Novel capacitor

A capacitor, a new type of technology, applied in the direction of laminated capacitors, fixed capacitor electrodes, multiple fixed capacitors, etc., can solve the problems of rapid decline in capacitor capacity, inability to make full use of space, and capacitor heating, so as to reduce the probability of breakdown and structure Simple, thickness-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

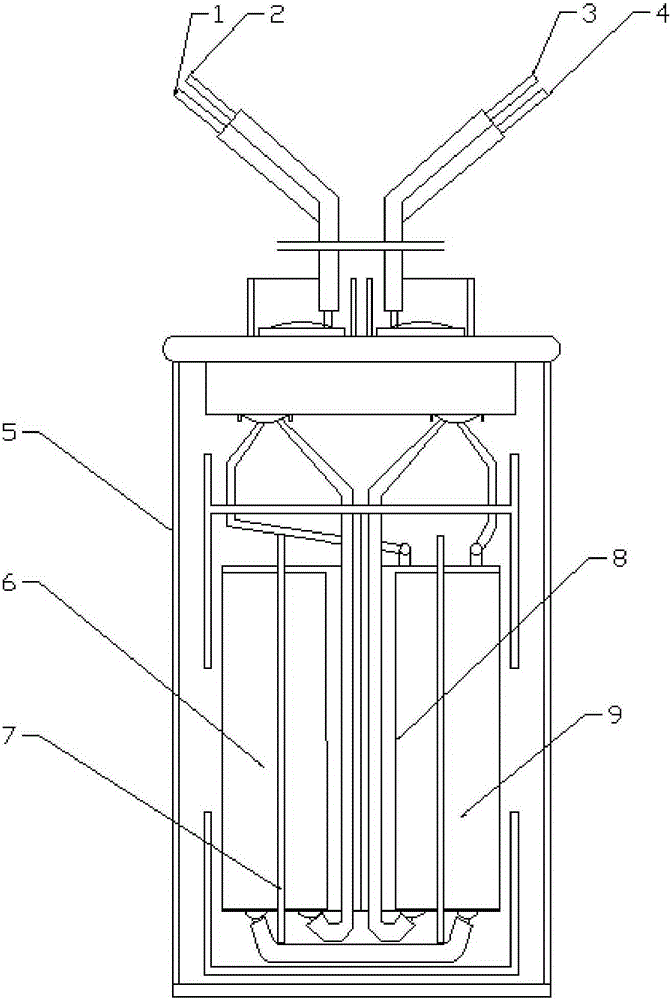

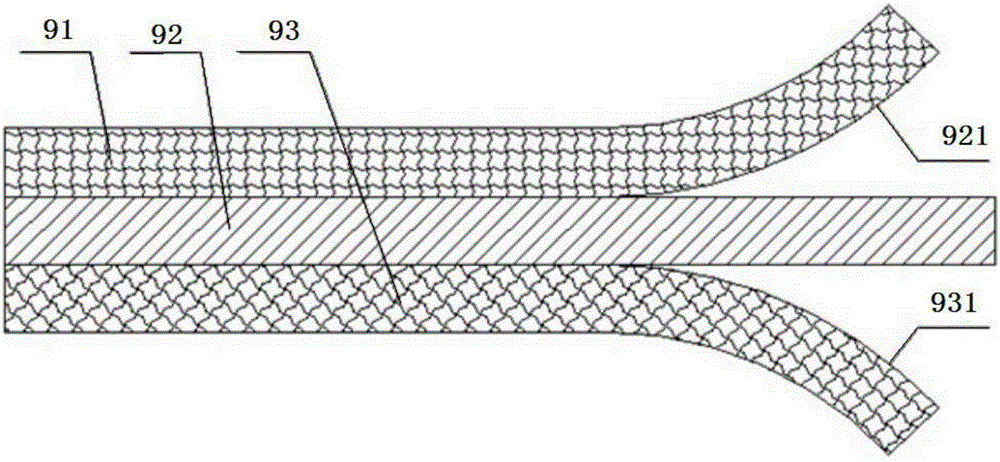

[0014] see Figure 1~2 , a new type of capacitor, including a housing 5, the upper end of the housing 5 is provided with a first left pin 2, a second left pin 1, a first right pin 3, and a second right pin that are independently insulated from each other 4. The inside of the housing 5 is provided with a vertical hollow mandrel 8, the mandrel 8 is made of insulating material such as plastic, and the first metallized film 6 is wound on the mandrel 8; the first left pin 2 It is electrically connected to the upper end of the first metallized film 6 through a wire, and the second left pin 1 is electrically connected to the lower end of the first metallized film 6 through a wire passing through the mandrel 8, that is, the The first metallized film 6 and the first left pin 2 and the second left pin 1 electrically connected to it form a first independent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com