A method of manufacturing a high-reliability electrolytic capacitor

A technology of electrolytic capacitors and manufacturing methods, applied in the direction of electrolytic capacitor manufacturing, electrolytic capacitors, capacitors, etc., can solve the problems of complex and cumbersome secondary deoxidation and carbon processes, to ensure voltage resistance and delay the rise of internal temperature , the effect of inhibiting expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

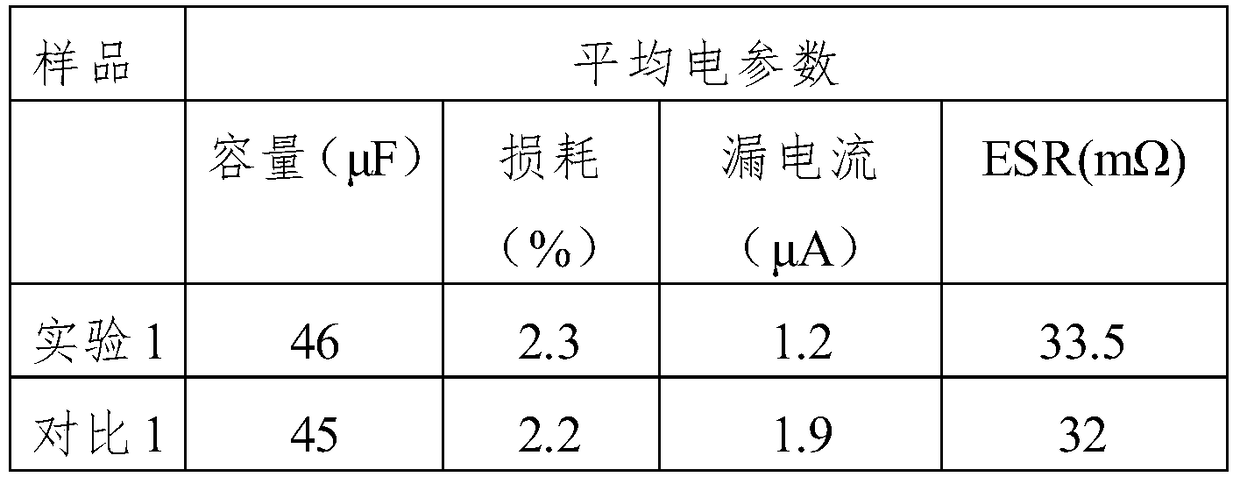

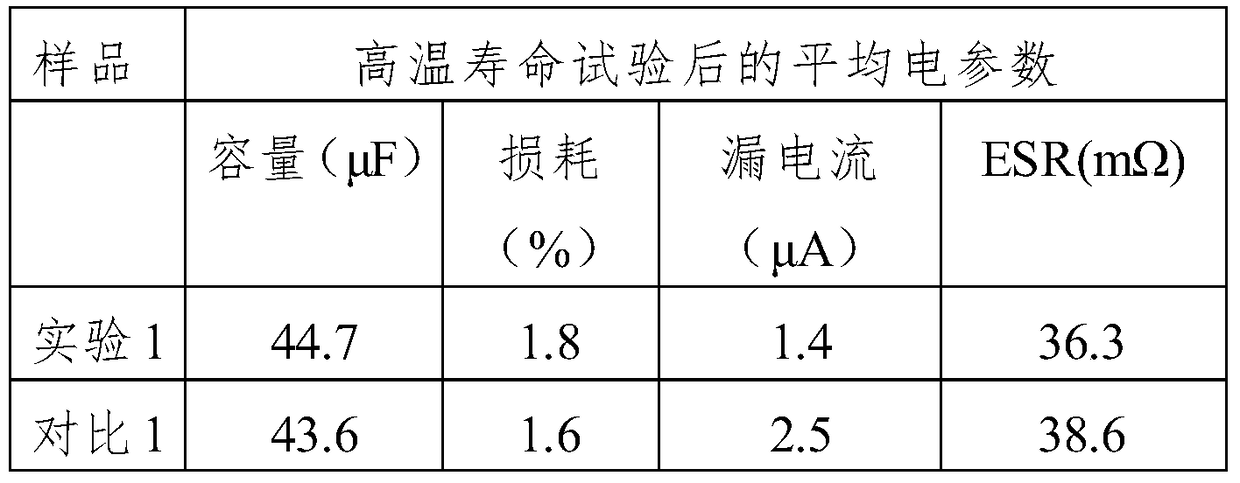

experiment example 1

[0045] Place the sintered tantalum block in a mixed solution of carboxylic acid, tartaric acid, nitric acid, sulfuric acid and hydrofluoric acid for 0.5 hours, wash it with deionized water at 65°C for 20 minutes, and dry it in water, ethylene glycol / polyethylene glycol Electrochemical formation is carried out in a mixed solution of alcohol, citric acid and phosphoric acid, the solution temperature is 10-20°C, the conductivity is 1-35mS / cm, and the current density is 25mA / (μF·V). After the voltage rises to a predetermined level, the pressure is lowered in a cross flow, and the solution temperature is 55-75°C. After the constant pressure is finished, it is annealed in a high-temperature oven at 300°C, and then repaired in an electrolyte at room temperature, and then the defect points are shielded in deionized water at 65-95°C.

[0046] After the anode block is dried, the coating of the electrolyte is completed according to the known process, and then respectively immersed in gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com