An Adaptive Antistatic Enhanced Intelligent Power Module

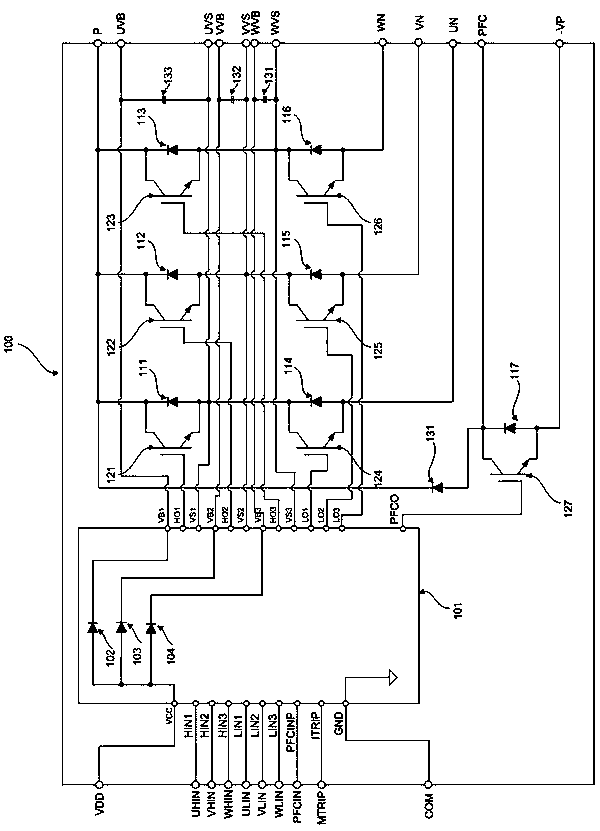

An intelligent power module and adaptive circuit technology, which is applied to output power conversion devices, electrical components, etc., can solve problems such as overheating and burning, the intelligent power module 100 being vulnerable to static electricity threats, and fires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

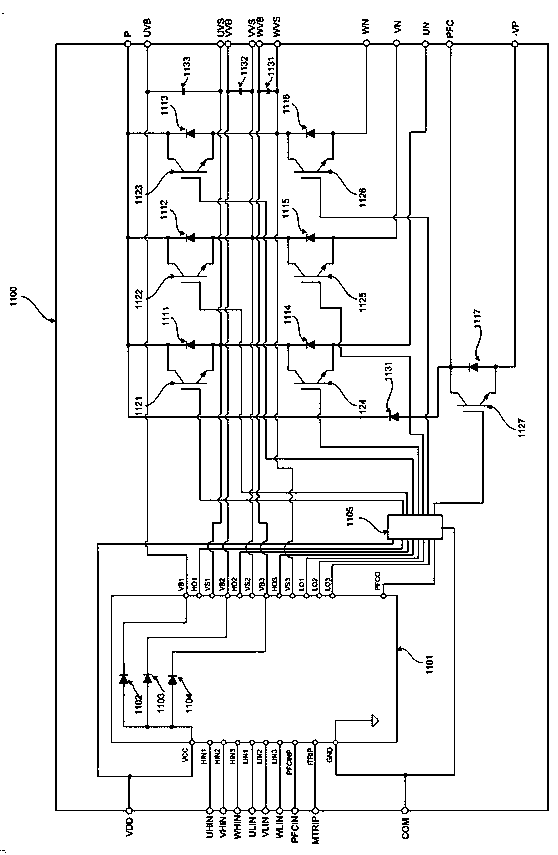

[0065] This embodiment provides an intelligent power module with self-adaptive antistatic enhancement. The structure diagram of the intelligent power module 1100 is as follows figure 2 shown. Wherein, the VCC terminal of the HVIC tube 1101 is used as the positive terminal VDD of the power supply in the low-voltage area of the intelligent power module 1100, and VDD is generally 15V;

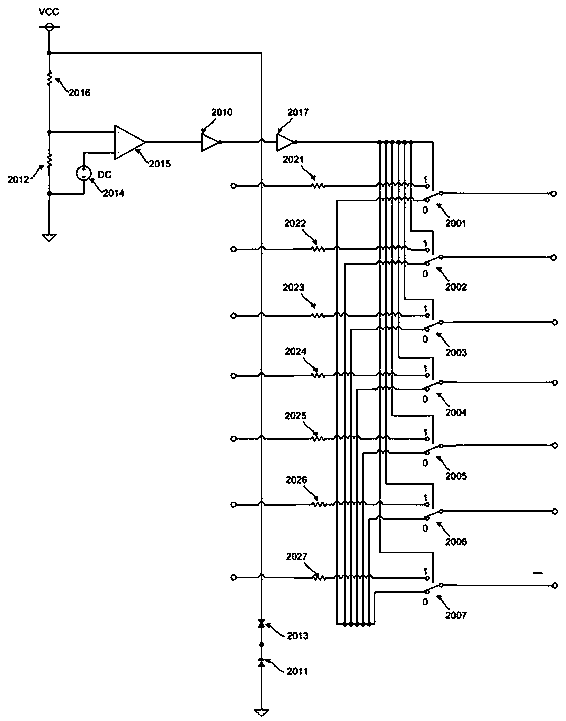

[0066] There is also a bootstrap circuit structure inside the HVIC tube 1101 as follows:

[0067] The VCC terminal is connected to the anodes of the bootstrap diode 1102, the bootstrap diode 1103, and the bootstrap diode 1104;

[0068] The cathode of the bootstrap diode 1102 is connected to the VB1 of the HVIC tube 1101;

[0069] The cathode of the bootstrap diode 1103 is connected to the VB2 of the HVIC tube 1101;

[0070] The cathode of the bootstrap dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com