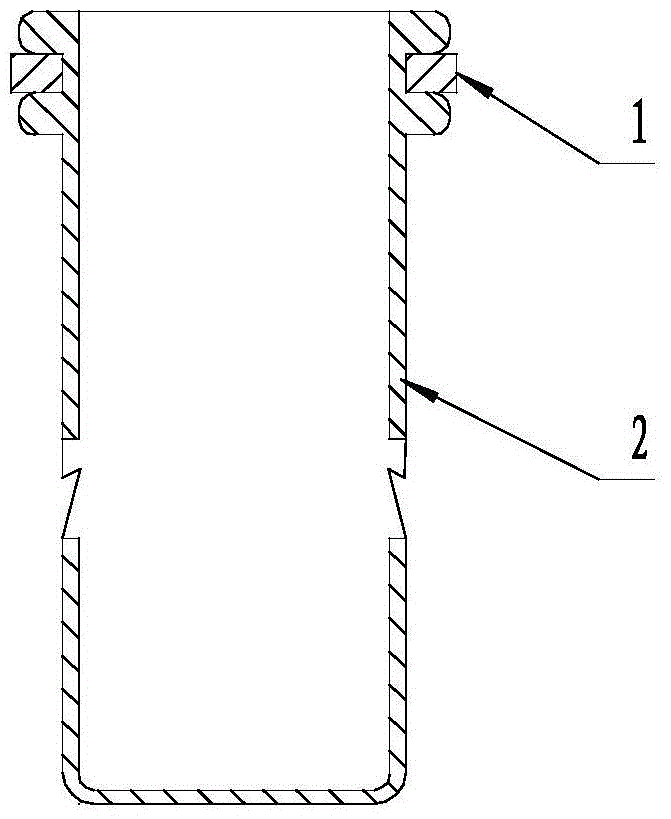

Filter bag detachment prevention and sealing device of electric pulse bag filter

A bag-type dust collector and sealing device technology, which is applied in the filtration of dispersed particles, chemical instruments and methods, separation of dispersed particles, etc. The equipment cannot operate normally, etc., to achieve good anti-dropping effect, promote tighter and firmer, and promote the effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

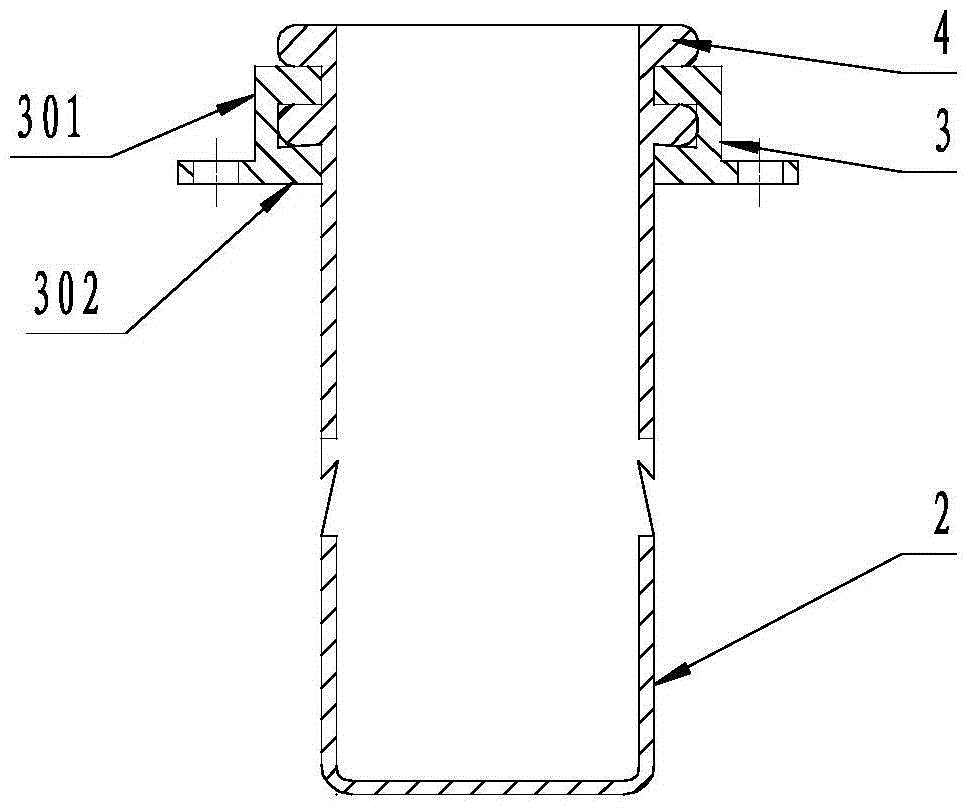

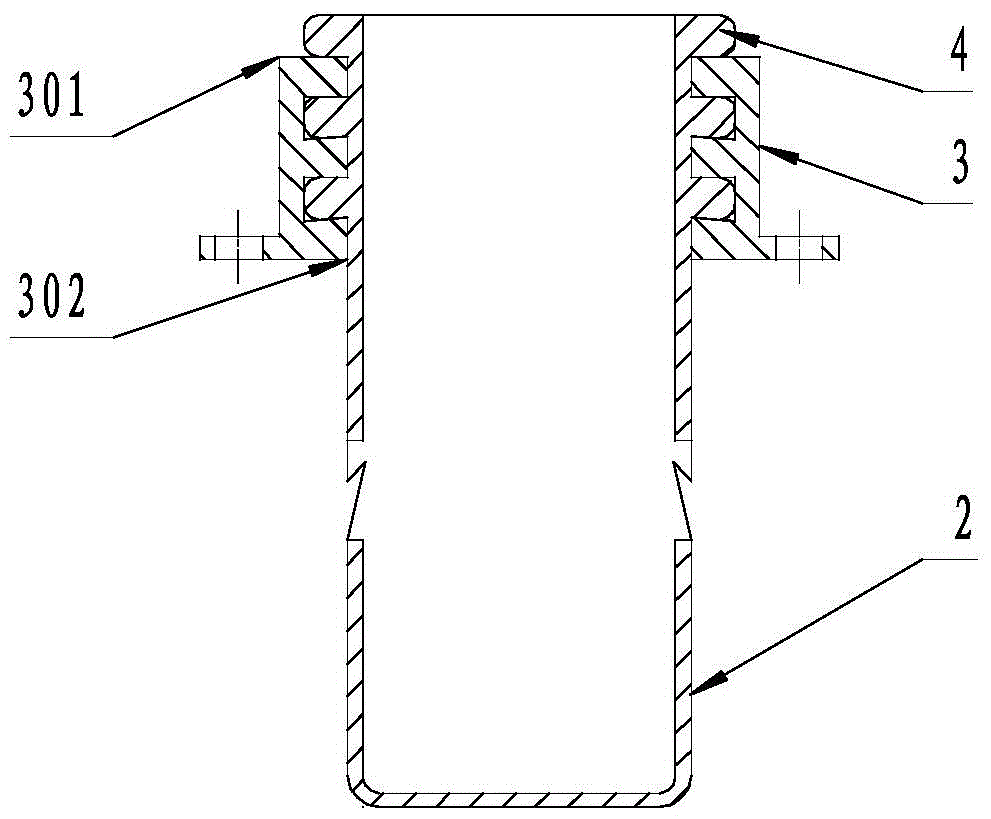

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0015] figure 2 It shows an implementation form according to the present invention, wherein the filter bag anti-off sealing device 3 is a cylinder, the thickness of the cylinder wall is 1-5cm, and an annular groove is arranged in the cylinder wall, and the annular groove The size is suitable for the edge 4 of the filter bag mouth to be embedded, and elastic parts are arranged in the ring groove, and the elastic parts used can be elastic materials such as tight springs or elastic materials, and the lower side of the ring groove is a slope, and the slope is formed with the horizontal plane. The included angle is 2-6 degrees, the opening edge of the ring groove is not an edge but a circular arc transition, and the diameter of the circular arc is equal to the outer diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com