Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce dust rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

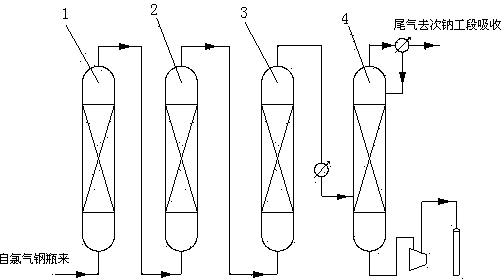

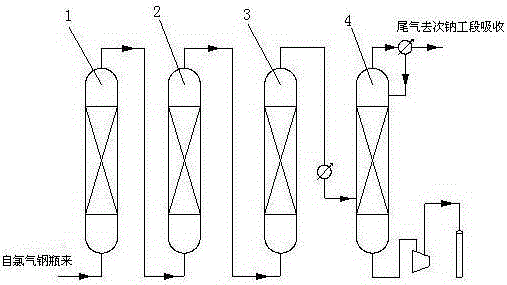

Method for preparing electronic grade high-purity hydrogen chloride from industrially synthesized hydrogen chloride

ActiveCN103387211ALow costIncrease incomeChlorine/hydrogen-chloride purificationNitrogen gasLiquid chlorine

Owner:HANGZHOU ELECTROCHEM GROUP

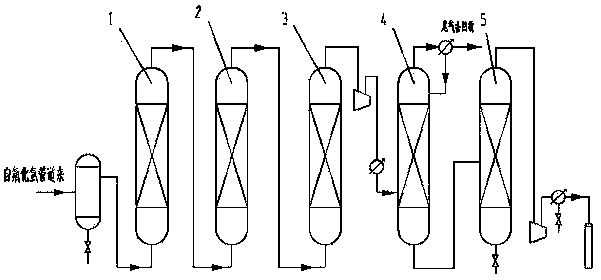

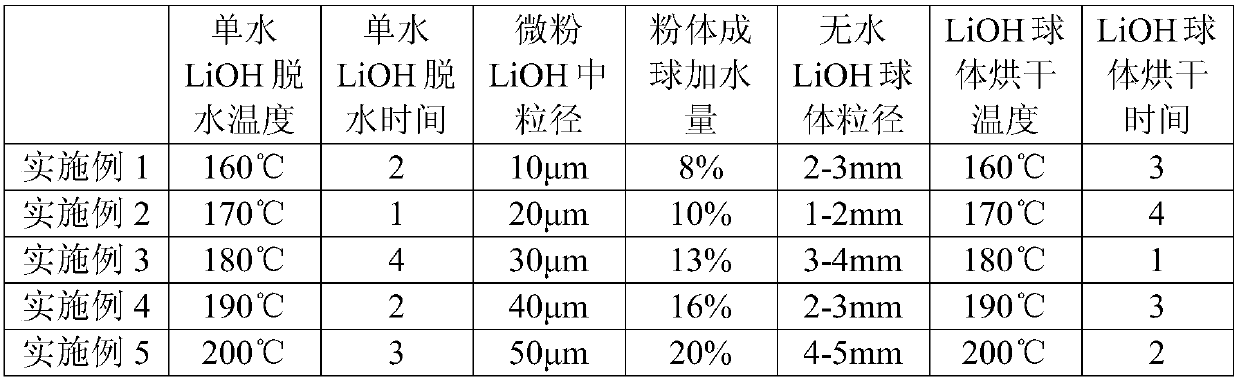

Method for industrially producing anhydrous lithium hydroxide balls

ActiveCN109553118AAchieve recyclingPrevent hardeningCarbon compoundsLithium oxides/hydroxidesLithium hydroxidePhysical chemistry

The invention provides a method for industrially producing anhydrous lithium hydroxide balls, comprising the steps of dehydration drying, fine powder, ball forming of powder, sieving, drying, and thelike. Medicine grains, which do not cause powder falling and do not have irritating smell, are prepared from anhydrous lithium hydroxide by a powder forming process. When the anhydrous lithium hydroxide balls are applied to a CO2 absorbent, the absorption efficiency of carbon dioxide by the absorbent is tested to be 85% or more according to a coal standard MT454-2008.

Owner:GANFENG LITHIUM CO LTD

Sintering combined oxygen-enriched side-blown smelting process of vertical drying kiln

InactiveCN108998661AHigh recovery rateGood sealingProcess efficiency improvementSludgeNon-ferrous extractive metallurgy

The invention discloses a sintering combined oxygen-enriched side-blown smelting process of a vertical drying kiln in the technical field of environmental protection systems. The smelting process comprises the following steps of adding little lime and fine anthracite to copper and nickel-contained sludge, mixing the lime, the fine anthracite and the copper and nickel-contained sludge proportionally and stirring evenly to obtain a mixture; pelletizing the mixture by a pelletizer to obtain pellets, and adding the pellets evenly into the vertical drying kiln from a kiln crown by a feeding device,wherein the pellets move down by dead weight; adding obtained agglomerated cakes from the furnace top of an oxygen-enriched side-blown smelting furnace continuously together with inorganic hazardouswastes, such as waste anode scraps, quartz stone, limestone, non-ferrous metal smelting waste and incineration disposal residues; making obtained slag enter an electric slag cleaning furnace after theobtained slag is discharged from the oxygen-enriched side-blown smelting furnace, reheating and clarifying and separating the slag by the electric slag cleaning furnace, thereby clarifying and separating copper and nickel mechanically entrained in the slag once again, and discharging the slag from the electric slag cleaning furnace and performing water quenching to make the slag become water-quenched slag; and disposing generated flue gas by processes of waste heat recovery, shock chilling, bag dust collection, sulfur removal, denitration, fluorine and chlorine removal and the like, thereby realizing up-to-standard discharge.

Owner:广州叶林环保科技有限公司

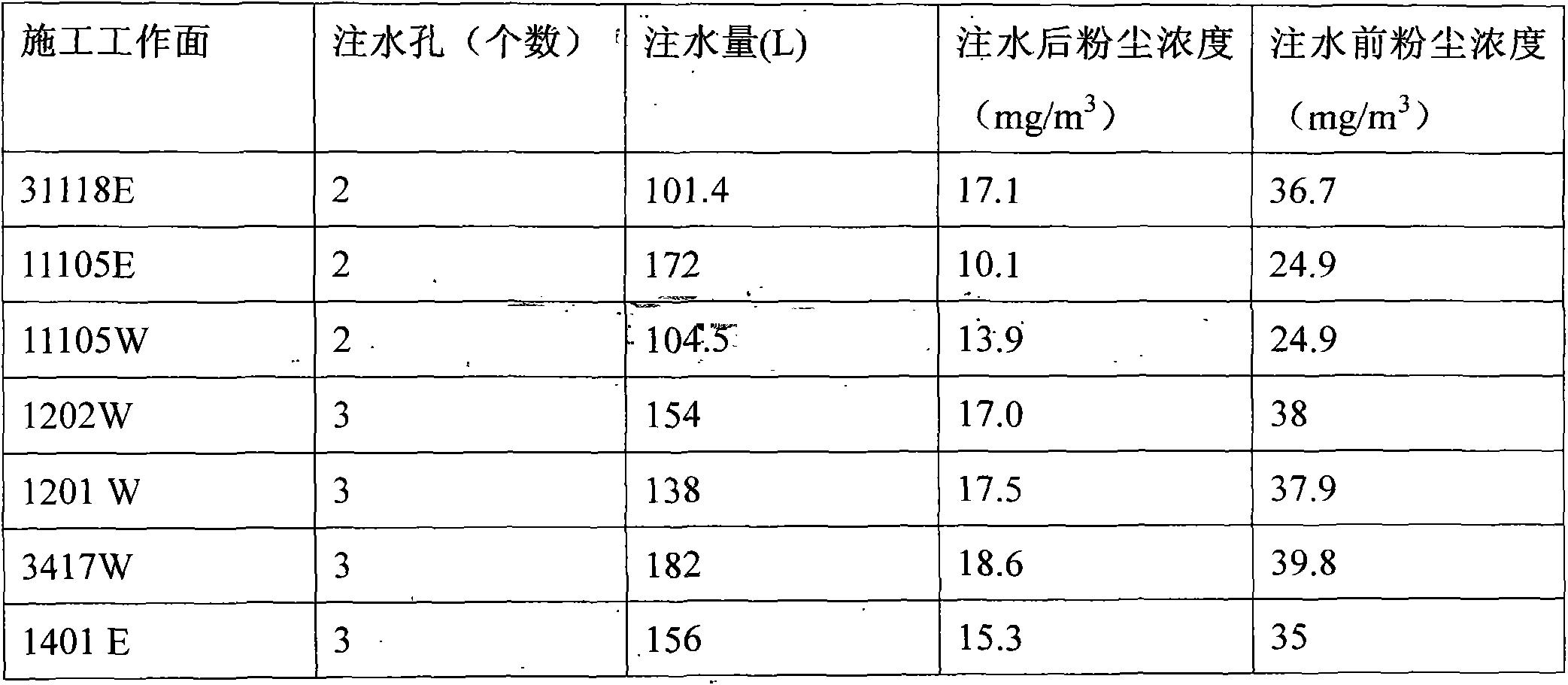

Coal seam water injection method of coal mining working face

InactiveCN103939126AEasy to operateEasy constructionDust removalFire preventionMining engineeringHigh pressure water

The invention provides a coal seam water injection method of a coal mining working face. The coal seam water injection method of the coal mining working face is characterized by comprising the following steps that before mining operation, an air drill or an air coal drill is used for conducting wet water injection hole punching on a driving working face coal seam, the water injection holes are formed to be perpendicular to a coal wall along the working face, the distance away from the top is no smaller than 0.8 m, and the hole depth is 1.5-6.0 m; a hole packer is used for sealing the water injection holes, a water tube is used for conducting high pressure water injection on the holes, and the water content of the driving coal seam is increased by 1% or more. Dust is removed to the largest extent, so that the dust rate of the driving working face is effectively lowered, and the effect for preventing gas from gushing out on the mining working face is obvious.

Owner:解波

Preparation method for electronic-grade high-purity chlorine from industrial liquid chlorine

ActiveCN103626129ALow costIncrease incomeChlorine/hydrogen-chloride purificationHydrogenBoiling point

The invention discloses a preparation method for electronic-grade high-purity chlorine from industrial liquid chlorine. The electronic-grade high-purity chlorine with purity of more than 99.999% is prepared from industrial liquid chlorine through gasification, multistage physical drying, removal of carbon dioxide through adsorption, compression condensation and rectification for removal of low-boiling-point gas like nitrogen, oxygen, hydrogen, carbon monoxide and methane. The preparation method has the advantages of low cost, high benefits and capacity of preparing a high-purity product; and the product is extensively applicable to preparation of optical fiber communication, microelectronic and high temperature superconducting materials.

Owner:HANGZHOU ELECTROCHEM GROUP

Painting pretreatment method of boards for furniture

InactiveCN106272788AStay hydratedHigh activityWood treatment detailsWood heatingPretreatment methodEngineering

The invention belongs to the technical field of treatment of boards for furniture and particularly relates to a painting pretreatment method of boards for furniture. The painting pretreatment method includes: selecting and soaking materials, polishing, fumigating and drying. Compared with the prior art, the painting pretreatment method has the advantages that the painting pretreatment method is simple, moisture in the boards can be balanced after the treatment, polishing is performed after the boards are soaked by soaking liquid, dust rate can be reduced, surface evenness can be achieved, the moisture in the boards can be kept effectively by the fumigation, cracking from the interior after long-term use can be prevented, the surface activity of the boards is improved, the board combination is benefited, paint stability can be increased, and the service life of furniture is prolonged.

Owner:安徽宏润工艺品有限公司

Production method of pad cotton of cover plate of automobile spare tire

InactiveCN105063890ASolve excessive formaldehyde contentSolve horizontal and vertical tearNon-woven fabricsAdhesivesFeltedMethods of production

The invention discloses a production method of pad cotton of a cover plate of an automobile spare tire. The production method comprises following steps of material weighing; pre-opening; precise opening; even and orderly weighing; material spreading and net forming; drying at a set temperature; cold rolling and shaping; and cutting. In this way, problems of excessive formaldehyde, horizontal and longitudinal tearing and poor stretching performance of pad cotton of a spare tire are solved; dust producing rate of a hair felt is reduced; small of the product is improved; and production environment is improved.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

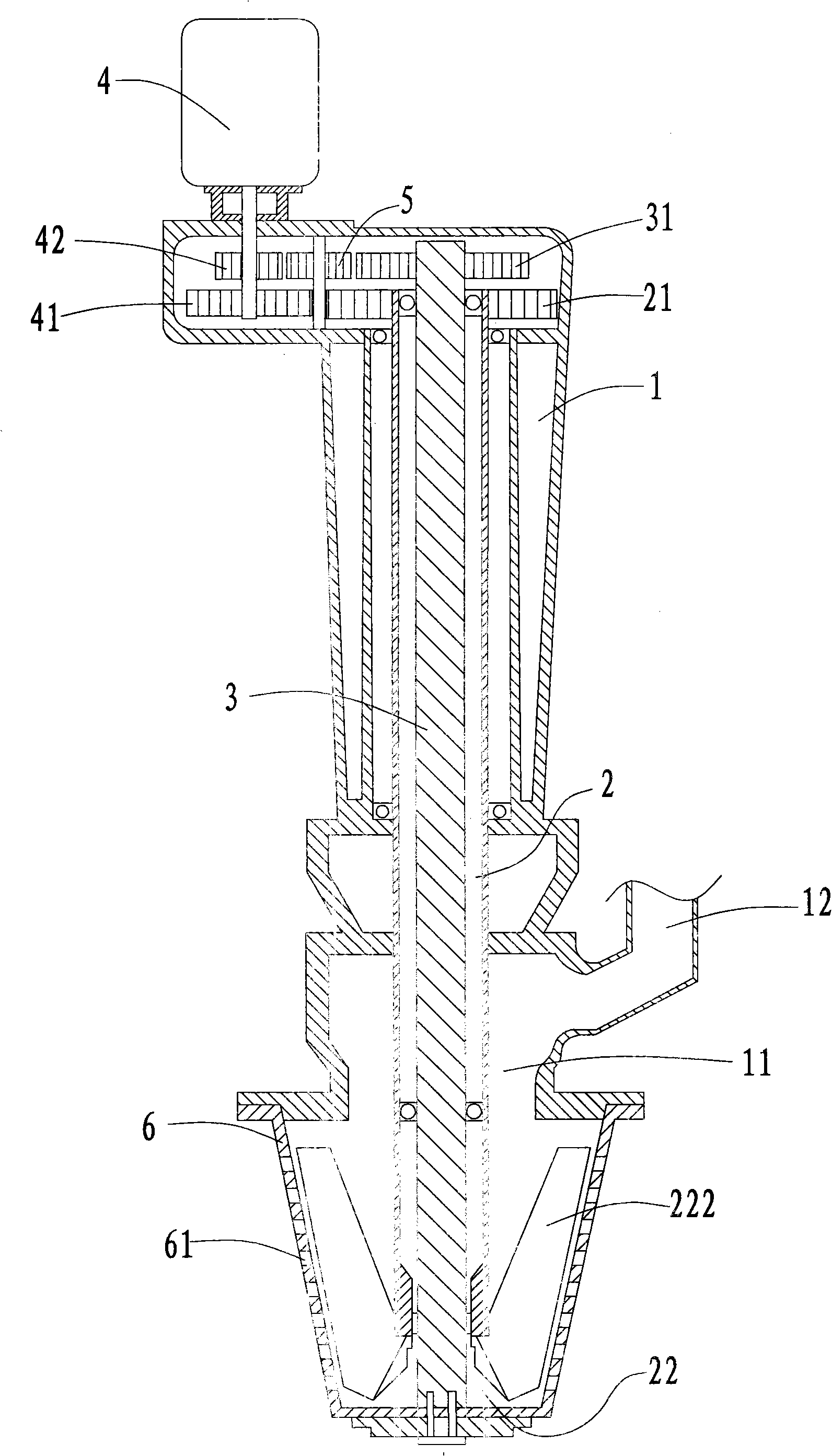

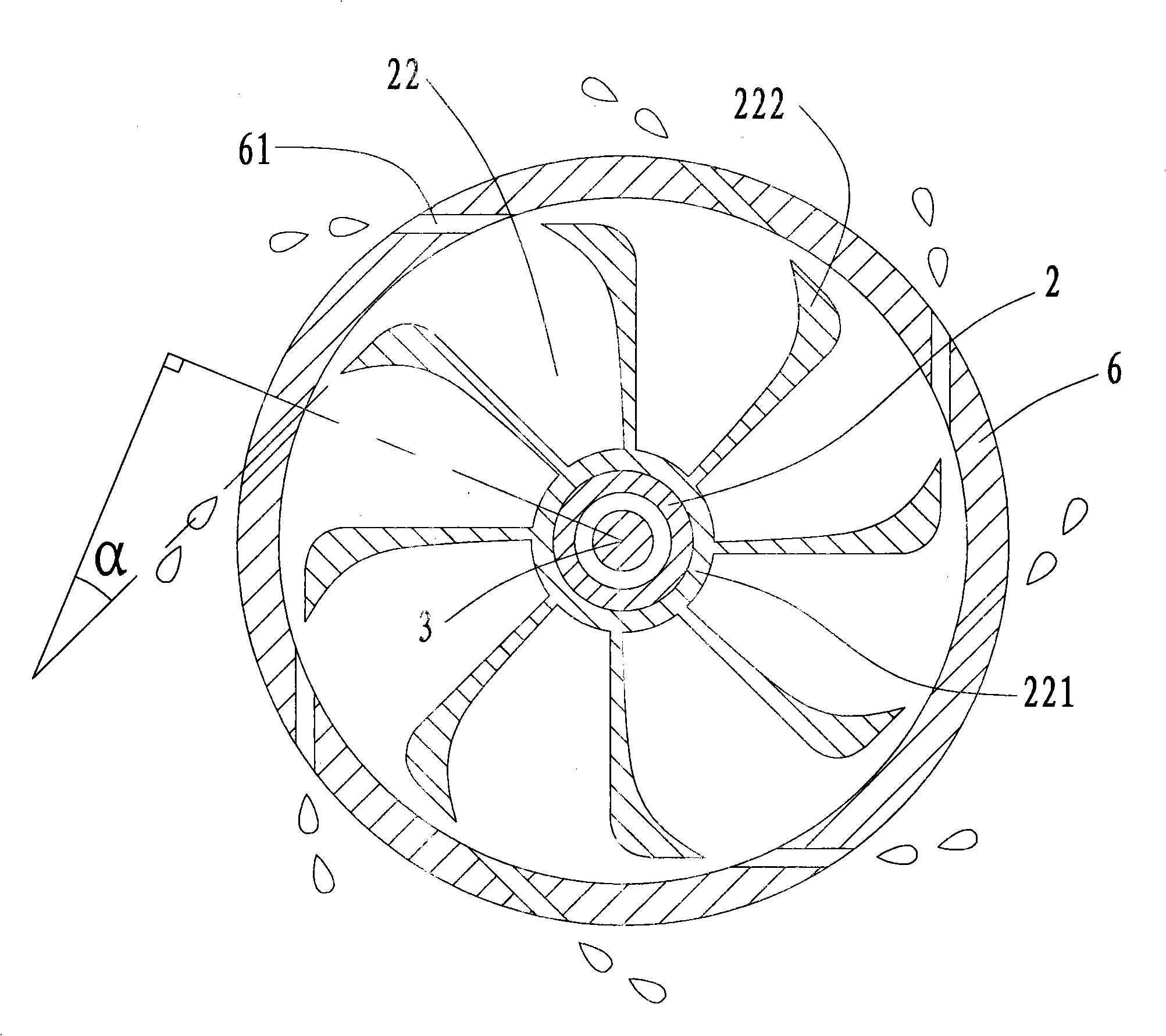

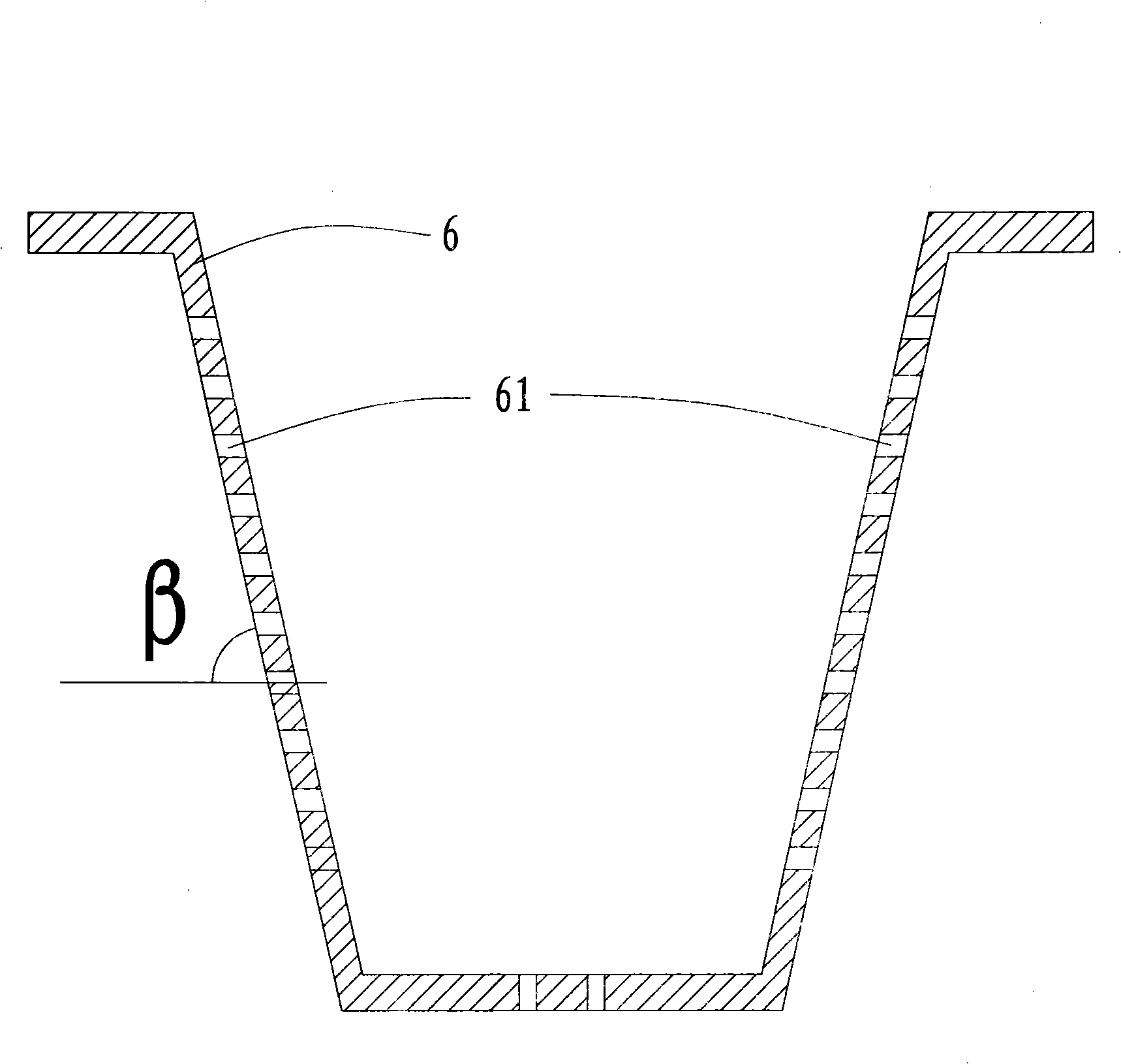

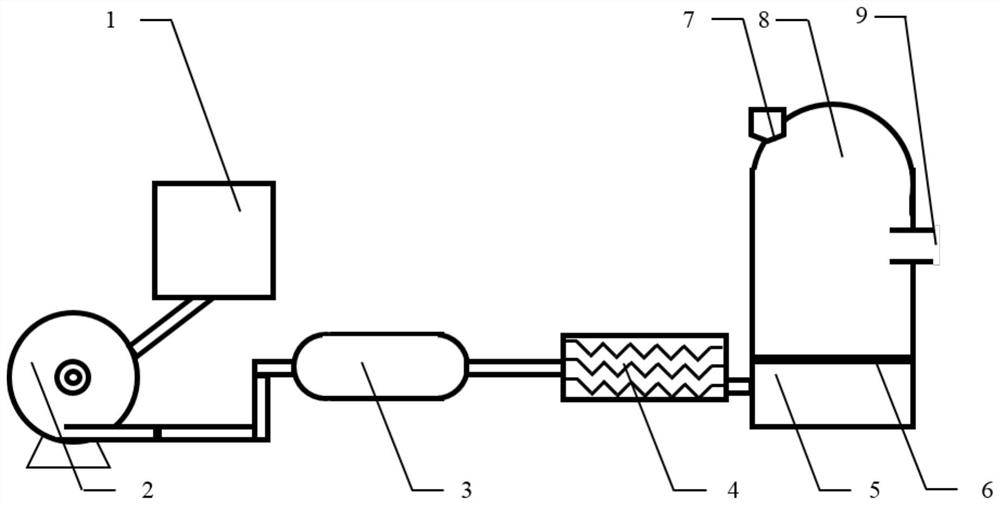

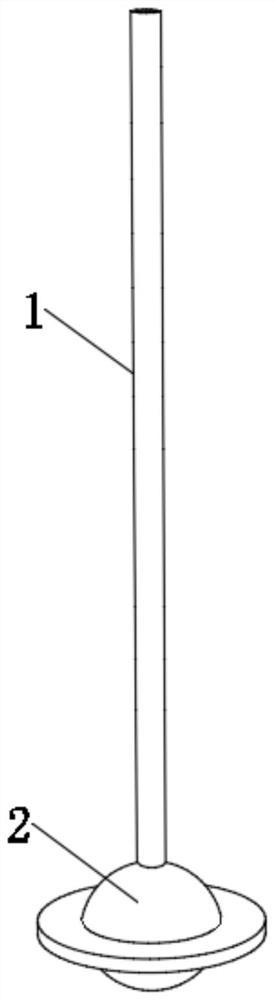

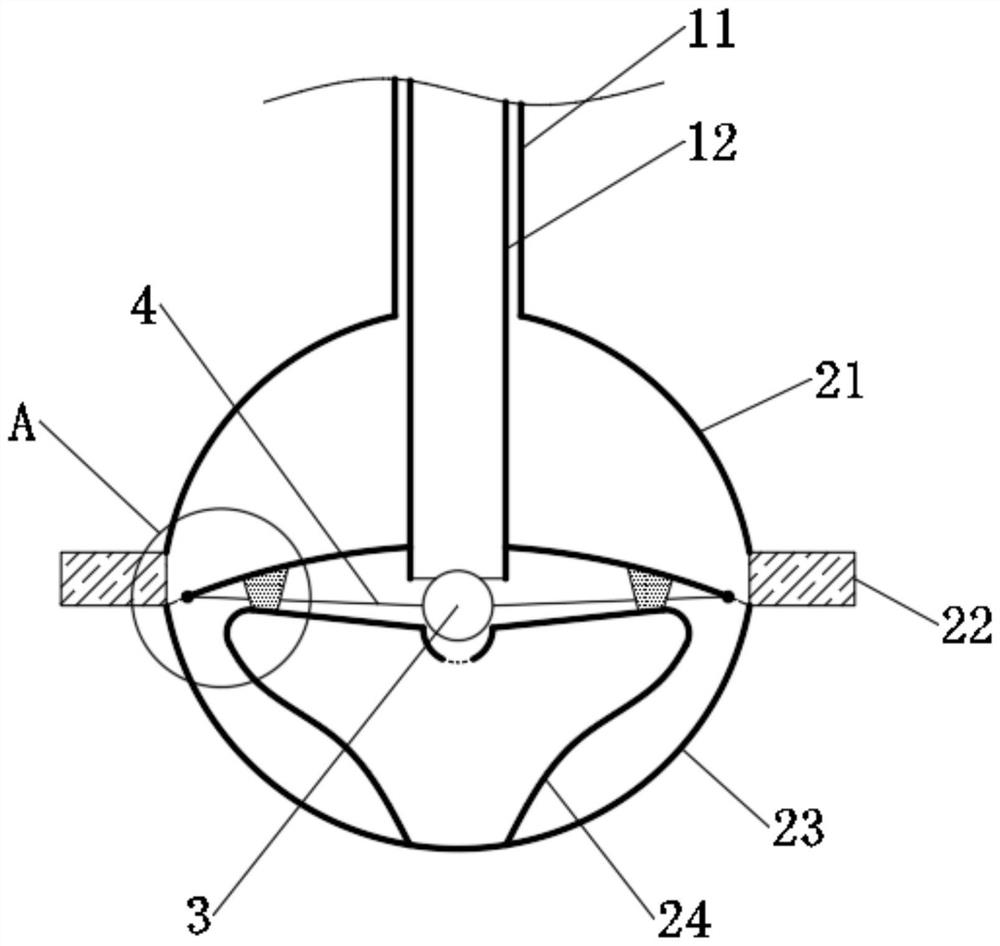

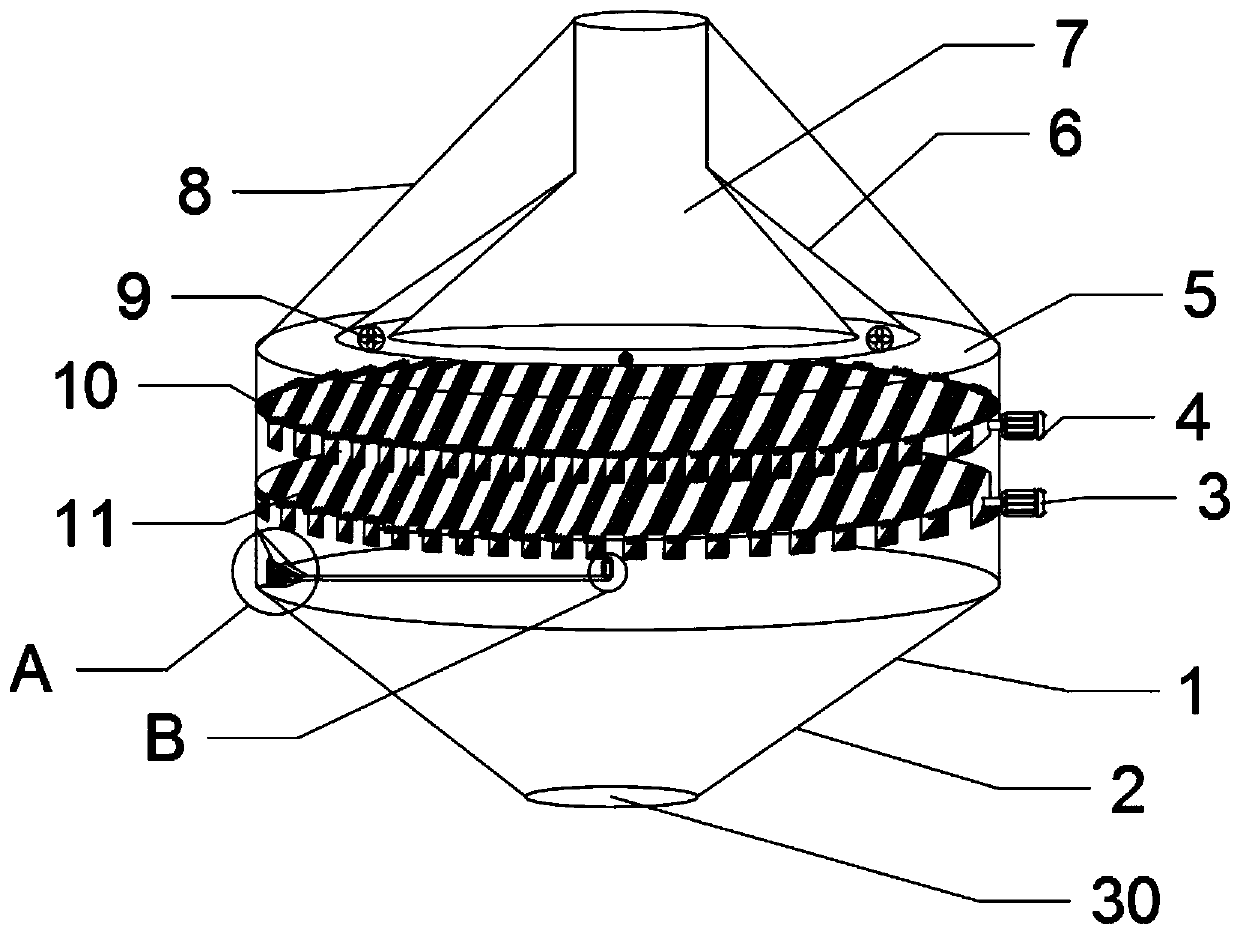

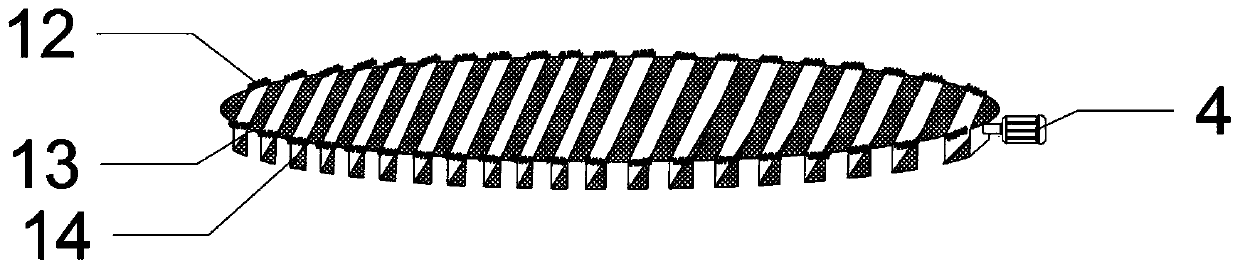

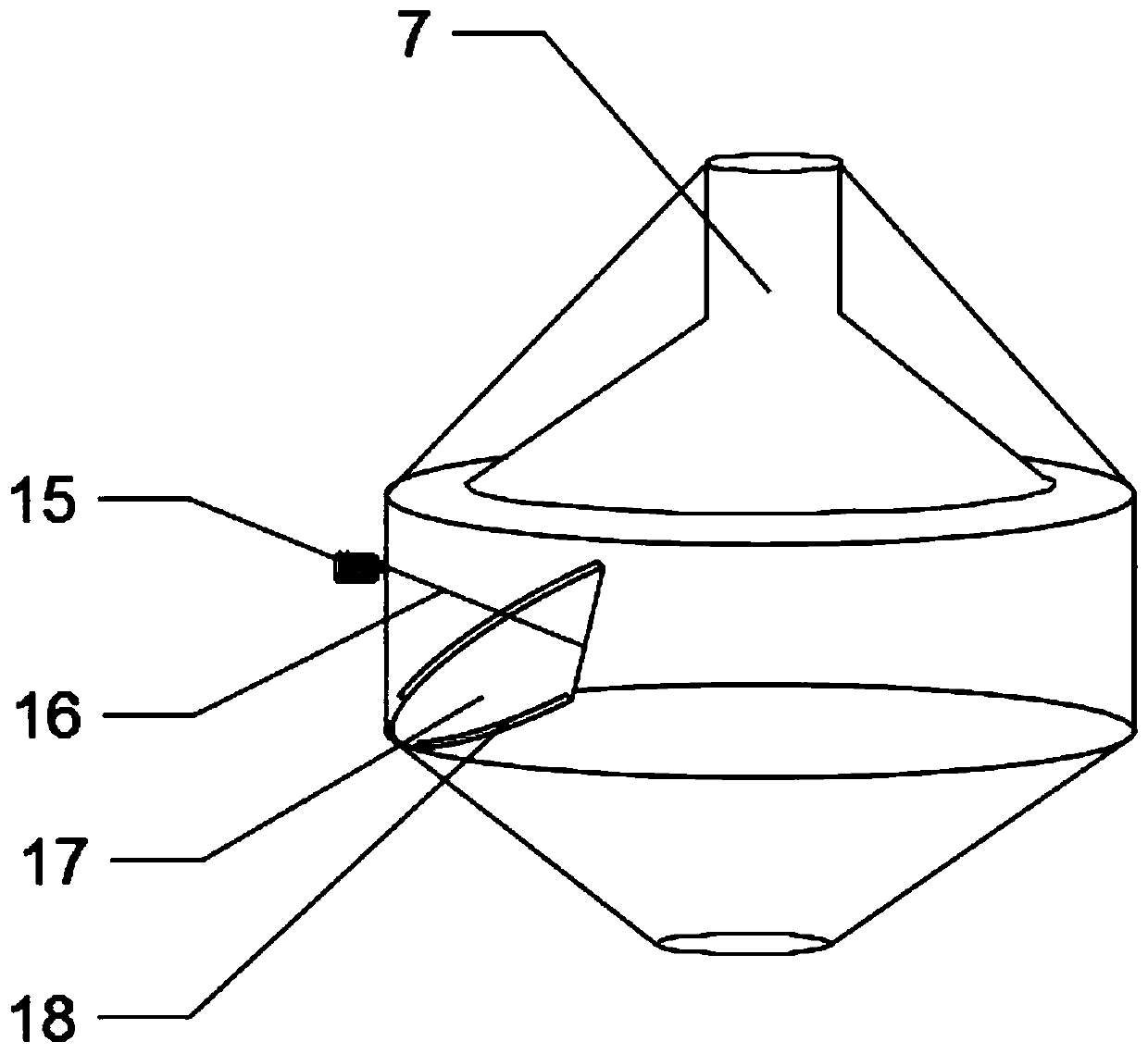

Tower type prilling apparatus

ActiveCN101302132AEasy to replaceSolve the blockageFertiliser formsFertilizer mixturesImpellerGear drive

The invention discloses a towered granulating device, comprising a housing which is provided with an electric motor, wherein, an internal rotating shaft and an external rotating shaft which are arranged inside the housing are driven by the electric motor to rotate in opposite directions with the gear wheel transmission way. The reverse direction rotation drives a rotating impeller and a nozzle housing which are arranged at the bottoms of the internal rotating shaft and the external rotating shaft to rotate in opposite directions, thereby ensuring that the solution positioned inside the nozzle housing is thrown out from holes of the nozzle housing and enters a cooling medium in a liquid dropping way; the rotating speed is adjusted simply by replacing speed adjusting gear wheels with different diameters through the design of engagement of the speed adjusting gear wheels, a driven gear wheel of the internal rotating shaft and a driving gear wheel of the internal rotating shaft, thereby being convenient to change the speed; one electric motor is adopted to drive the rotating impeller and the nozzle to rotate in opposite directions, and the gear wheel transmission way is adopted, thereby the energy consumption is reduced; a cross section and a lengthwise section inside the nozzle housing are provided with holes forming certain angles with the nozzle external wall, thereby reducing the dust rate when the solution is thrown out and the particles are made and solving the problem of jet hole blockage.

Owner:广东福利龙复合肥有限公司

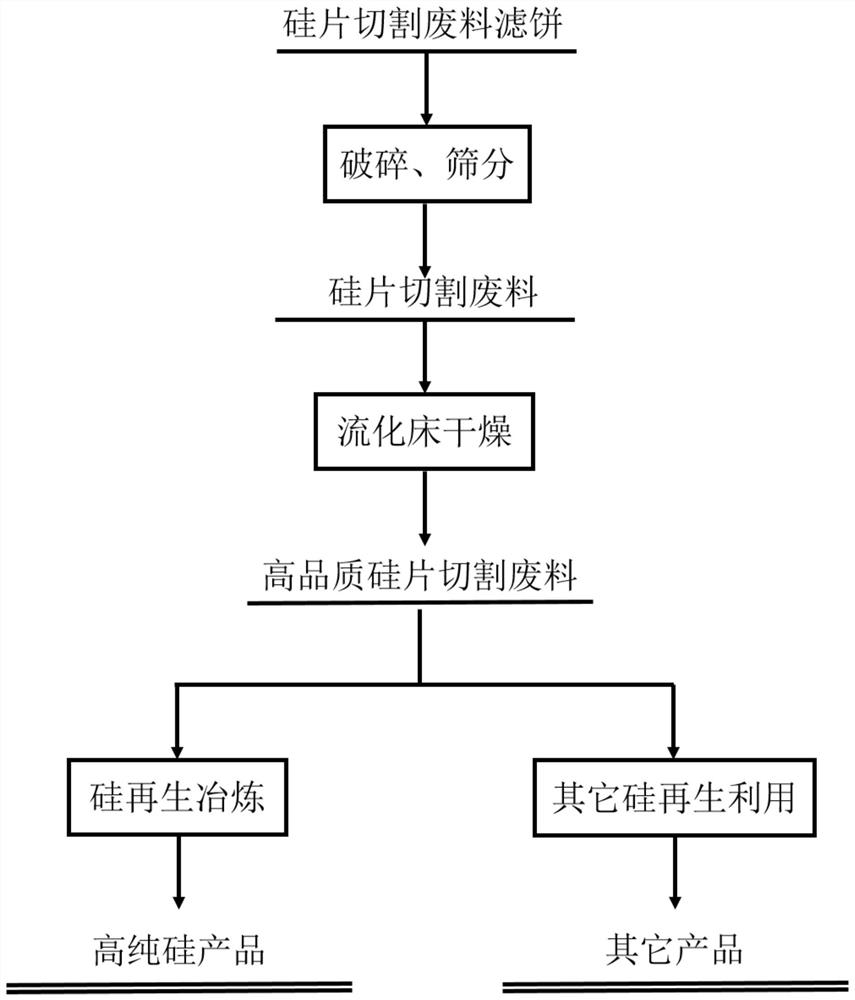

Method for drying silicon wafer cutting waste by fluidized bed

InactiveCN111829293APrevent oxidationReduce pollutionDrying solid materials with heatDrying gas arrangementsSilicon chipSilicon particle

The invention relates to a method for drying silicon wafer cutting waste by a fluidized bed, and belongs to the technical field of recycling of silicon secondary resources. The method aims at the problems that the moisture content of a filter cake after pressure filtration of the silicon wafer cutting waste is high, and conventional steam drying, microwave drying and other methods are adopted, sothat the drying efficiency is low, the moisture removal is incomplete, and secondary oxidation of the silicon wafer cutting waste and reduction of a recovery rate of the silicon are caused and the like, and the fluidized bed drying treatment of the silicon wafer cutting waste is provided. The fluidized bed drying is carried out in advance before the silicon wafer cutting waste is subjected to high-temperature treatment and recycling, so that the moisture remaining in the filter cake of the silicon wafer cutting waste is efficiently and rapidly removed, and meanwhile, the oxidation of silicon particles in a drying process is inhibited. The moisture content in raw materials is reduced through the fluidized bed drying, so that the drying efficiency is improved, the utilization efficiency of the silicon wafer cutting waste in the subsequent process is improved, and the recovery rate of the silicon is further improved. The dried silicon wafer cutting material can be directly smelted to recover the silicon, or combined with a silicon raw material for refining.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing electronic grade high-purity chlorine gas with industrial liquid chlorine as raw material

The invention discloses a preparation method for electronic-grade high-purity chlorine from industrial liquid chlorine. The electronic-grade high-purity chlorine with purity of more than 99.999% is prepared from industrial liquid chlorine through gasification, multistage physical drying, removal of carbon dioxide through adsorption, compression condensation and rectification for removal of low-boiling-point gas like nitrogen, oxygen, hydrogen, carbon monoxide and methane. The preparation method has the advantages of low cost, high benefits and capacity of preparing a high-purity product; and the product is extensively applicable to preparation of optical fiber communication, microelectronic and high temperature superconducting materials.

Owner:HANGZHOU ELECTROCHEM GROUP

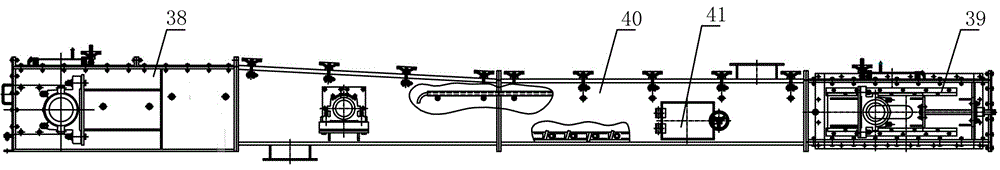

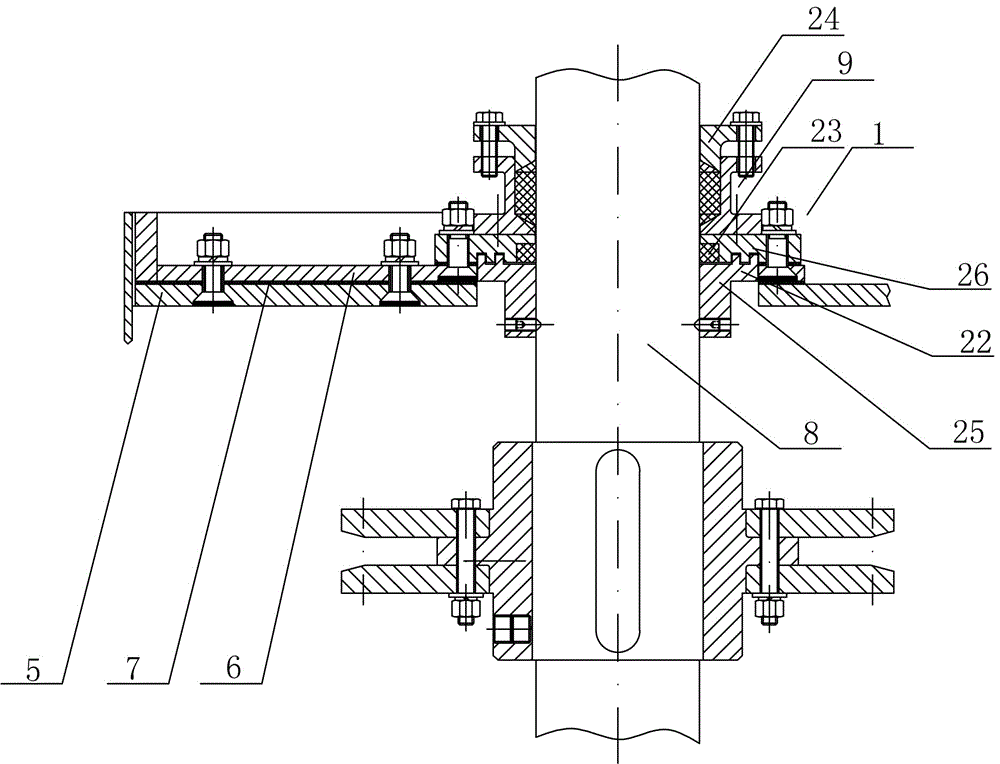

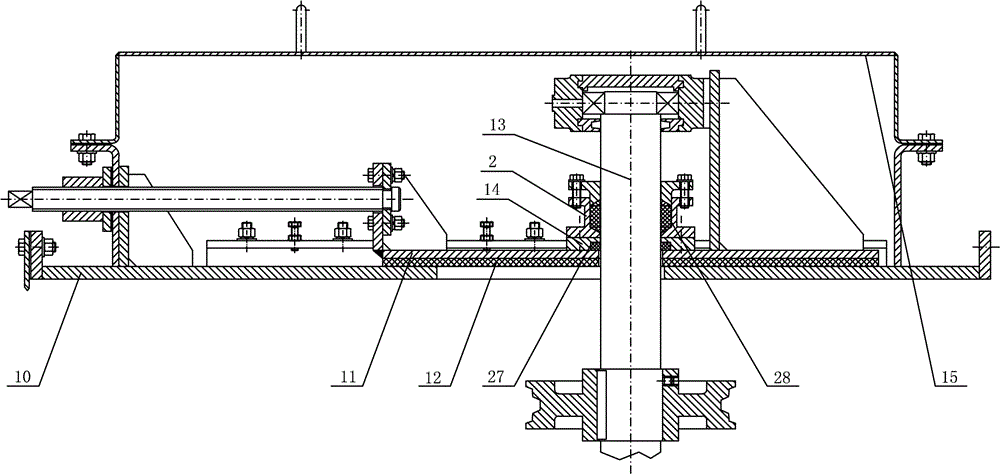

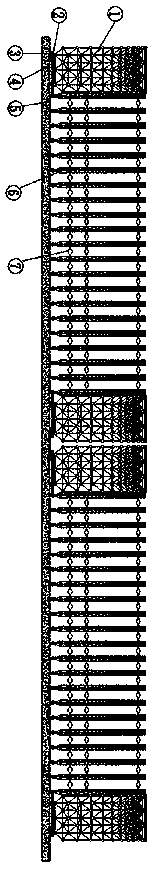

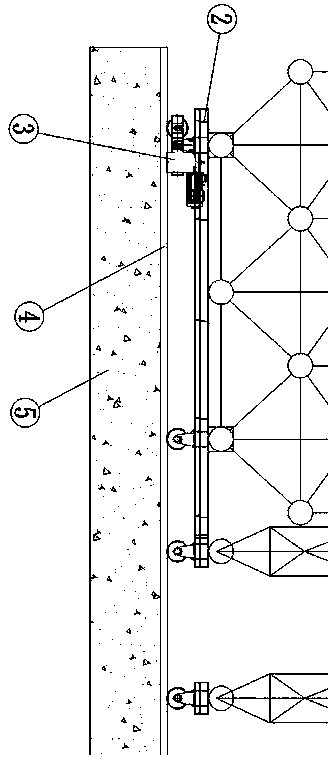

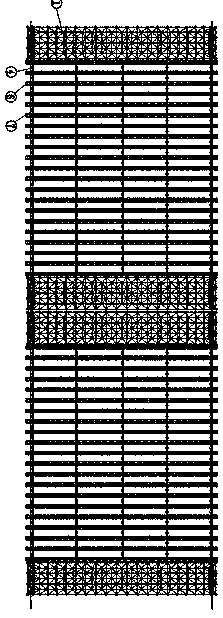

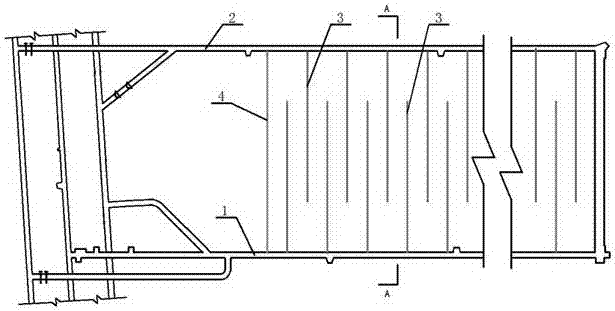

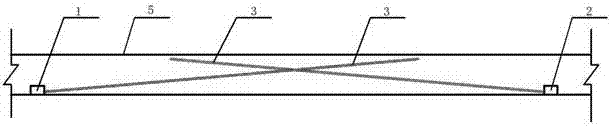

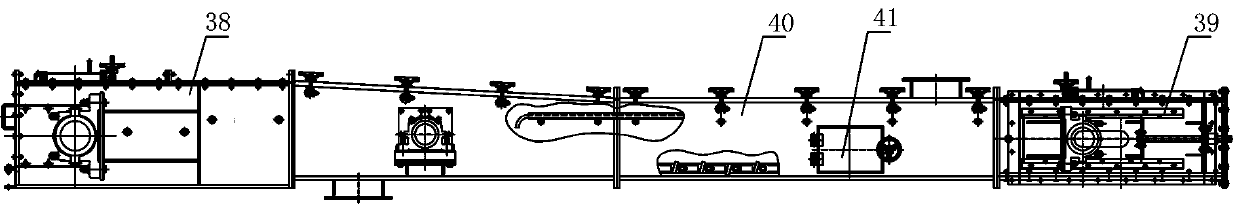

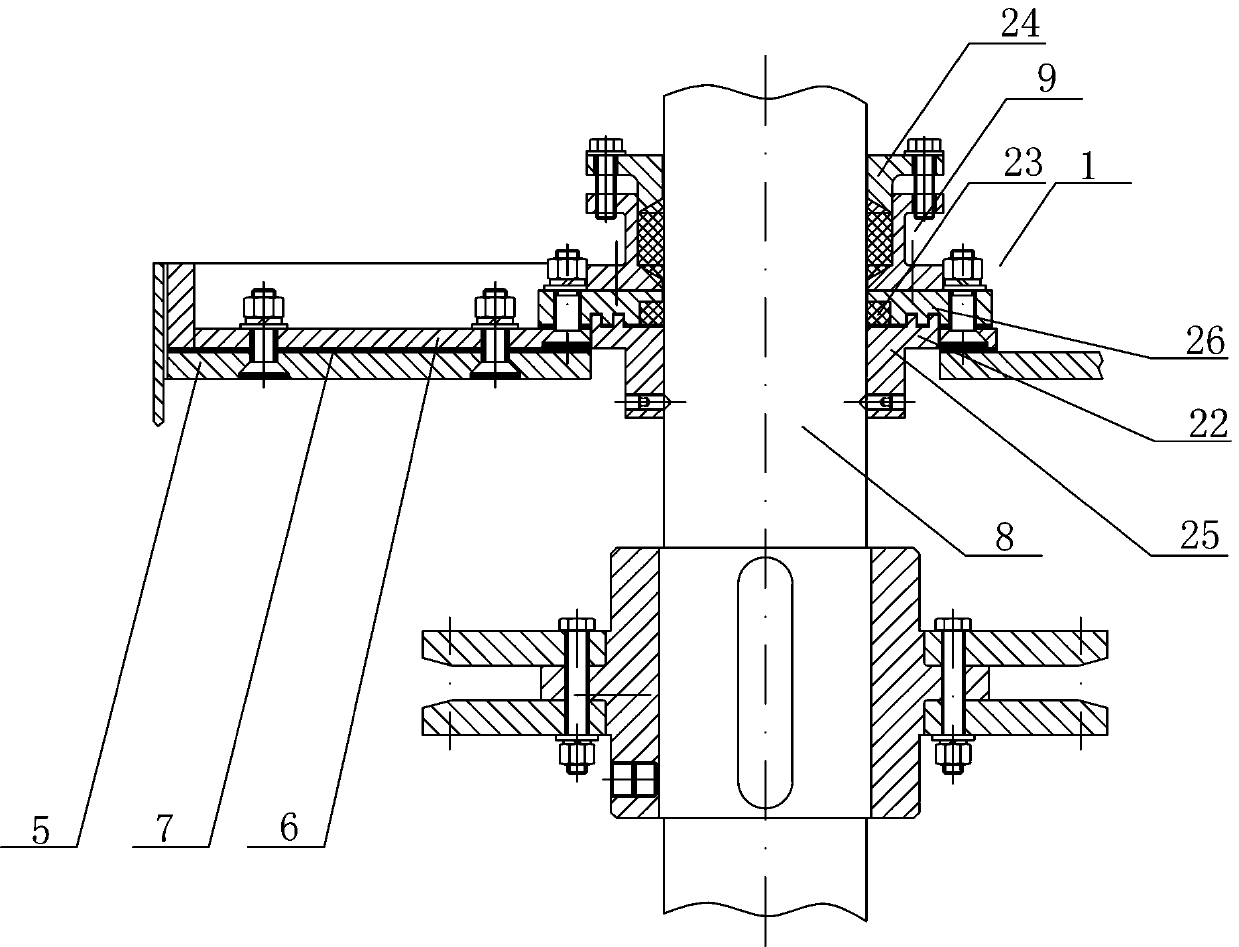

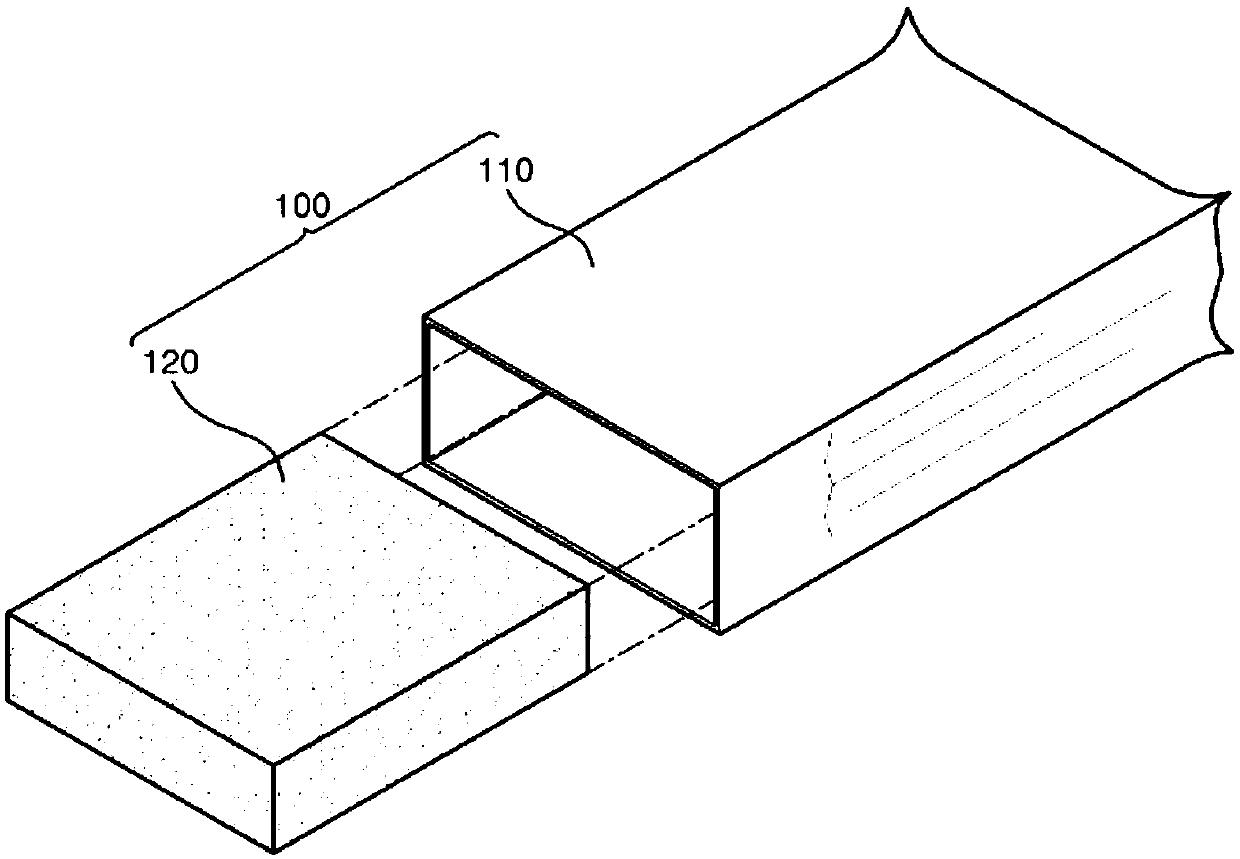

Positive-pressure sealing and rapid cover plate opening embedded scraper transporter

ActiveCN106379693AReduce dust leakageReduce dust rateConveyorsPackagingLocking mechanismPositive pressure

A positive-pressure sealing and rapid cover plate opening embedded scraper transporter comprises a head part, a tail part and an intermediate section, all of which are provided with access doors. The head part is provided with a head sealing mechanism, and the tail part is provided with a tail sealing mechanism. The intermediate section is provided with a sealing and rapid upper cover opening mechanism, and the access doors are provided with sealing and rapid viewing door opening mechanisms. According to the positive-pressure sealing and rapid cover plate opening embedded scraper transporter, through well sealing on the shaft stretching-out end of the embedded scraper transporter, the access doors, an upper cover and other places where dust is possibly generated, environment pollution is reduced; and through the improvement on the access doors and an upper cover locking mechanism, rapid cover opening is convenient, and time is saved.

Owner:HUBEI YIDU YIYUN ELECTROMECHANICAL ENG CO LTD

Combined type telescopic movable storage bin

PendingCN110356726ALarge working spaceRealize remote automatic controlLarge containersStorage devicesEngineeringYard

The invention discloses a combined type telescopic movable storage bin, and belongs to environment-friendly facilities. The storage bin is mainly used for piling open-air bulk materials. The storage bin consists of arched net frames, arched pipe trusses, a box-shaped structure base, a traveling mechanism, a base, a guide rail, a hydraulic rod system and telescopic scissors-truss supports, whereinthe guide rail is arranged on the base; the travelling mechanism travels on the guide rail; the box-shaped structure base is welded to the bottom of the arched net frames and is connected with the arched pipe truss in the middle; the arched pipe trusses are positioned between two arched net frames; every two arched pipe trusses are connected by one telescopic scissor-truss support; and the telescopic scissor-truss supports drive the arch-shaped pipe truss in the middle to stretch out and retract back under the drive of the hydraulic rod system. The storage bin has the advantages of convenientmovement, flexible operation space, low manufacturing cost, good sealing effect and long service life, and the dust pollution in a bulk material storage yard is effectively eliminated.

Owner:山西尚风抑风墙科技有限公司

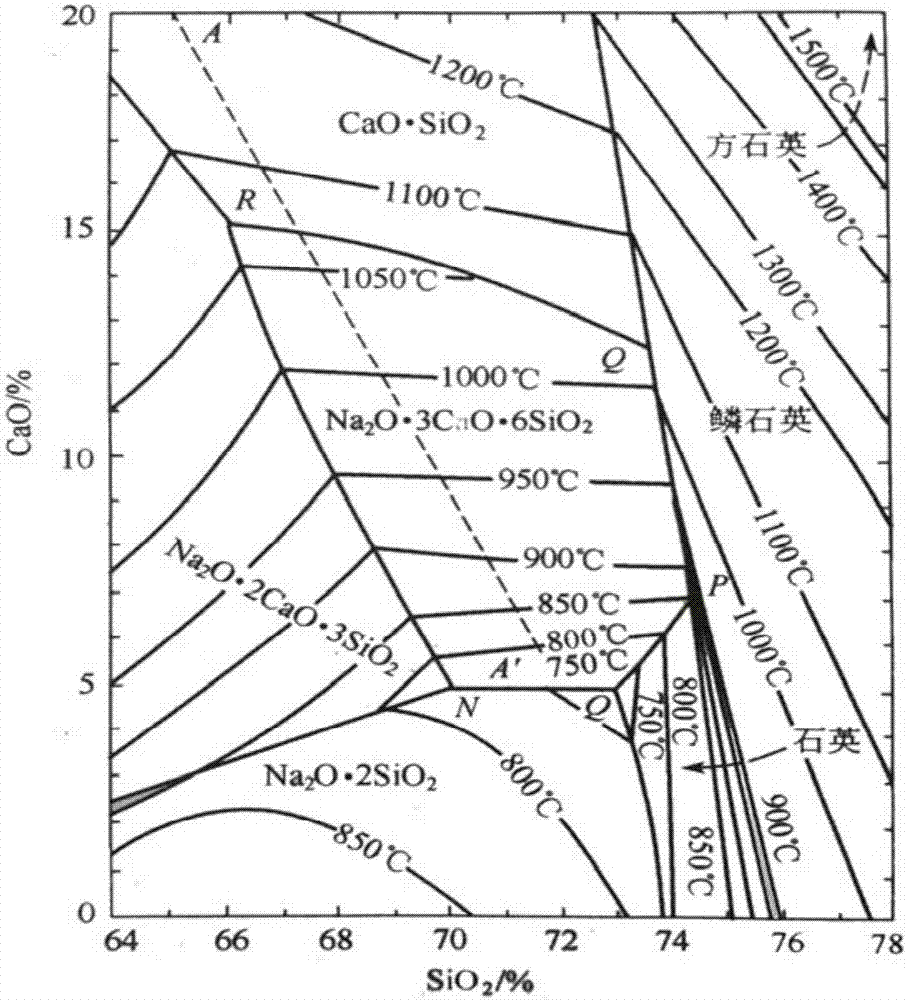

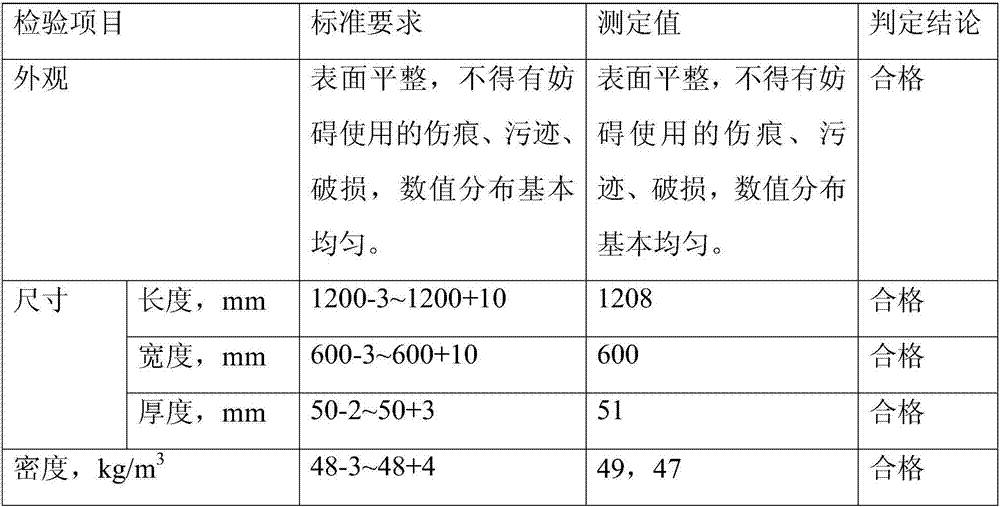

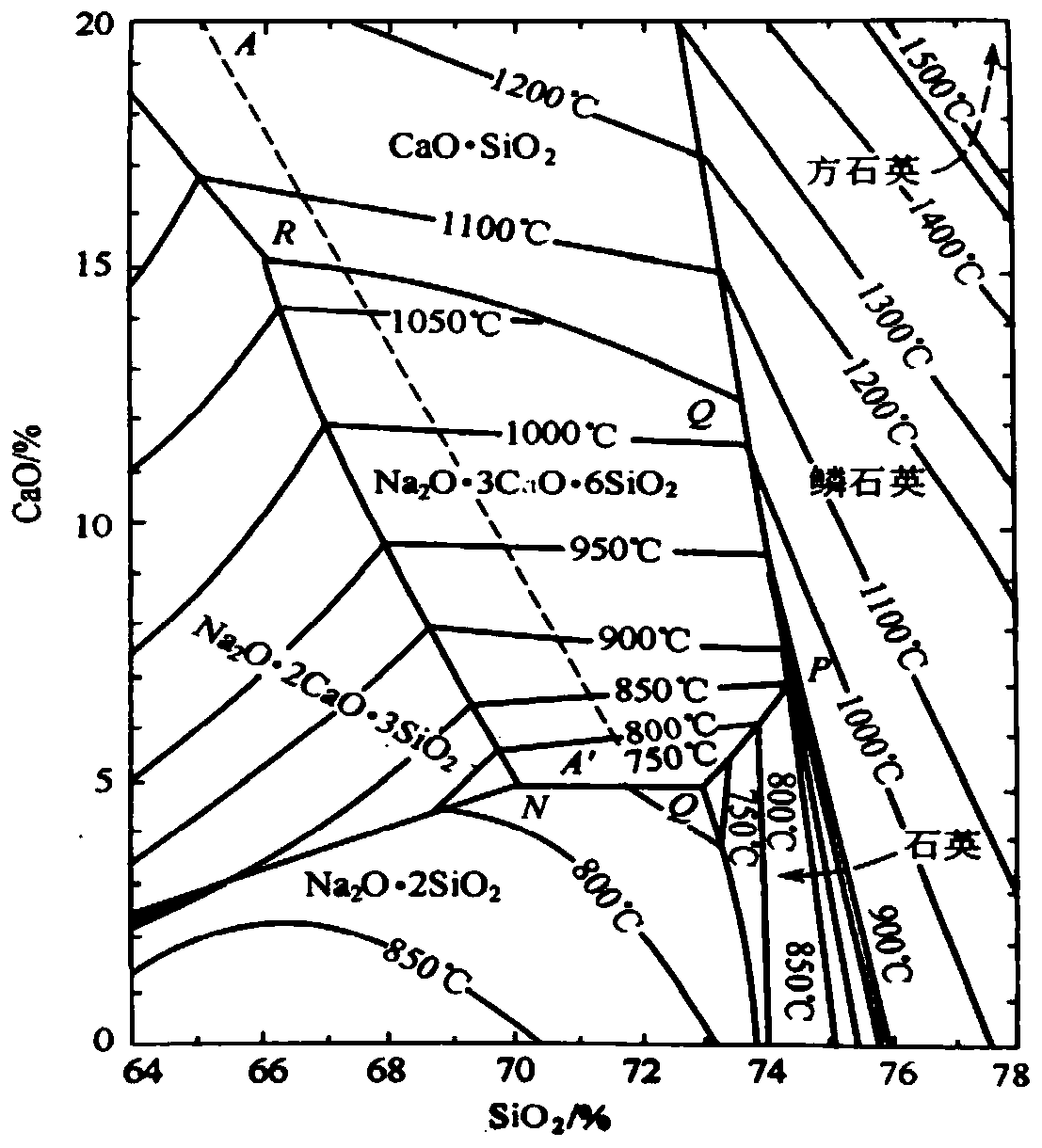

Glass wool powder for large-scale production of glass wool and production method thereof as well as glass wool

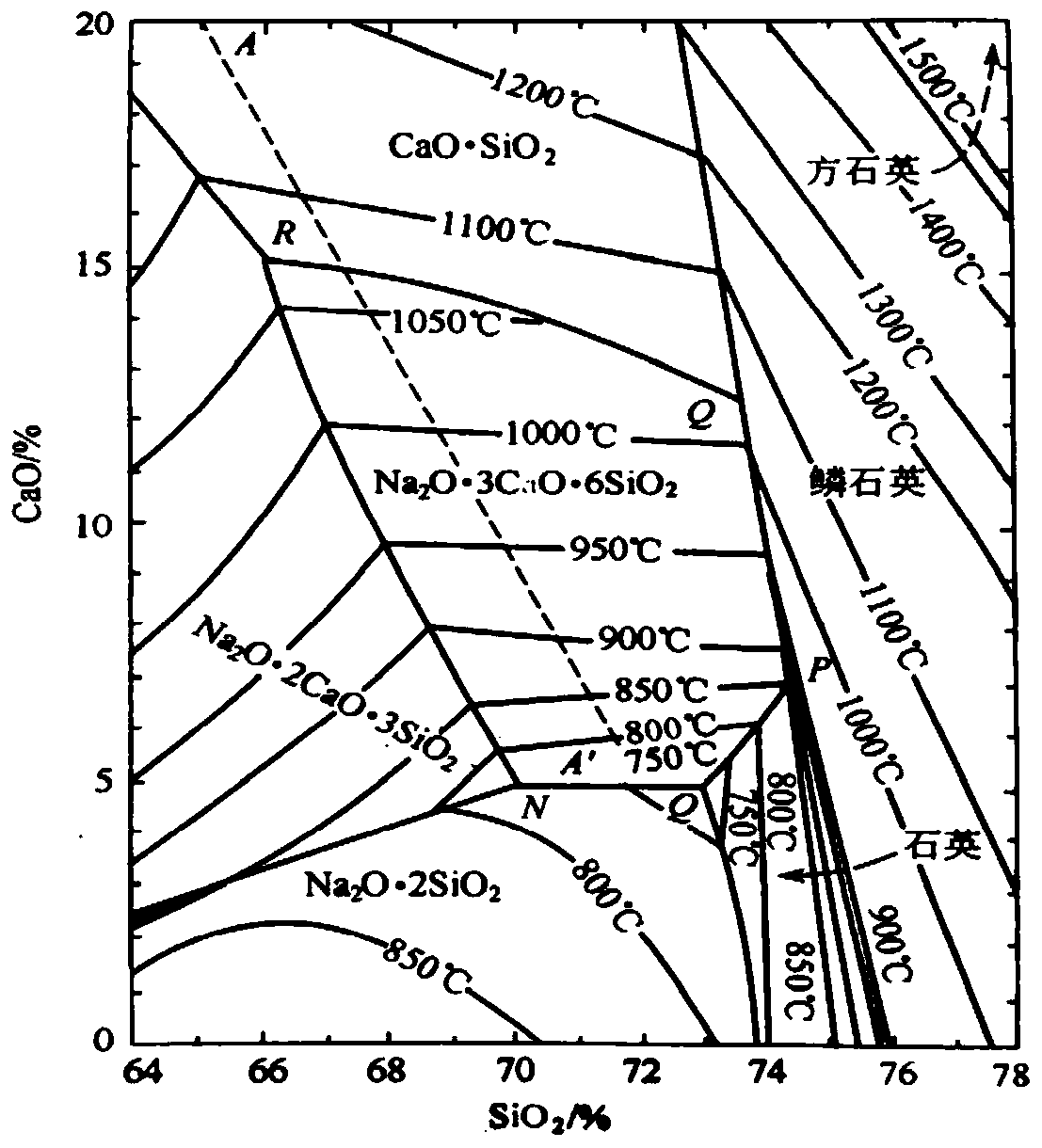

ActiveCN106892568ALow priceReduce manufacturing costGlass making apparatusGlass productionLoss rateGlass wool

The invention discloses glass wool powder for large-scale production of glass wool and a production method thereof as well as the glass wool. The glass wool powder comprises the following components in parts by weight: 75-85 parts of waste glass, 5-10 parts of borax pentahydrate, 1-3 parts of sodium carbonate, 1-3 parts of dolomite, 1-3 parts of potash feldspar, 1-2 parts of potassium carbonate, 0.5-1.5 parts of sodium nitrate, 0.3-1 part of table salt and 0.5-1 part of sodium sulfate. The glass wool powder and the production method thereof as well as the glass wool disclosed by the invention have the benefits that the production cost is low, resources are comprehensively utilized, and the environmental protection is facilitated; as the waste glass is used as a main raw material, the cost is low, so that the price of the glass wool is greatly reduced, the product competitiveness is improved, and meanwhile a large quantity of waste glass is treated, therefore, the environmental protection is facilitated; the compression resilience ratio of the glass wool is more than or equal to 96.1 percent; the average fiber diameter of the glass wool is 3.5 [mu]m; the moisture content is less than or equal to 0.3 percent; a thermal conductive coefficient is less than or equal to 0.032 W / (m.K); the mass loss rate is less than or equal to 4.8 percent, the raised temperature in a furnace is less than or equal to 3 DEG C, and the continuous flame time is 0 second.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL

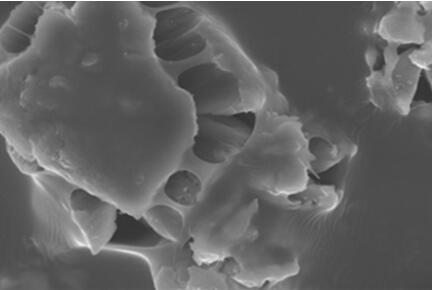

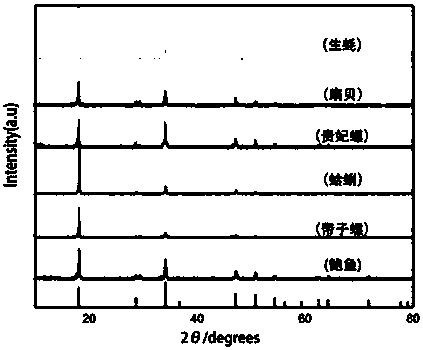

Preparation method of high-quality environment-friendly dust-free shell chalk prepared from waste shells

The invention relates to a preparation method of a high-quality environment-friendly dust-free shell chalk made of waste shells, and belongs to the technical field of chalk preparation. The high-quality environment-friendly dust-free shell chalk is suitable for classroom teaching. The method comprises the following steps of: carrying out ultrasonic cleaning and hydrogen peroxide bleaching on the waste shells; crushing the treated shells into 200-mesh shell powder; carrying out microscopic morphology analysis on the shell powder by using a scanning electron microscope (SEM) to show a loose porous structure; according to the special structure of the shell powder, adding a water-soluble binder prepared by mixing polyethylene alcohol and water according to a ratio of 1: 50 into the shell powder, adding talcum powder as a lubricant, or adding a pigment to prepare a colored dust-free shell chalk; and drying the prepared chalk to obtain the high-quality, environment-friendly non-toxic dust-free shell chalk. The dust rate of the chalk prepared by the method is obviously reduced, the probability of causing respiratory discomfort or even diseases of teachers and students is greatly reduced,the skin of the teachers is not corroded, and the health of the teachers and students is protected.

Owner:LINGNAN NORMAL UNIV

Dust-fall method for coal body in extra-thick fully-mechanized caving face through high-pressure water injection

InactiveCN106869986AReduce dust rateReduce the temperatureDust removalFire preventionSpontaneous combustionHigh pressure water

The invention relates to a dust-fall method for coal mining, in particular to a dust-fall method for a coal body in an extra-thick fully-mechanized caving face through high-pressure water injection. By adoption of the dust-fall method, the problem of lacking a method for controlling dust concentration in the process of mining the coal body in the extra-thick fully-mechanized caving face is solved. According to the scheme, the dust-fall method comprises the following steps that a, after a stope working face is circled, water injection holes are drilled in an inlet air forward groove and a return air forward groove of the stope working face, and included angles between the water injection holes and the forward grooves are 90 degree; b, the water injection holes are sealed through hole packers; and c, water is injected into the water injection holes through a water injection pump. The dust-fall method for the coal body in the extra-thick fully-mechanized caving face through high-pressure water injection has the advantages that (1) through water injection of the coal body in the extra-thick fully-mechanized caving face, dust production is eliminated from the source to the maximum extent, and thus the dust rate of the stope working face is effectively reduced; (2) through water injection of the coal body in the extra-thick fully-mechanized caving face, the temperature of the coal body in the stope range is effectively decreased and the spontaneous combustion control effect is obvious; and (3) the drilled water injection holes are arranged and designed reasonably, operation is easy, construction is convenient, and the dust-fall effect is remarkable.

Owner:DATONG COAL MINE GRP

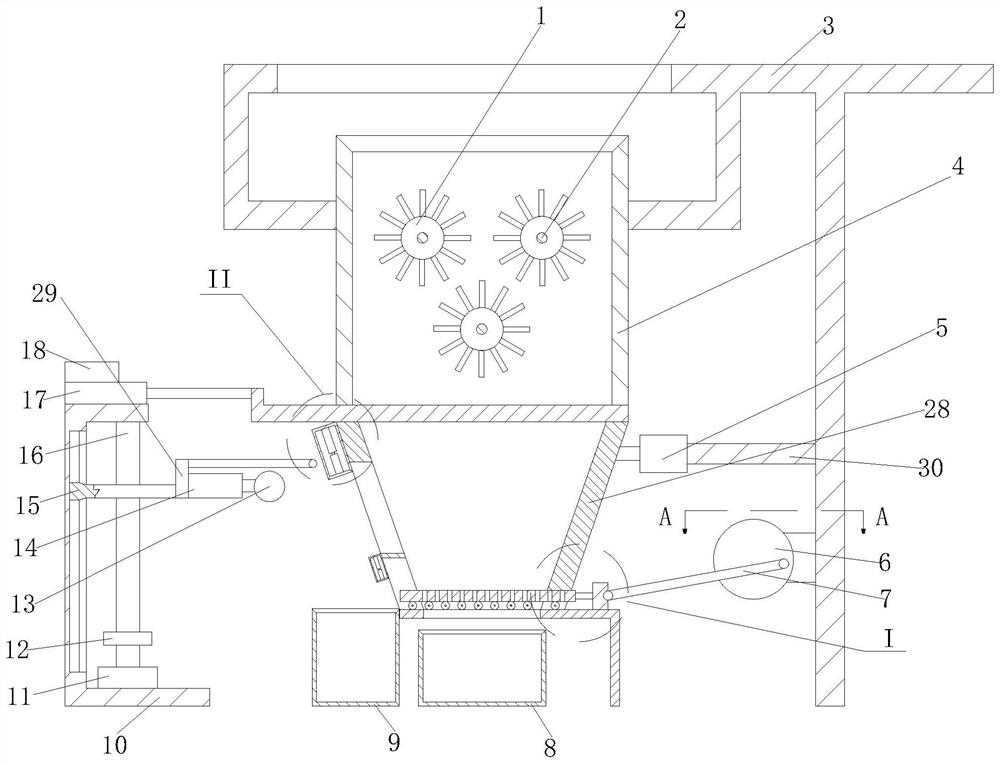

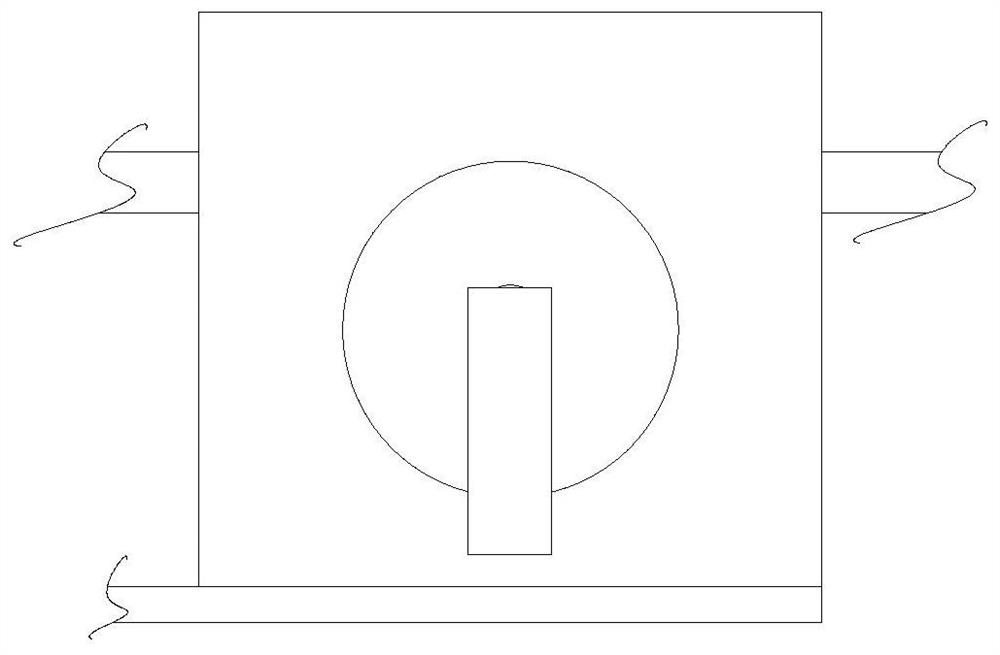

Coal particle and pulverized coal separation device for hot blast stove

The invention relates to the field of hot blast stoves, in particular to a coal particle and pulverized coal separation device for hot blast stoves, which includes a crushed coal box, a separation box matched with the crushed coal box, and a support frame for supporting the crushed coal box. A coal crushing device for crushing coal into coal powder and coal particles is provided in the box, and a coal leakage device for leaking coal particles and coal powder into the separation box is provided at the lower end of the coal crushing box; The separation box is provided with a dust-proof device, the bottom of the separation box is provided with a separation device for packing the coal particles and coal powder respectively, and the lower end of the separation device is provided with a separation device for respectively loading coal particles and coal powder. Coal particle box and coal powder box, the fuel of the hot blast stove is divided into coal particles and coal powder, which can reduce the phenomenon of insufficient combustion caused by the accumulation of coal powder, and reduce production costs; Manufacture and maintenance; when vibrating, the dust is blown to the bottom and precipitated, which improves the utilization rate, reduces the dust rate, and reduces air pollution.

Owner:芜湖新农夫机械股份有限公司

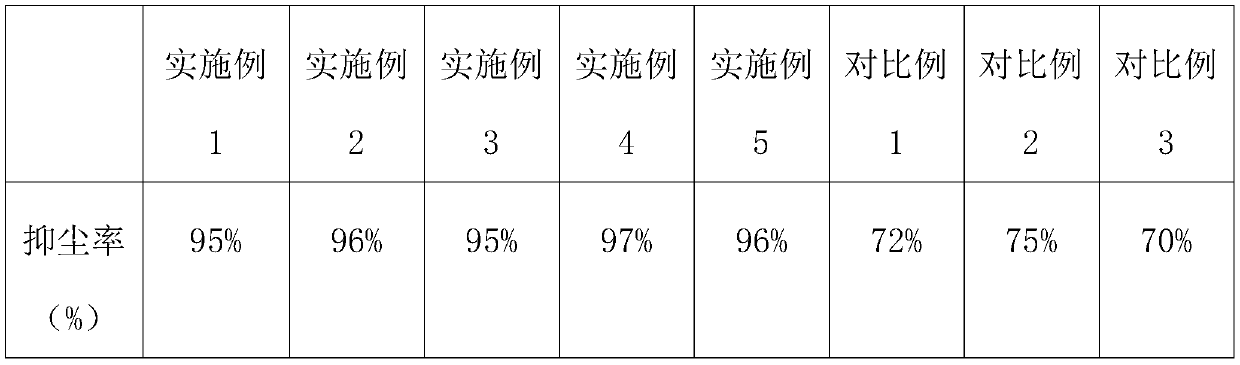

Mixed clay for environment-friendly wet mold casting and preparation method thereof

ActiveCN110814272BReduce dust rateImprove working environmentFoundry mouldsMould handling/dressing devicesPolyvinyl alcoholCellulose compounds

The invention discloses an environment-friendly mixed soil for wet casting, which comprises raw coal powder, bentonite and dust-proof slurry, wherein the raw coal powder, bentonite and dust-proof slurry are uniformly dispersed, and the weight of the dust-proof slurry is the raw coal 3%~8% of the total weight of powder and bentonite; the dust-proof slurry is a solution of polyvinyl alcohol, xylitol, cellulose compound, α-starch, monosaccharide or disaccharide, or polyvinyl alcohol, A mixed solution of two or more of xylitol, cellulose compound, α-starch, monosaccharide or disaccharide. The surface of the powdered coal particles and bentonite particles of the mixed soil for wet casting of the present invention is coated with a layer of dust-proof slurry film, which will not affect the mechanical airflow of the mixed soil during dry mixing and feeding while suppressing dust, and will not It will affect the fluidity of green sand; while maintaining the functions of coal powder and bentonite, the components of the slurry are also conducive to improving the performance of green sand, and these components can be used as additives for improving the performance of molding sand.

Owner:姚立猛

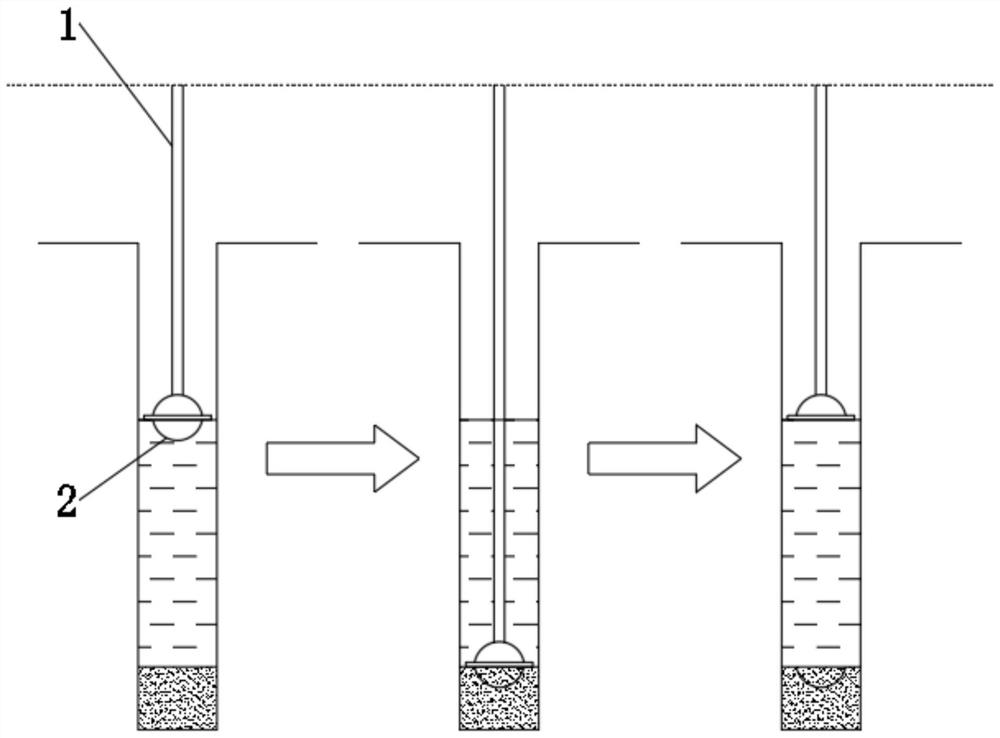

Open air water hole float-and-sink sounding type detonating method

InactiveCN113310370AImprove blasting efficiencyImprove blasting effectBlastingDetonationExplosive Agents

The invention discloses an open air water hole float-and-sink sounding type detonating method and belongs to the technical field of detonation. A double-layered pipe is spirally connected to a detonating sink plate, the detonating sink plate is transferred down to a water surface in a water hole to measure depth of an air layer, then a balance weight material is injected into the double-layered pipe, the detonating sink plate gained in weight sinks continuously to the surface of sludge in the water hole to measure the depth of the water layer, the balance weight material is continuously injected into the double-layered pipe till the detonating sink plate sinks downwards to the bottom of the water hole to measure the depth of a sludge layer, explosive components are prepared reasonably according to depths of the air layer, the water layer and the sludge layer, then water is injected into the double-layered pipe, so that the detonating sink plate is separated, the lower half part of the detonating sink plate is left in the sludge layer and the upper half part floats to the water surface, the upper half part is filled with macadams to a hole opening with a plugging material, detonation is reserved in the lower half part to adjust measures to local conditions, and explosive bags are distributed and mounted while sounding is achieved, and therefore, the detonating efficiency and effect can be improved remarkably.

Owner:庄杰成

Straw powder sieving apparatus and powder sieving process thereof

InactiveCN111545449AAvoid damageExtended service lifeSievingScreeningElectric machineProcess engineering

The invention discloses a straw powder sieving apparatus and a powder sieving process thereof and belongs to the technical field of straw smashing. The straw powder sieving apparatus comprises a casing and a powder sieving chamber mounted on the casing. A feeding hopper is fixedly mounted at the top of the powder sieving chamber. A feeding pipe is arranged in the feeding hopper. A protection hoodis arranged outside the feeding pipe in a sleeving mode. A plurality of fans are arranged between the protection hood and the feeding pipe. A first motor is fixedly mounted on the outer wall of the powder sieving chamber. The output end of the first motor is fixedly connected with a first screen plate. A second motor is arranged above the first motor. The output end of the second motor is fixedlyconnected with a second screen plate. According to the straw powder sieving apparatus and the powder sieving process thereof, the fans are arranged to blow dust generated in the sieving process of straw powder into a discharging hopper, so that the dust raising rate in the casing is reduced, and meanwhile the waste of powder is reduced; and the first motor and the second motor are arranged to rotationally overturn the second screen plate and the first screen plate, so that the straw powder on the second screen plate and the first screen plate fall down, and accordingly residual powder is reduced.

Owner:安徽淮宿建材有限公司

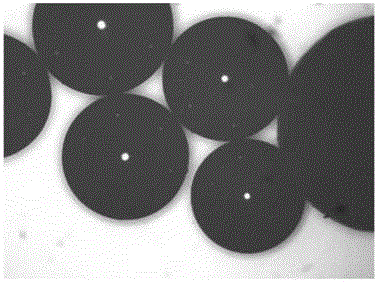

A kind of supported spherical activated carbon catalyst and preparation method thereof

ActiveCN104084195BLarge specific surface areaIncrease profitDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCarbonizationBiological activation

The invention relates to a supported spherical activated carbon catalyst and a preparation method thereof, belonging to the technical field of chemical catalysts. The catalyst is supported by Pt or Pd or both, with an average diameter of 0.6-1.5mm and a specific surface area of ≥600m 2 / g, the surface of spherical activated carbon carrier with dust rate <0.5%. By mixing pitch and naphthalene and heating it, then preparing pitch balls by suspension method, and then performing oxidation infusion, carbonization and activation treatment in sequence to obtain pitch-based spherical activated carbon, which is washed with acid and water until neutral to obtain a catalyst carrier; The catalyst is obtained by impregnating the carrier in an alcoholic aqueous solution containing a metal precursor, drying it and reducing it with hydrogen or a reducing solution. The catalyst carrier has high specific surface area, high metal utilization rate, smooth catalyst surface, uniform shape, small resistance, high mechanical strength, low dust rate, long service life, and high catalytic activity and stability for formaldehyde at room temperature .

Owner:中国船舶集团有限公司第七一八研究所

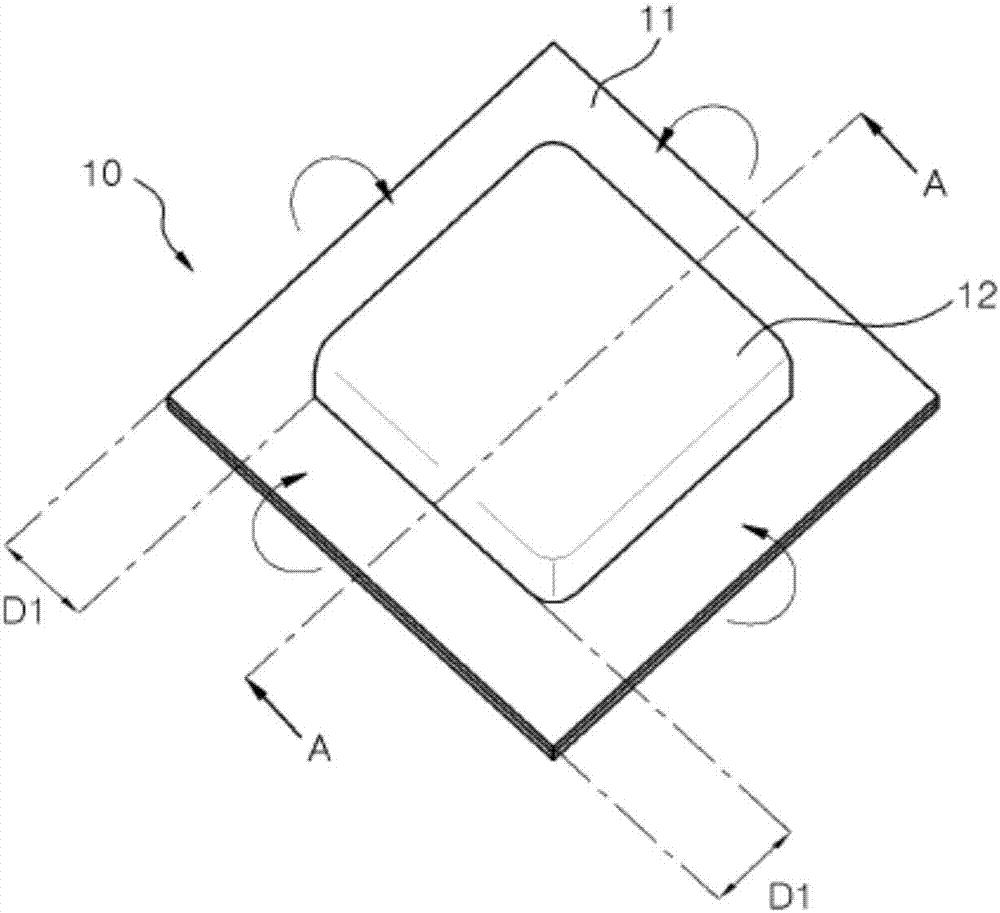

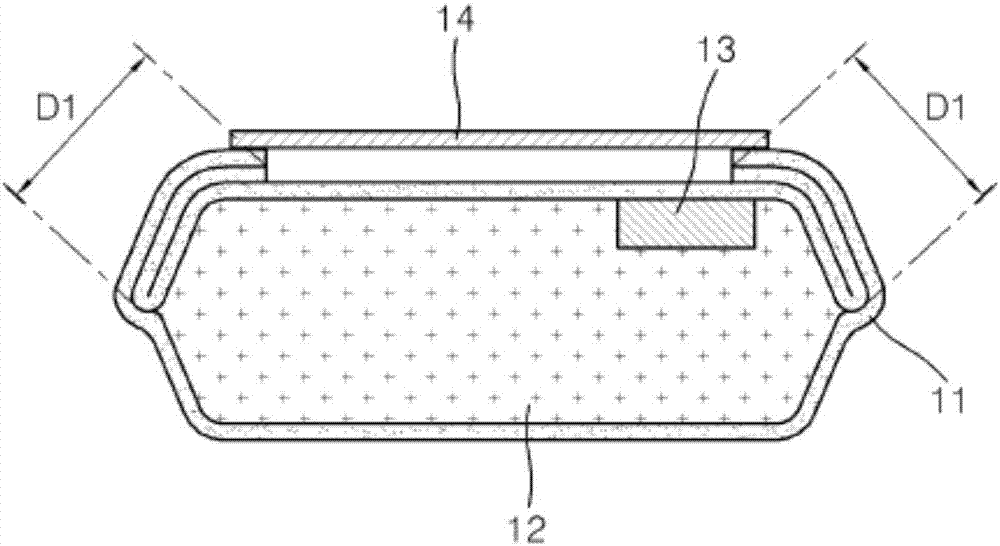

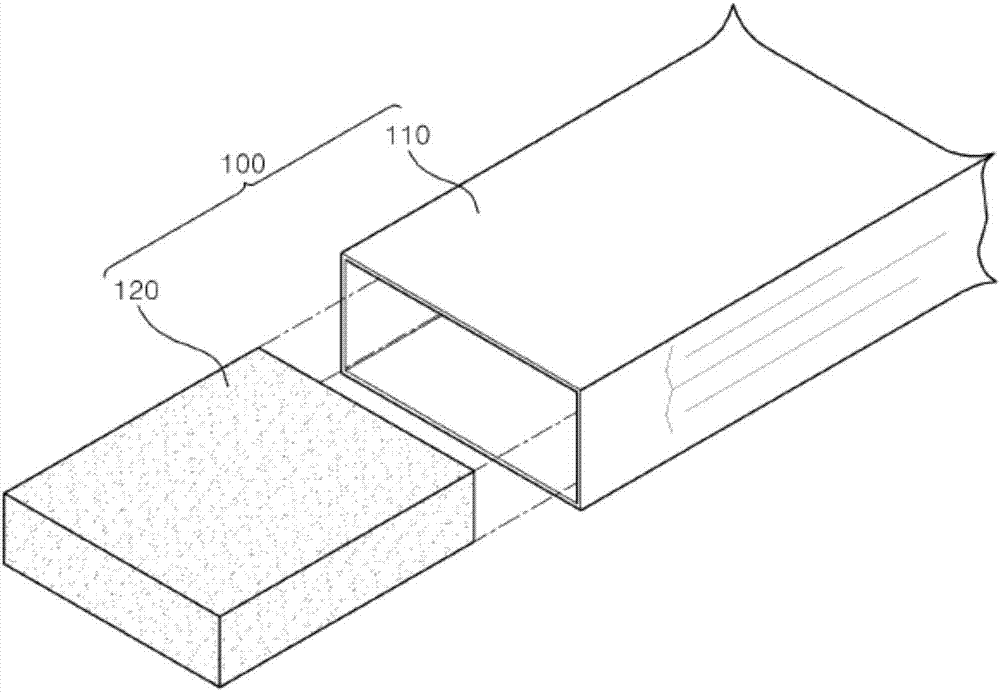

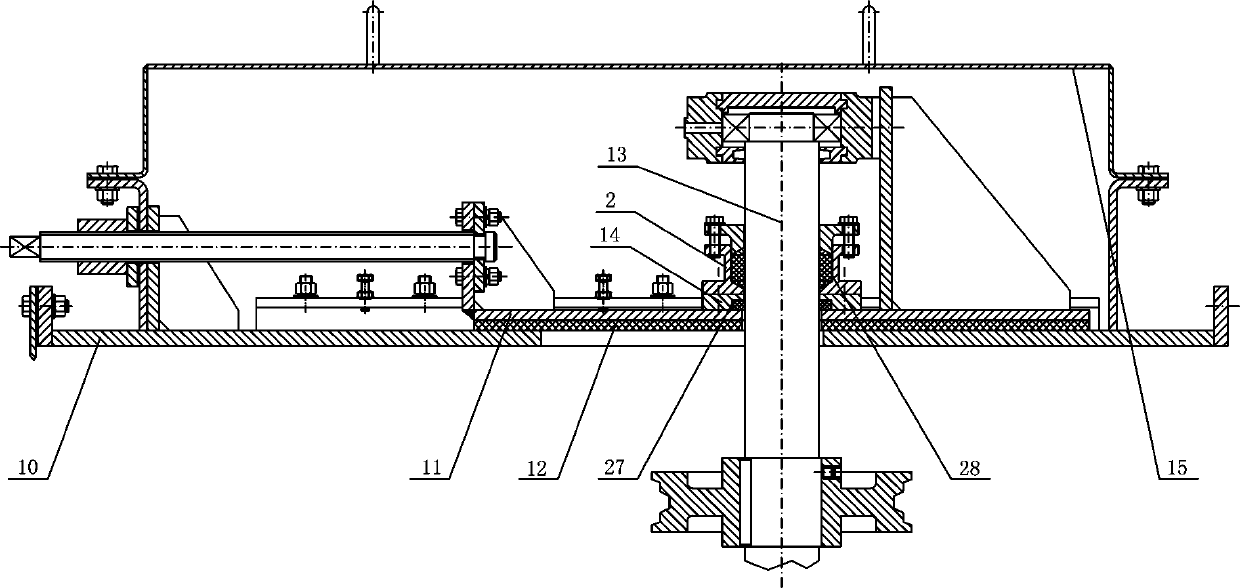

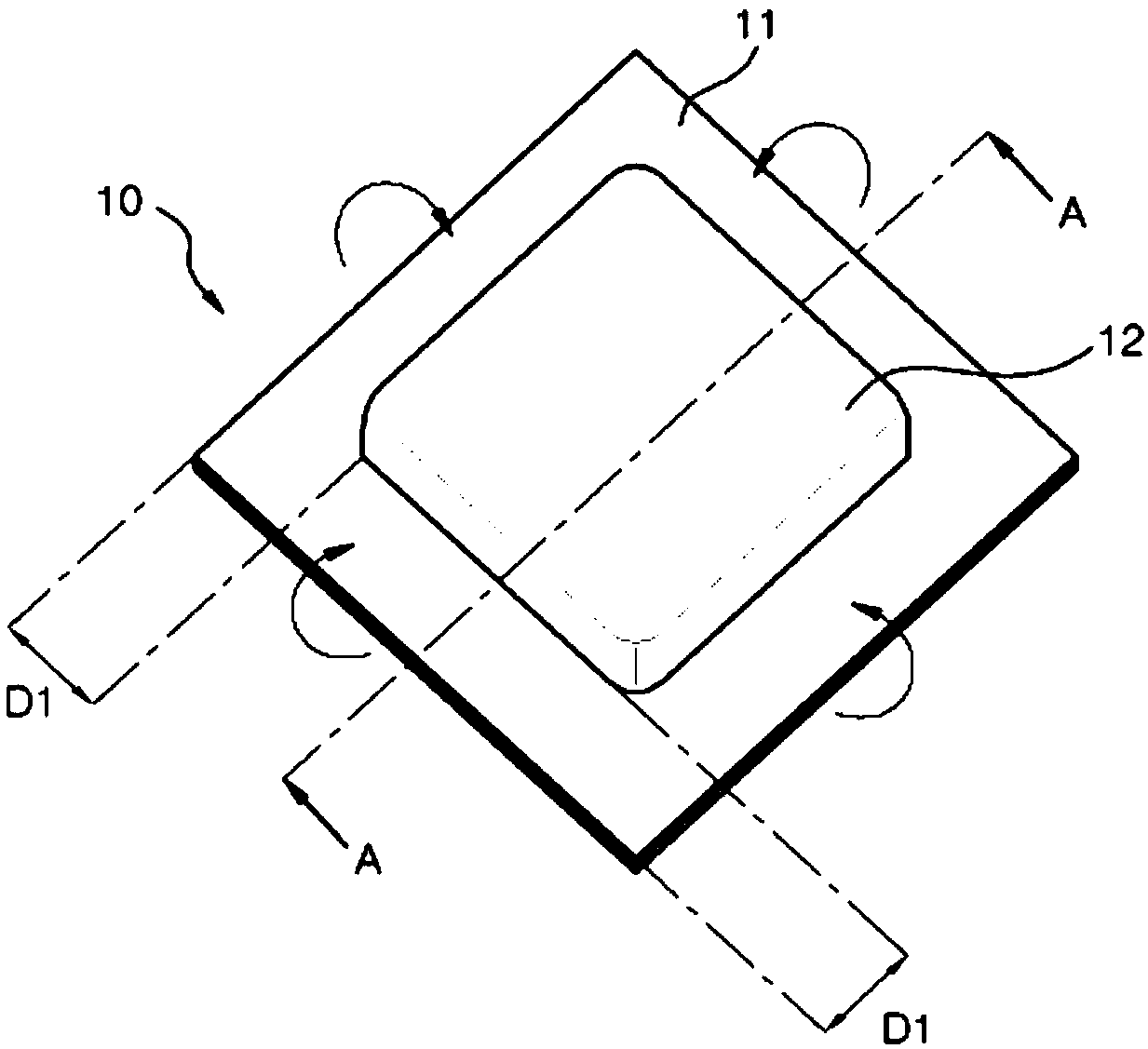

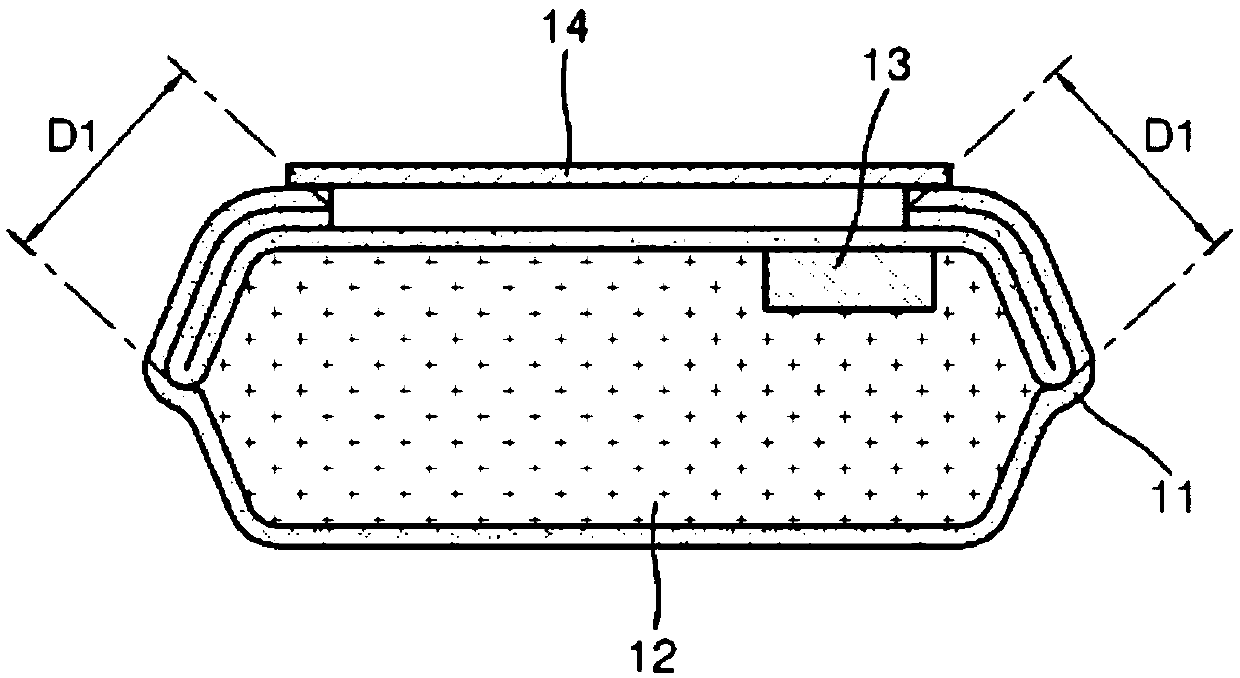

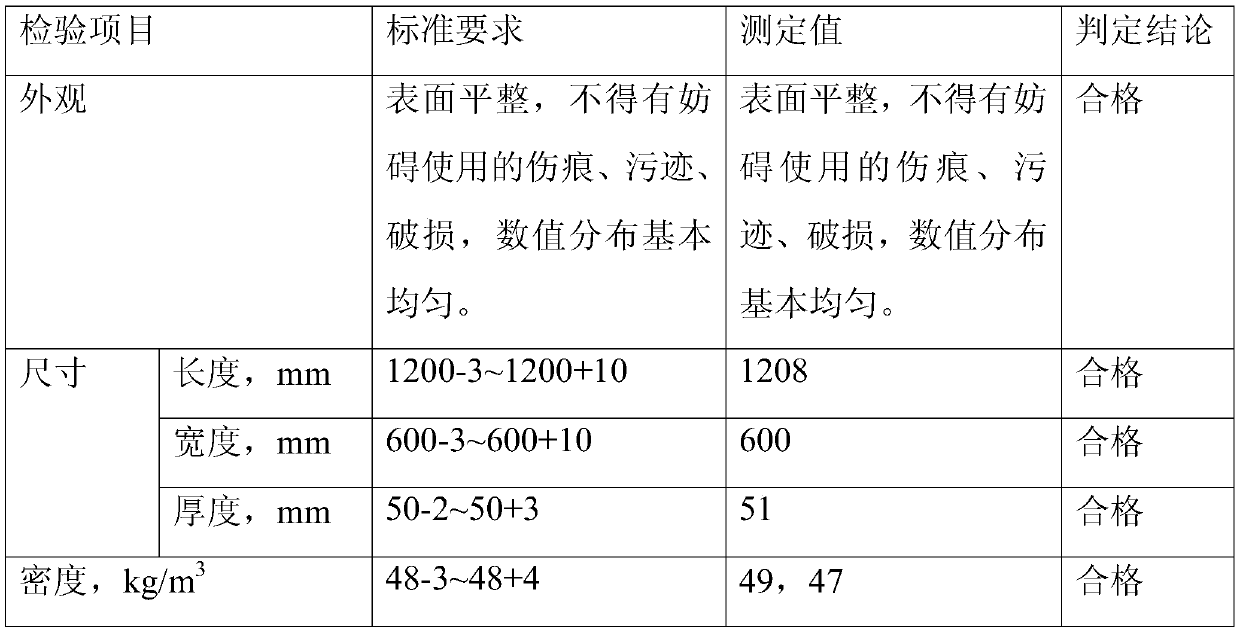

Method and apparatus for manufacturing vacuum insulation panel

ActiveCN107023735ALow thermal conductivityReduce dust rateThermal insulationPipe protection by thermal insulationVacuum pressureVacuum pump

After the method for manufacturing vacuum insulator according to the invention settles the core in the jig upper side of panel in which the upper side is covered with the compression film and it discharges air between the jig panel and the compression film and it compresses the core it pressurizes the core in the state inserting all or part of the jig panel inside the coating material of the form of pouch and it leads inside the coating material and it seals up the opening part of the coating material since exhausting the air within the coating material. The vacuous insulator manufacturing device according to the invention comprises the jig panel of the flat pattern in which the core is possible to mount in the upper side; the rest three-way edge except for one side or the compression film in which the other side edge is closely connected to the jig panel the core settled in the jig upper side of panel is covered; the jig panel; and the pressing unit which pushes the vacuum pump forming the vacuum pressure between the compression film and compresses the core and the core compacted by the vacuum pump with one side and discharged.

Owner:KCC CORP CO LTD

A kind of positive pressure sealing quick opening cover buried scraper conveyor

ActiveCN106379693BReduce dust leakageReduce dust rateConveyorsPackagingLocking mechanismPositive pressure

A positive-pressure sealing and rapid cover plate opening embedded scraper transporter comprises a head part, a tail part and an intermediate section, all of which are provided with access doors. The head part is provided with a head sealing mechanism, and the tail part is provided with a tail sealing mechanism. The intermediate section is provided with a sealing and rapid upper cover opening mechanism, and the access doors are provided with sealing and rapid viewing door opening mechanisms. According to the positive-pressure sealing and rapid cover plate opening embedded scraper transporter, through well sealing on the shaft stretching-out end of the embedded scraper transporter, the access doors, an upper cover and other places where dust is possibly generated, environment pollution is reduced; and through the improvement on the access doors and an upper cover locking mechanism, rapid cover opening is convenient, and time is saved.

Owner:HUBEI YIDU YIYUN ELECTROMECHANICAL ENG CO LTD

Manufacturing method and manufacturing device of vacuum heat insulating material

ActiveCN107023735BLow thermal conductivityReduce dust rateThermal insulationPipe protection by thermal insulationVacuum pressureVacuum pump

After the method for manufacturing vacuum insulator according to the invention settles the core in the jig upper side of panel in which the upper side is covered with the compression film and it discharges air between the jig panel and the compression film and it compresses the core it pressurizes the core in the state inserting all or part of the jig panel inside the coating material of the form of pouch and it leads inside the coating material and it seals up the opening part of the coating material since exhausting the air within the coating material. The vacuous insulator manufacturing device according to the invention comprises the jig panel of the flat pattern in which the core is possible to mount in the upper side; the rest three-way edge except for one side or the compression film in which the other side edge is closely connected to the jig panel the core settled in the jig upper side of panel is covered; the jig panel; and the pressing unit which pushes the vacuum pump forming the vacuum pressure between the compression film and compresses the core and the core compacted by the vacuum pump with one side and discharged.

Owner:KCC CORP CO LTD

A method for industrially producing anhydrous lithium hydroxide balls

ActiveCN109553118BAchieve recyclingPrevent hardeningCarbon compoundsLithium oxides/hydroxidesLithium hydroxidePhysical chemistry

The invention provides a method for industrially producing anhydrous lithium hydroxide balls, comprising the steps of dehydration drying, fine powder, ball forming of powder, sieving, drying, and thelike. Medicine grains, which do not cause powder falling and do not have irritating smell, are prepared from anhydrous lithium hydroxide by a powder forming process. When the anhydrous lithium hydroxide balls are applied to a CO2 absorbent, the absorption efficiency of carbon dioxide by the absorbent is tested to be 85% or more according to a coal standard MT454-2008.

Owner:GANFENG LITHIUM CO LTD

Coal powder for environment-friendly wet mold casting and preparation method thereof

ActiveCN110681816BReduce dust rateImprove working environmentFoundry mouldsMould handling/dressing devicesMetallurgyPolyvinyl alcohol

The invention discloses an environment-friendly wet mold casting coal powder, which is composed of raw coal powder and dust-proof slurry, the dust-proof slurry and the raw coal powder are evenly dispersed, and the weight of the dust-proof slurry is 2 times the weight of the raw coal powder. %~8%; the dustproof slurry is a solution of polyvinyl alcohol, xylitol, cellulose compounds, α-starch, monosaccharide or disaccharide, or a solution of polyvinyl alcohol, xylitol, cellulose A mixed solution of two or more of compounds, alpha-starch, monosaccharides or disaccharides. The pulverized coal for wet casting of the invention has a low dust fugitive rate, basically does not fugitive dust when it is dry mixed with raw sand, clay, etc., solves the problem of blackness and dirt, and improves the working environment.

Owner:姚立猛

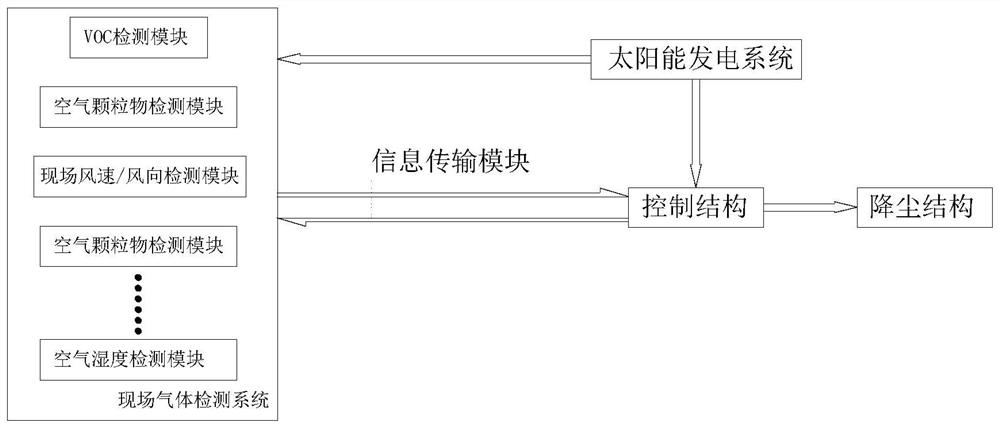

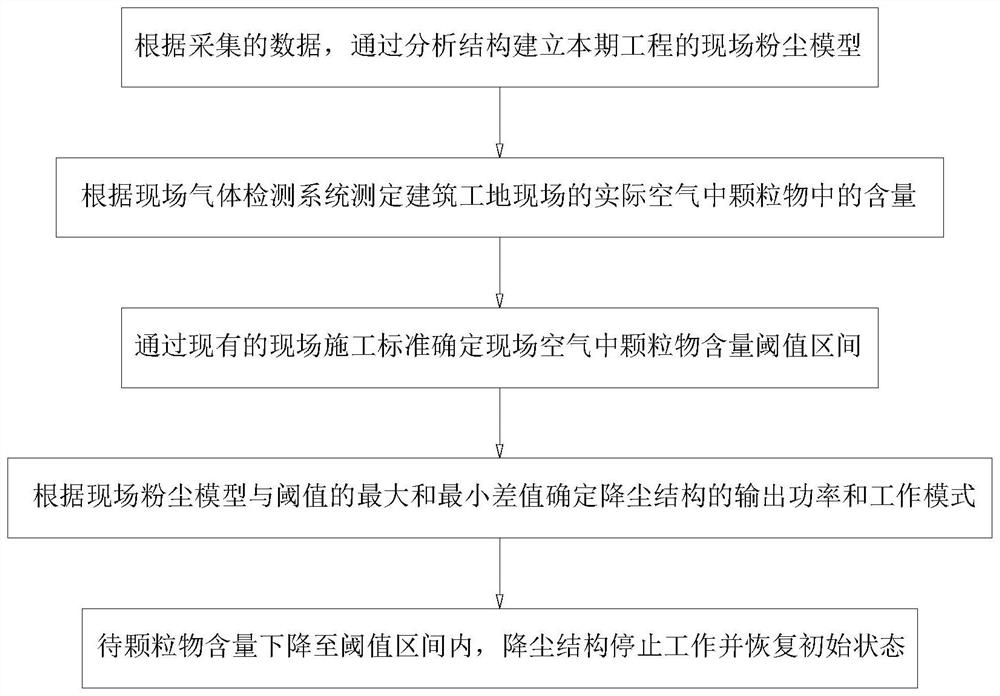

Intelligent dust fall control method and system for construction site

PendingCN114471034AReduce dust rateProtect the urban environmentUsing liquid separation agentSeparation devicesParticulatesEnvironmental engineering

The invention discloses an intelligent dust fall control method and system for a construction site, and the method comprises the steps: 1, inputting local meteorological information and the engineering information of the current construction site into a control structure, and building an on-site dust model of the current engineering according to a data analysis structure; 2, the content of particulate matter in actual air of the construction site and other air information are measured according to an on-site gas detection system; step 3, determining a threshold interval of the content of particulate matters in the field air according to a field construction standard; 4, the output power and the working mode of the dust falling structure are determined according to the maximum difference value and the minimum difference value of the field dust model and the threshold value, the dust content, the humidity and the wind speed in air can be detected through the internal structure of the dust falling structure, detection values are output to a control device, and the control device controls a spraying assembly to conduct dust falling according to the detection values. The dust raising condition of the construction site can be monitored, the dust raising rate of the construction site is reduced through the spraying assembly, and the urban environment is protected.

Owner:HUNAN CITY UNIV

Stone etching solution and preparation method thereof

The invention relates to a stone etching solution and a preparation method thereof, and belongs to the technical field of stone processing. The preparation method comprises the following steps modifying corncobs through a pre-emulsification technology in emulsion polymerization to prepare alkali-treated corncob powder grafted acrylate emulsion; then compounding the alkali-treated corncob powder grafted acrylate emulsion with a corrosion solution; diluting with water to prepare the stone etching solution. According to the stone etching solution and the preparation method thereof, etched surfaces of stones are rapidly wetted, small-particle dust covers the stones while the stones are corroded and softened, and films are formed on the surfaces of the stones so as to effectively prevent the small-particle dust in subsequent treatment from flying off, reduce the dust rising rate and reduce damages, caused by the dust in a stone etching process, to workers; the stone etching solution and thepreparation method thereof have the advantages of high working efficiency, simple technology, labor saving and time saving, and raw material saving and have a wide application prospect.

Owner:常州海瑞纺织品有限公司

Glass wool powder for large-scale production of glass wool, production method and glass wool

ActiveCN106892568BLow priceReduce manufacturing costGlass making apparatusGlass productionLoss rateGlass wool

The invention discloses glass wool powder for large-scale production of glass wool and a production method thereof as well as the glass wool. The glass wool powder comprises the following components in parts by weight: 75-85 parts of waste glass, 5-10 parts of borax pentahydrate, 1-3 parts of sodium carbonate, 1-3 parts of dolomite, 1-3 parts of potash feldspar, 1-2 parts of potassium carbonate, 0.5-1.5 parts of sodium nitrate, 0.3-1 part of table salt and 0.5-1 part of sodium sulfate. The glass wool powder and the production method thereof as well as the glass wool disclosed by the invention have the benefits that the production cost is low, resources are comprehensively utilized, and the environmental protection is facilitated; as the waste glass is used as a main raw material, the cost is low, so that the price of the glass wool is greatly reduced, the product competitiveness is improved, and meanwhile a large quantity of waste glass is treated, therefore, the environmental protection is facilitated; the compression resilience ratio of the glass wool is more than or equal to 96.1 percent; the average fiber diameter of the glass wool is 3.5 [mu]m; the moisture content is less than or equal to 0.3 percent; a thermal conductive coefficient is less than or equal to 0.032 W / (m.K); the mass loss rate is less than or equal to 4.8 percent, the raised temperature in a furnace is less than or equal to 3 DEG C, and the continuous flame time is 0 second.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL

Urban construction dust control method

InactiveCN107587469BImprove performanceReduce usageOther chemical processesPolyvinyl alcoholDust control

The invention provides a kind of city construction dust control method, comprises the following steps: (1) the polyvinyl alcohol resin of 40-50 weight part, the plasticizer of 1-2 weight part, the inorganic filler of 20-30 weight part, 20-30 parts by weight of starch, 0.5-1 parts by weight of surfactant, and 400-560 parts by weight of water are mixed to form a film-forming liquid at 70-80°C, and then cast the film-forming liquid onto On a glass plate, remove the film after drying to obtain a water-soluble film, and open a through hole with a diameter of 100-200 μm on the water-soluble film; (2) lay a layer of film on the excavated construction surface, and water it to moisten it; (3) Lay a layer of film on the excavated surface after excavating to a depth of 1m, and water it to moisten it. The method is simple, low in cost, does not affect the construction of the construction site, and the prepared film has a better effect of preventing dust, quick effect, low cost, environmental protection and no pollution.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com