Solid tantalum electrolytic capacitor and manufacturing method thereof

A tantalum electrolytic capacitor, solid technology, applied in the field of solid tantalum electrolytic capacitors and its preparation, can solve problems such as poor conductivity, achieve the effects of increasing conductivity, increasing working life, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

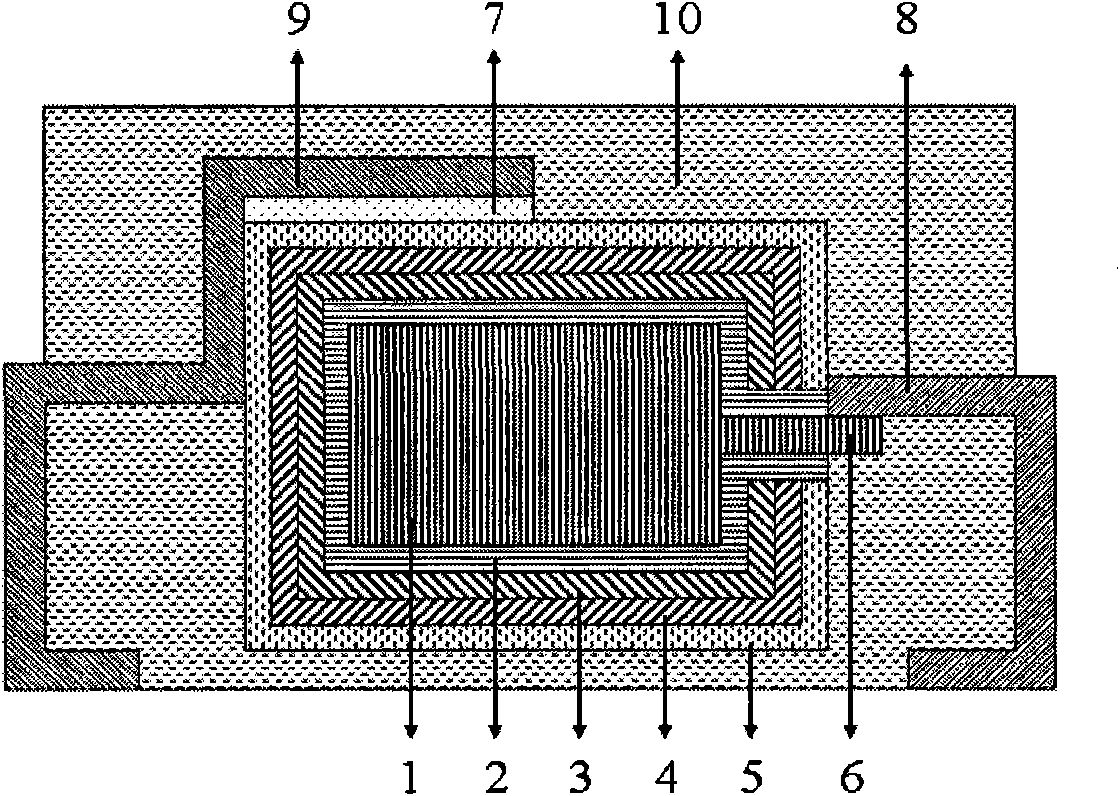

[0035] based on figure 1 Be explained. Wherein, the conductive layer 3 is polythiophene doped with 1wt% magnetic carbon nanotubes, and the magnetic carbon nanotubes are magnetic Fe with a diameter of 10nm evenly attached to the surface. 3 o 4 The particles are multi-walled carbon nanotubes, and the length of the multi-walled carbon nanotubes is 50 μm.

[0036]The preparation method is as follows:

[0037] ① Press nano-tantalum metal particles into blocks, plant cylindrical tantalum wires in the formation of tantalum particles, and sinter them into porous tantalum anode bodies under high temperature and vacuum conditions;

[0038] ② Anodize the sintered tantalum anode body to form a layer of Ta on its surface 2 o 5 Dielectric coating;

[0039] ③ Disperse the magnetic carbon nanotubes evenly in the mixed solution containing oxidant and polythiophene monomer, and then put the tantalum-containing anode body and Ta 2 o 5 The positive substrate of the dielectric coating is i...

Embodiment 2

[0048] The conductive layer 3 is poly(3,4-ethylenedioxythiophene) doped with 5wt% magnetic carbon nanotubes. 2 o 3 The particles are multi-walled carbon nanotubes, and the length of the multi-walled carbon nanotubes is 60 μm.

[0049] The preparation method is as follows:

[0050] ① Press nano-tantalum metal particles into blocks, plant cylindrical tantalum wires in the formation of tantalum particles, and sinter them into porous tantalum anode bodies under high temperature and vacuum conditions;

[0051] ② Anodize the sintered tantalum anode body to form a layer of Ta on its surface 2 o 5 Dielectric coating;

[0052] ③ Evenly disperse the magnetic carbon nanotubes in the mixed solution containing oxidant and poly(3,4-ethylenedioxythiophene) monomer, and then spray the mixed solution on the tantalum-containing anode body and Ta 2 o 5 On the positive substrate of the dielectric coating, a 350mT magnetic field is applied in the vertical direction of the surface of the tant...

Embodiment 3

[0057] The conductive layer 3 is polypyrrole doped with 10wt% magnetic carbon nanotubes, the magnetic carbon nanotubes are single-walled carbon nanotubes with magnetic nickel particles with a diameter of 20nm evenly attached to the surface, and the length of the single-walled carbon nanotubes is 70 μm.

[0058] The preparation method is as follows:

[0059] ① Press nano-tantalum metal particles into blocks, plant cylindrical tantalum wires in the formation of tantalum particles, and sinter them into porous tantalum anode bodies under high temperature and vacuum conditions;

[0060] ② Anodize the sintered tantalum anode body to form a layer of Ta on its surface 2 o 5 Dielectric coating;

[0061] ③ Evenly disperse the magnetic carbon nanotubes in the mixed solution containing oxidant and polypyrrole monomer, and then drop-coat the mixed solution on the tantalum-containing anode body and Ta 2 o 5 On the positive substrate of the dielectric coating, a 400mT magnetic field is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com