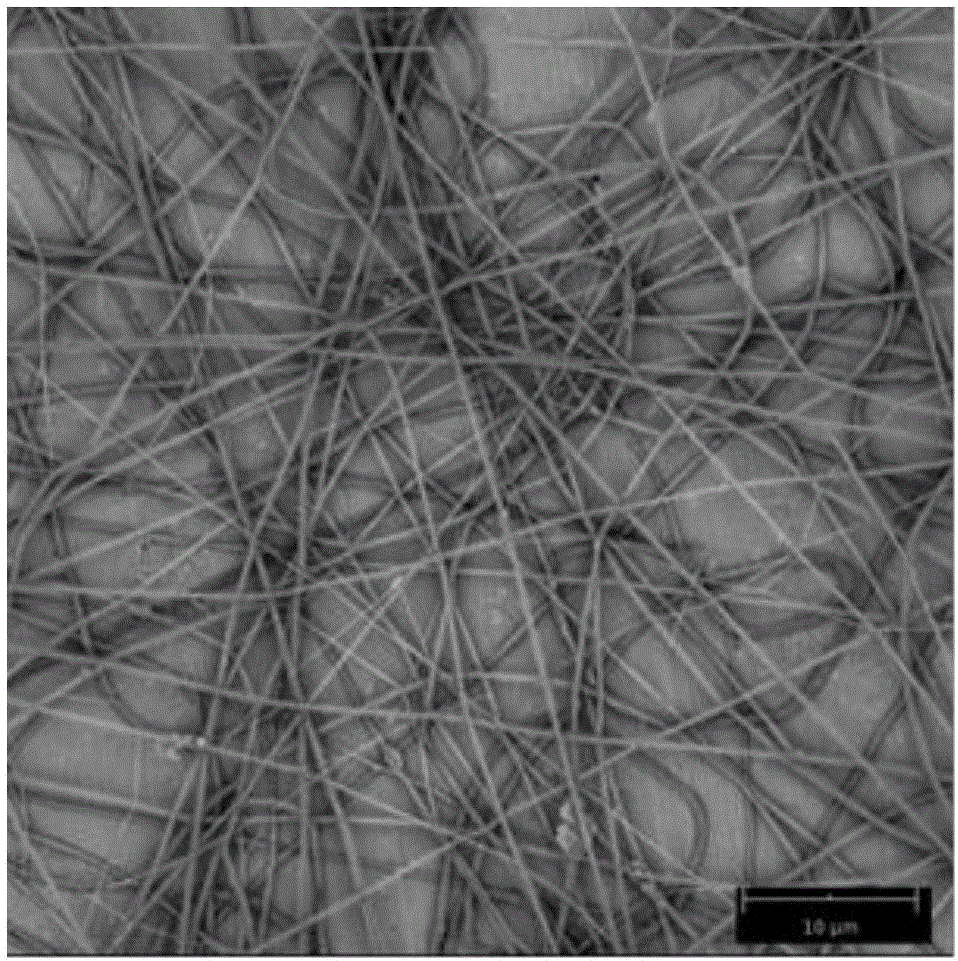

Edible corn protein-based food packaging material and preparation method for same

InactiveCN106567143AWon't hurtSatisfy consumptionFlexible coversWrappersNODALEnvironmental resistance

The invention provides edible corn protein-based food packaging material and a preparation method for the same and belongs to the technical filled of food packaging material. In the method, biamacromolecules / and high polymer material having nodal points and solvents are mixed to achieve mixed solution; then the mixed solution is injected into a reaction impeller; constant impelling flow speed of 0.5-50mL / h is maintained; static spinning voltage is 5-50kV; a positive electrode of voltage is connected to an outlet metal part of the reaction impeller; a negative electrode is connected to a filament receiver connected to the ground; a distance between the reaction impeller outlet metal part and the filament receiver is 5 to 50cm; the static spinning time is 0.5 to 24hours; and with the above steps, the corn protein-based food packaging material can be prepared. The invention further provides edible corn protein-based food packaging material prepared by the method. The preparation method is simple, raw material can be easily achieved and no harm is caused to human bodies; and demands of edibility, greenness and environment protection for packaging material can be met.

Owner:JILIN AGRICULTURAL UNIV +1

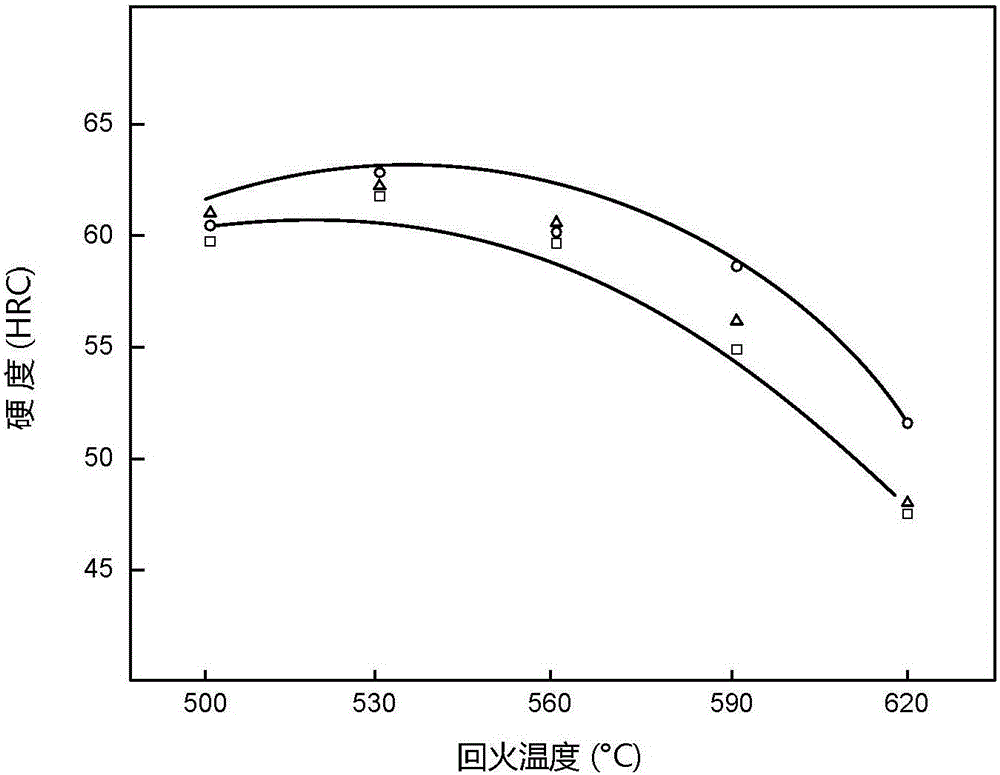

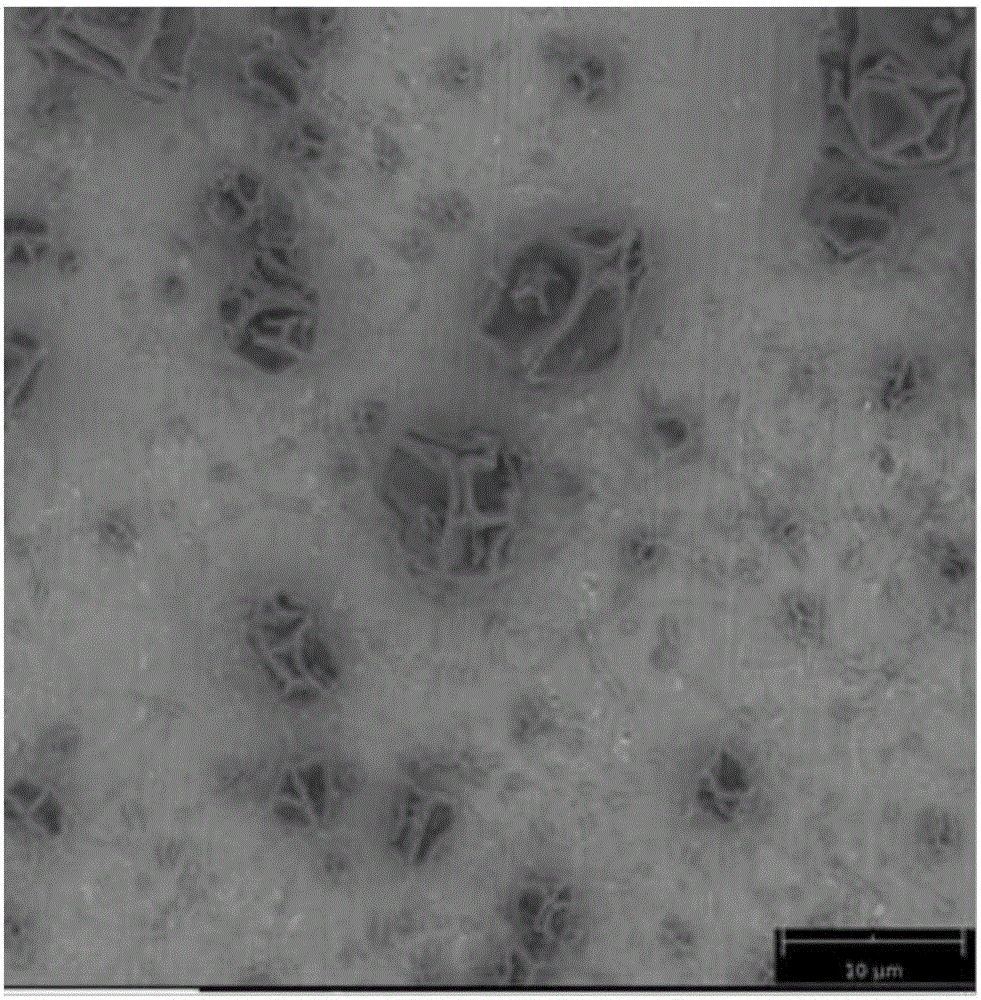

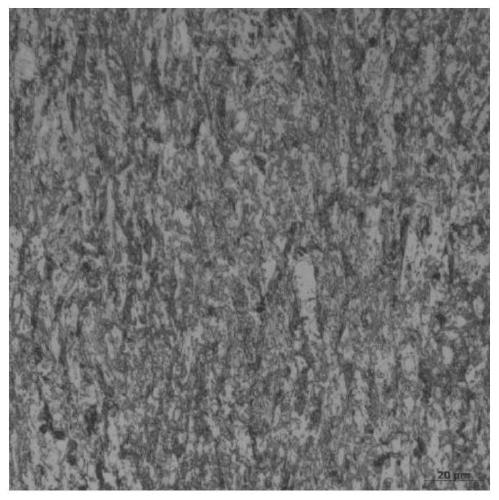

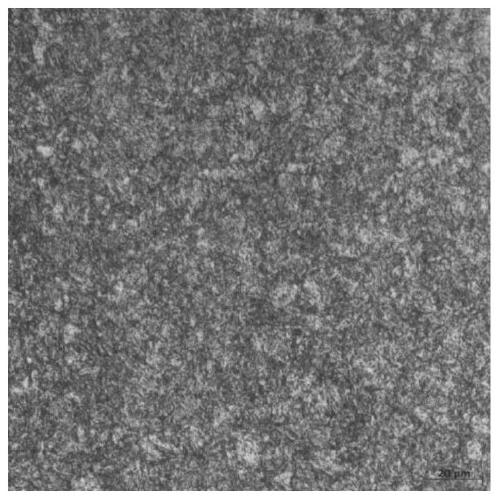

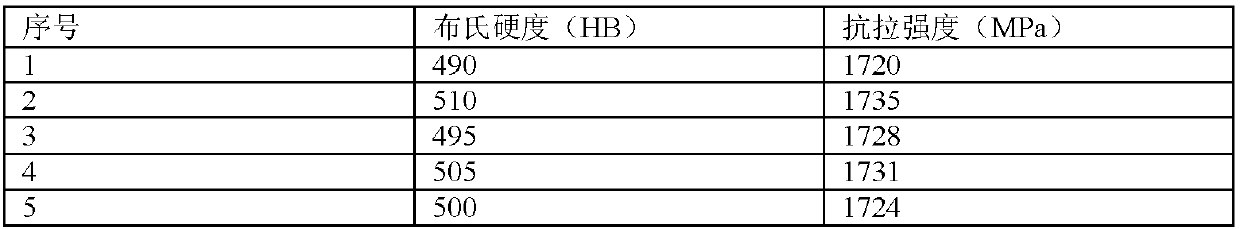

Bulletproof steel plate and manufacturing method thereof

The invention belongs to the technical field of steel making, and particularly relates to a bulletproof steel plate and a manufacturing method thereof. The high strength and high toughness are reachedthrough quenching and tempering treatment, cover annealing is conducted after normal hot rolling for reducing the strength of a hot rolled coil, later unwinding and shaping are facilitated, and thenpressure quenching is conducted, so that a good plate shape is maintained. By adopting the bulletproof steel produced by the invention, the gaps of enterprises are filled, the variety of steel products is increased, the high finished product quality and yield rate are reached, and good economic benefits are achieved.

Owner:BENGANG STEEL PLATES

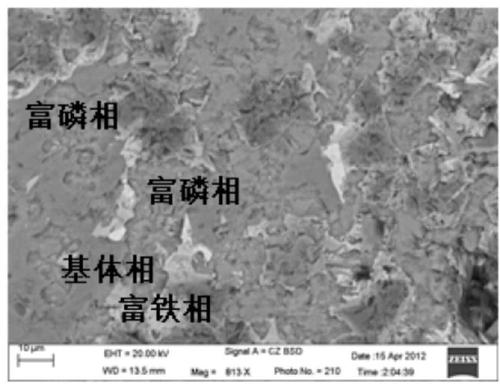

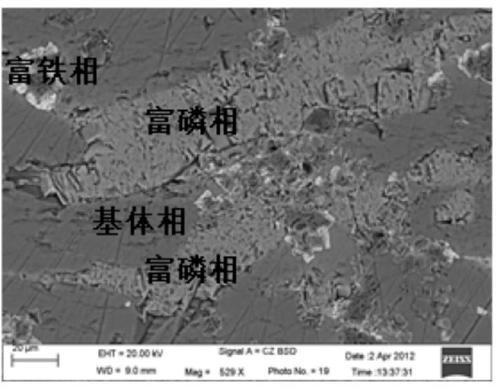

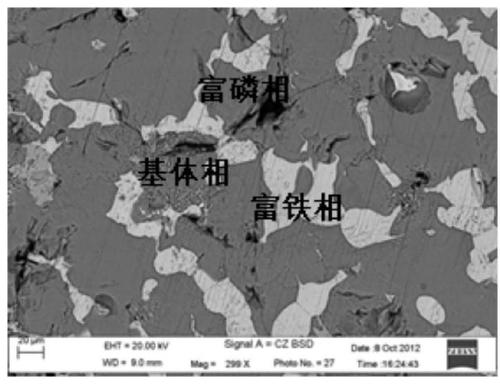

Method for improving phosphorus efficient enriching effect in phosphorus-contained steel slag

ActiveCN109897934AEfficient migrationAchieve high concentration enrichmentManufacturing convertersProcess efficiency improvementLiquid stateSlag

The invention discloses a method for improving a phosphorus efficient enriching effect in phosphorus-contained steel slag, and belongs to the technical field of recycling of metallurgy industry wasteslag. After the smelting completion, and in the discharge process of high-temperature furnace slag, a certain quantity of modifying agents are fed at the bottom of a slag tank or along with liquid-state slag currents; the melting modification is performed on the liquid-state phosphorus-contained slag by using afterheat of the steel slag; then, the cooling speed of the furnace slag is controlled tofully guarantee full melting and reaction of the furnace slag and the modifying agents; when the temperature of the furnace slag is reduced to the phosphorus enriching temperature, the furnace slag is insulated to fully accelerate separation of 3CaO.P2O5; and the temperature of the furnace slag is lowered at a certain cooling speed to condense the furnace slag to realize efficient enrichment of phosphorus in the phosphorus-contained slag. The method has the following advantages: the adverse effects of incapability of meeting the requirements of higher phosphorus contents in phosphorus fertilizers or additives due to lower phosphorus content in phosphorus-enriched phases in actual production and incapability of utilizing the afterheat of the steel slag in the enriching process are overcome. The method is simple, reliable, high in operability and convenient to realize, prominently increases the P2O5 content in the phosphorus-enriched phases in the phosphorus-contained slag, and greatlyimproves the enriching effect of phosphorus in the phosphorus-contained slag.

Owner:CENT IRON & STEEL RES INST

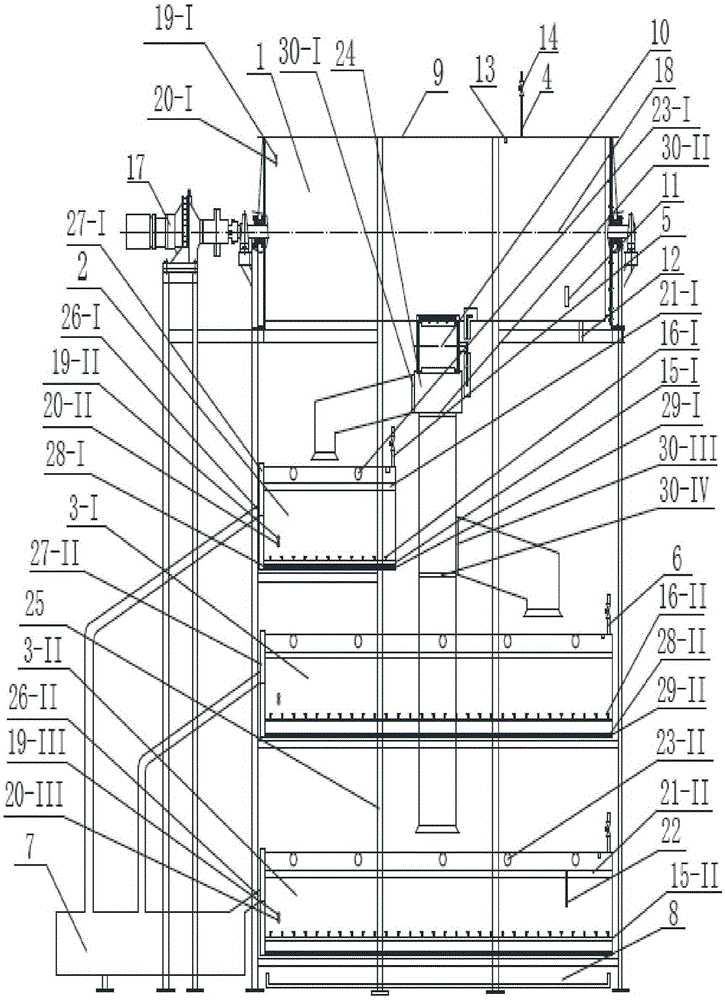

A high-efficiency facility earthworm culture device and its application

ActiveCN103931561BImprove farming efficiencyIncrease productionAnimal husbandryAgricultural scienceVermicompost

An efficient facility earthworm breeding device is composed of a rotten reactor, an earthworm cultivation device, two earthworm breeding device bodies, an earthworm cast collecting box, an earthworm collecting box and a support. The rotten reactor is provided with a stirring device, and a material conveying device is arranged below an outlet. An earthworm cast outlet of the earthworm cultivation device is communicated with the earthworm cast collecting box. The two earthworm breeding device bodies are the same in structure, a rake-shaped scraper blade is arranged on each earthworm breeding device body so that materials can be discharged out, and the earthworm cast outlets of the earthworm breeding device bodies are communicated with the earthworm cast collecting box. The rotten reactor, the earthworm cultivation device, the two earthworm breeding device bodies and the earthworm collecting box are respectively fixedly connected with the support from top to bottom. The facility earthworm breeding device is used, a one-time earthworm inoculation method and a two-step growing method are used for conducting reducing and resource utilization of biomass. The efficient facility earthworm breeding device has the advantages that the structure is simple, operation is easy, the earthworm breeding efficiency can be effectively improved, the breeding time is shortened, the earthworm yield is improved, energy consumption is reduced, breeding cost is lowered, and safety and reliability are achieved.

Owner:NANKAI UNIV

Casting process for producing precoated sand shell core rotor with steel shots as filling material

InactiveCN109676087ASpeed up coolingDense structure of castingFoundry mouldsFoundry coresFilling materialsCooling speed

The invention discloses a casting process for producing a precoated sand shell core rotor with steel shots as a filling material, and relates to the technical field of casting. The casting process comprises the following steps that firstly, a shell core and a built-in core are manufactured through precoated sand, the shell core is combined into a precoated sand shell, and the built-in core is placed in the precoated sand shell; secondly, the precoated sand shell is placed in a container, the container is filled with the steel shots, thus, the precoated sand shell is wrapped with the steel shots, and finally the steel shots are compacted through vibration; thirdly, a pouring cup and a riser are arranged at the top of the precoated sand shell; fourthly: molten iron of nodular cast iron is injected into the precoated sand shell smoothly through the pouring cup, and casting molding is conducted; and fifthly, after the molten iron is completely cured, the casting rotor is obtained. The functions of rapid heat absorption and heat transfer chilling of the steel shots are used for increasing the cooling speed of the molten iron, the cooling speed of the cast iron eutectic stage is changed,an as-cast microstructure of the cast iron can be changed in a large range, and thus casting structure is dense.

Owner:济宁市兖州区联诚机械零部件有限公司 +1

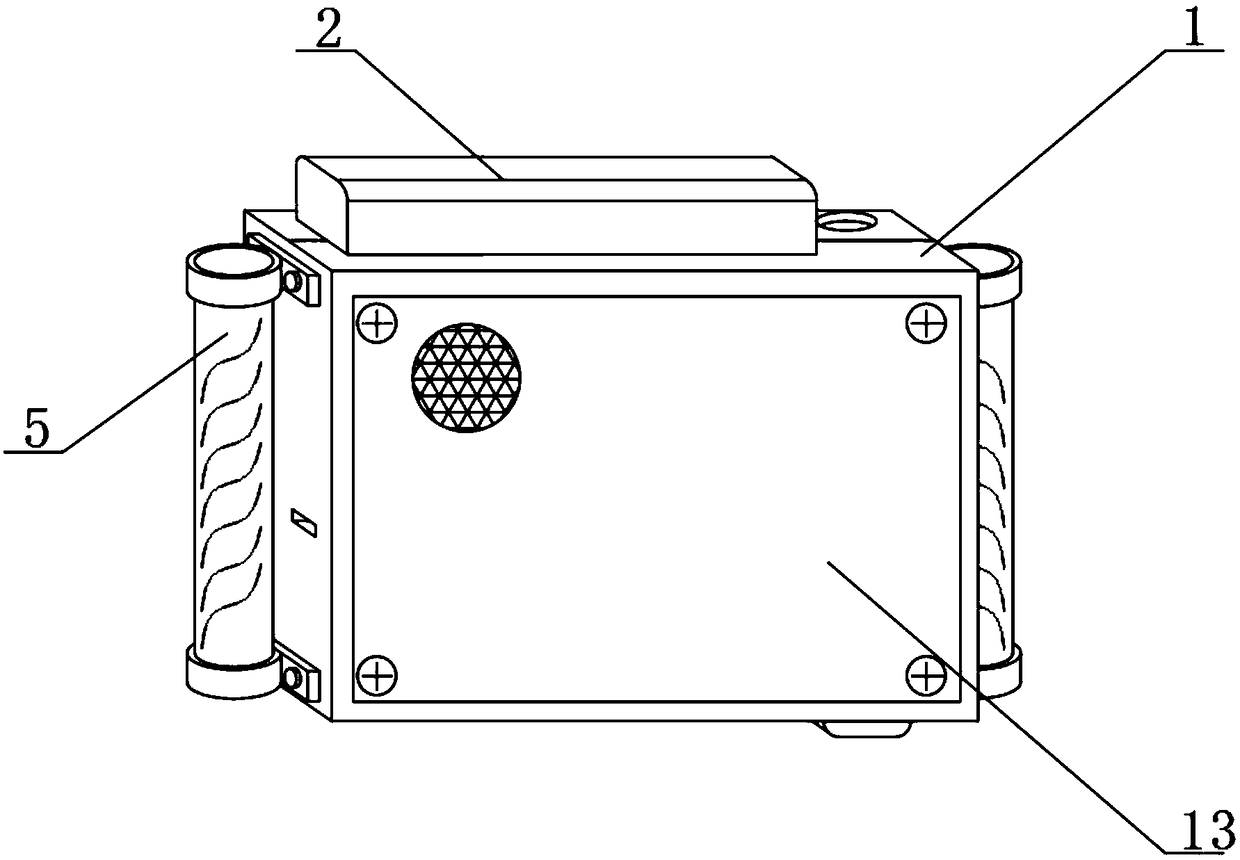

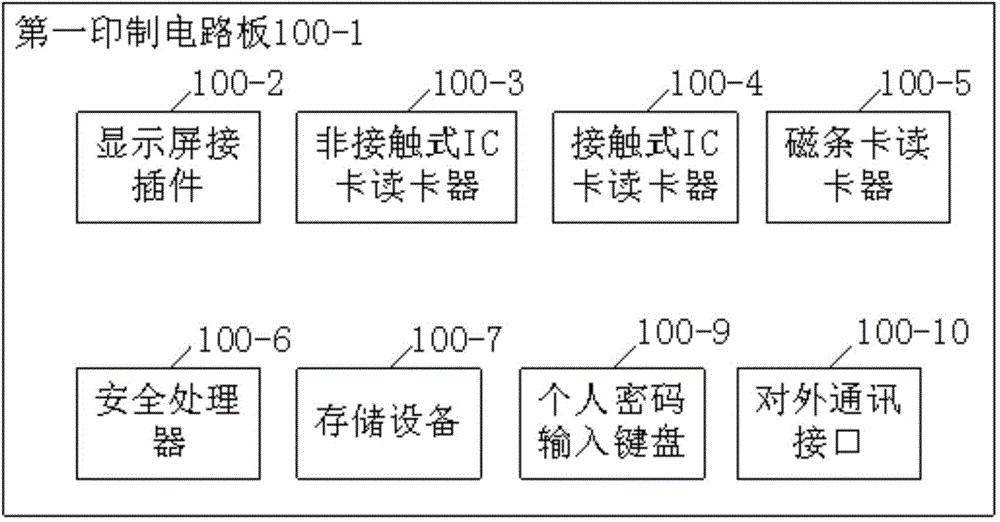

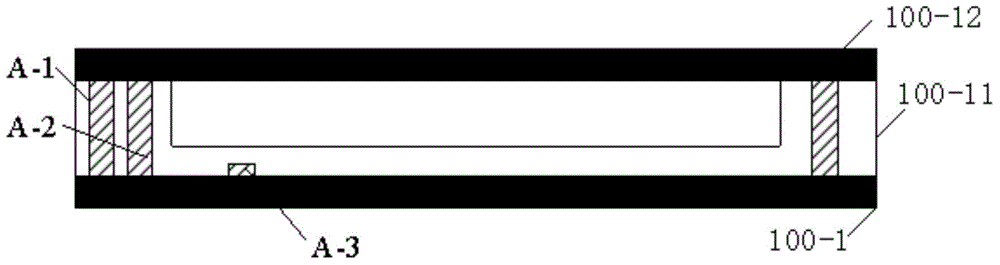

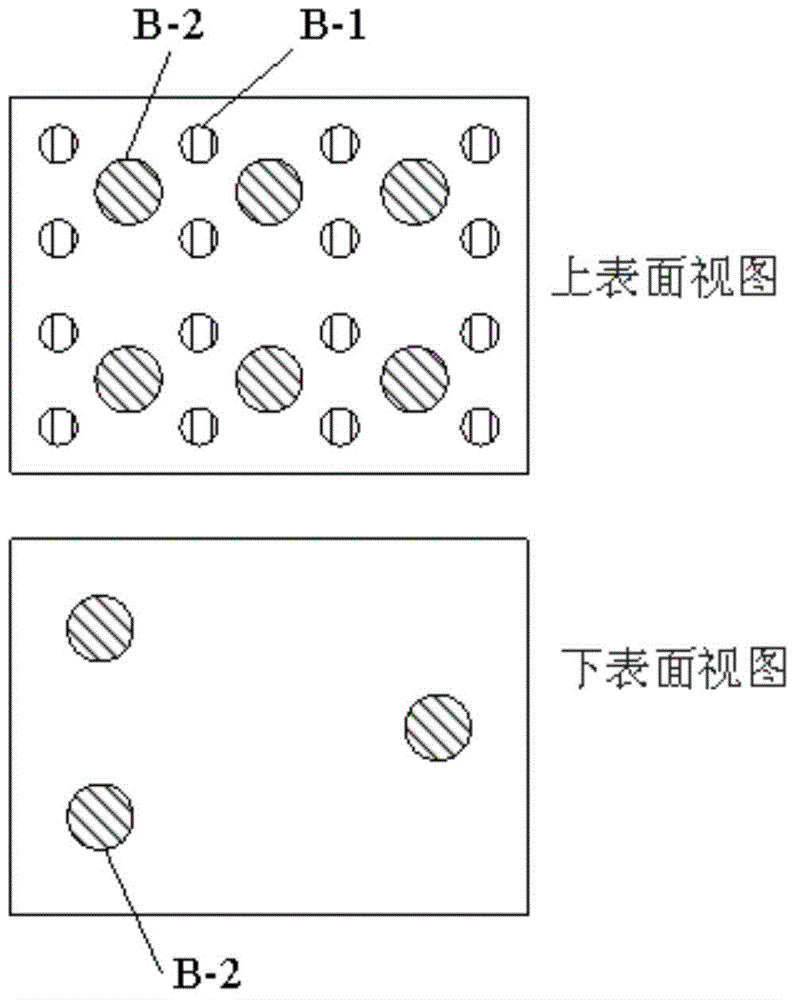

Integrated financial security device

PendingCN104952162AImprove compatibilityLow costPaper-money testing devicesCash registersFinancial securityComputer compatibility

The invention provides an integrated financial security device. The device comprises a first printed circuit board, a display screen connector assembly, a non-contact IC-card reader, a contact IC-card reader, a magnetic stripe card reader, a security processor, a storage device, a display screen interface, a personal code input keyboard and an external communication interface, wherein the display screen connector assembly, the non-contact IC-card reader, the contact IC-card reader, the magnetic stripe card reader, the security processor, the display screen interface, the personal code input keyboard and the external communication interface are arranged on the first printed circuit board. The device can support three financial interface cards, namely contact IC-cards, non-contact IC-cards and magnetic strip cards, and the consumption of all the finance-related cards at present can be met, so that the compatibility of the integrated financial security device is improved, and the implementation cost of the integrated financial security device is further reduced.

Owner:SHANGHAI HAIZHE INFORMATION TECH

Solar gridded fireproof monitoring and prewarning system for forestry

The invention relates to a solar fireproof monitoring and prewarning system for gridding forestry. The solar fireproof monitoring and prewarning system is characterized by comprising front-end acquisition systems and a monitoring center, wherein the plurality of front-end acquisition systems transmit acquired fire information to the monitoring center in a wired or wireless manner; and the fire information comprises video, smoke and / or temperature information. The solar fireproof monitoring and prewarning system has the advantages of avoiding the limitation of the traditional manual fire overseeing and observing method, realizing digitalization and scientization of forestry management, greatly reducing the charge against revenue and the management cost of a forestry department and enhancing the effect of a forestry enterprise.

Owner:WINCHANCE TECH

Air energy circulation power-driven generator

InactiveCN103362556AConvenient sourceNovel structureBatteries circuit arrangementsElectric powerAutomotive engineeringElectric generator

An air energy circulation power-driven generator comprises an air energy storage device, an engine air supply control device, an electromagnetic valve air control system, an electricity generating, charging, supplying and storage device, an electricity generating and supplying device, an air energy engine, an engine starting device, a direct current motor transmission device and an air supply circulation control device. By adopting an electronic program control system and structural optimization of devices, the air energy circulation power-driven generator is novel in structure, convenient to operate, energy-saving, environment-friendly, free from high temperature and capable of working in multiple adverse environments. A high-performance storage battery is used for the power supply work of a motor, so that the air energy circulation power generator is formed without air-entrapping by external auxiliary gas station equipment, an air collector is small in size, air supply completely relies on a self-service power control system, air is circularly supplied to the engine by a compressor through the driving of the motor, and the problems of power generation, fuel consumption and environmental pollution of the air energy circulation power-driven generator are solved. The air energy circulation power-driven generator can meet the power utilization requirements of different environments and can replace existing fuel generators which are energy-consuming and pollute the environment.

Owner:SHENZHEN PINCHUAN ENERGY ELECTRIC CO LTD

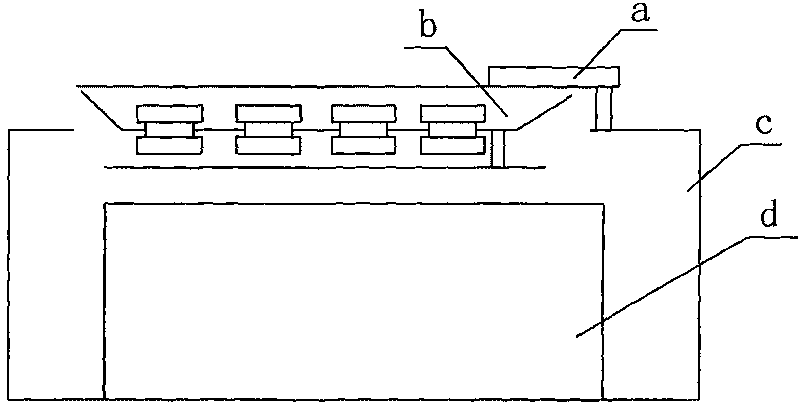

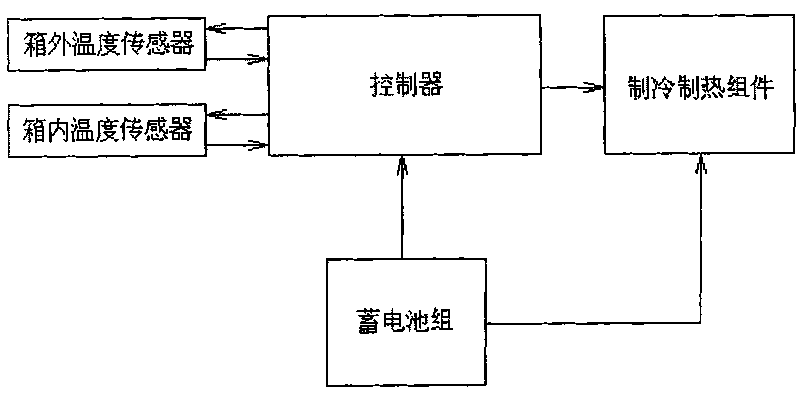

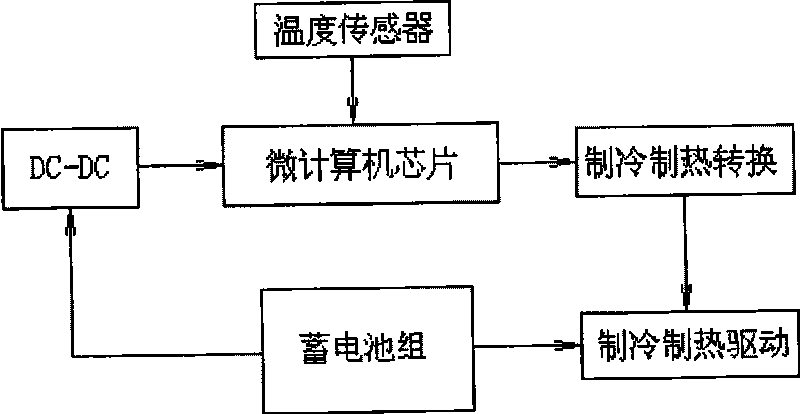

Constant temperature cabinet for accumulator and temperature-controlling method thereof

InactiveCN101409374BAvoid consumptionSatisfy consumptionTemperatue controlSecondary cellsTemperature controlAutomatic control

The invention relates to a thermotank and a temperature control method thereof, in particular to a thermotank of a storage battery and a temperature control method thereof. The thermotank comprises a thermotank body, heating and refrigerating components and a controller; the heating and refrigerating components comprise an air course outside the thermotank, an air course inside the thermotank, a radiator of the air course outside the thermotank, a radiator of the air course inside the thermotank, an air inlet door, an air outlet door, a ventilator of the air course outside the thermotank, a ventilator of the air course inside the thermotank, a cold clapboard and a hot clapboard as well as a semiconductor refrigerating device and a semiconductor heating device. When the temperature inside the thermotank is higher than the ceiling temperature for constant-temperature starting, then the temperature outside the thermotank is judged; if the temperature outside the thermotank is higher thanthe refrigerating starting temperature, then the refrigerating function is started; if the temperature outside the thermotank is lower than the refrigerating starting temperature, the ventilation is carried out; when the temperature inside the thermotank is lower than the floor temperature for constant-temperature starting, then the working condition is opposite. The invention is used for movablecommunication bases, uninterruptible power supply, and the like and has the advantages of automatic temperature control and regulation, energy saving, safety and convenient operation.

Owner:南京科迅科技有限公司 +1

Fuel supply device and vehicle power system

PendingCN111852692AEnsure safetyAvoid lostFuel cell heat exchangeInternal combustion piston enginesHeat transmissionProcess engineering

The invention belongs to the technical field of liquefied gas fuel supply, and discloses a fuel supply device, which is used for conveying fuel in a liquefied gas storage tank to a vehicle power module. The fuel supply device comprises at least two fluid communication flow paths, a heat exchange flow path and a high-pressure gas storage module, wherein the at least two fluid communication flow paths communicate with a low-pressure gas slow storage module, and the low-pressure gas slow storage module is connected to the vehicle power module; the first fluid communication flow path is used for receiving boiloff gas (BOG) of the liquefied gas storage tank, and the second fluid communication flow path is used for receiving liquefied gas from the liquefied gas storage tank and heating the liquefied gas so as to be gasified; the heat exchange flow path is used for heat transfer with the second fluid communication flow path; and the high-pressure gas storage module is used for supplying high-pressure gas fuel to the vehicle power module. The fuel supply device is integrated and can be applied in various environments. Additionally, the invention further provides the vehicle power system. The vehicle power system comprises the fuel supply device, and the application range is wide.

Owner:SHANGHAI FUEL CELL VEHICLE POWERTRAIN

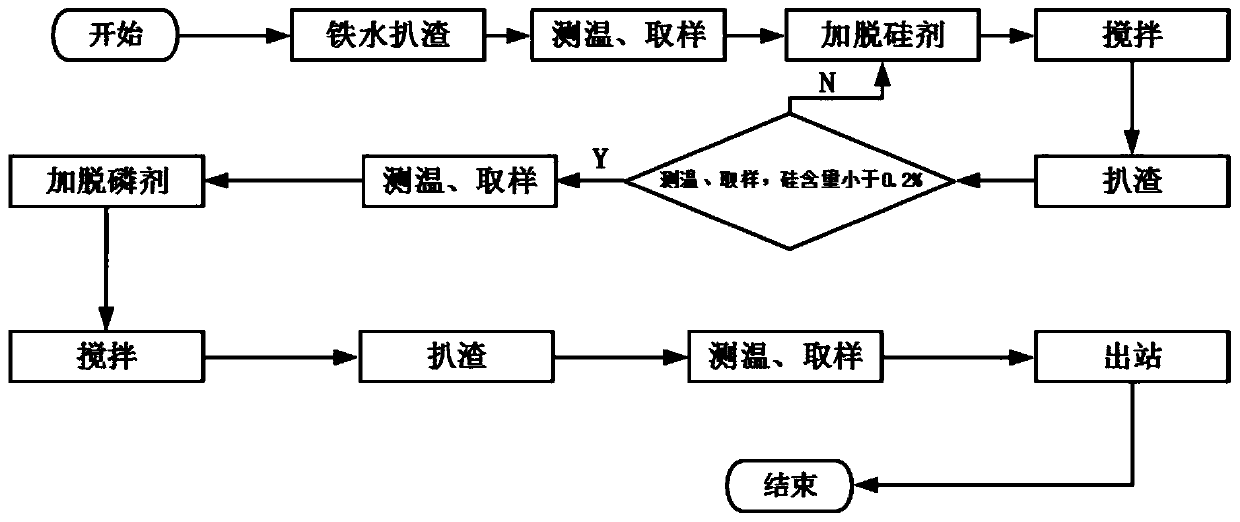

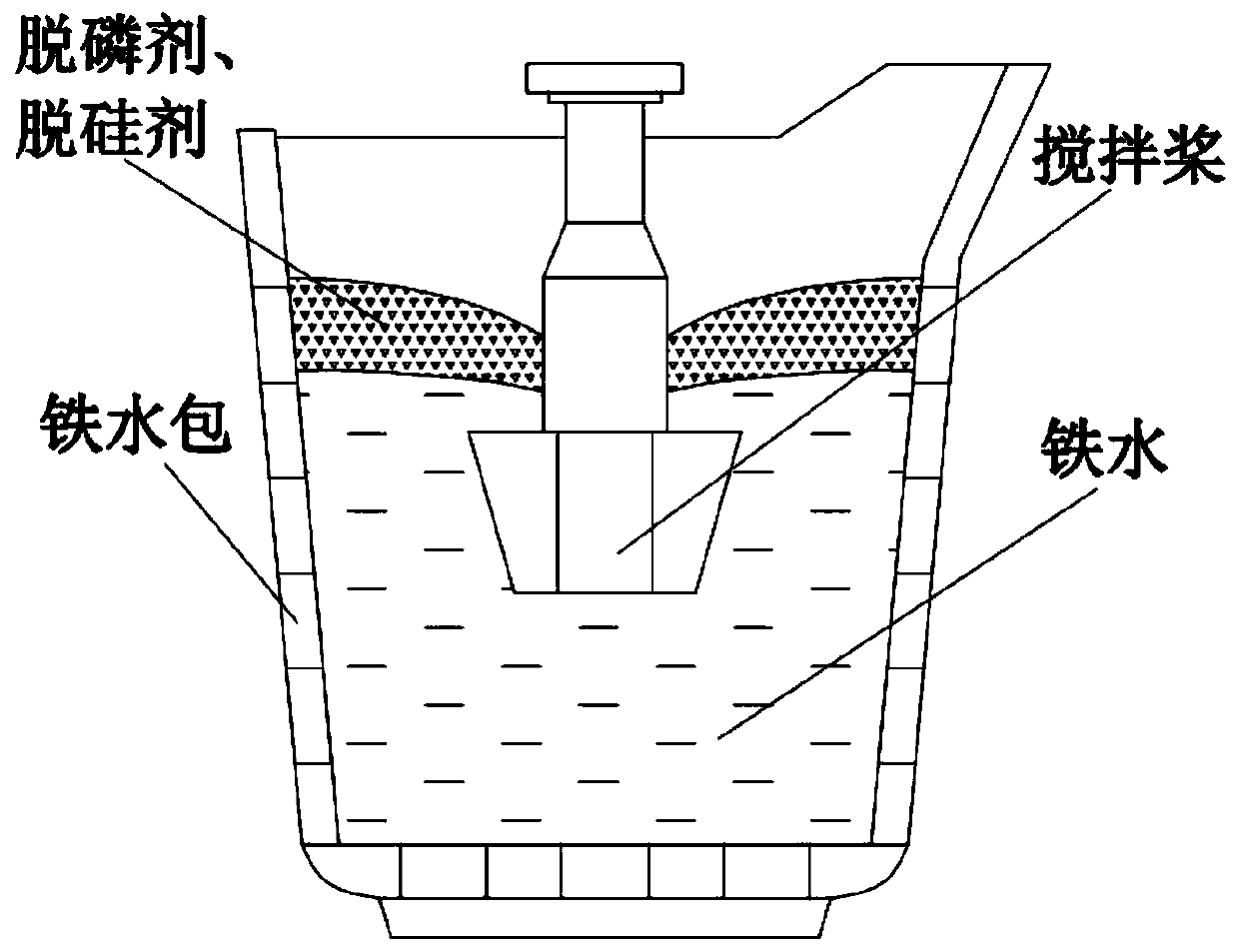

Technology for KR liquid iron pretreatment desilicication and dephosphorization

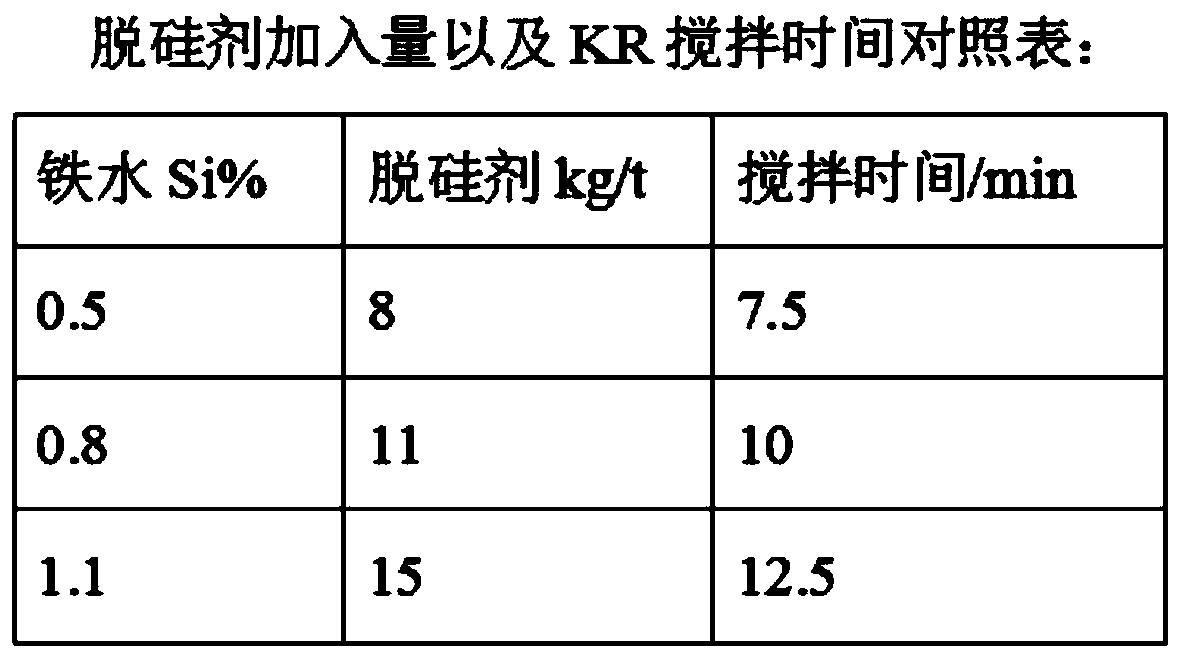

The invention is suitable for the technical field of steel and iron smelting and provides a technology for KR liquid iron pretreatment desilicication and dephosphorization. A desilicication agent formed by mixing 90% of oxidized scale and 10% of white ash is added into liquid steel, the matter of FeO and Fe2O3 contained in the oxidized scale and white ash are used for generating a chemical reaction with Si in liquid iron under the high-temperature condition of 1150 DEG C to 1400 DEG C, SiO2 is generated to enter slag, Fe is generated to enter the liquid iron, and the purpose of reducing the silicon content of the liquid iron is achieved; and meanwhile, after the silicon in the liquid iron is lower than 0.2%, a dephosphorization agent formed by mixing 55% of oxidized scale, 35% of white ashand 10% of fluorite powder is added into the liquid iron, phosphorus in the liquid iron can generate a chemical reaction with FeO and CaO contained in the dephosphorization agent, phosphorus is oxidized and forms a stable compound (4CaO.P2O2) with CaO to enter the slag, normal smelting production of a converter is achieved, production of certain low-phosphorus steel balls is achieved, consumptionof steel and iron materials is reduced, and considerable economic benefits are created.

Owner:山西建龙实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com