Filter drum deduster

A filter cartridge dust collector and filter cartridge technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve problems that cannot be effectively solved, affect the service life of filter materials, and increase linearly in filter resistance. To achieve the effect of prolonging the dust residence time, prolonging the service life and reducing the purification load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

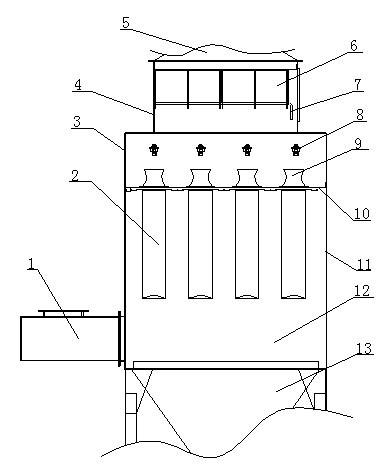

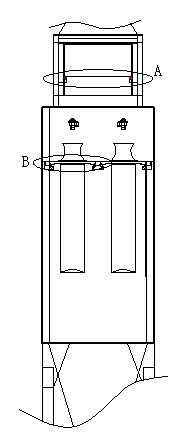

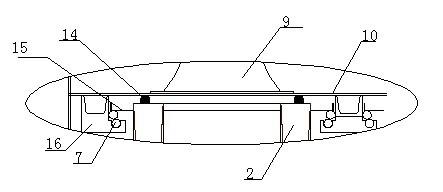

[0032] Embodiment 1: Referring to the accompanying drawings, the filter cartridge dust collector of the present invention includes a filter box 11 with a height of 50 cm higher than the filter cartridge, and the upper part is sealed and connected with the air outlet transition box 3 and the uppermost second filter box 4 in sequence. There is a conical ash collecting hopper 13 at the bottom of the filter box body 11, and there is an outwardly convex U-shaped air inlet connection section 1 on the back of the bottom of the filter box body 11 without a filter cartridge buffer section 12, on which a vertical air inlet interface is arranged. There is an orifice plate 10 for suspending the filter cartridge on the top surface of the filter box 11, and each orifice on one side (below) of the orifice plate 10 is connected with a vertical suspension filter cartridge 2 through a rigid non-compressed eccentric rotation interference compression member 7 for sealing assembly. (A filter box un...

Embodiment 2

[0035] Embodiment 2: As in Embodiment 1, the requirement for filtration accuracy is relatively low, and the upper secondary filter box can be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com