Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Reduce the chance of breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

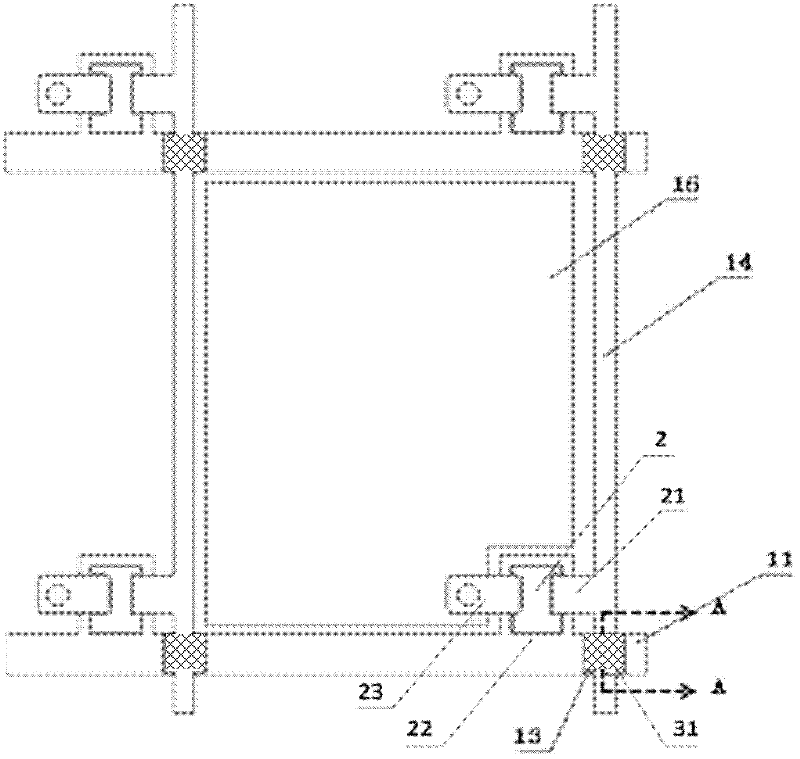

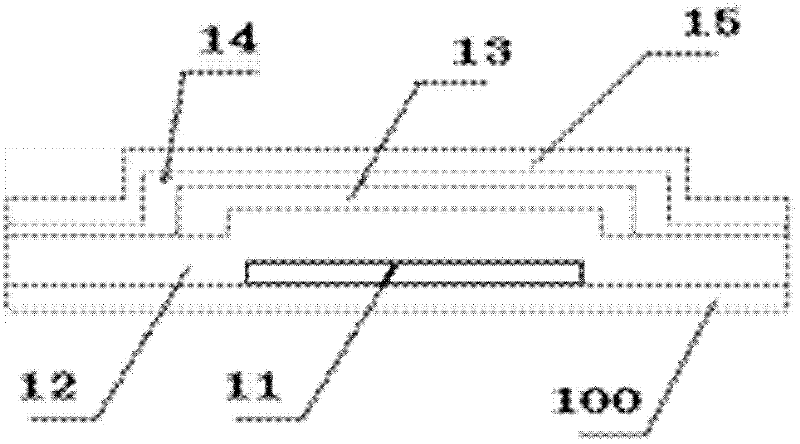

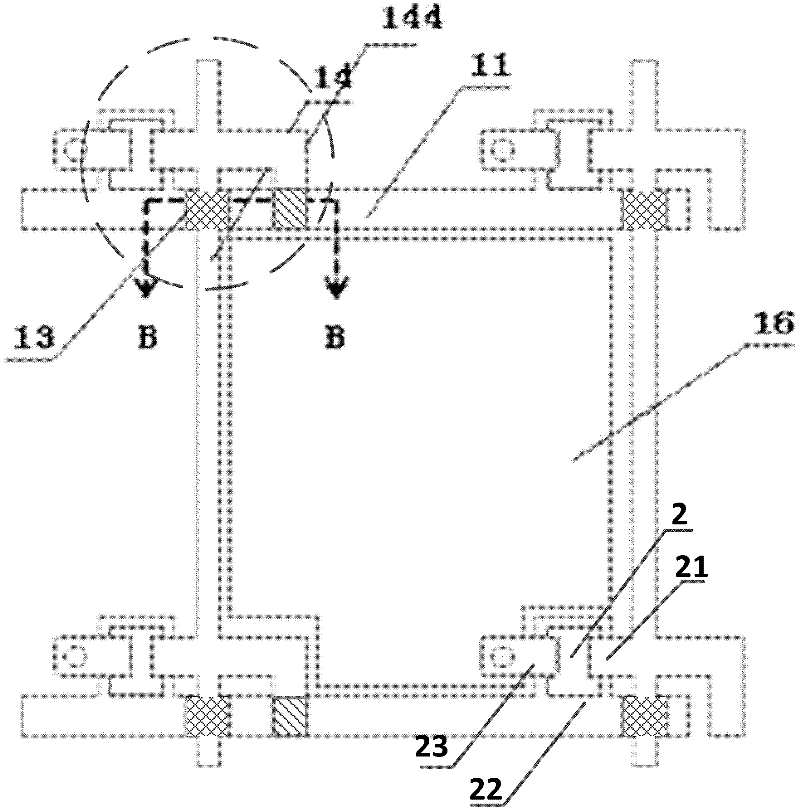

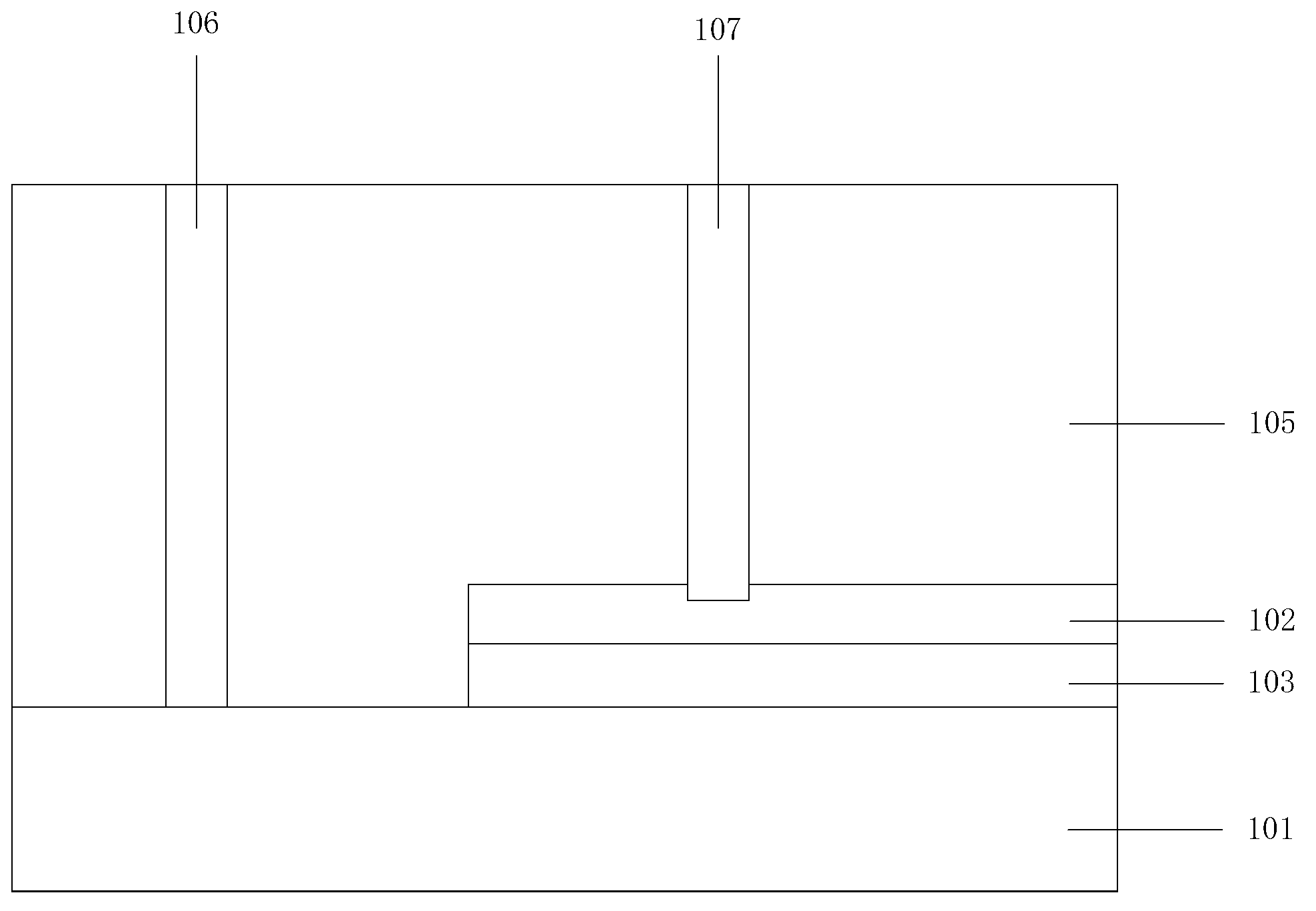

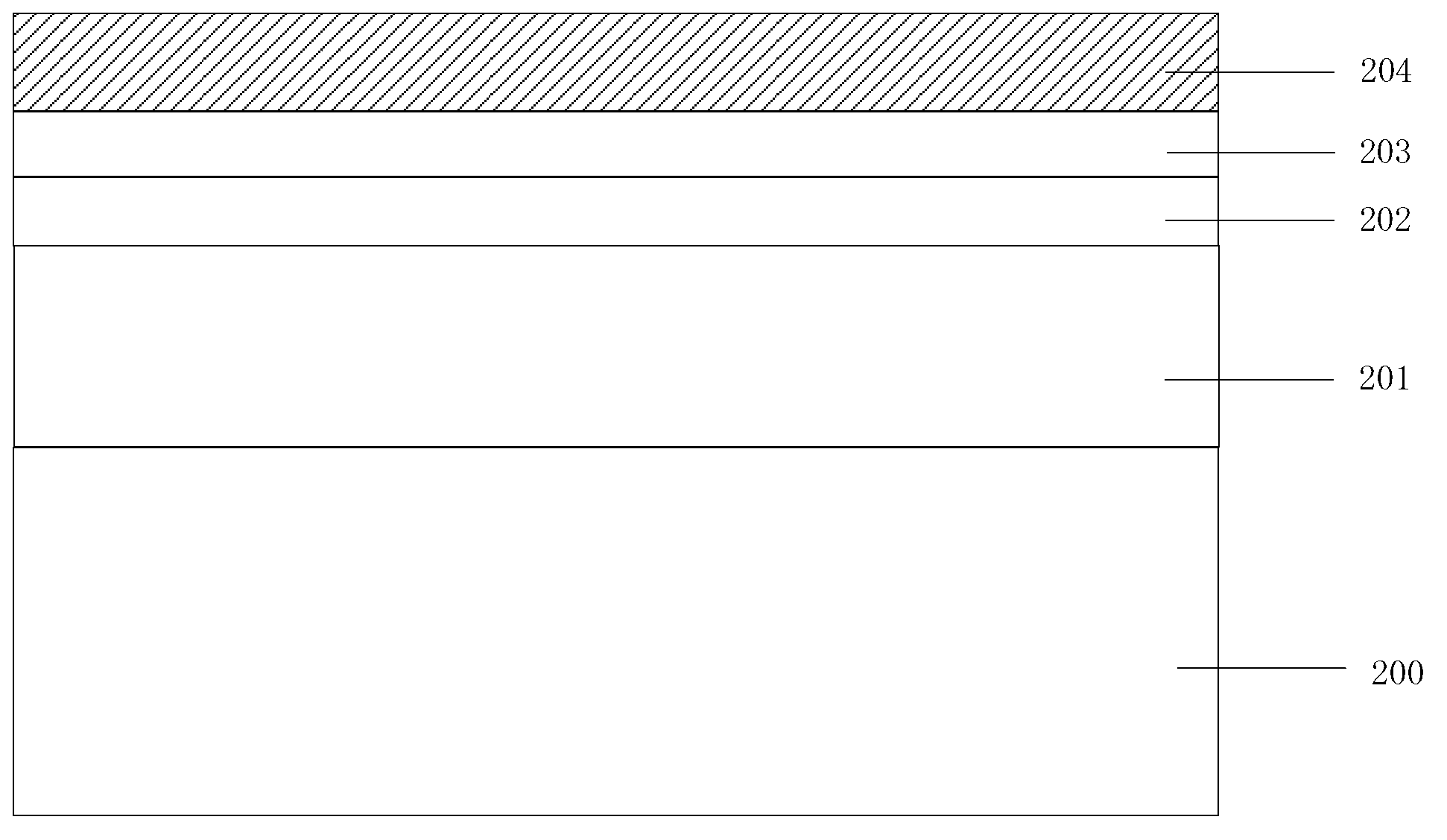

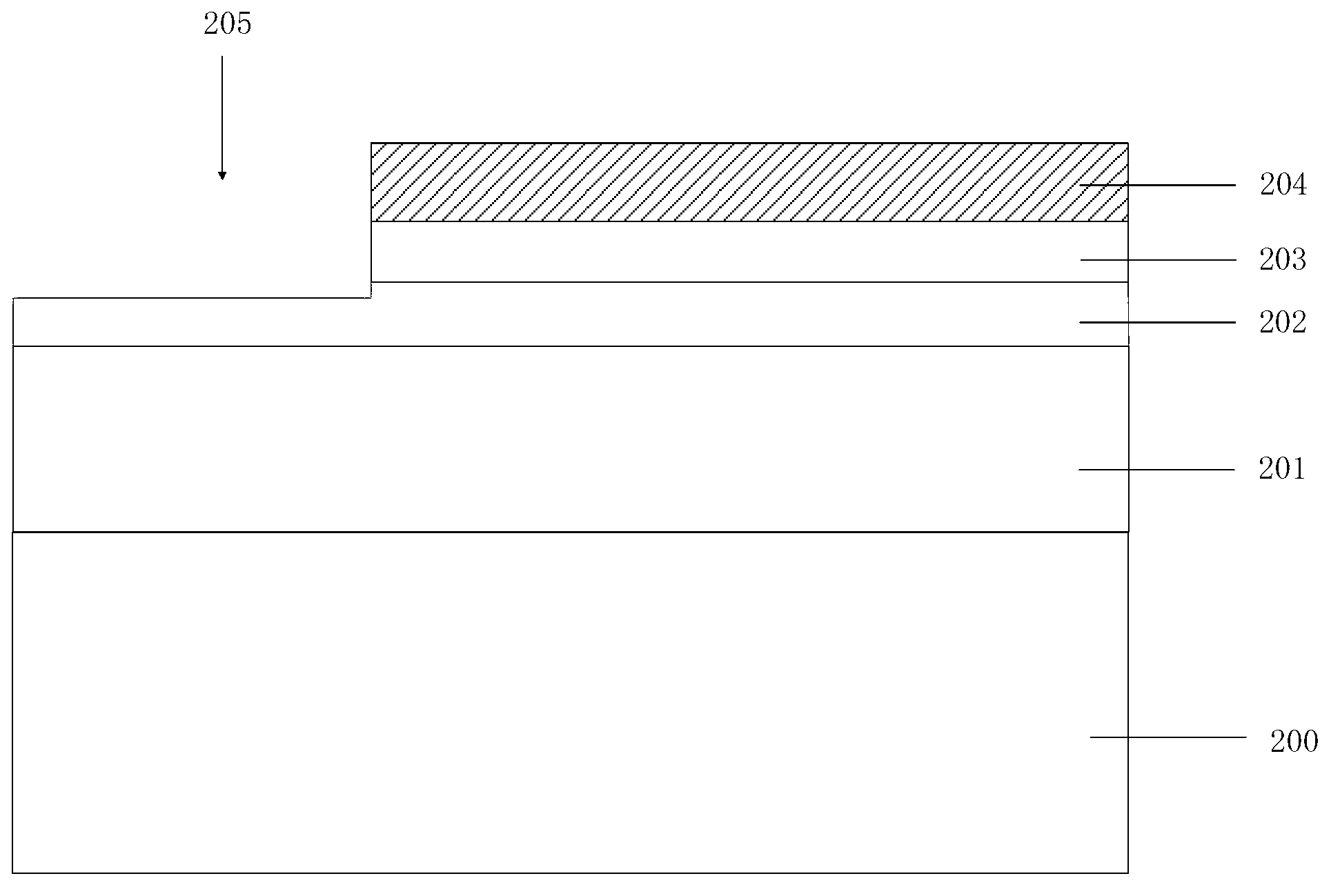

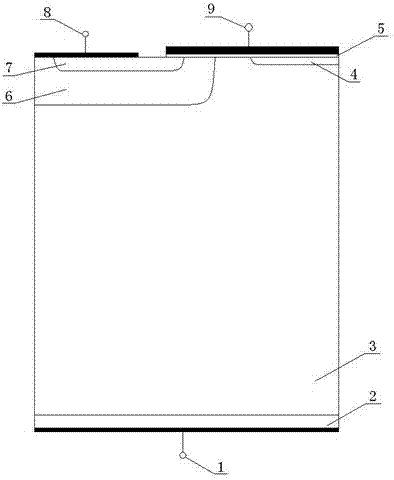

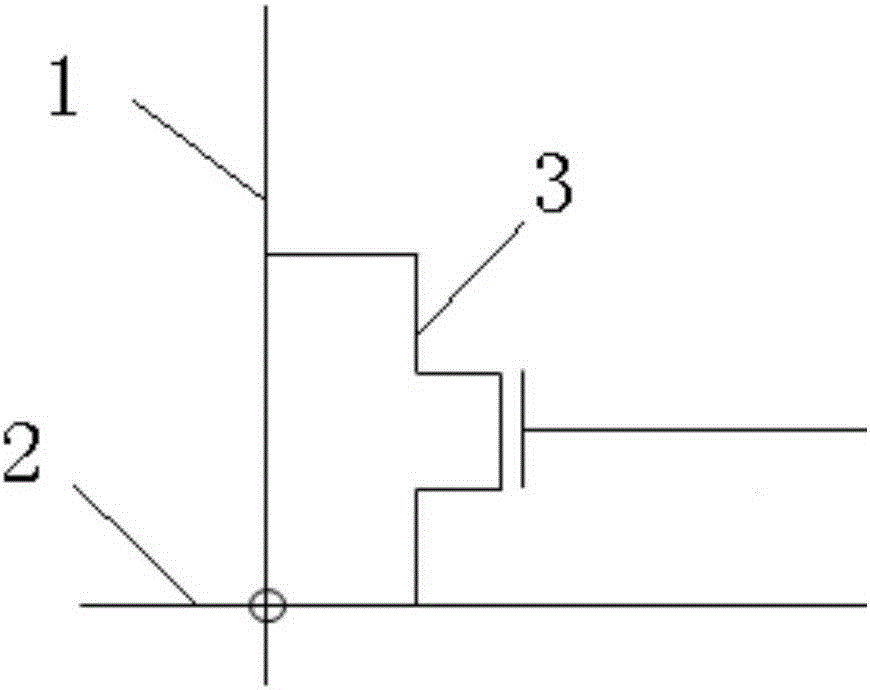

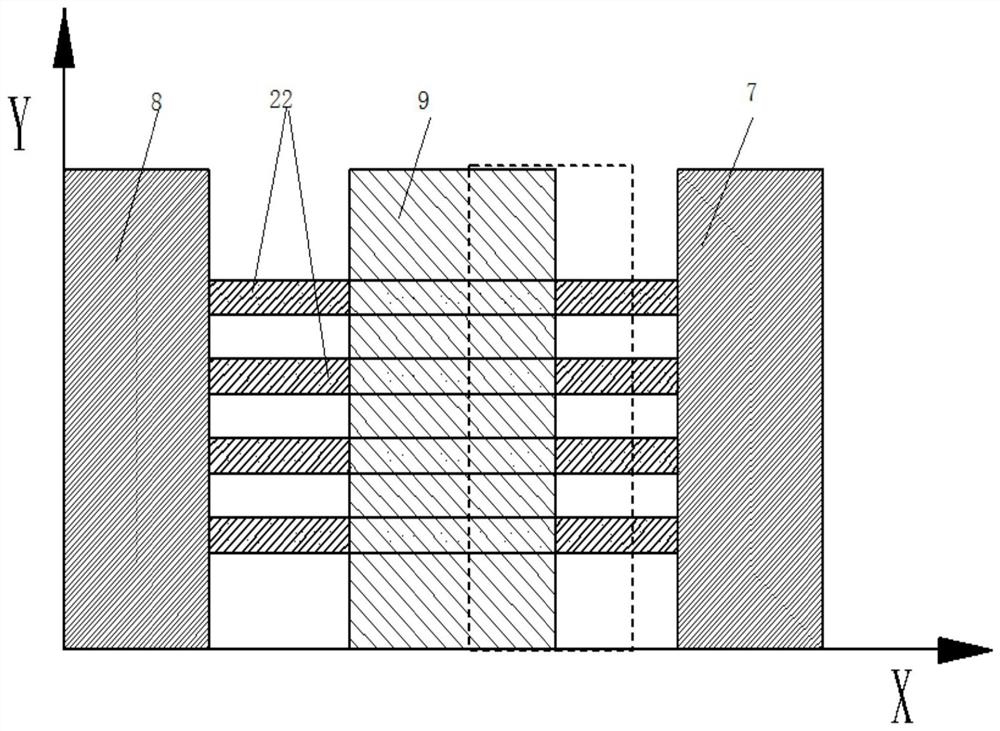

Array substrate, liquid crystal display device as well as manufacturing and repairing method of array substrate

InactiveCN102338959AReduce the chance of breakdownGuaranteed to workNon-linear opticsLiquid-crystal displayParasitic capacitance

The invention discloses an array substrate, a liquid crystal display device as well as a manufacturing and repairing method of the array substrate. The array substrate of a liquid crystal display with a thin film transistor comprises a pixel electrode, a grid line and a data line, wherein a parasitic capacitor is formed at an overlapping position of the grid line and the data line, the data line is also provided with a branch part overlapped with the grid line to form a protective capacitor connected in parallel with the parasitic capacitor, and the withstand voltage of the protective capacitor is smaller than that of the parasitic capacitor. In the invention, the data line is provided with the branch part overlapped with the grid line to form the protective capacitor which has smaller withstand voltage and is connected in parallel with the parasitic capacitor, and the data line is arranged at a top layer, therefore, it is easier for later repairing.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

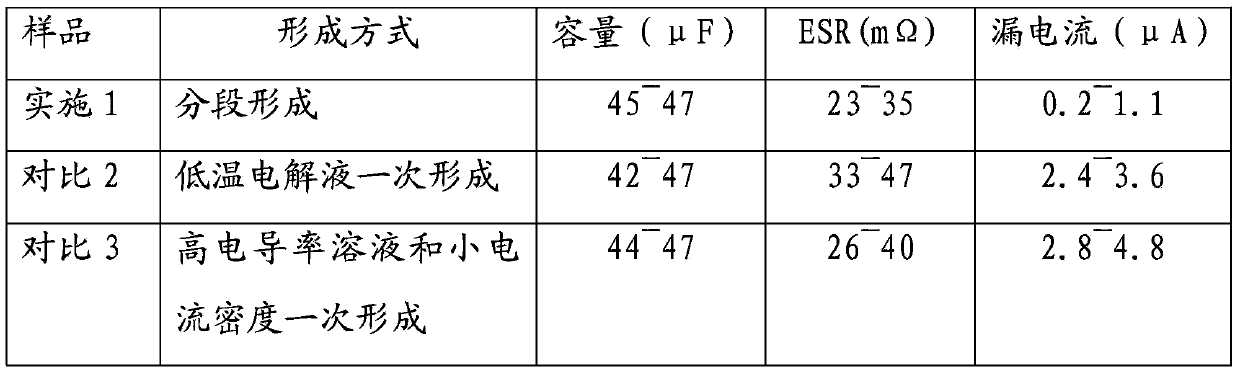

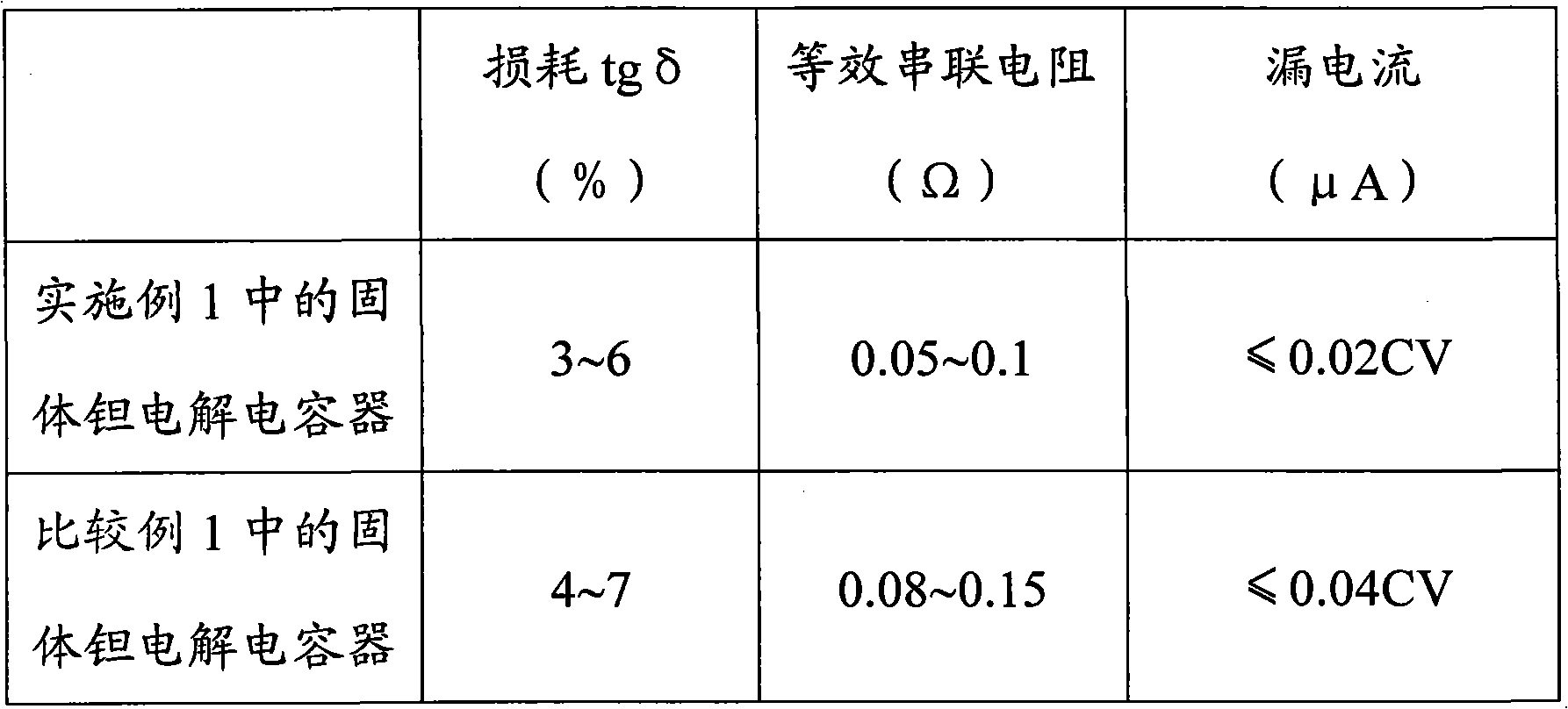

Method for manufacturing high-voltage electrolytic capacitor

ActiveCN103400694AReduce the chance of breakdownGuaranteed withstand voltageSurface reaction electrolytic coatingCapacitor dielectric layersElectrolysisHigh pressure

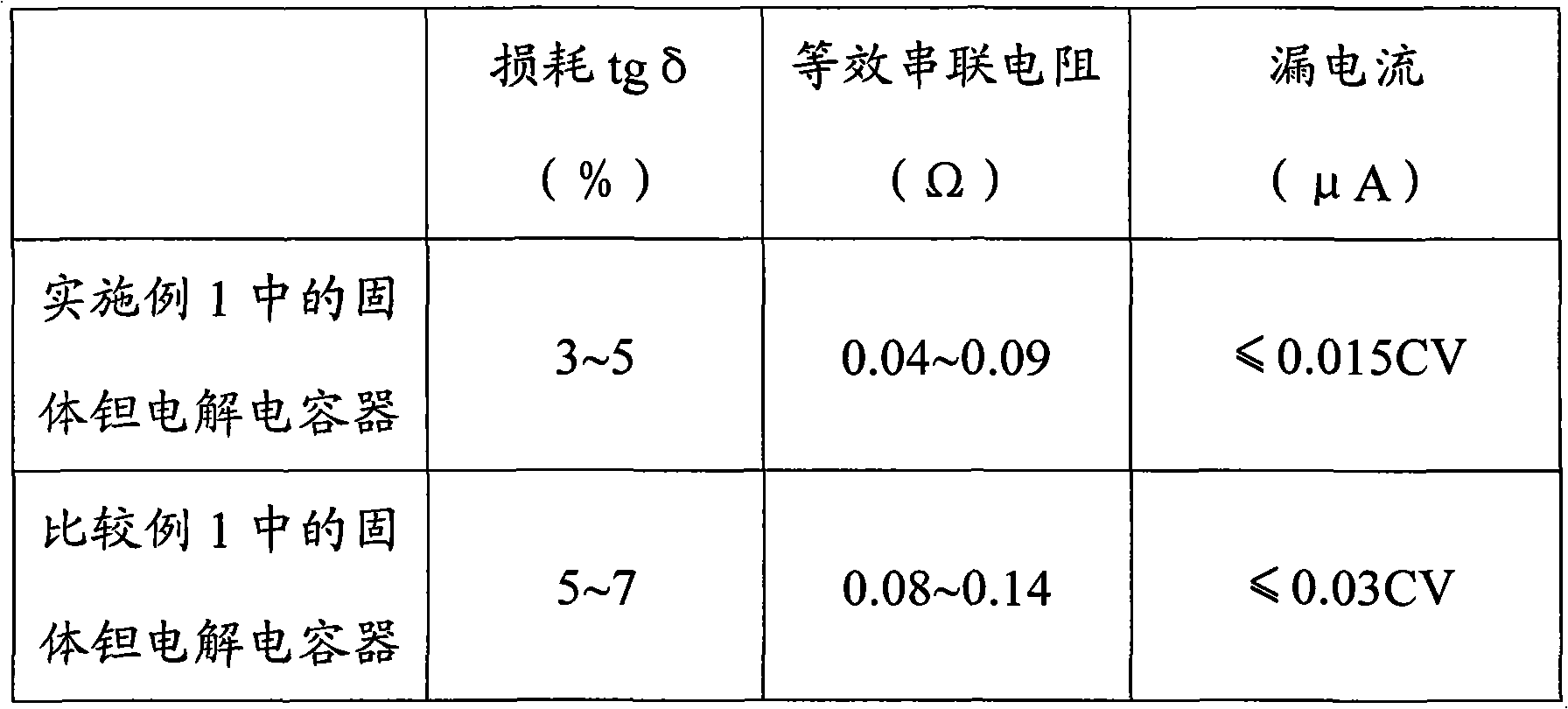

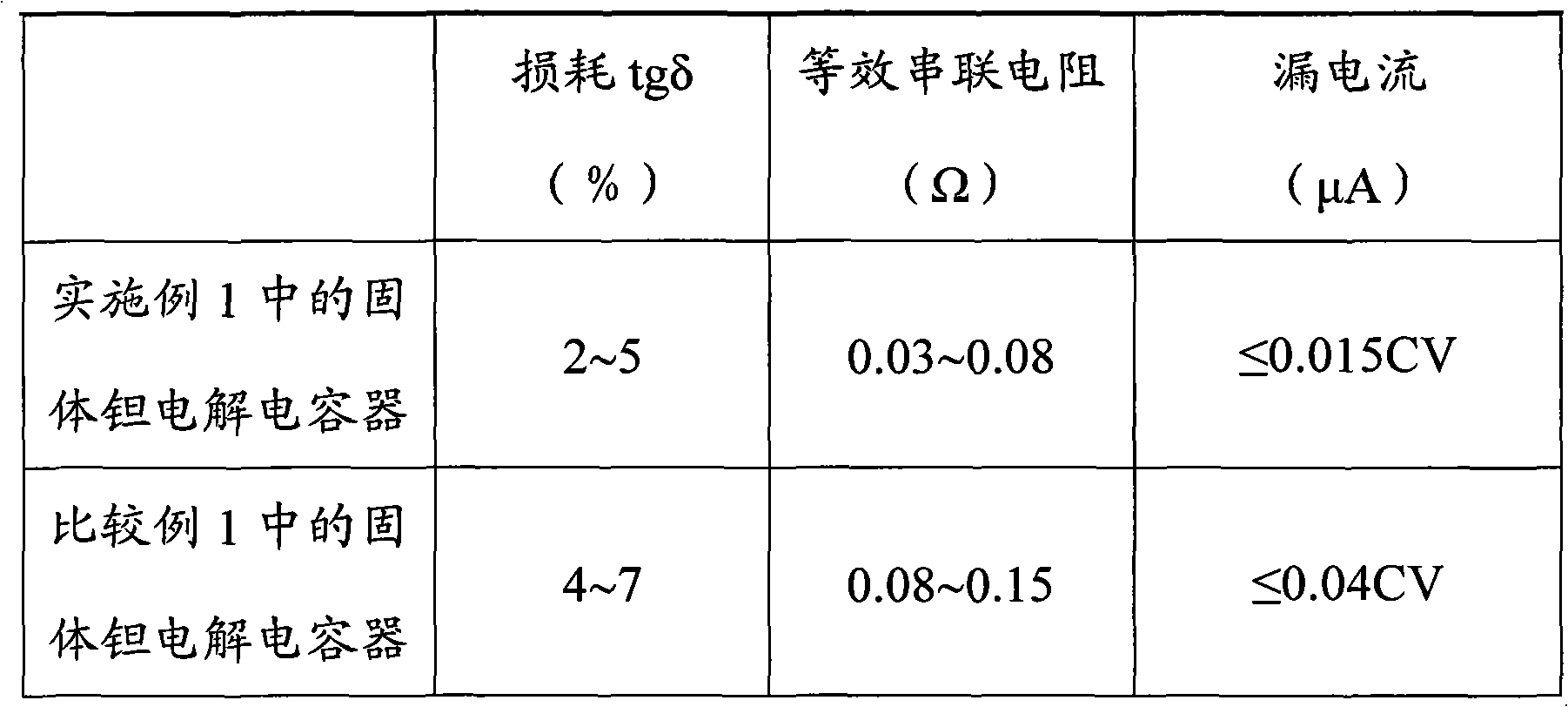

The invention discloses a method for manufacturing a high-voltage electrolytic capacitor. The method comprises the following steps: forming and sintering a valve metal anode block; cleaning the formed anode block; preparing an electrolyte; performing primary film coating; electrochemically forming, and cleaning and thermally treating a medium oxide film; performing secondary film coating; removing residual impurities on the surface of medium oxide film; coating a cathode electrolyte; coating a graphite layer and a silver paste layer on a tantalum core surface coated with the electrolyte in sequence; performing spot welding, bonding, assembling, die pressing and packaging; and shaping to obtain a finished product, and testing the electric performance of the product. The method has the beneficial effects that the temperature of the electrolyte and the current density are changed, and the medium oxide film is formed on the surface of anode block via an electrochemical oxidization method under the condition of relatively constant conductivity, so that the voltage resistance of the product is ensured, and the probability of break-through of the capacitor is effectively lowered.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

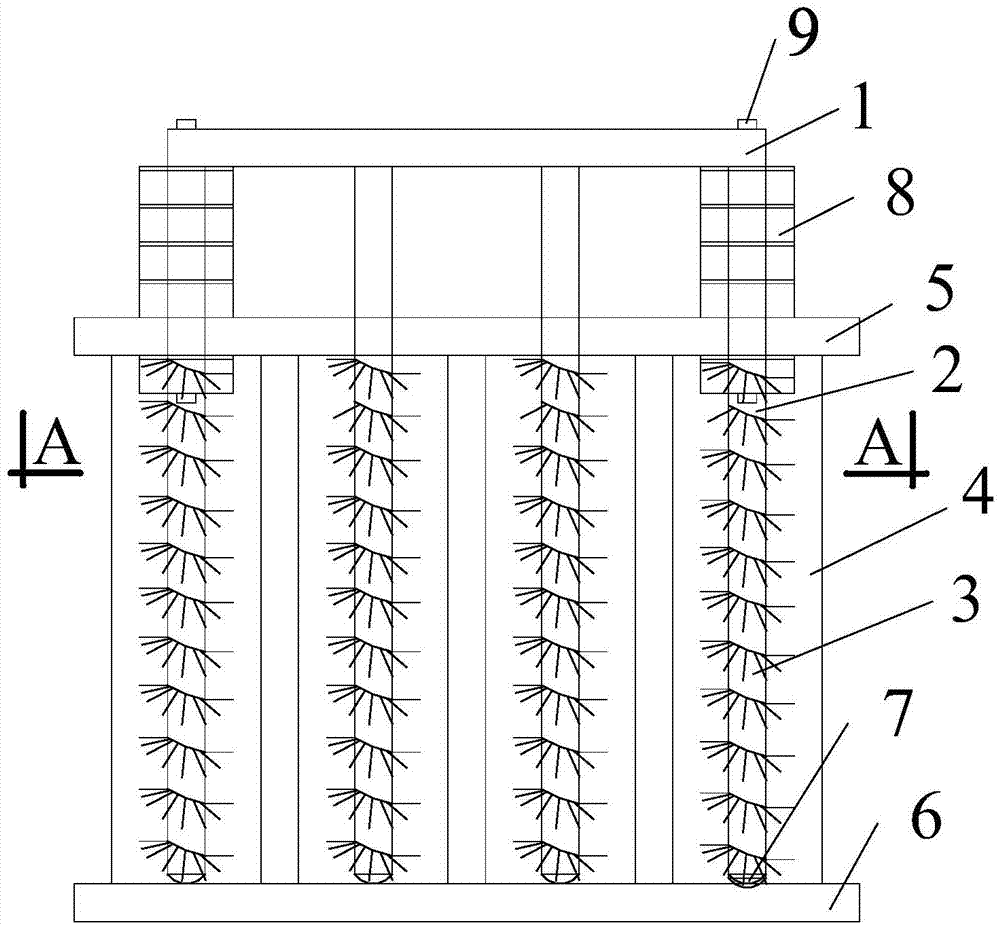

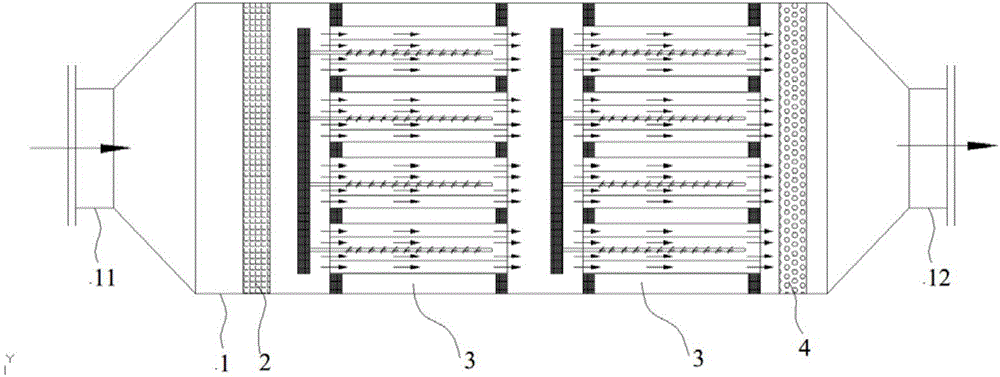

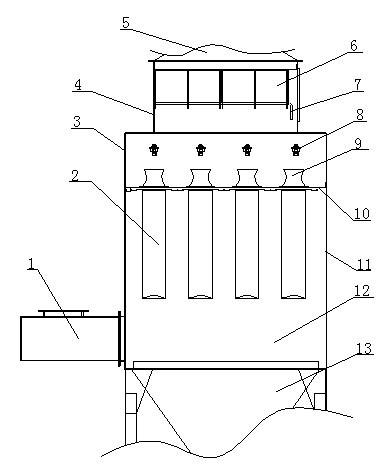

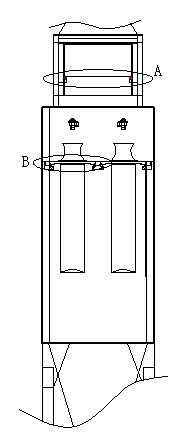

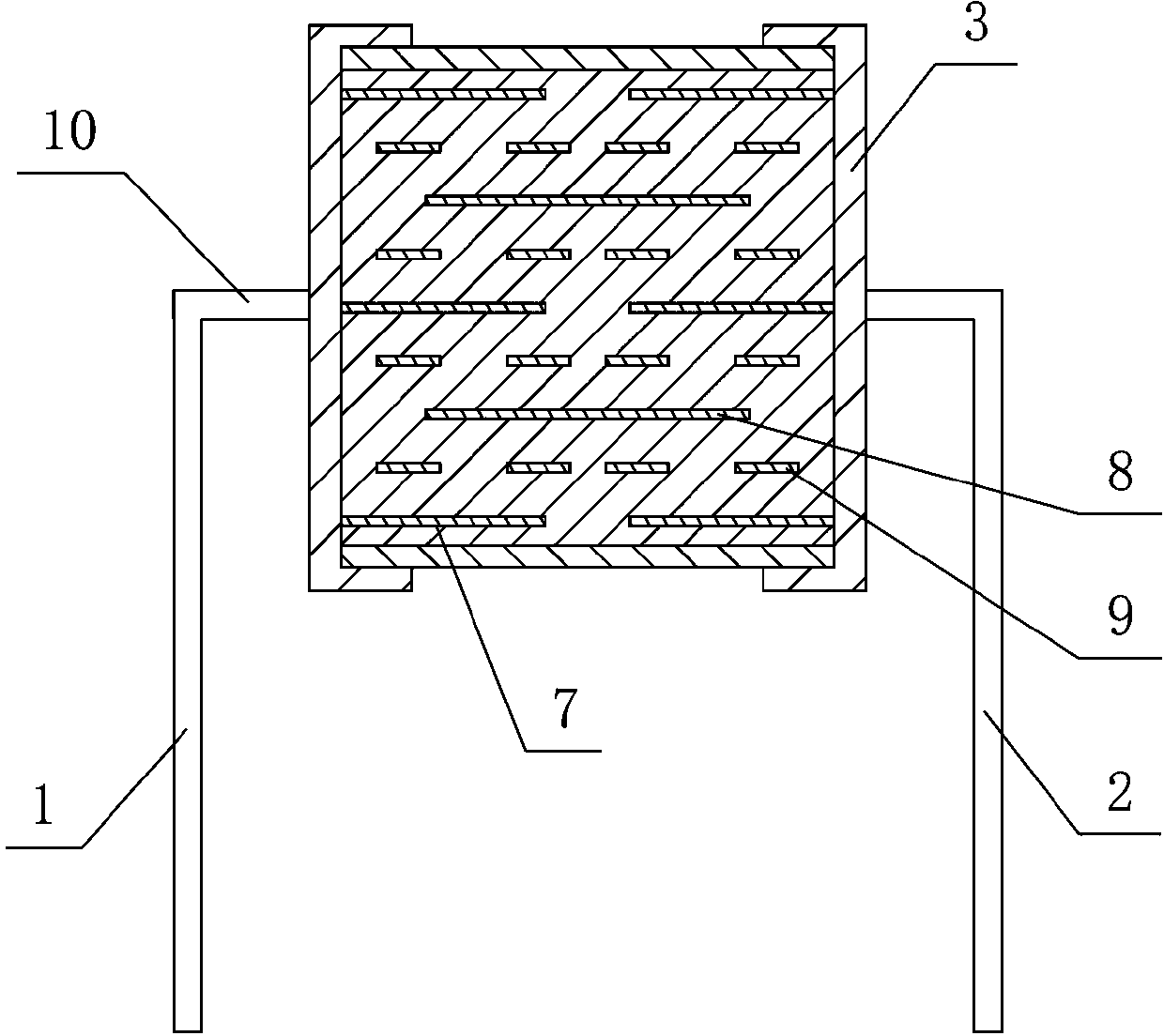

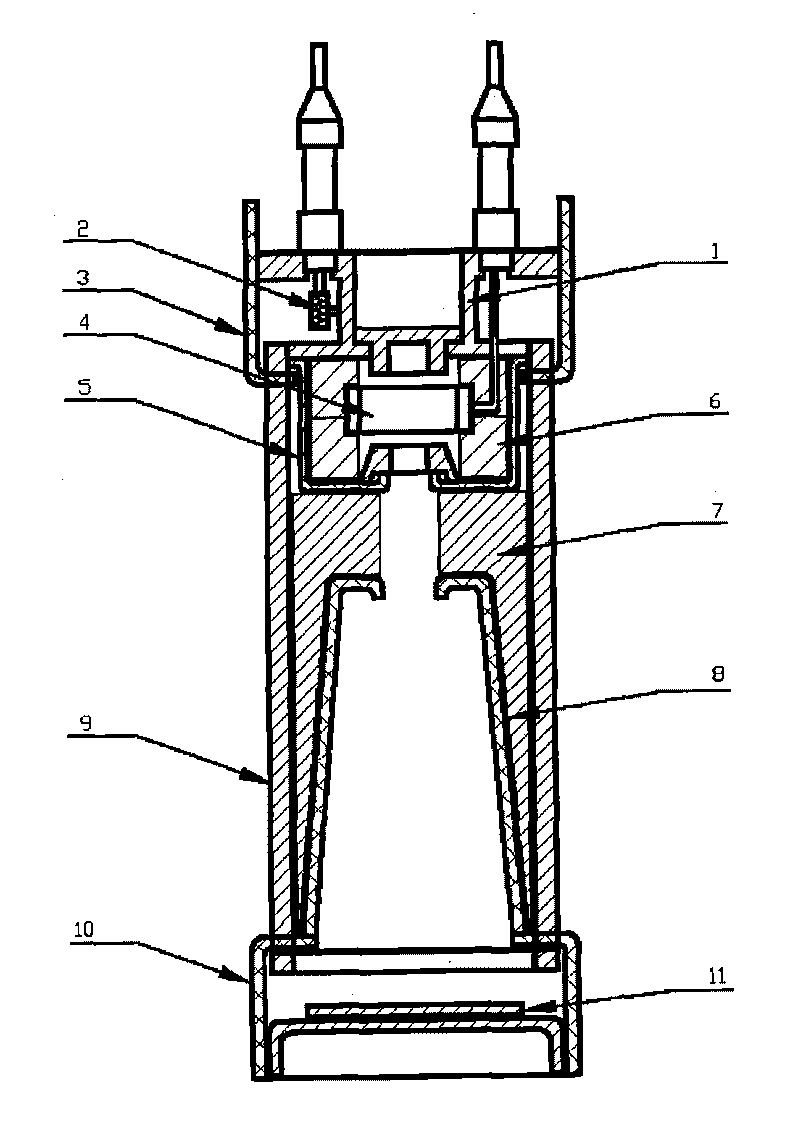

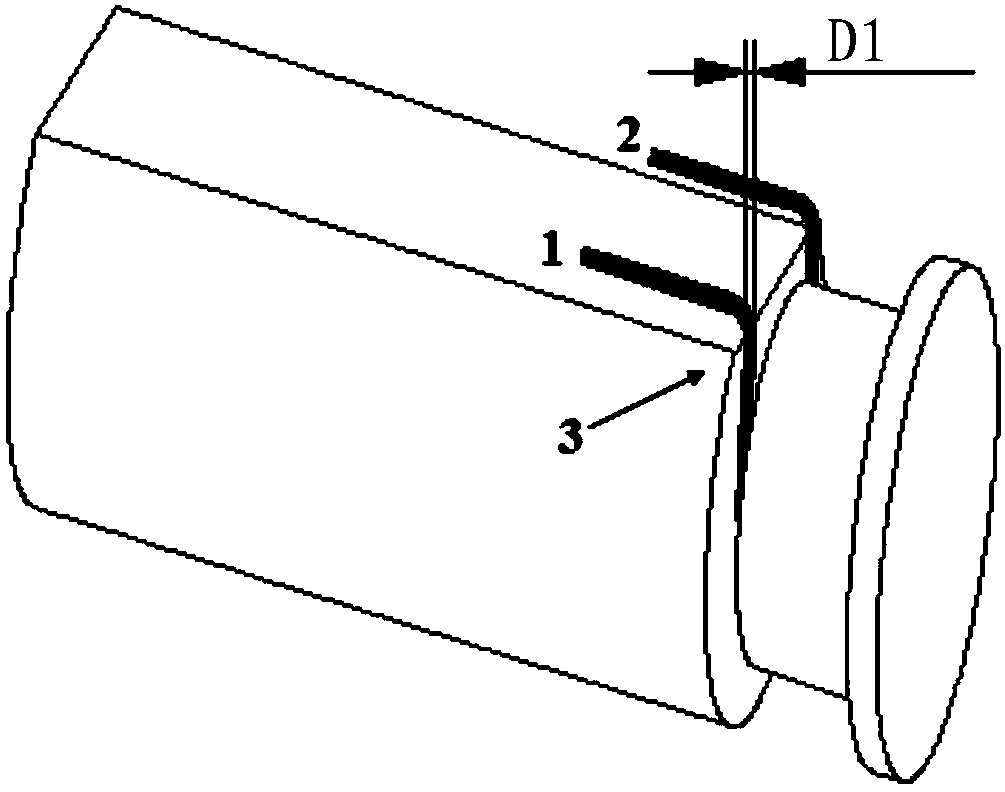

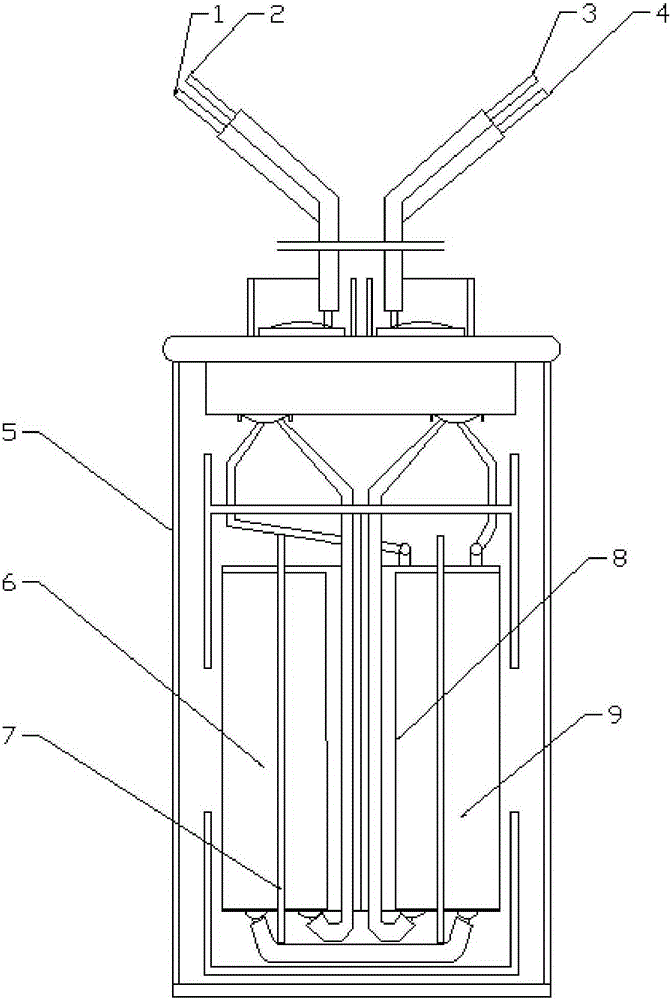

Low-temperature plasma generating device

InactiveCN103906334AIncrease reaction spaceReduce the chance of breakdownPlasma techniqueHigh energyEngineering

The invention relates to the technology of purifying organic waste gas in the industry and aims to provide a low-temperature plasma generating device. A reactor of the device comprises an electric corona tube support, insulators, an upper baffle and a lower baffle in a sequential connection mode, and n plasma reacting cavities are formed in parallel. Outer shells of the reacting cavities are in a hollow cylinder shape, and electric corona tubes and the outer shells of the reacting cavities are coaxial. Multiple bars of discharging fluff made of metal material are evenly distributed on the outer walls of the electric corona tubes in a spiral step shape. Inward extending lines of the discharging fluff pass through the axes of the electric corona tubes. The electric corona support is provided with supporting pillars perpendicular downwards, the supporting pillars are sleeved with the electric corona tubes, and rain caps are arranged at the bottoms of the electric corona tubes. High-energy electrons, ions, atoms in an excited state, free radical particles and other high-activity substances generated by the device are improved by 35% on the basis of the same-size reactor, and effective reaction space is enlarged. Because fluff-shaped electrodes are adopted, the probability of breakdown of a positive electrode and a negative electrode is greatly reduced, and energy consumption is greatly reduced.

Owner:浙江菲尔特环保工程有限公司

MIM (metal-insulator-metal) capacitor and manufacturing method thereof

InactiveCN103021813AAvoid over etchingReduce the chance of breakdownSemiconductor/solid-state device detailsSolid-state devicesMetal-insulator-metalCapacitance

Disclosed are a MIM capacitor and a manufacturing method thereof. The manufacturing method includes: setting a covering layer on a second conducting layer (used for forming an upper electrode plate of an MIM capacitor). Etching gas which is slower in etching the covering layer than etching dielectric layers is selected in the process of dry etching performed to form through holes respectively exposing a first conducting layer (a lower electrode plate) and a second conducting layer, so that excessive etching of the second conducting layer (the upper electrode plate) is avoided when the dielectric layers embedding the second conducting layer and the first conducting layer are etched simultaneously at the same height. Thus, probability of breakdown of the MIM capacitor is lowered, and reliability of the MIM capacitor is increased.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

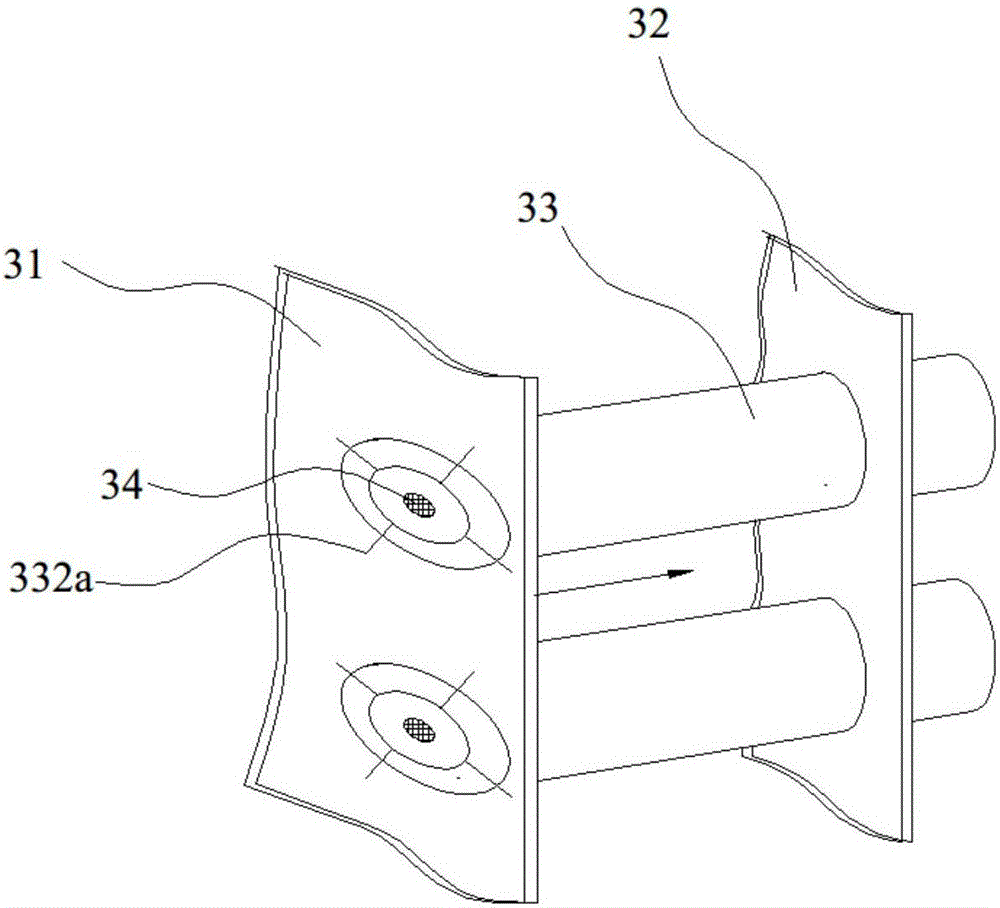

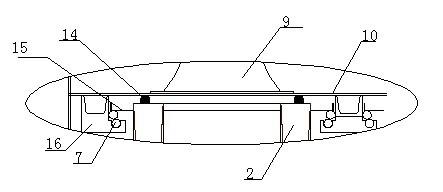

Low-temperature plasma waste gas treatment apparatus

PendingCN106823707APromote degradationImprove purification effectGas treatmentDispersed particle separationFiberActivated carbon

The present invention relates to a low-temperature plasma waste gas treatment apparatus, which comprises a housing, a filtration module, a low-temperature plasma reaction module and an active carbon fiber filtration module, wherein the filtration module, the low-temperature plasma reaction module and the active carbon fiber filtration module are arranged in the housing, the low-temperature plasma reaction module comprises a first fixation plate, a second fixation plate and n low-temperature plasma reaction tubes arranged between the first fixation plate and the second fixation plate at intervals, the n low-temperature plasma reaction tubes penetrate through the first fixation plate and the second fixation plate and extend along the flowing path of a fluid, the n low-temperature plasma reaction tubes respectively comprise a cathode outer tube, an insulating medium inner tube and an anode rod arranged in the insulating medium inner tube, the cathode outer tube, the insulating medium inner tube and the anode rod form a concentric circle structure, an annular gap is arranged between the cathode outer tube and the insulating medium inner tube, the anode rod is fixed on an anode rod bracket, and a plurality of discharging fluffs prepared from a metal are uniformly distributed on the outer wall of the anode rod in a spiral ladder manner. According to the present invention, the low-temperature plasma waste gas treatment apparatus has advantages of simple structure, low manufacturing cost, good waste gas treatment effect, convenient operation, and convenient maintenance.

Owner:苏州盟力环境科技有限公司

Filter drum deduster

ActiveCN102553365ADecreased filtration rateReduce the load of filtration and purificationDispersed particle filtrationFiltrationEmission standard

The invention is an improvement of a filter drum deduster. The deduster is characterized in that a rigid non-compression eccentric rotating interference compressing piece is used for compressing between an air-out end surface of the filter drum and an overhung pore plate; a cushion space which is not less than 30cm is reserved between the bottom of the filtering drum and the bottom plane of a filtering drum box body; and a filtering air inlet is arranged in the cushion space at the lower part of the filtering drum. According to the deduster provided by the invention, over-diameter particles are ensured not to exist in the filtered gas, the filtering material is prevented from being damaged effectively, the service life of the filtering drum is prolonged, two main defects which are hard to solve by a traditional filtering drum deduster are solved completely, and the effective service life of the filtering drum is prolonged from originally maximum twelve months to eighteen months. A frame type filter is added above a filtering drum air outlet by being connected with a transition section interval, the filter precision of the frame type filter is higher than the filter grade of the lower filtering drum, thereby forming secondary filtration of upper and lower inter-phase serial connection; the minimum filtering precision can be 0.1 microns; the filter drum deduster provided by the invention can be used in the lead-acid battery industry for filtering lead dust and fume, and the dust content of the filtered gas is not more than 0.07mg / m<3>, which is far less than the national emission standard; the filtration resistance is increased by more or less than 10% on the basis of previous grade, so that the contradiction between the filtering precision and the filtering resistance is balanced well.

Owner:江苏二环环保科技有限公司

Polarization method of polyvinylidene fluoride thin film

InactiveCN104425705AReduce manufacturing costSimple processPiezoelectric/electrostrictive device manufacture/assemblyPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a polarization method of a polyvinylidene fluoride thin film. The polarization method comprises the following steps: S1. evaporating silver which is 90-100nm on the upper and lower planes of the polyvinylidene fluoride thin film as a metal electrode; S2. pouring silicon oil into a heater and putting the polyvinylidene fluoride thin film plated with the metal electrode into silicon oil of the heater; S3. adjusting the temperature of silicon oil in the heater to 80-90 DEG C and applying a voltage to the polyvinylidene fluoride thin film plated with the metal electrode, wherein the voltage applied to the polyvinylidene fluoride thin film plated with the metal electrode is 130-140MV / m for 50-60 minutes; and S4. taking out the polyvinylidene fluoride thin film in the heater and cooling at normal temperature to obtain the polarized polyvinylidene fluoride thin film. The polarized polyvinylidene fluoride thin film disclosed by the invention is good in piezoelectricity, ferroelectricity and pyroelectricity and low in film puncture rate, so that the manufacturing cost of the polyvinylidene fluoride thin film can be lowered, and the polarization method is convenient to popularize and apply.

Owner:龚伶

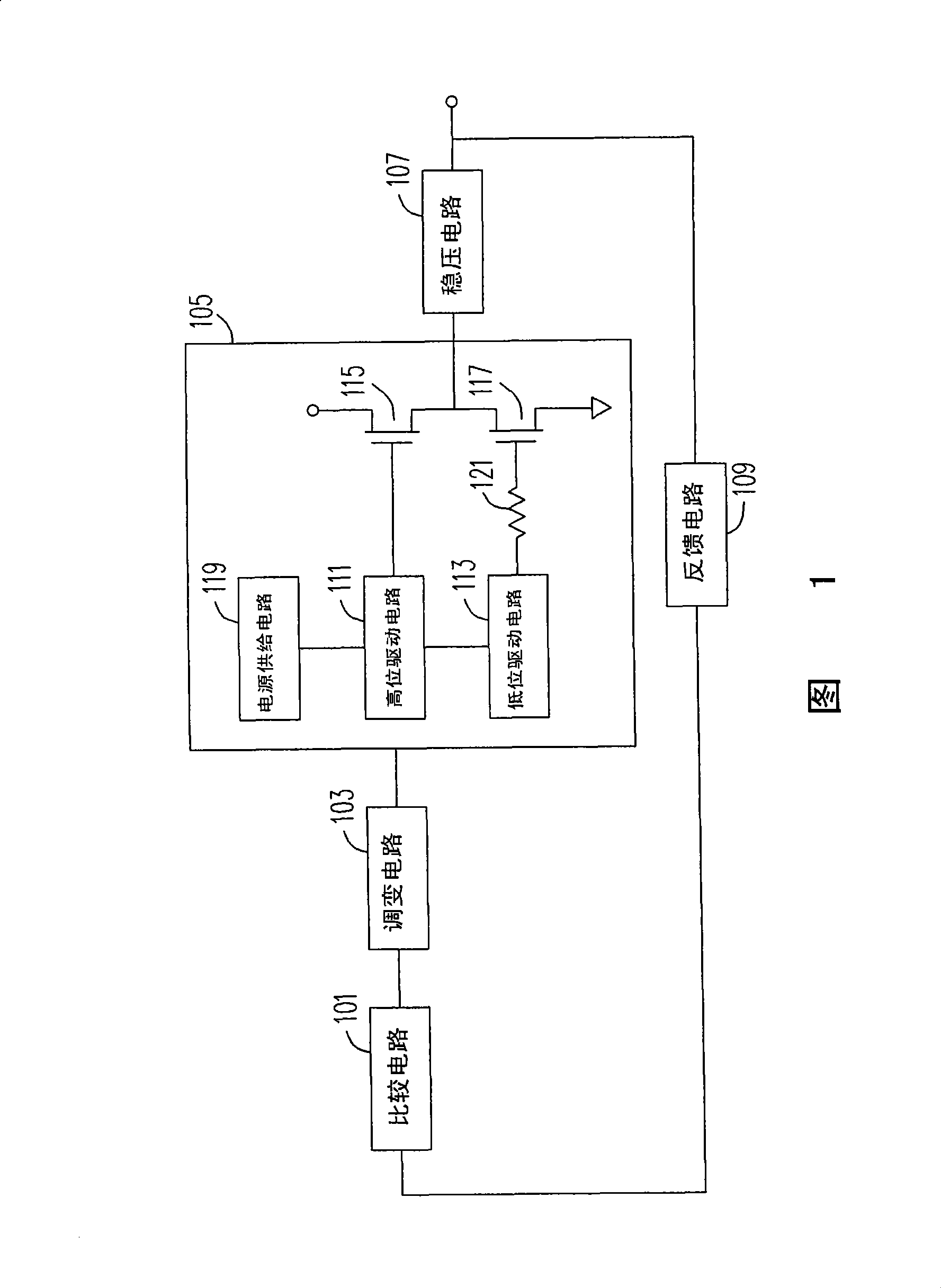

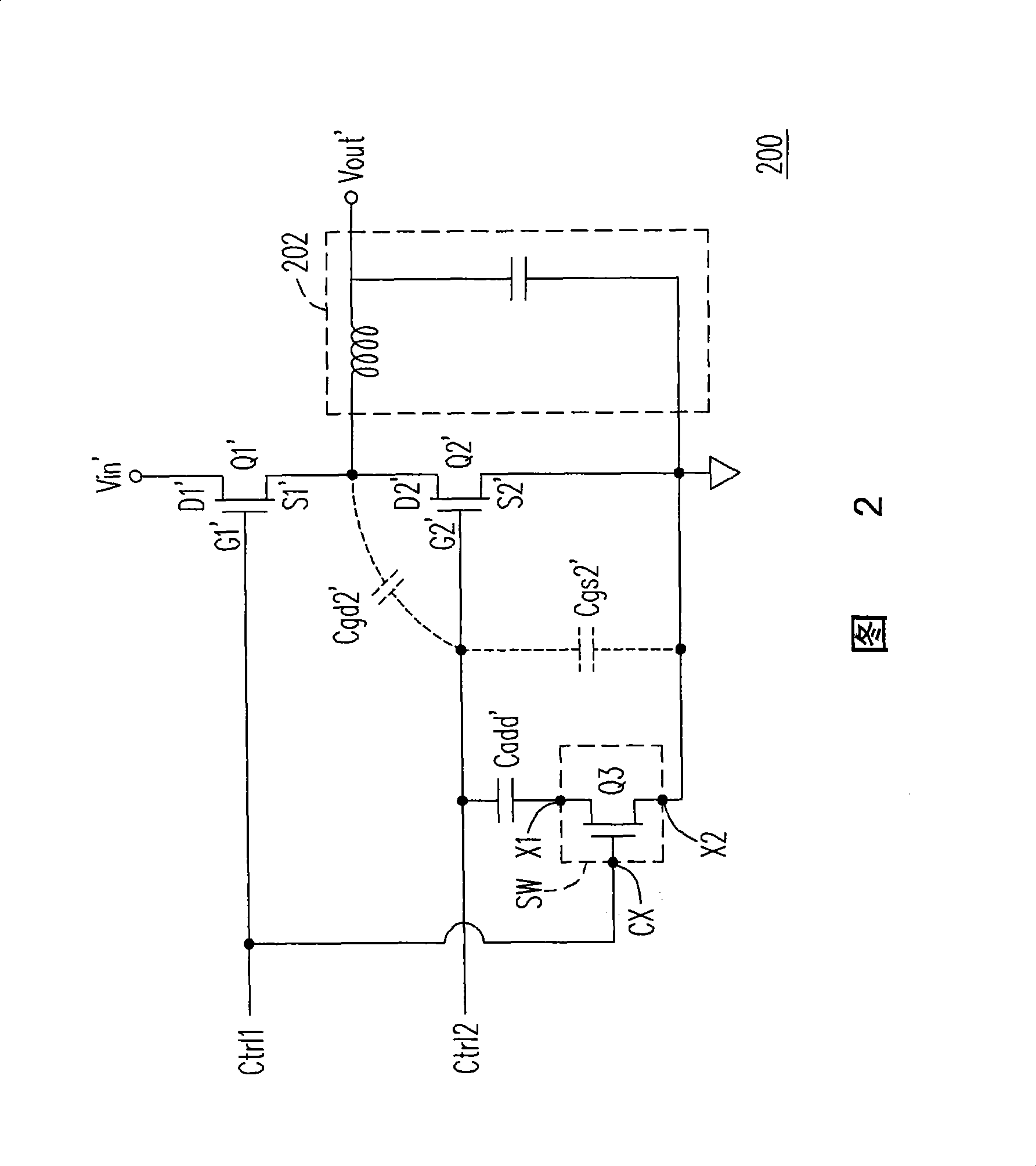

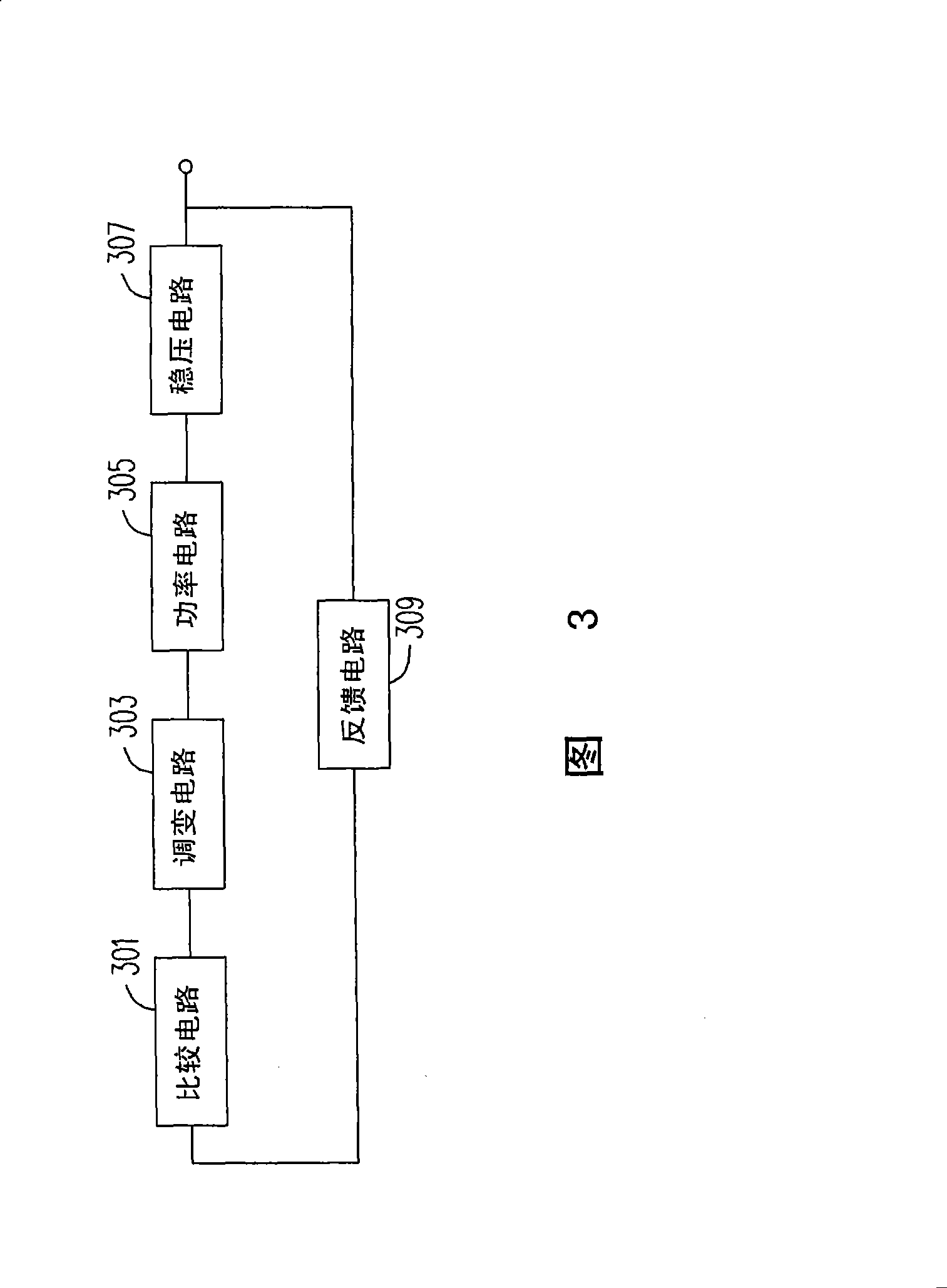

Power source converter improving synchronous rectifying loop breakdown

InactiveCN101420177AExtended service lifeShorten rise timeDc-dc conversionElectric variable regulationElectrical resistance and conductanceTransistor

Owner:INVENTEC CORP

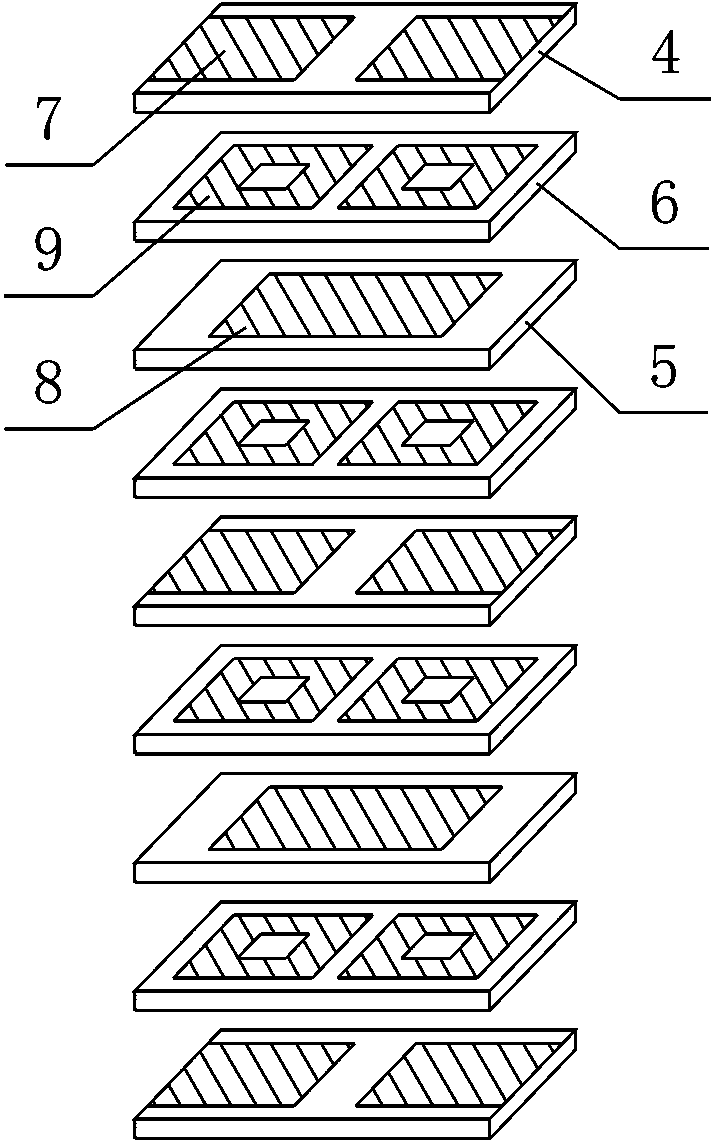

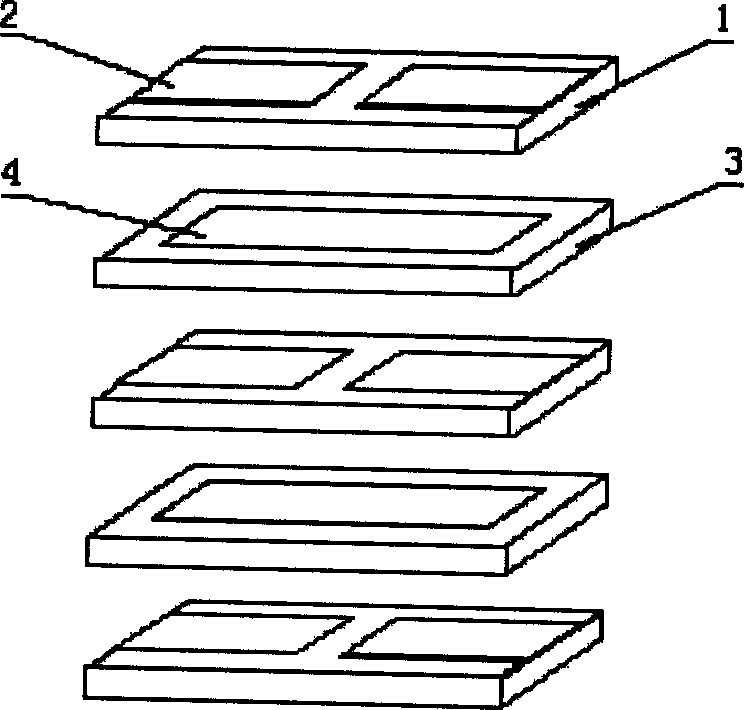

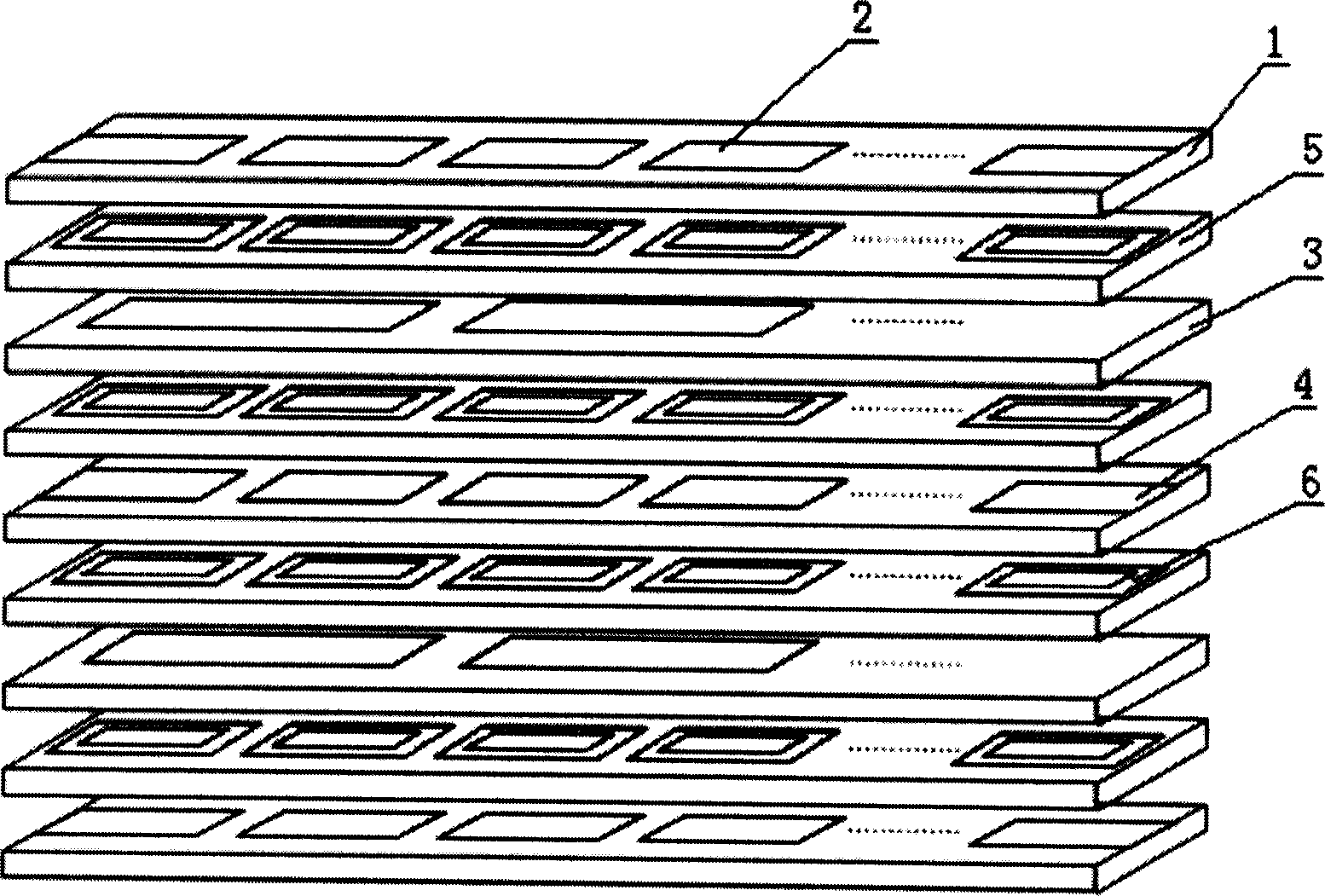

Multi-layer ceramic laminar capacitor

InactiveCN103811182ASmall physical areaThere will be no problem of separation from each otherFixed capacitor electrodesStacked capacitorsPuncture resistanceHigh pressure

The invention discloses a multi-layer ceramic laminar capacitor. The multi-layer ceramic laminar capacitor comprises a laminar main body, a first lead and a second lead, wherein the laminar main body comprises two outer electrodes, and a first medium layer, a second medium layer and a third medium layer which are positioned between the two outer electrodes; the first medium layer is provided with two inner electrodes a which are distributed at a certain interval and are in the forms of small rectangles, and the two inner electrodes a are connected with the two outer electrodes respectively; the second medium layer is provided with two inner electrodes b which correspond to the positions of the two inner electrodes a and are in the forms of large rectangles; the third medium layer is provided with two inner electrodes c which correspond to the positions of the inner electrodes a and the inner electrodes b and are in the forms of frame-type quadrangles; the third medium layer is positioned between the first medium layer and the second medium layer, and the three medium layers are overlapped in sequence; the first lead and the second lead are arranged outside the outer electrodes respectively, and transverse epitaxial segments are arranged on portions connected with the outer electrodes. By adopting the multi-layer ceramic laminar capacitor, the high-voltage puncture resistance can be improved greatly under the condition of not basically increasing the overall dimensions.

Owner:CHENGDU RONGHUA ELECTRONICS

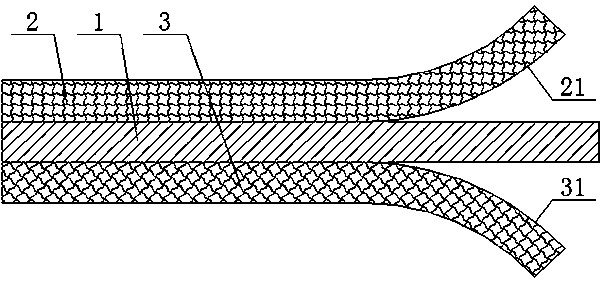

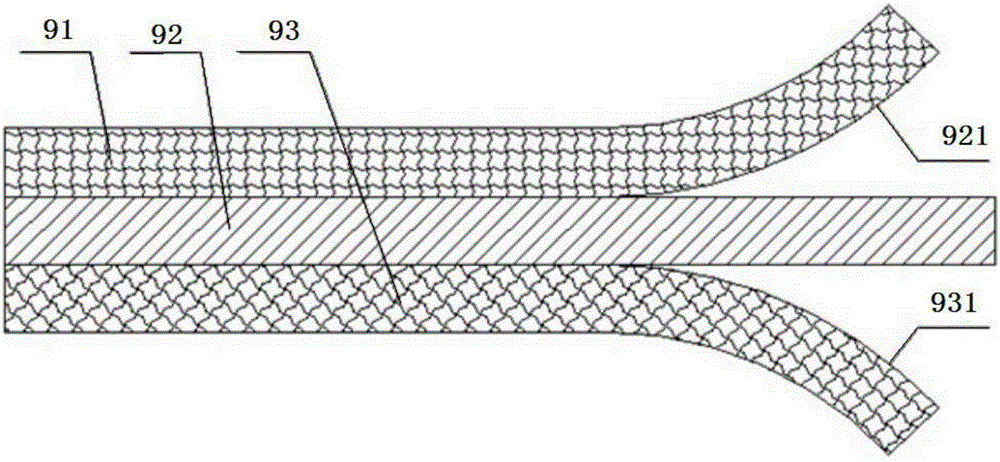

Metallized capacitor film with improved oxidation resistance

InactiveCN103996534AReduce penetrationReduce thicknessFixed capacitor electrodesPolyolefinOxidation resistant

The invention discloses a metallized capacitor film with improved oxidation resistance. The metallized capacitor film comprises metal plating, a plastic film top layer and a plastic film bottom layer, wherein the plastic film top layer and the plastic film bottom layer are arranged on the two surfaces of the metal plating respectively, the metal plating is made of zinc and / or aluminum, the plastic film top layer and the plastic film bottom layer are made of polyolefin, the plastic film top layer is provided with a contact bottom surface making contact with the metal plating, the plastic film bottom layer is provided with a contact top surface making contact with the metal plating, and the contact bottom surface and the contact top surface have the same surface charge density. According to the metallized capacitor film with improved oxidation resistance, penetrability of charged particles with oxidability in air to the plastic film top layer and the plastic film bottom layer is reduced, the dielectric property of the plastic film top layer and the plastic film bottom layer is improved, and the probability of breakdowns is reduced. The invention further discloses a manufacturing method of the metallized capacitor film with improved oxidation resistance.

Owner:ANHUI NINGGUO HAIWEI ELECTRONICS

Ceramic filled type neutron tube

InactiveCN101699612AGuaranteed collimationHigh outputIon beam tubesNeutron sourcesUltimate tensile strengthMachining

The invention belongs to an improved turn-off neutron source, and in particular relates to a neutron tube. In the neutron tube, a ceramic insulating ring is filled between an anode cylinder and an ion source cover and another ceramic insulating ring is filled between the ion source cover and an accelerating cylinder, so an air-out space in the neutron tube is reduced, insulating strength is improved, sealing difficulty is reduced and the coaxiality of a system is effectively guaranteed. The neutron tube has the advantages of greatly reducing discharging and puncturing probabilities, guaranteeing the collimation of the neutron tube, improving the product yield, service life and stability of the neutron tube and realizing the industrialization of the machining and manufacturing of the neutron tube, wherein phi50 is taken as an example, the service life of an improved product is increased by more than 3 times, while the product yield is increased by about 5 times, the stability is not more than 3 percent and the finished product ratio is over 90%.

Owner:NORTHEAST NORMAL UNIVERSITY

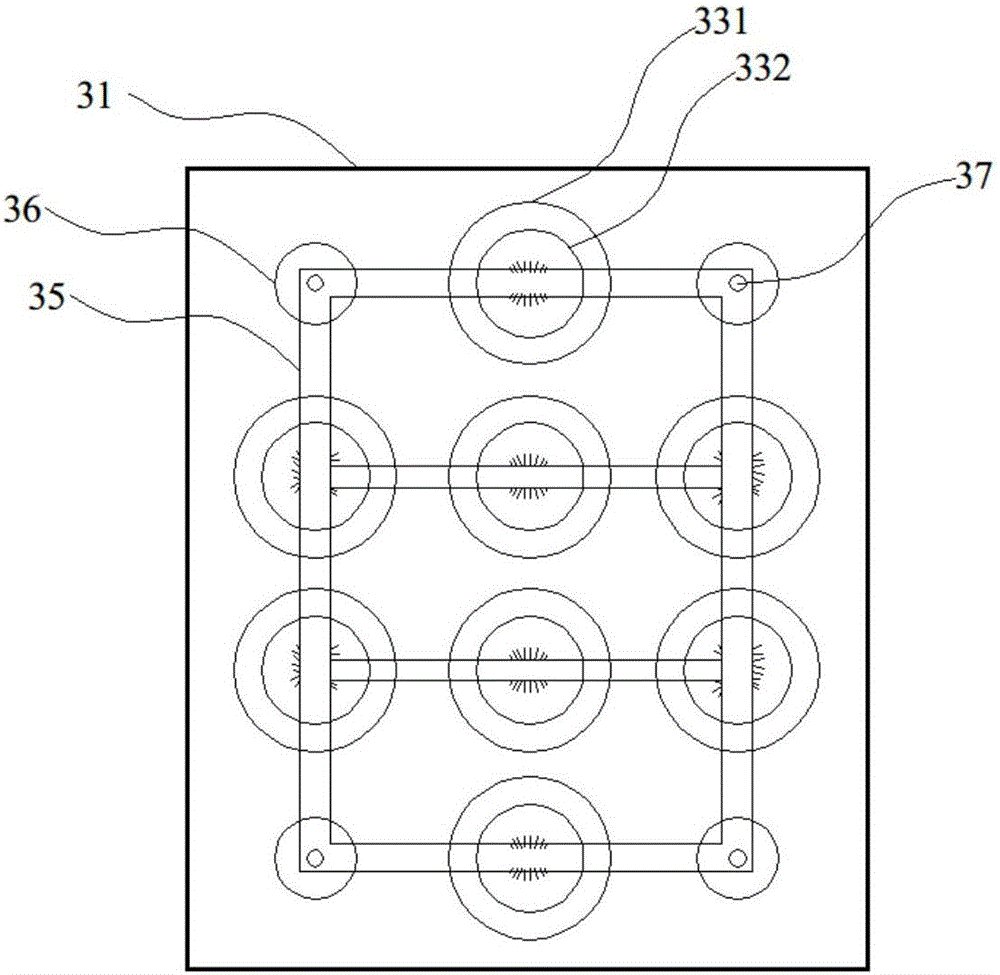

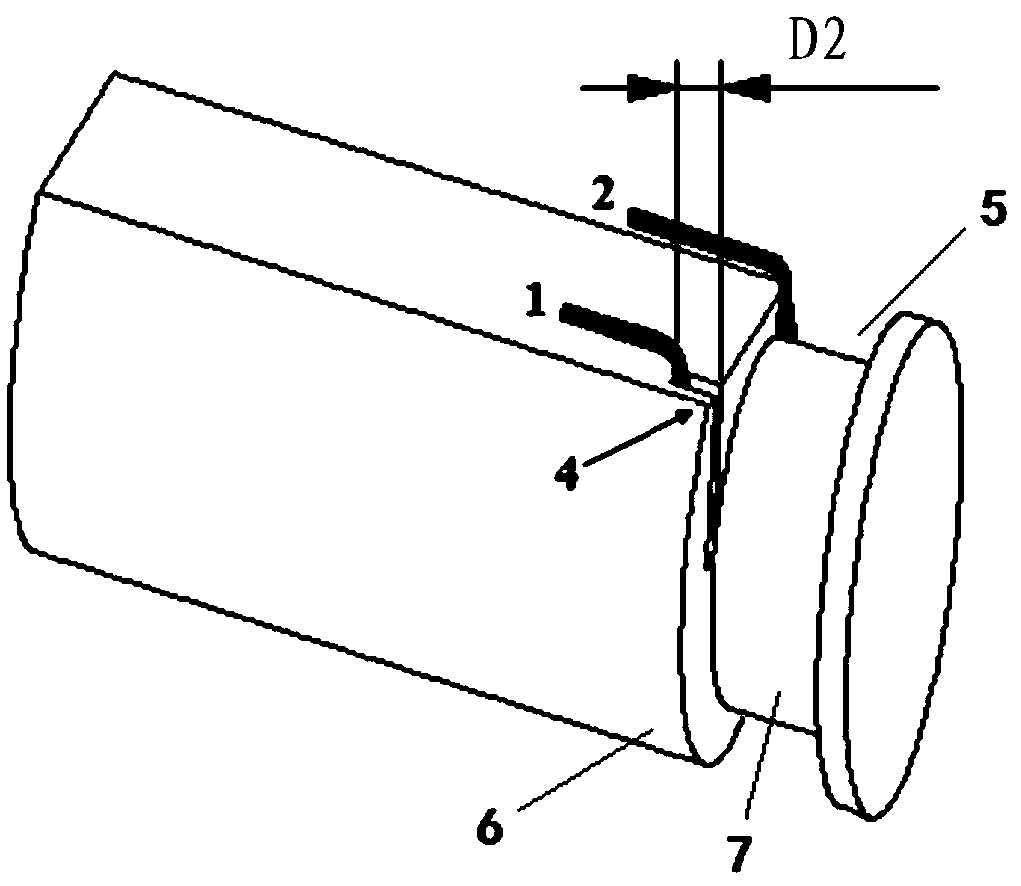

Coil assembly structure and magnetoelectric crankshaft speed sensor

PendingCN108666068AImprove reliabilityImprove manufacturing yieldTransformers/inductances coils/windings/connectionsDevices using electric/magnetic meansMagnetizationConductor Coil

The invention discloses a coil assembly structure and a magnetoelectric crankshaft speed sensor. The coil assembly structure comprises a coil frame and a coil, wherein the coil frame has a winding groove, and the coil is wound within the winding groove of the coil frame. A sidewall of the winding groove is provided with a lead groove recessed to the outside. The lead groove extends from the insideof the winding groove outwards to a surface of the coil frame. The recess of the lead groove is filled with an incoming line of the coil, which enters the winding groove along the lead groove, so that a spacing distance created by the incoming line of the coil filling the recess is at least formed between the incoming line of the coil and an outer layer winding line of the coil. The invention canimprove voltage withstand reliability between the incoming line and coil winding line without changing the magnetization and number of windings of the coil assembly structure.

Owner:SHENZHEN SENSOR TECH CO LTD

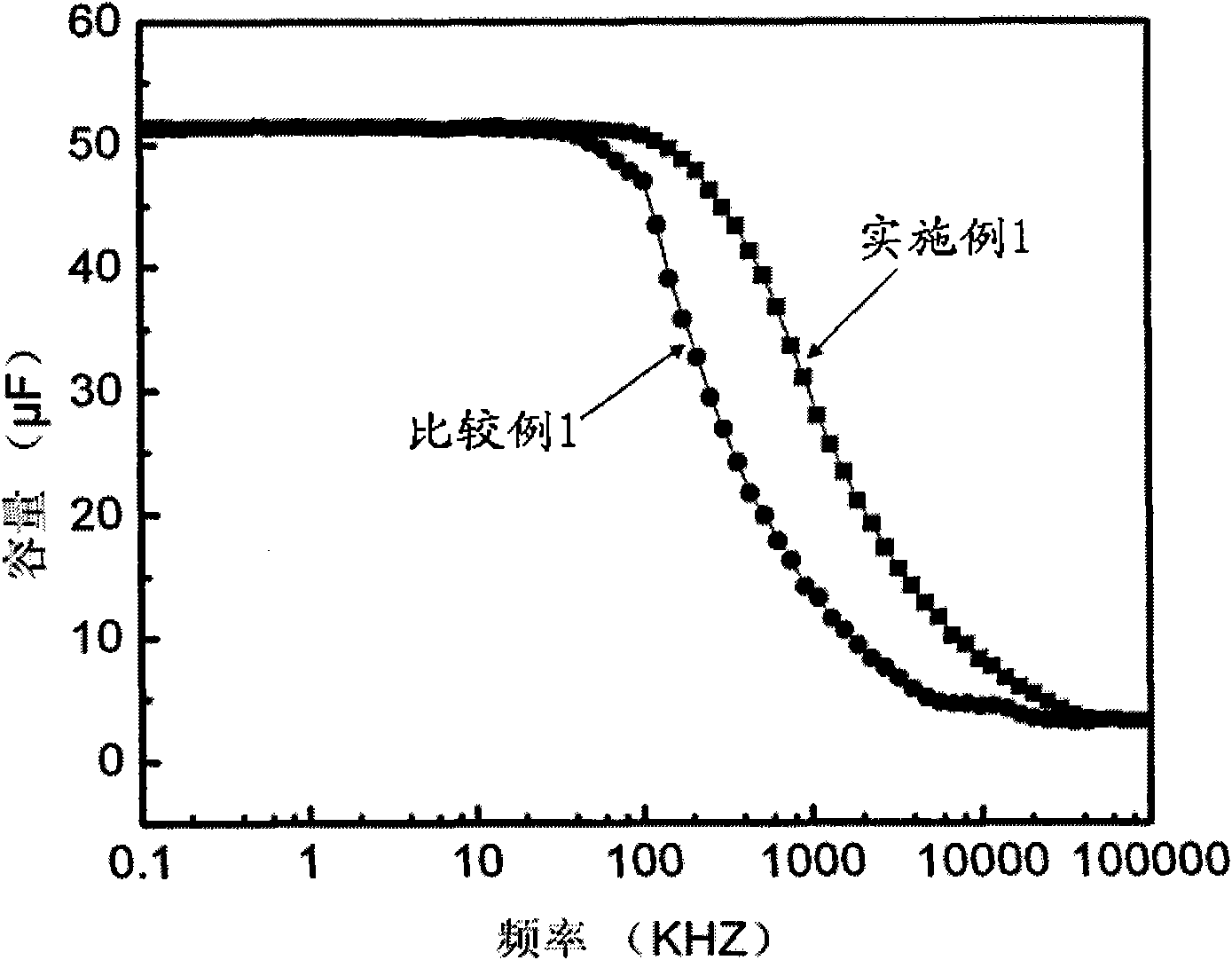

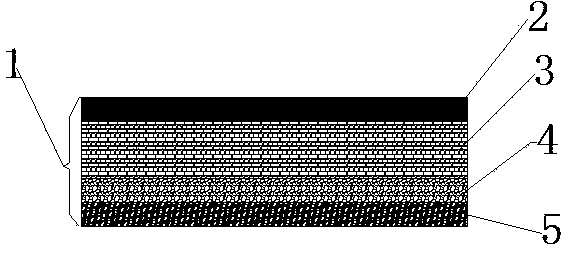

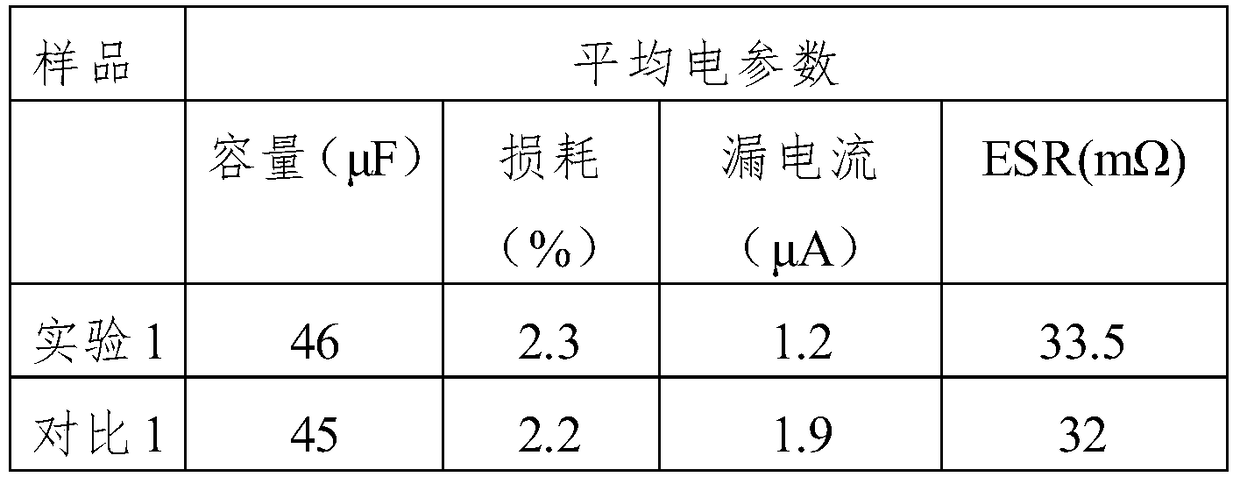

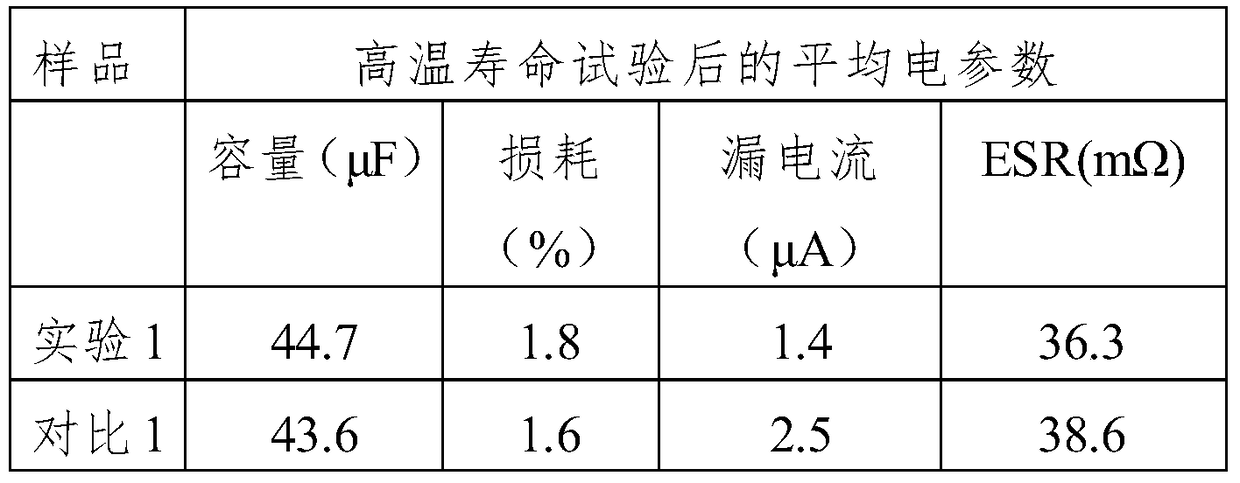

Solid tantalum electrolytic capacitor and manufacturing method thereof

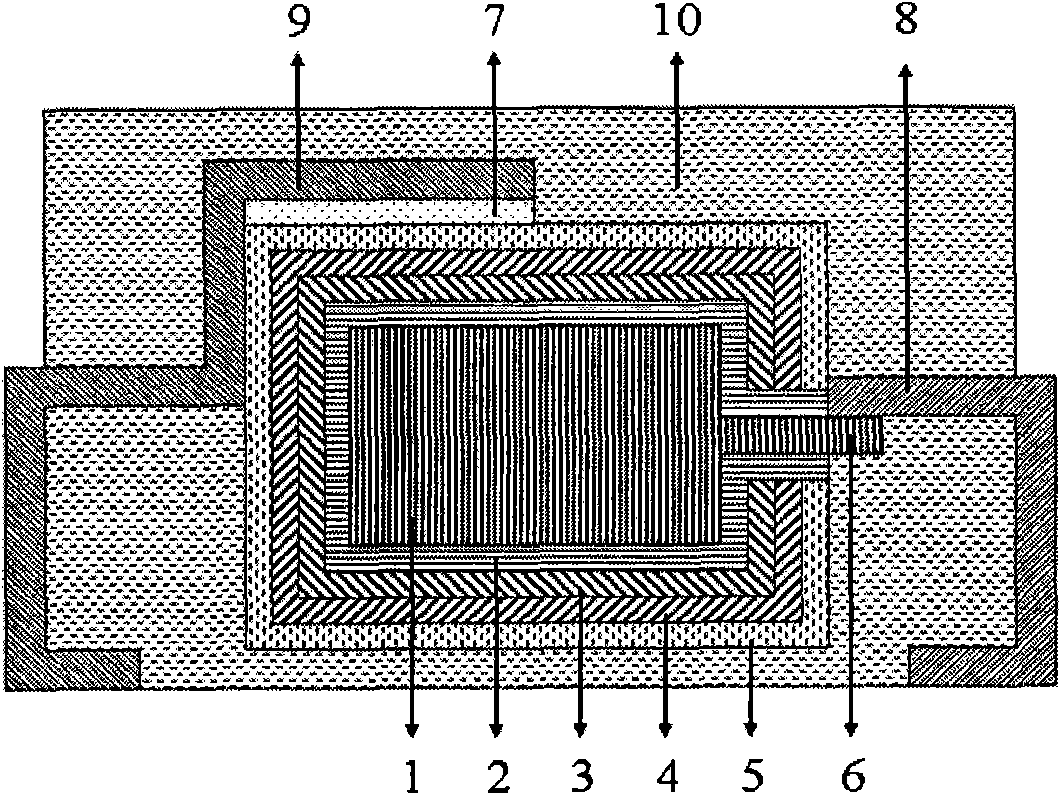

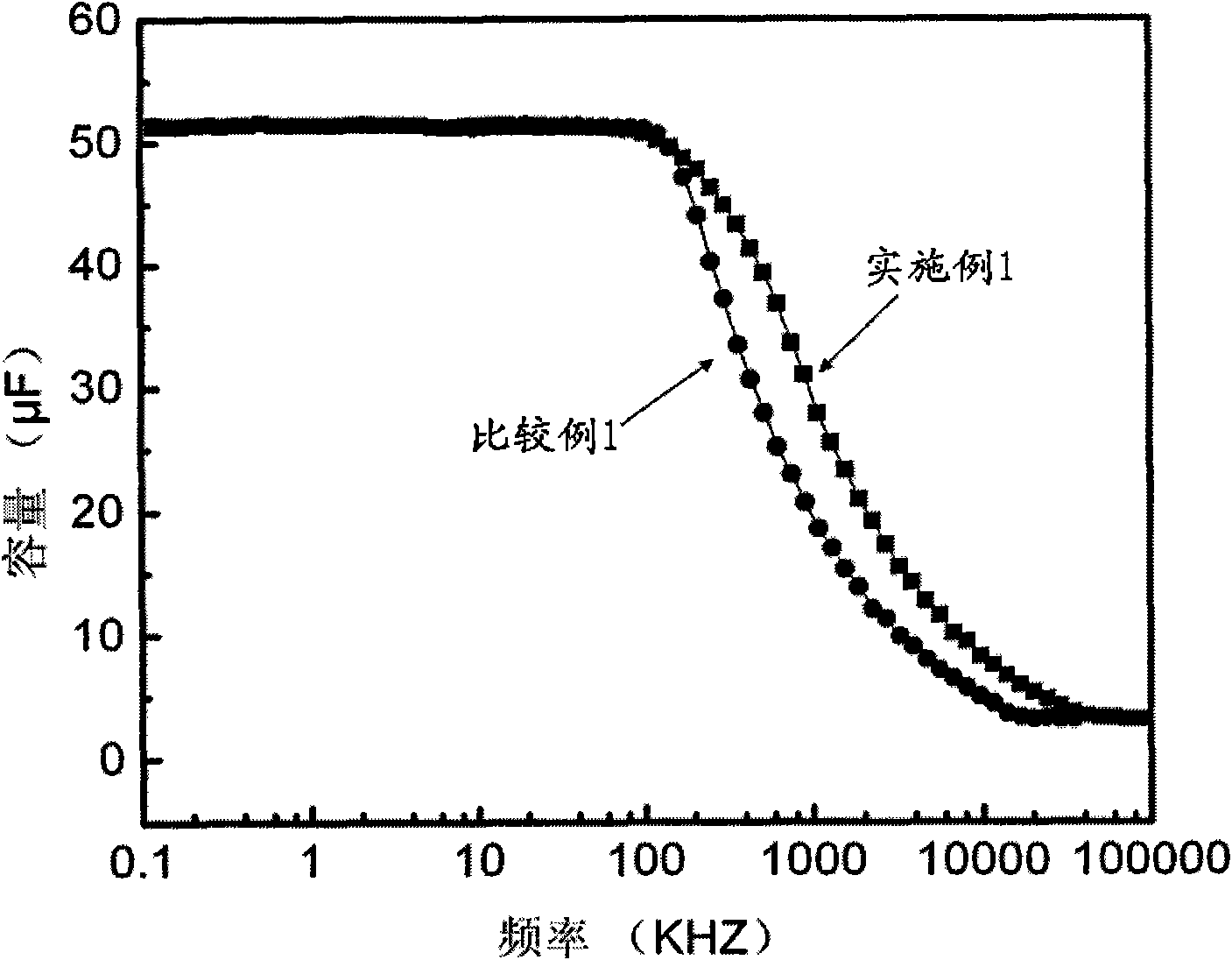

InactiveCN101923964AImprove conductivityLower equivalent series resistanceSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCarbon nanotubeHigh polymer

The invention discloses a solid tantalum electrolytic capacitor comprising a tantalum anode body, an Ra2O5 dielectric envelope, a conducting layer, a graphite layer and a silver coating, wherein the Ra2O5 dielectric envelope is positioned on the surface of the tantalum anode body, the conducting layer is positioned on the Ra2O5 dielectric envelope, and the graphite layer and the silver coating are coated on the conducting layer. The solid tantalum electrolytic capacitor is characterized in that the conducting layer is a mixed system of composite carbon nano tubes and high-polymer conducting materials, the length directions of the composite carbon nano tubes are perpendicular to the surface of the tantalum anode body, the composite carbon nano tubes are carbon nano tubes with the surfaces uniformly attached with nano particles in a shell-core structure, and the nano particles in the shell-core structure are nano particles using magnetic nano particles as cores, wherein the surfaces of the nano particles are coated with conducting shell layers. Because the directionally arranged composite carbon nano tubes are adopted in the conducting layer, the conductivity of the conducting layer is increased, and the equivalent series resistance of the capacitor is reduced, thereby the high-frequency characteristic of the capacitor is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

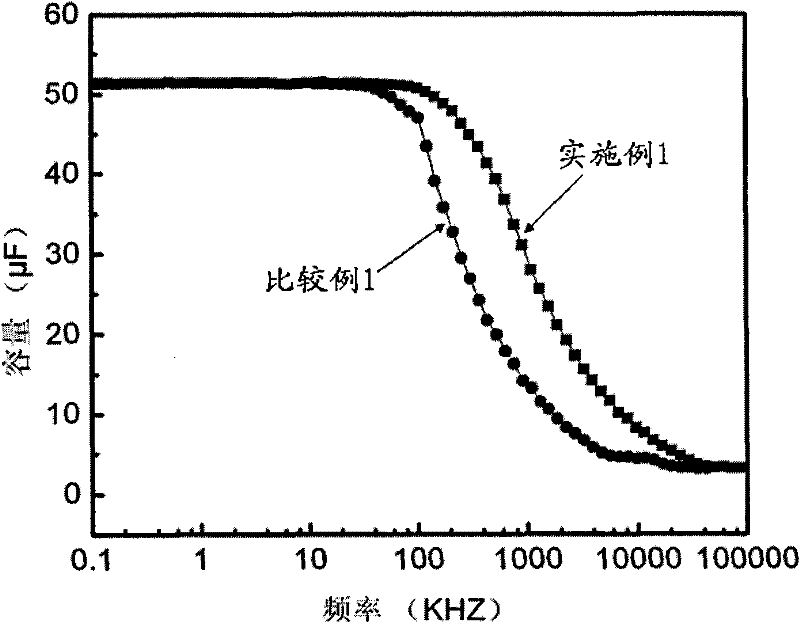

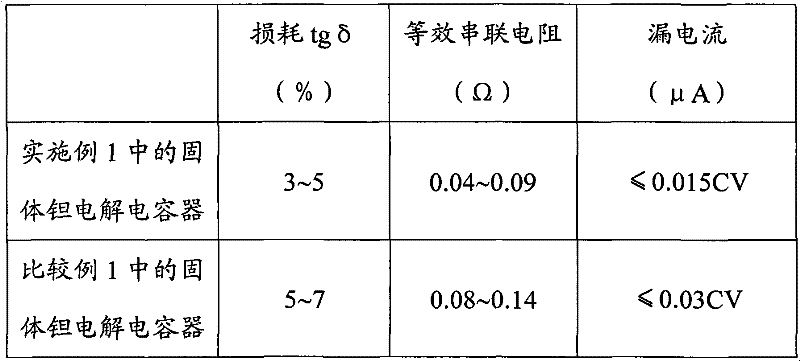

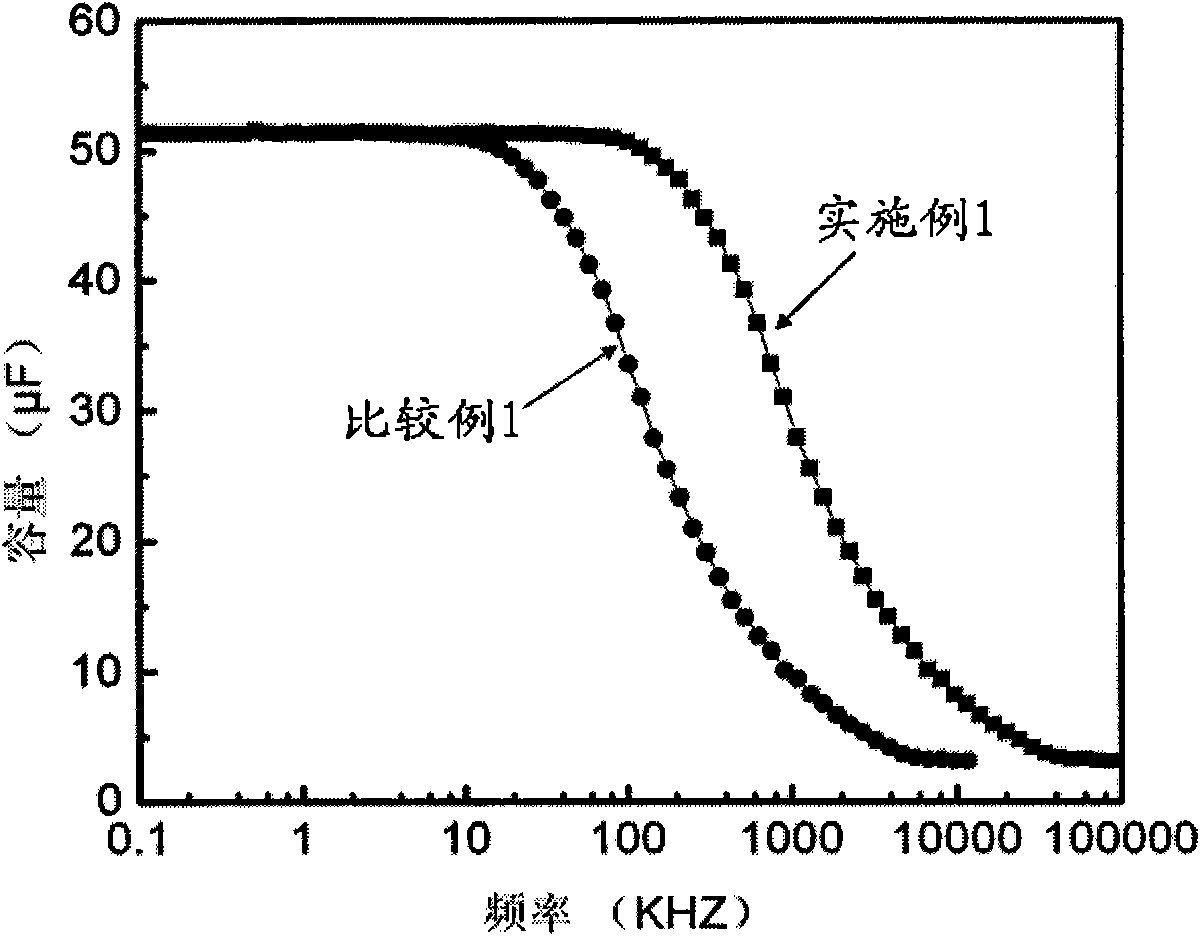

Solid tantalum electrolytic capacitor and manufacturing method thereof

InactiveCN101923967ALower equivalent series resistanceGood high frequency characteristicsSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCarbon nanotubeMagnetite Nanoparticles

The invention discloses a solid tantalum electrolytic capacitor. The capacitor comprises a tantalum anode body, a Ta2O5 dielectric envelope, a conducting layer, a graphite layer and a silver-coated layer, wherein the Ta2O5 dielectric envelope is positioned on the surface of the tantalum anode body; the conducting layer is positioned on the Ta2O5 dielectric envelope; and the graphite layer and the silver-coated layer are coated on the conducting layer. The capacitor is characterized in that: the conducting layer is a mixed system consisting of a composite carbon nano-tube and a conducting high molecular material; the composite carbon nano-tube is a carbon nano-tube of which the surface is attached to conductive nano-particles and magnetic nano-particles uniformly; and the length direction of the composite carbon nano-tube is vertical to the surface of the tantalum anode body. Directionally-arrayed composite carbon nano-tubes are adopted in the conducting layer, so that the conductivity of the conducting layer is enhanced, the equivalent series resistance of the capacitor is reduced and the high-frequency characteristic of the capacitor is improved; simultaneously, the carbon nano-tube has high thermal conductivity, so that the capacitor has higher heat resistance, the service life of the capacitor is prolonged and the leakage current is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

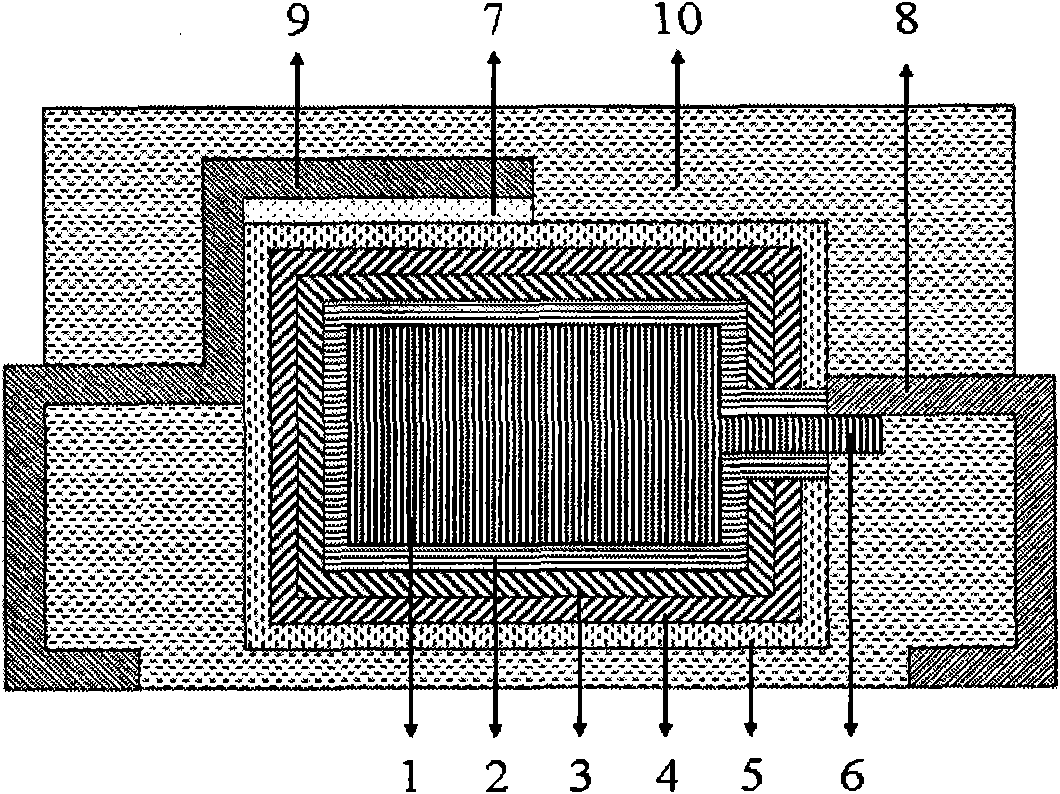

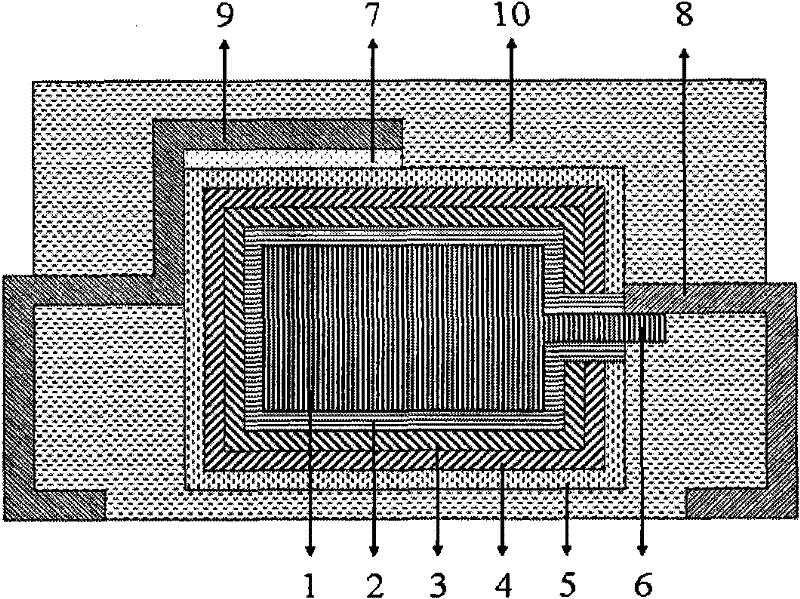

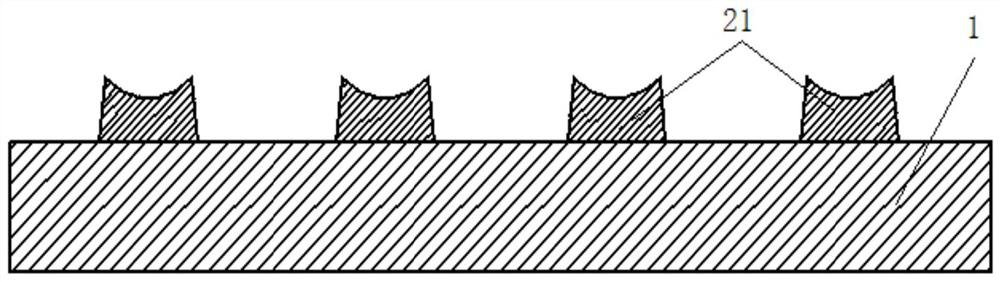

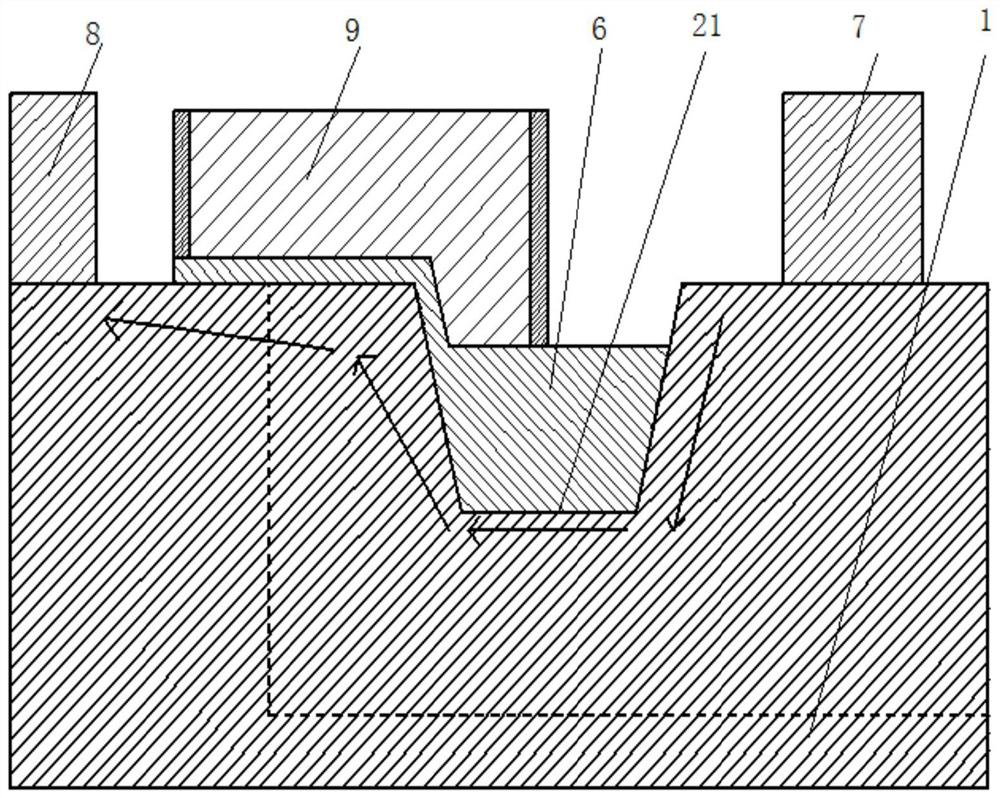

Novel silicon carbide MOSFET (Metal Oxide Semiconductor Field Effect Transistor)

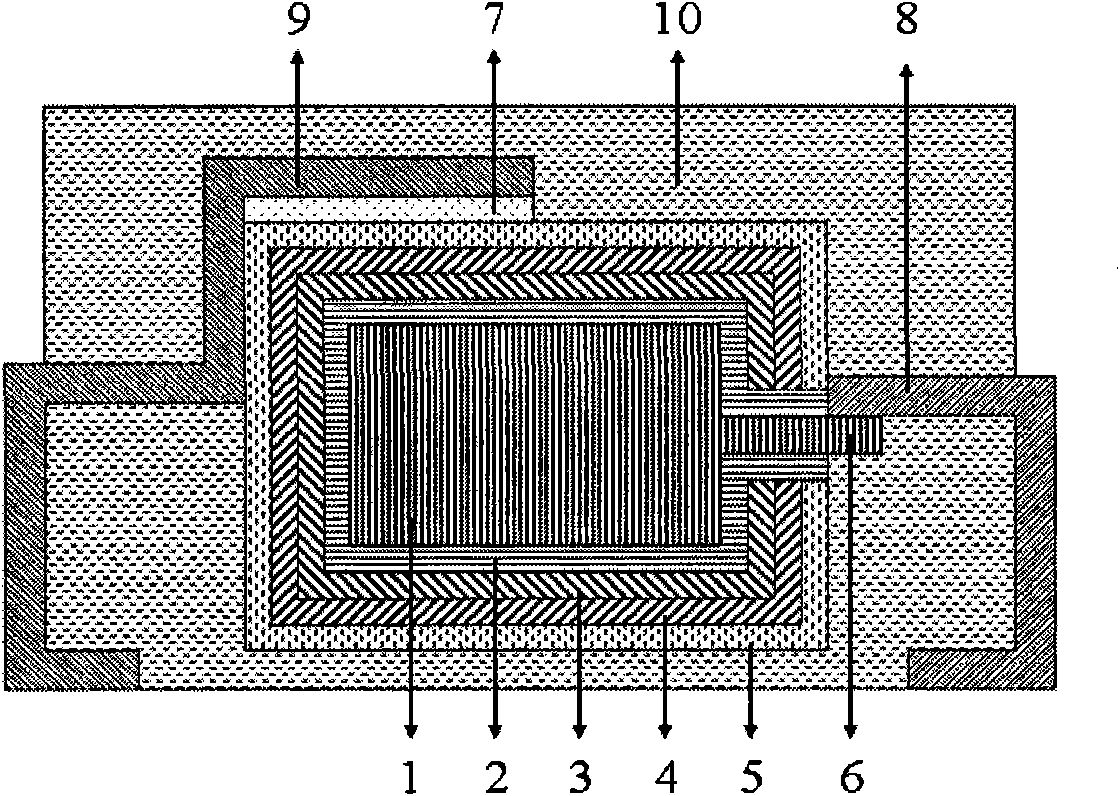

InactiveCN102544091AThe overall thickness is thinImprove the withstand voltage levelSemiconductor devicesMOSFETFrequency changer

The invention relates to a semiconductor device, and in particular discloses a novel silicon carbide MOSFET (Metal Oxide Semiconductor Field Effect Transistor) which is applied to occasions of electrical equipment such as an alternating current motor, a frequency converter, a switch power supply, traction transmission equipment and the like under high-voltage conditions. The novel silicon carbide MOSFET comprises a drain electrode (1) which is arranged at a lower end as well as a source electrode (8) and a gate electrode (9) which are arranged at an upper end, wherein a buffer region (2) and a drift region (3) are sequentially connected above the drain electrode (1), a source region (7) is arranged below the source electrode (8), a gate insulation layer (5) is arranged below the gate electrode (9), a P-type well region (6) is arranged below the source region (7), and a P-type doping region (4) is arranged below the gate insulation layer (5). According to the invention, on the basis of a common MOSFET structure, the doping region with low concentration is additionally arranged on the surface of a substrate below the gate electrode so that an electric field in the gate insulation layer is weakened when the high voltage is applied to the device, thereby lowering the breakdown probability of the insulation layer and improving the integral withstand voltage of the silicon carbide MOSFET.

Owner:ZHEJIANG UNIV

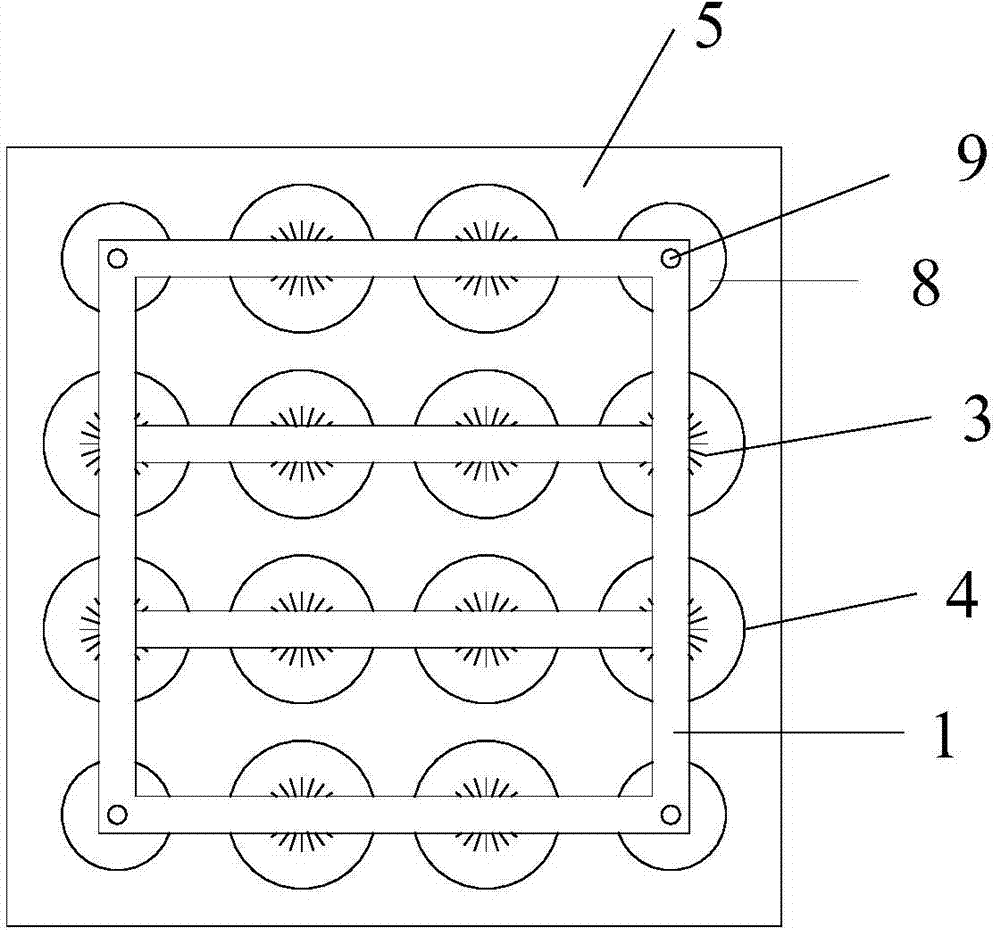

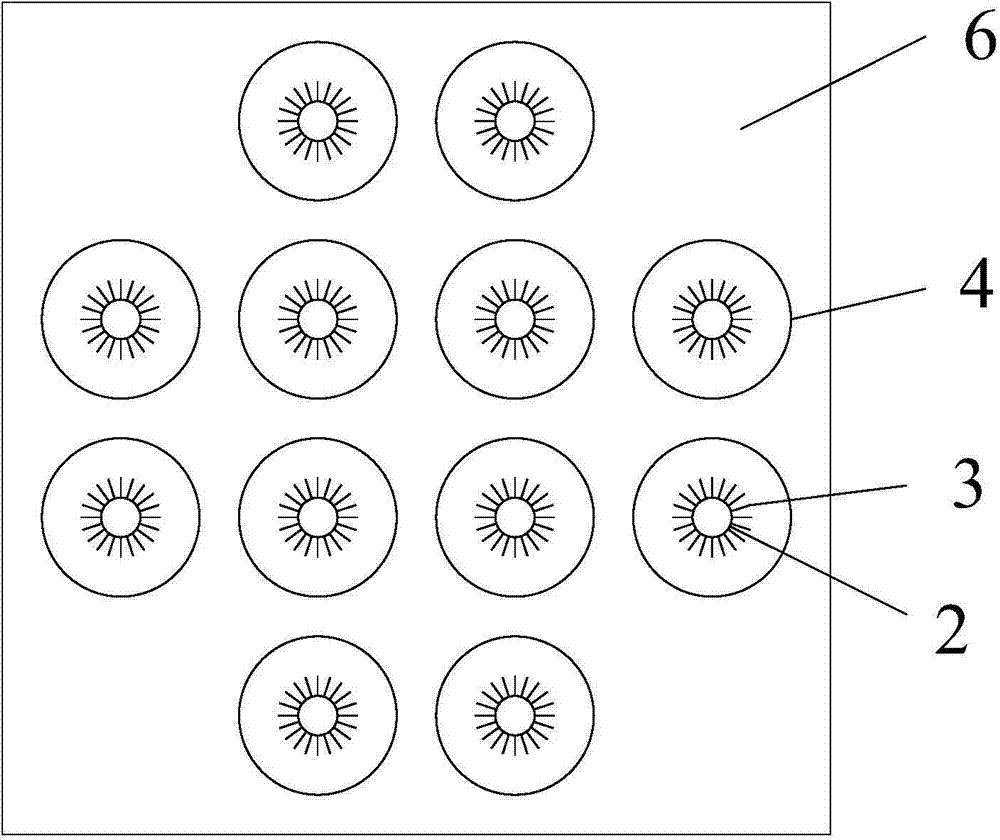

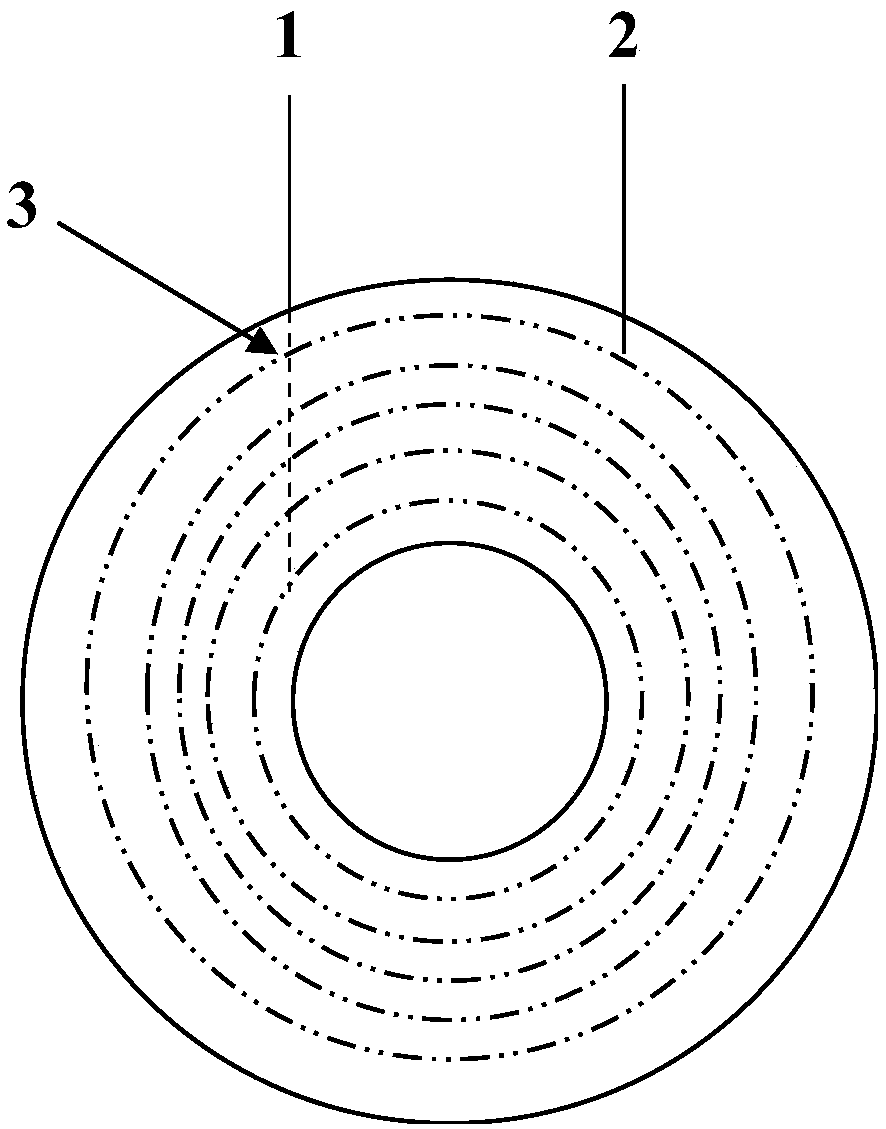

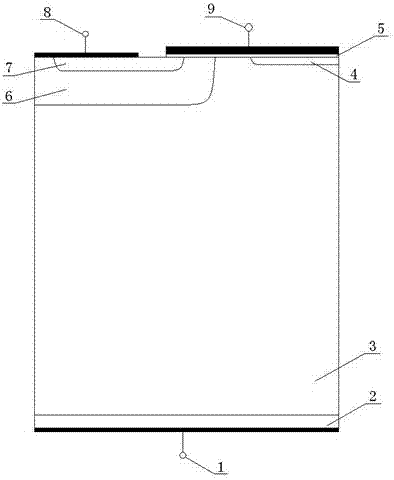

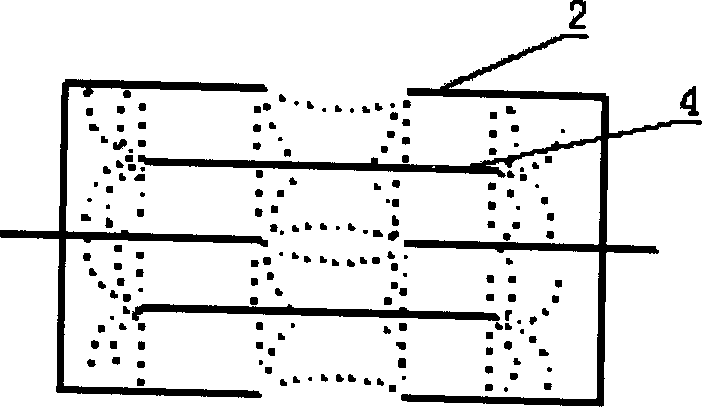

Multiple layered sheet structured ceramic capacitor in use for middle and high voltages

InactiveCN1797626AThere will be no problem of separation from each otherImprove high voltage breakdown strengthFixed capacitor electrodesFixed capacitor dielectricBreakdown strengthCeramic capacitor

Ceramic capacitor includes outer electrodes at two ends, three types of inner electrode composed of multiple plate dielectric layers. The inner electrode 1 in first type of dielectric layer is in structure: shape of inner electrode includes 2 to N pieces of rectangle arranged in distance; and external rims of inner electrodes arranged on two sides are connected to outer electrodes at two ends. The inner electrode 2 in second type of dielectric layer is in structure: shape of inner electrode includes 2 to (2N-2) pieces of loop type rectangle. The inner electrode 3 in third type of dielectric layer is in structure: shape of inner electrode includes 2 to (N-1) pieces of rectangle arranged in distance. N is natural number larger than 2. The said three kinds of dielectric layer are stacked in sequence. Comparing with prior art, the invention reduces probability of breakdown caused by distortion of edge electric field, and raises breakdown strength in high voltage.

Owner:TSINGHUA TONGFANG CO LTD

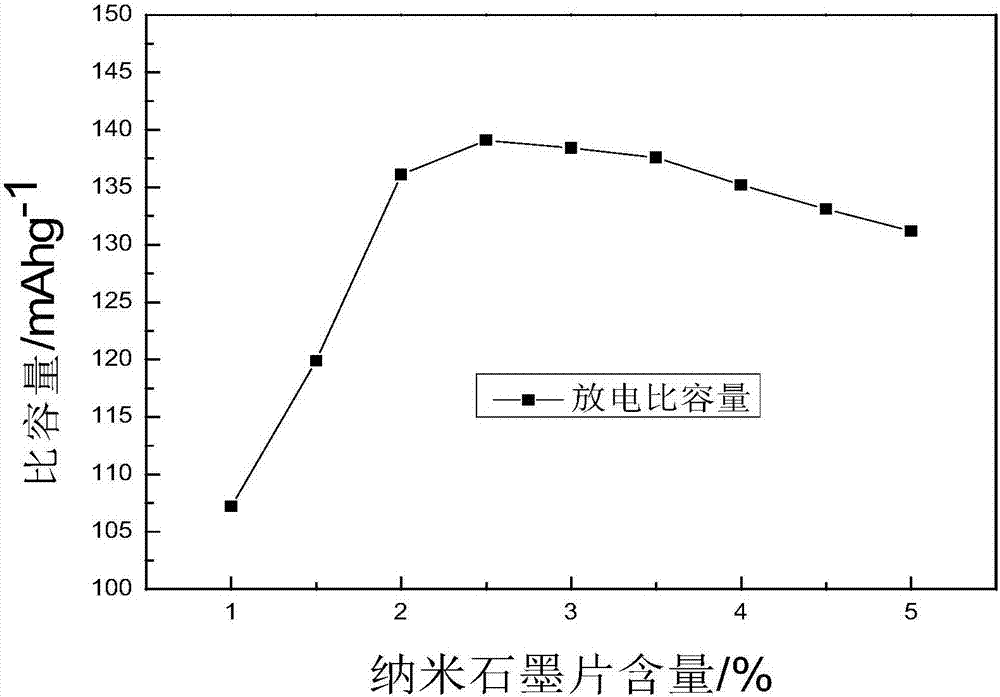

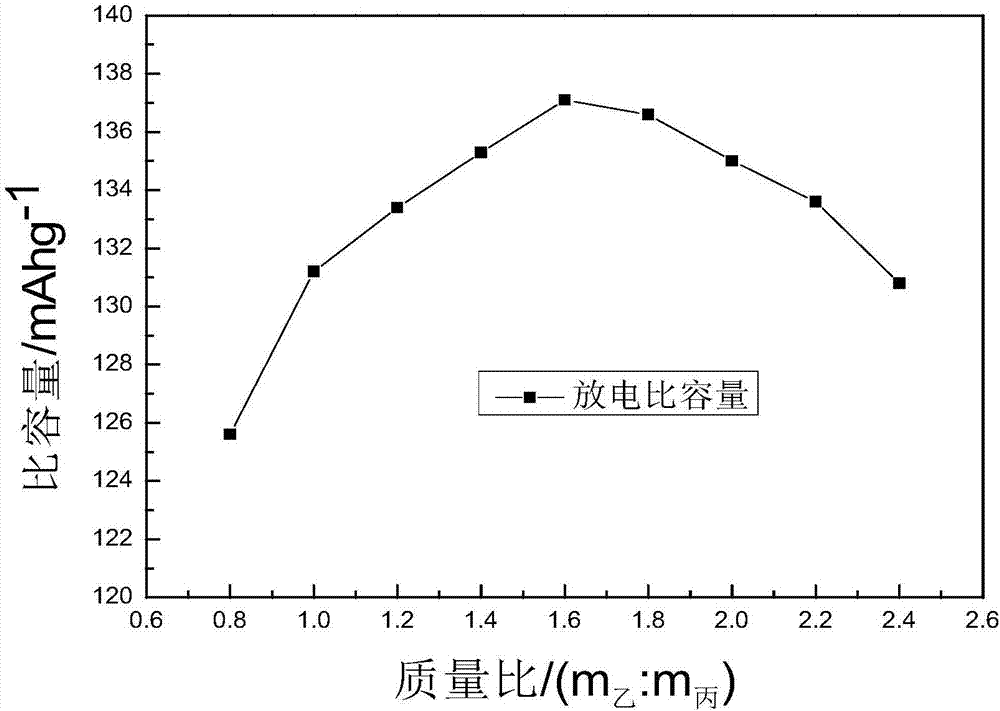

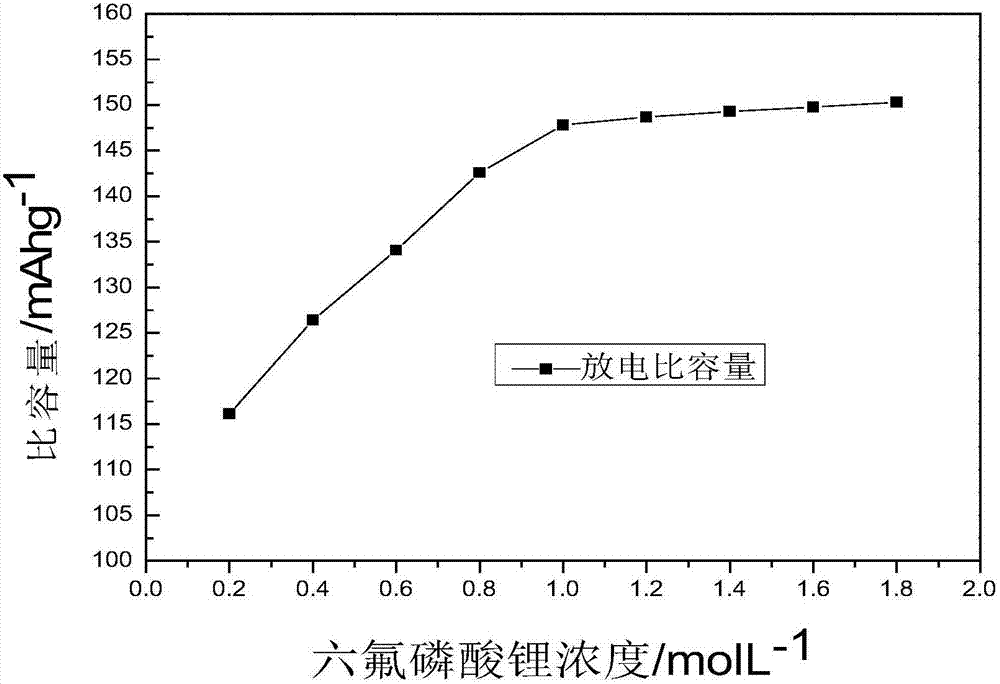

Graphene-polyaniline secondary battery and preparation method thereof

ActiveCN107293749AGood reversibilityLow thermal expansionCell seperators/membranes/diaphragms/spacersCell electrodesLithiumGlass fiber

The invention provides a graphene-polyaniline secondary battery and a preparation method thereof to overcome the technical problem that the capacity of graphite on a negative electrode is not matched with polyaniline in conventional preparation methods for lithium-polyaniline batteries. The negative electrode material of the secondary battery is a graphene or graphene oxide material; the positive electrode of the secondary battery is a polyaniline / carbon material; an electrolyte of the secondary battery is an organic solvent containing lithium hexafluorophosphate; and a diaphragm is a glass fiber diaphragm or polyethylene microporous diaphragm. The invention also provides the preparation method. The graphene-polyaniline secondary battery and the preparation method thereof are applied to the field of battery preparation.

Owner:威海天鲲新能源科技有限公司

Carbon fiber reinforced anti-corrosion PA66 (polyamide 66)/PP (propene polymer) electric power fitting material and preparation method thereof

InactiveCN106497040AHigh phosphorus contentImprove flame retardant performanceCoatingsCarbon fibersOctene

The invention discloses a carbon fiber reinforced anti-corrosion PA66 (polyamide 66) / PP (propene polymer) electric power fitting material and a preparation process thereof. The carbon fiber reinforced anti-corrosion PA66 / PP electric power fitting material and the preparation process thereof are characterized by using PA66, carbon fibers, glass fibers, PP, melamine cyanurate, zinc borate, aluminum hypophosphite, bamboo charcoal, silicon rubber, waterborne polyurethane, maleic anhydride grafted polypropylene, a bovine serum albumin solution, potassium hexatitanate whiskers, graphene oxide, multiwalled carbon nanotubes, epoxy resin, hollow glass beads, dibutyl phthalate, dimethyl silicone oil, polyamide, ethylene-octene copolymer-grafted-maleic anhydride, epoxy resin, guar gum, diethylenetriamine, petroleum pitch, silica sol, sodium silicate and the like as raw material. The preparation process of the carbon fiber reinforced anti-corrosion PA66 / PP electric power fitting material uses the zinc borate to wrap the melamine cyanurate so as to obtain composite flame retardant, uses bovine serum albumin to modify surfaces of glass fibers, prepares a graphite oxide-coated glass fiber composite by adopting an electrostatic adsorption principle, obtains the carbon fiber reinforced PA66 having excellent mechanical performance, self-lubrication performance and conductivity, and obtains the carbon fiber reinforced anti-corrosion PA66 / PP electric power fitting material.

Owner:马鞍山市华能电力线路器材有限责任公司

Chip aluminum electrolytic capacitor

ActiveCN109448994AReduce evaporation rateReduce the chance of breakdownLiquid electrolytic capacitorsCapacitor electrolytes/absorbentsSteam pressureTemperature resistance

The invention discloses a chip aluminum electrolytic capacitor. The chip aluminum electrolytic capacitor comprises a shell provided with an opening; a core bag is arranged in the shell; an electrolyteis immersed in the core bag; the core bag comprises stacked cathode foil and anode foil; electrolytic paper serving as substrates is arranged on the same sides of the cathode foil and the anode foil;a flash voltage of the electrolyte is higher than 300V, and the temperature resistance of the electrolyte reaches 125 DEG C; the tightness of the electrolytic paper is not less than 0.60g / cm<3>; theanode foil and the cathode foil adopt aluminum foils with high cubic structures; and the content of the cubic structures is more than 80%. According to the chip aluminum electrolytic capacitor, the electrolyte can ensure the flash voltage and obtain relatively high electrical conductivity; the voltage resistance and the high temperature resistance of the capacitor can be improved; the volatilization speed of the electrolyte during high-temperature working can be reduced; the saturated steam pressure can be reduced; the high-voltage resistance and the high-temperature resistance of the aluminumelectrolytic capacitor are improved; the probability that the capacitor is broken down is effectively reduced; and the stability and reliability of a product are improved.

Owner:ZHAOQING BERYL ELECTRONICS TECH

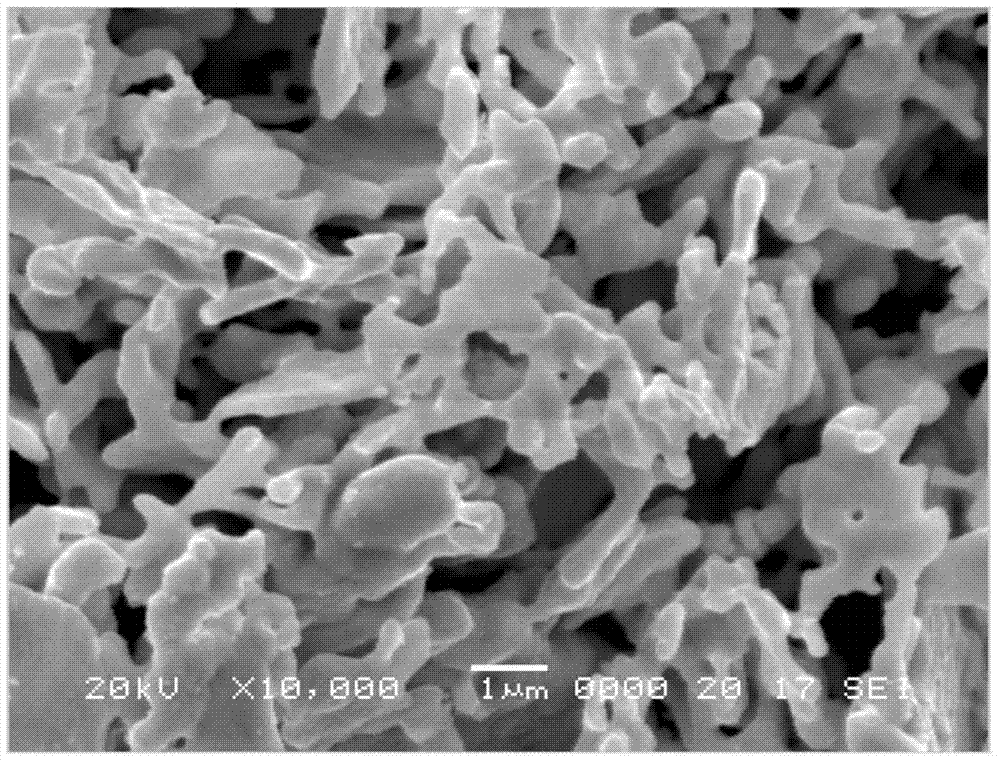

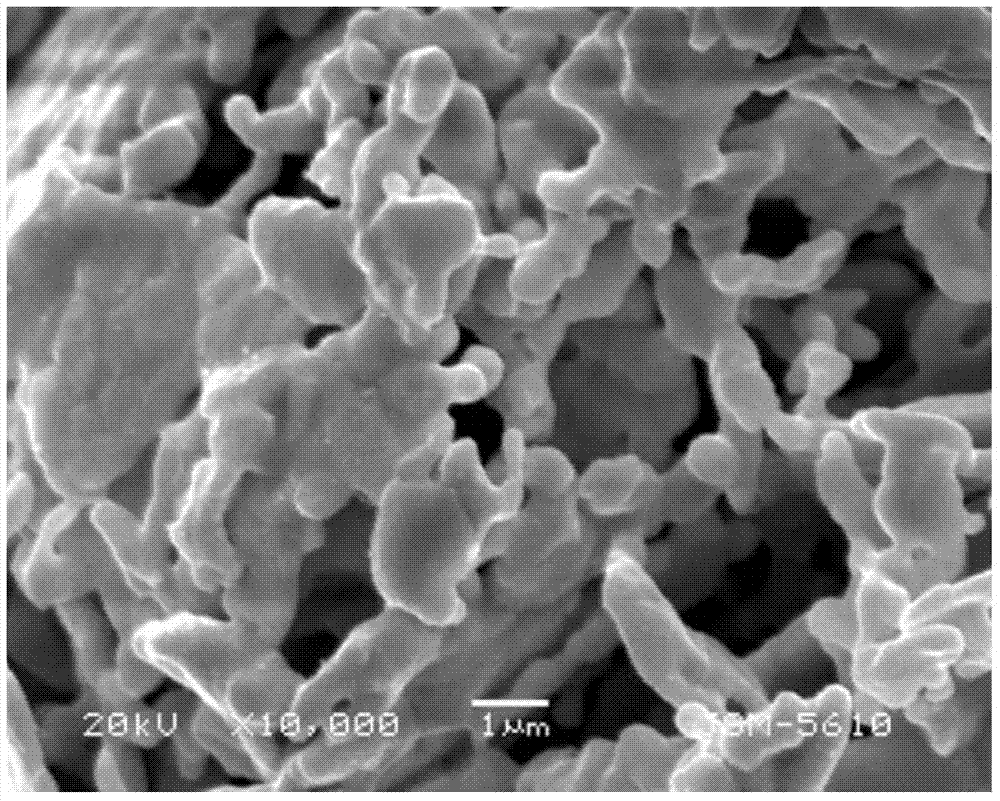

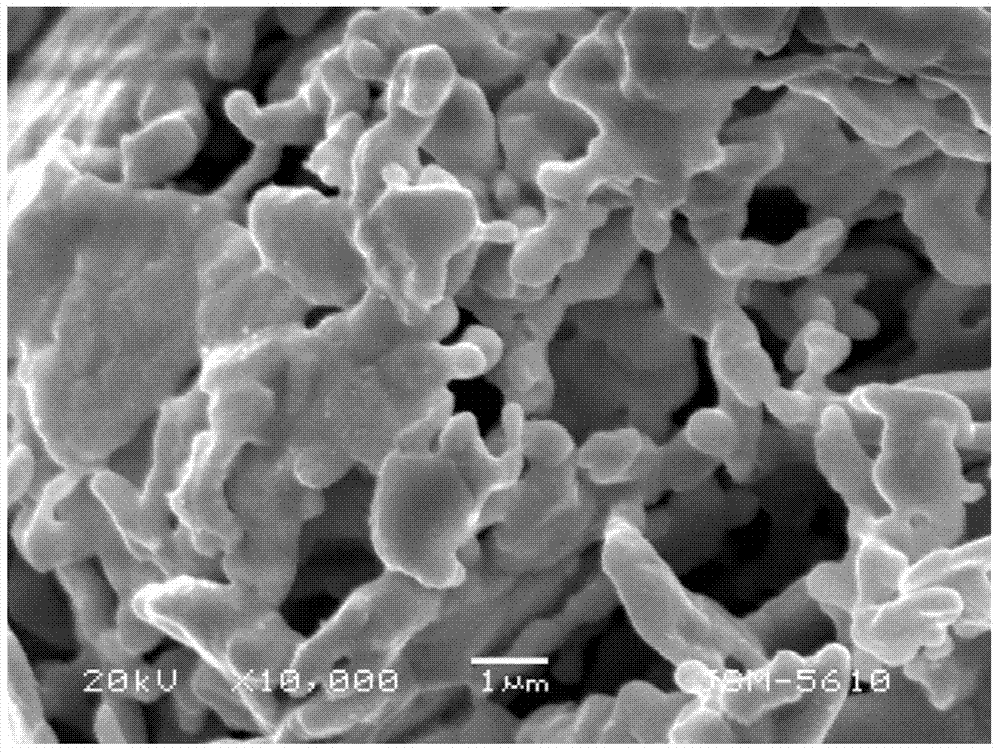

Method for preparing medium-voltage tantalum powder with improved voltage resisting performance

The invention relates to a method for preparing medium-voltage tantalum powder with the improved voltage resisting performance and tantalum powder prepared with the method. The technical scheme that oxygen reduction is carried out after twice heating treatment, the third heating treatment is carried out and the oxygen reduction is performed finally is introduced to the method for preparing the medium-voltage tantalum powder with the improved voltage resisting performance. The oxygen content is controlled, the particle morphology of the tantalum powder is improved, the breakdown resisting performance of a product is improved, leaked currents are modified, and the method for preparing the medium-voltage tantalum powder with the improved voltage resisting performance is applicable to preparing of the medium-voltage tantalum powder with the specific volume ranging from 15000 micron FV per gram and 50000 micron FV per gram.

Owner:NINGXIA ORIENT TANTALUM IND +1

Solid tantalum electrolytic capacitor and manufacturing method thereof

InactiveCN101923964BGood high frequency characteristicsImprove heat resistanceSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCarbon nanotubeMagnetite Nanoparticles

The invention discloses a solid tantalum electrolytic capacitor comprising a tantalum anode body, an Ta2O5 dielectric envelope, a conducting layer, a graphite layer and a silver coating, wherein the Ta2O5 dielectric envelope is positioned on the surface of the tantalum anode body, the conducting layer is positioned on the Ra2O5 dielectric envelope, and the graphite layer and the silver coating are coated on the conducting layer. The solid tantalum electrolytic capacitor is characterized in that the conducting layer is a mixed system of composite carbon nano tubes and high-polymer conducting materials, the length directions of the composite carbon nano tubes are perpendicular to the surface of the tantalum anode body, the composite carbon nano tubes are carbon nano tubes with the surfaces uniformly attached with nano particles in a shell-core structure, and the nano particles in the shell-core structure are nano particles using magnetic nano particles as cores, wherein the surfaces of the nano particles are coated with conducting shell layers. Because the directionally arranged composite carbon nano tubes are adopted in the conducting layer, the conductivity of the conducting layer is increased, and the equivalent series resistance of the capacitor is reduced, thereby the high-frequency characteristic of the capacitor is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Solid tantalum electrolytic capacitor and manufacturing method thereof

InactiveCN101923965ALower equivalent series resistanceGood high frequency characteristicsSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCarbon nanotubeAluminum electrolytic capacitor

The invention discloses a solid tantalum electrolytic capacitor comprising a tantalum anode body, a Ta2O5 dielectric envelope, a conducting layer, a graphite layer and a silver coating, wherein the Ta2O5 dielectric envelope is positioned on the surface of the tantalum anode body, the conducting layer is positioned on the Ta2O5 dielectric envelope, and the graphite layer and the silver coating are coated on the conducting layer. The solid tantalum electrolytic capacitor is characterized in that the conducting layer is a high-polymer conducting layer doped with magnetic carbon nano tubes, wherein the length directions of the magnetic carbon nano tubes are perpendicular to the surface of the tantalum anode body. Because the directionally arranged magnetic carbon nano tubes are adopted in the conducting layer, the conductivity of the conducting layer is increased, the equivalent series resistance of the capacitor is reduced so that the high-frequency characteristic of the capacitor is improved, and meanwhile, because the carbon nano tubes have excellent thermal conductivity, the capacitor has higher thermal resistance, prolonged service life, and reduced leakage current.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Insulating gloves

InactiveCN103445346AReduce the chance of breakdownAvoid LeakageProtective garmentEngineeringElectrical and Electronics engineering

The invention discloses a pair of insulating gloves. Each insulating glove comprises a glove main body, insulating plastic, a waterproof layer, a void-free epoxy glass cloth laminated insulating layer, a drying layer and a moisture absorption layer. Each glove main body comprises the corresponding moisture absorption layer, the corresponding drying layer, the corresponding void-free epoxy glass cloth laminated insulating layer and the corresponding insulating plastic in sequence from inside to outside. Each void-free epoxy glass cloth laminated insulating layer is packaged by waterproof cloth in a sealing manner, and is formed by overlapping and compressing multiple layers of epoxy glass cloth. The insulating plastic is made from electrical insulation plastic. Each moisture absorption layer is used for absorbing moisture on the inner surface of the corresponding glove and transferring the moisture to the corresponding drying layer which is internally provided with a desiccant. By adopting the mode, the pair of insulating gloves disclosed by the invention has the functions of moisture absorption and electrical insulation.

Owner:苏州艺汇纺织有限公司

A method of manufacturing a high-reliability electrolytic capacitor

ActiveCN105489376BGuaranteed thicknessInhibit swellingSurface reaction electrolytic coatingCapacitor dielectric layersElectrolysisElectrolytic capacitor

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Novel capacitor

InactiveCN105206425APromotes self-healingGood security protection levelMultiple fixed capacitorsFixed capacitor electrodesElectricityCapacitor

The invention discloses a novel capacitor. The novel capacitor comprises a shell, the upper end of the shell is provided with a first left pin, a second left pin, a first right pin and a second right pin which are independently insulated. A vertical hollow mandrel is arranged in the shell and made of plastics and other insulating materials. A first metallized film is wound on the mandrel. The first left pin is electrically connected to the upper end of the first metallized film through a connection line. The second left pin is electrically connected to the lower end of the first metallized film through a connection line penetrating through the mandrel, that is, the first metallized film, the first left pin electrically connected with the first metallized film and the second left pin form a first independent capacitor body. The capacitor has the advantages of being low in cost, little in loss, good in self-healing performance, long in service life, high in safety protection level and the like.

Owner:CHONGQING ZEQINGJU SCI & TECH DEV

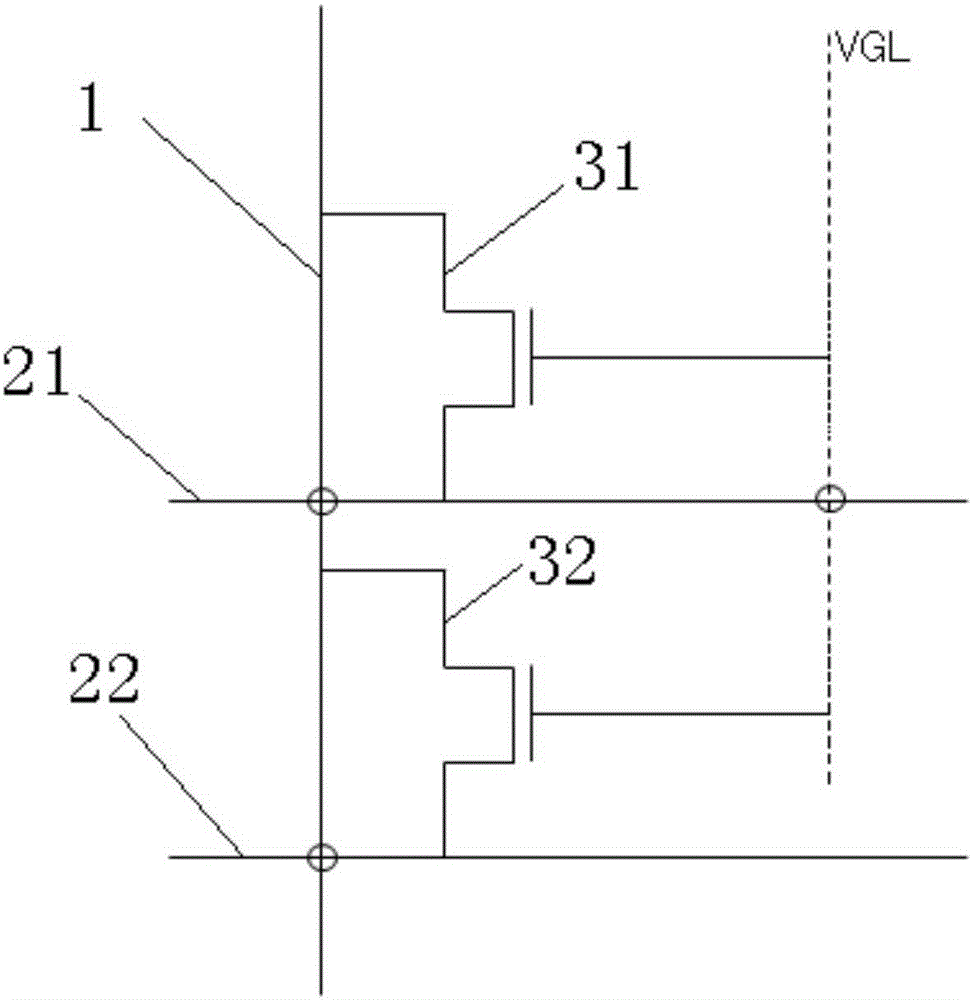

ESD protecting unit, array base plate, liquid crystal display panel and display device

ActiveCN105204257AImprove protectionReduce differential pressureTransistorSolid-state devicesLiquid-crystal displayEngineering

The invention discloses an ESD (Electronic Static Discharge) protecting unit, an array base plate, a liquid crystal display panel and a display device and belongs to the technical field of liquid crystal display. The invention aims to solve the problem of poor ESD protecting effect during a preparation process of the array base plate. The ESD protecting unit comprises a thin film transistor, a gate line and a data line, wherein a grid electrode of the thin film transistor is exposed in an area formed by the data line and the gate line; a source electrode of the thin film transistor is connected with the data line; a drain electrode of the thin film transistor is connected with the gate line; or the source electrode of the thin film transistor is connected with the gate line and the drain electrode of the thin film transistor is connected with the data line. The liquid crystal display panel comprises the array base plate containing the ESD protecting unit, wherein the drain electrode of the thin film transistor is connected with a direct current negative voltage source in each ESD protecting unit. The ESD protecting unit provided by the invention is applicable to the display device.

Owner:BOE TECH GRP CO LTD

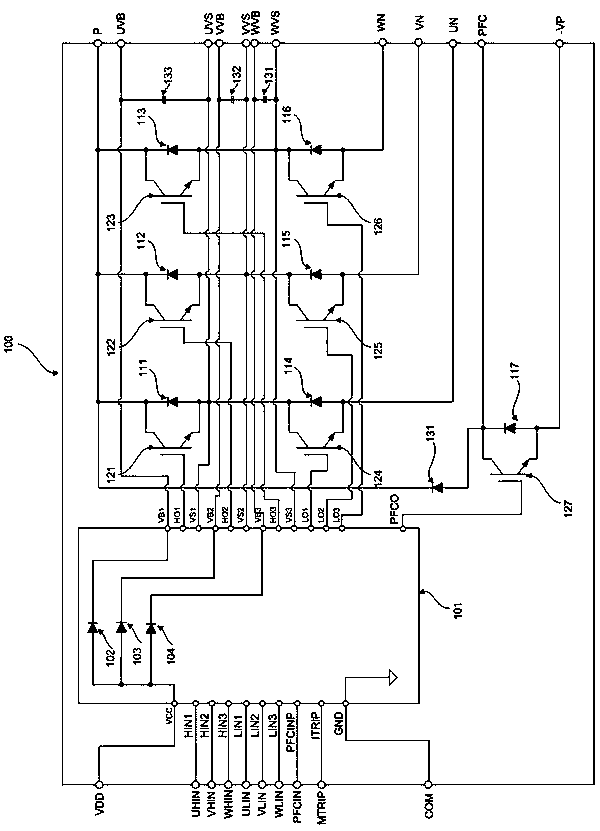

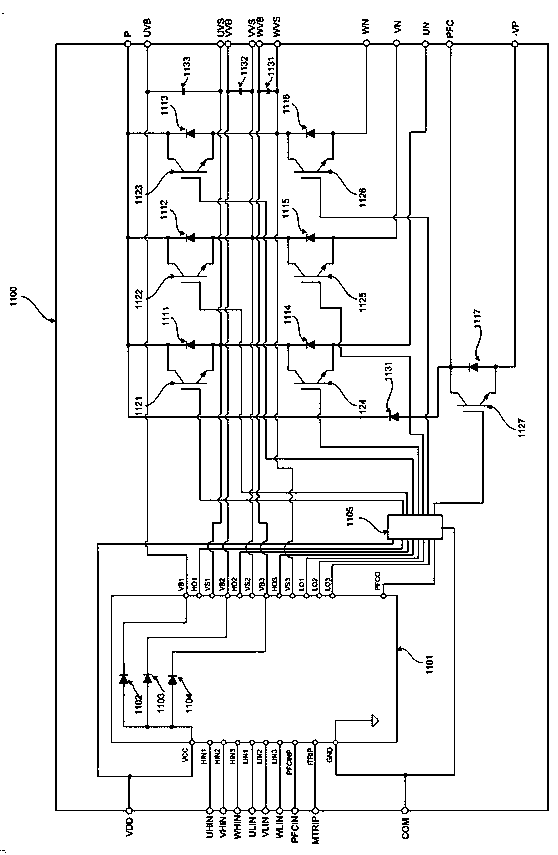

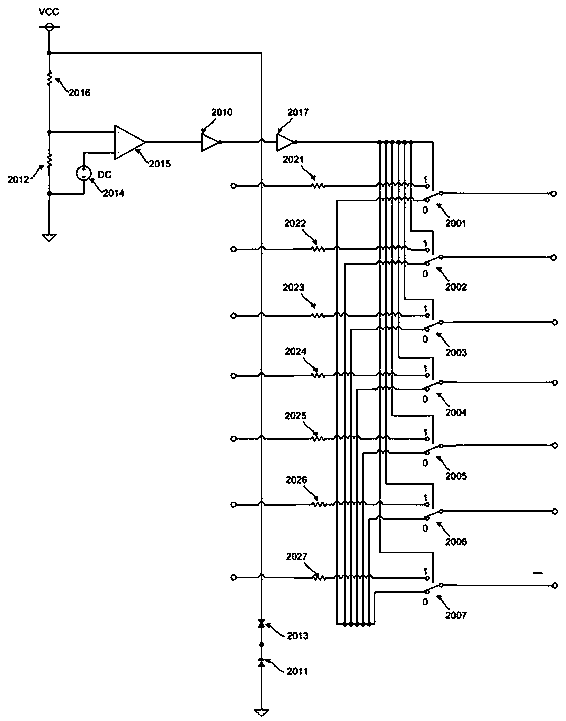

An Adaptive Antistatic Enhanced Intelligent Power Module

ActiveCN105896954BReduce the chance of breakdownGuaranteed qualityPower conversion systemsElectricityComputer module

The invention discloses an adaptive antistatic property-enhanced intelligent power module. An HO1 end, an HO2 end, an HO3 end, an LO1 end, an LO2 end, an LO3 end and a PFCO end of an HVIC tube are connected with a first input end, a second input end, a third input end, a fourth input end, a fifth input end, a sixth input end and a seventh input end of an adaptive circuit respectively; a first output end, a second output end, a third output end, a fourth output end, a fifth output end, a sixth output end and a seventh output end of the adaptive circuit are connected with gates of various IGBT tubes respectively; and diodes which are connected with a power supply end and a GND end respectively are arranged in the adaptive circuit. When the adaptive antistatic property-enhanced intelligent power module is not powered on, the gates of the IGBT tubes have electric connection, so that direct voltage impacts on the gates are reduced; the antistatic capacity of the gates of the IGBT tubes is improved; and the probability that the intelligent power module is broken down by static electricity is reduced.

Owner:SHENZHEN XIN YUPENG ELECTRONICS TECH CO LTD

Semiconductor device and forming method thereof

PendingCN111755515AAdapt to different usage scenariosImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

The invention provides a semiconductor device and a forming method thereof, and the method comprises the following steps: providing a substrate, and forming a first sub-fin part after removing a partof fin parts in thickness on the substrate; adjusting the end, away from the substrate, of the first sub-fin part to enable S1 to be greater than or equal to S2, wherein S1 is the distance from the middle area of the end face of one end of the first sub-fin part to the substrate, and S2 is the distance from the edge area of the end face of the first sub-fin part to the substrate, and in a cross section formed perpendicular to the length direction of the first sub-fin part, the contour line of one side, far away from the substrate, of the first sub-fin part is in smooth transition. The semiconductor device is manufactured through the forming method of the semiconductor device. The distance from the middle area of the end face of one end of the first sub-fin part to the substrate is greaterthan or equal to the distance from the edge area of the first sub-fin part to the substrate, the contour line of the side, away from the substrate, of the first sub-fin part is in smooth transition, the probability that the bottom area of the first sub-fin part is broken down by voltage can be reduced, and therefore the performance of the semiconductor device is optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A Chip Type Aluminum Electrolytic Capacitor

ActiveCN109448995BReduce evaporation rateReduce the chance of breakdownLiquid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolytic agentElectric conductance

Owner:江华绿宝石新能源储能科技有限公司

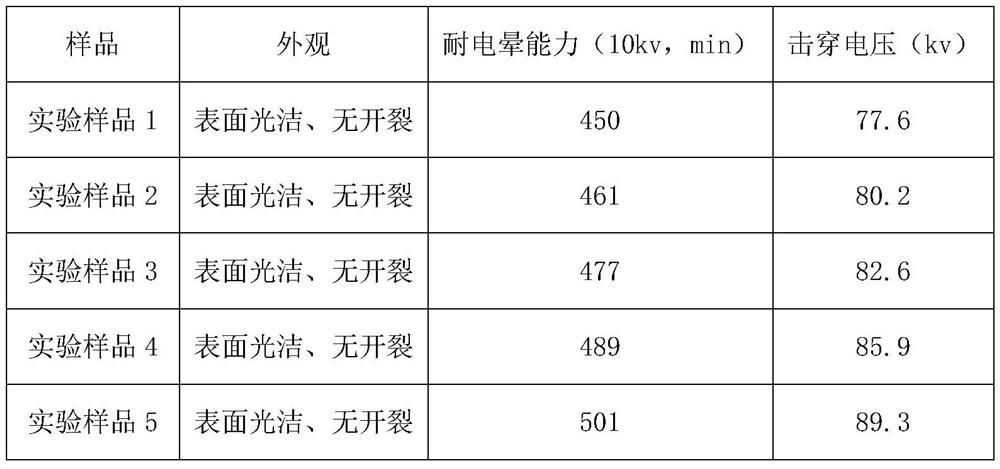

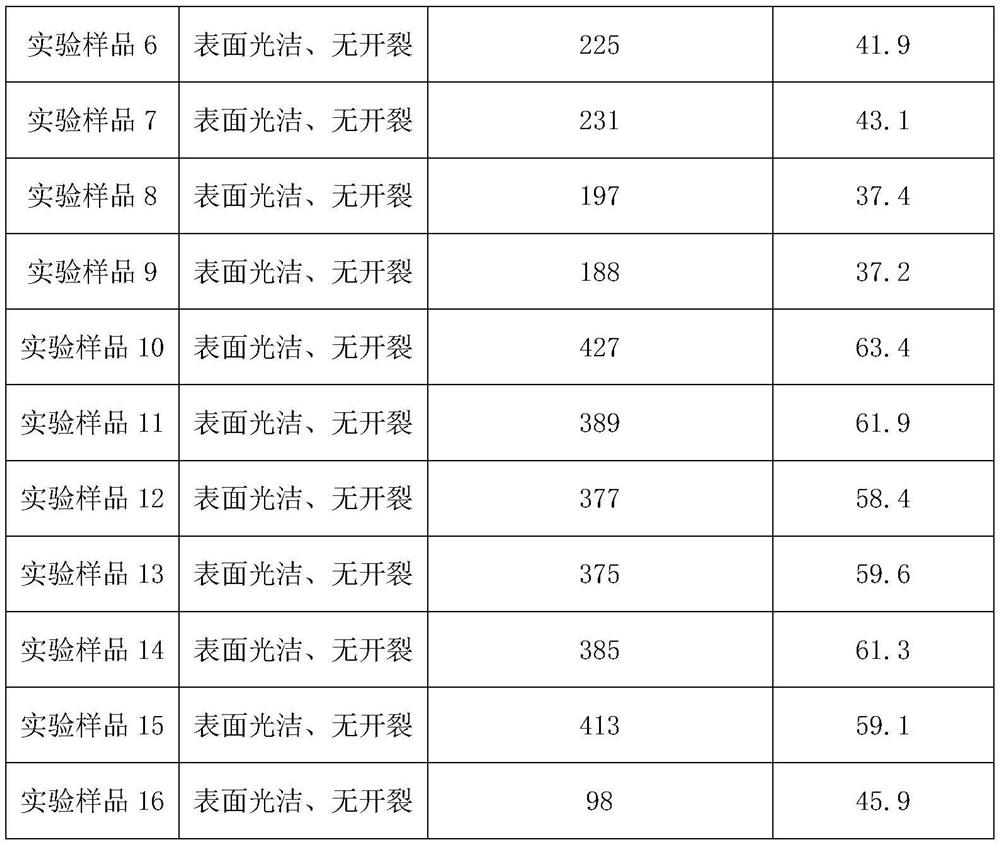

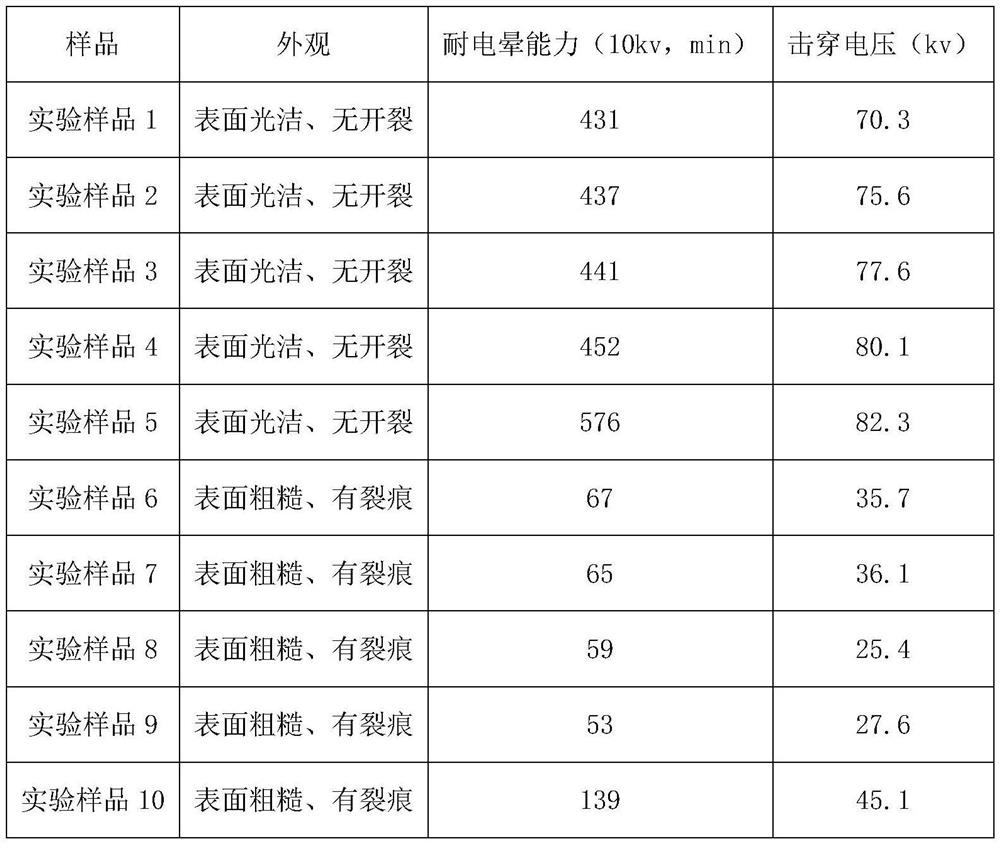

Corona-resistant cable and preparation method thereof

InactiveCN112102991AImprove corona resistanceImprove antioxidant capacityPlastic/resin/waxes insulatorsInsulated cablesRubber materialFiber

The invention provides a corona-resistant cable and a preparation method thereof, and particularly relates to the technical field of cable materials. Corona-resistant paint obtained by polymerizing acrylic resin, dragon's blood extract and porphyrin compounds is dip-coated on the surface of a wire, and then dry ice powder is sprayed to reinforce the paint dip-coated on the wire. And then the wireis coated with a composite rubber material prepared from enzymolysis carbonate, guayule rubber, carbon aerogel mixing, peanut shell fiber extraction and zirconium oxide, and then coated with an outerprotective layer, so as to prepare the corona-resistant cable. The cable has good corona resistance, oxidation resistance, acid resistance and mechanical strength, the corona resistance can be as longas 450 minutes, the cable still has high corona resistance after being tested for 7 days in high-temperature, high-humidity, oxidizing and acid environments, and the cracking phenomenon does not occur; meanwhile, the insulating property is good, and breakdown is not likely to happen. The method is stable in process, controllable in parameter, easy to repeat and suitable for large-scale production.

Owner:广西昌用电线电缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com