Positive-pressure sealing and rapid cover plate opening embedded scraper transporter

A technology of buried scraper conveyor and sealing plate, applied in the field of buried scraper conveyor, can solve the problems of damaged cover plate and side plate gasket, inconvenient door edge, affecting the sealing effect, etc., to maintain self-lubricating and durable. Grinding performance, reducing the probability of dust leakage or dust, and enhancing the effect of sealing and dust-proofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

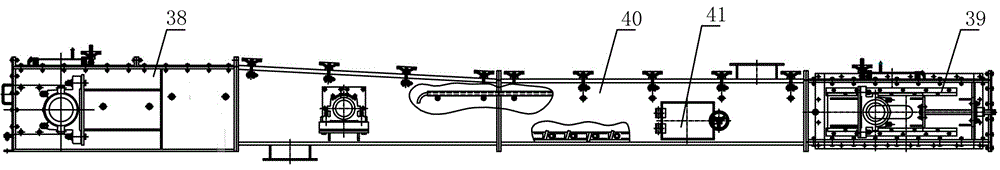

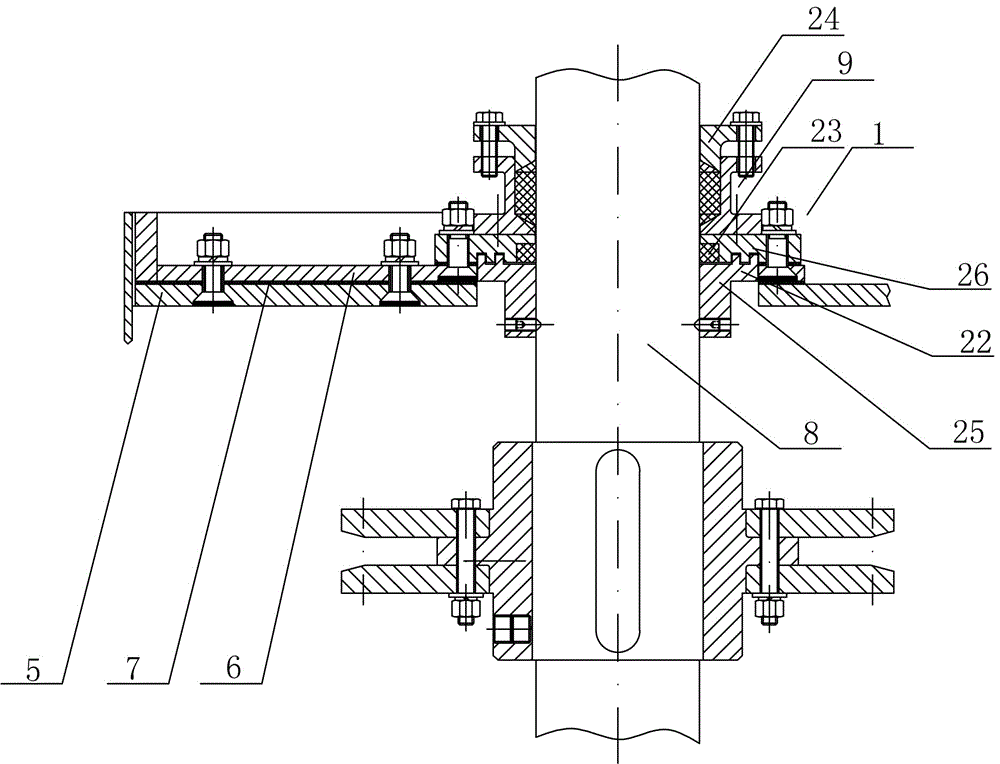

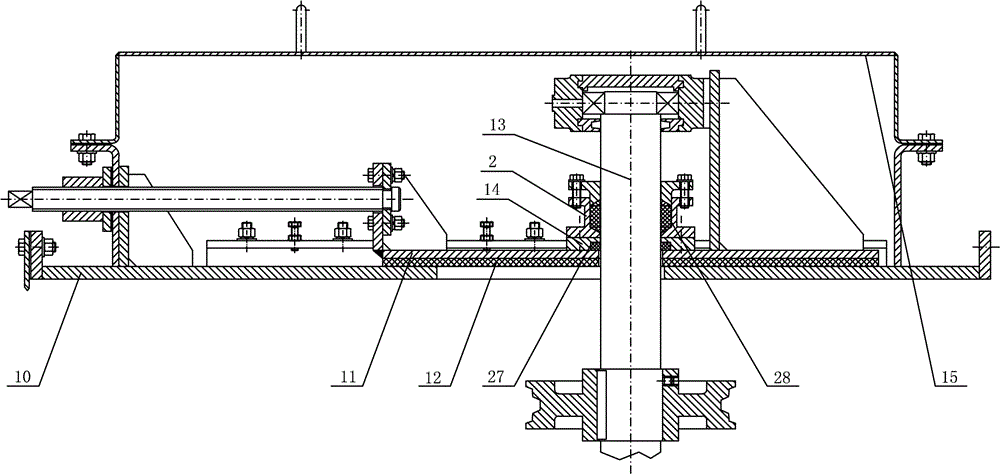

[0041] Such as Figure 1-11 As shown, a positive-pressure sealed quick-opening cover-buried scraper conveyor includes a head 38, a tail 39, a middle section 40 (including a transition section), a driving device, a tensioning device, mechanical and electrical protection devices, and the like. There is a head wheel assembly in the head shell; a tail wheel assembly in the tail shell; traction components—scraper chains, upper and lower guide rails, etc. in the middle shell; the body is equipped with inlet and outlet ports and multiple The inspection door 41 set at the place. When working, the driving device drives the head wheel in the head to rotate through the chain transmission, and the head wheel drives the scraper chain to run in the bearing chamber at the lower part of the middle casing towards the head, and transports the material to the discharge port; in the casing In the empty cavity at the upper part, the scraper chain runs around the head wheel assembly in the head an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com