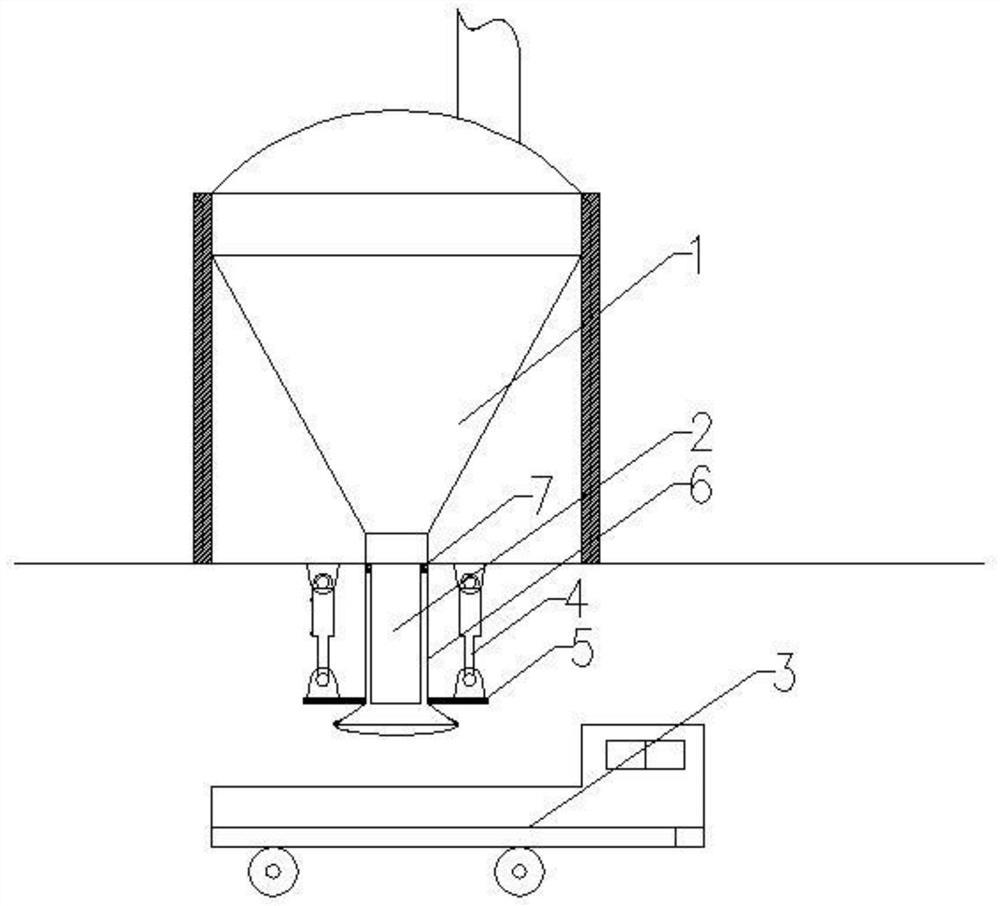

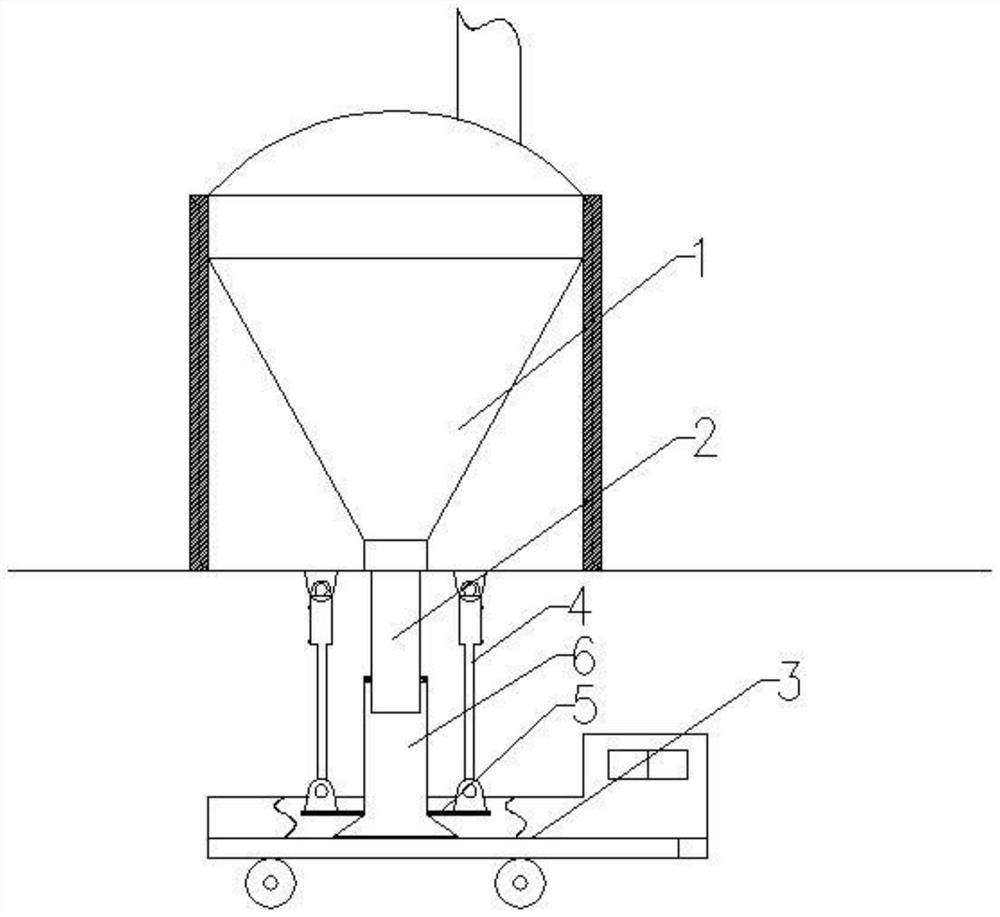

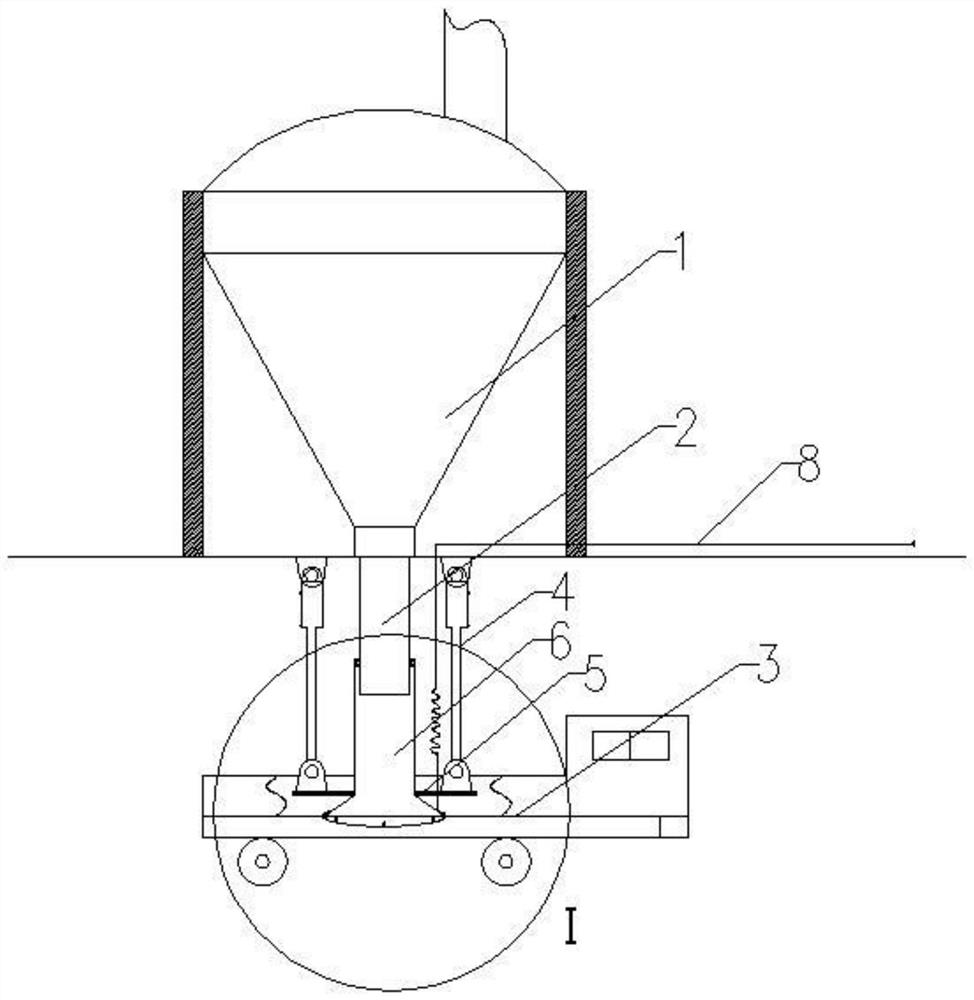

Device used for preventing dust raising during ash discharging of dust removal system of titanium slag smelting furnace

A technology for a dust removal system and a smelting furnace, which is applied in the field of titanium slag smelting, can solve the problems of inability to adjust the drop of dust removal, poor ash discharge conditions, and great harm, so as to reduce physical injuries, reduce the drop of ash discharge points, and reduce dust. leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] In April 2021, in order to change the current 3# titanium slag electric furnace gas purification system dust discharge dust, the titanium smelter carried out the 3# titanium slag electric furnace gas gas purification system dust discharge and dust control transformation work, the transformation was completed in July, and it was put into operation In 4 months, the newly designed anti-dust and ash unloading device has achieved remarkable results, no large dust has occurred at the ash unloading port, and observation and maintenance are very convenient, which ensures the ash unloading and normal operation of the dust collector in the gas purification system of the 3# titanium slag electric furnace The operation ensures the production capacity of the titanium slag electric furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com