Graphene-polyaniline secondary battery and preparation method thereof

A secondary battery and polyaniline technology, applied in battery electrodes, battery pack components, circuits, etc., can solve problems such as polyaniline mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

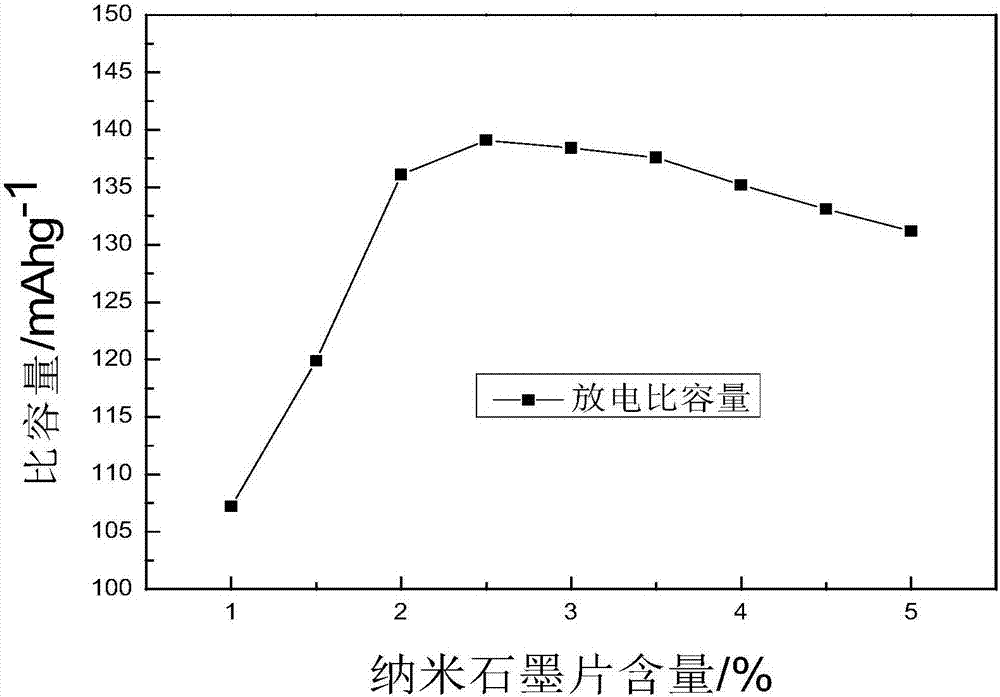

[0025] Positive electrode preparation: In a 2L reaction system, add 1.5g (accounting for 3% of the mass of aniline) activated carbon and 261ml of 7.5mol / L hydrochloric acid solution. After soaking for 10 minutes, add 522ml of 1mol / L aniline solution, stir for 30 minutes, and cool down the system solution to about 0-5°C. Dissolve 6.8g of manganese dioxide in 150ml of 7.5mol / L hydrochloric acid solution, and add it to the reaction system at one time. After 1 hour of reaction, slowly and evenly add 261ml of 2mol / L ammonium persulfate solution to the system (drip after about 2 hours), and let it react for about 4 hours. Then add nano-graphite sheets (accounting for different percentages of aniline mass), continue to react for 0.5h, and filter under reduced pressure. Add deionized water to the polyaniline wet powder, stir evenly, add solid ascorbic acid, and place in a water bath. Under the condition of 60°C, react for 2h. Then add ammonia water, dedope at room temperature for 1...

Embodiment 2

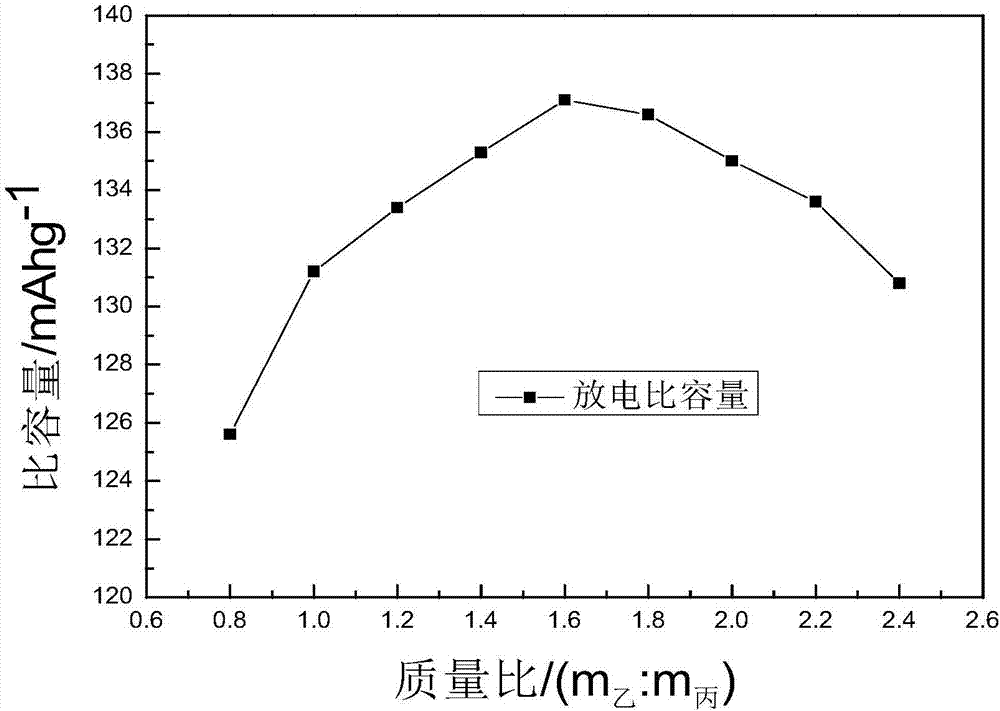

[0029] The film coated with polyaniline in Example 1 is used as the positive electrode of the battery, the film coated with graphene is used as the negative electrode of the battery, lithium hexafluorophosphate is used as the electrolyte, and the mixture of different mass ratios of ethylene carbonate and propylene carbonate is used as an organic solvent to prepare electrolyte , a graphene-polyaniline battery was assembled in a glove box by using a positive and a negative matching method. After standing still for 24 hours, the charge and discharge test was carried out. The relationship between the mass ratio of ethylene carbonate and propylene carbonate and the discharge specific capacity of polyaniline is as follows figure 2shown. It can be seen from the figure that when the mass ratio of ethylene carbonate to propylene carbonate is 1.6:1, the discharge specific capacity of polyaniline is higher, that is, the mass ratio of ethylene carbonate to propylene carbonate is 1.6:1, ...

Embodiment 3

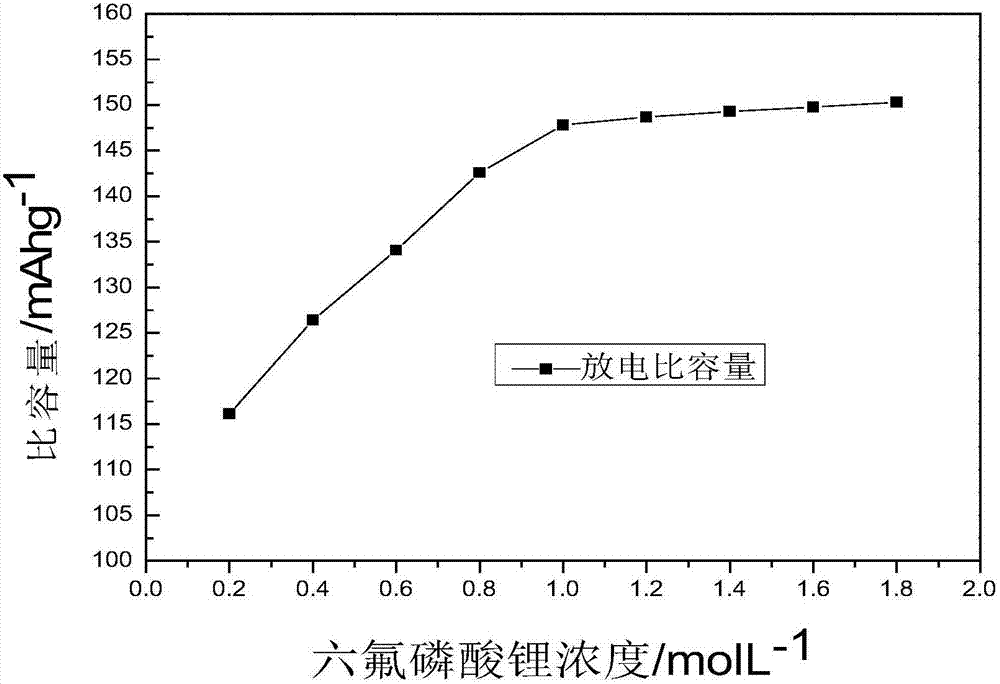

[0031] The film coated with polyaniline in Example 1 is used as the positive electrode of the battery, the film coated with graphene is used as the negative electrode of the battery, and the mixture of ethylene carbonate and propylene carbonate containing different concentrations of lithium hexafluorophosphate electrolyte is used as the electrolyte, and one positive and one negative are used. The positive and negative electrodes are matched, and the graphene-polyaniline battery is assembled in the glove box. After standing still for 24 hours, the charge and discharge test was carried out. The relationship between the discharge specific capacity of polyaniline and the concentration of lithium hexafluorophosphate in the electrolyte is as follows image 3 shown. It can be seen from the figure that the discharge specific capacity of polyaniline increases with the increase of lithium hexafluorophosphate concentration in the electrolyte. When the concentration of lithium hexafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com