Noise reducing device used for backlight module

A backlight module and noise technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as increasing complexity and manufacturing cost, increasing dust leakage, and popping noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

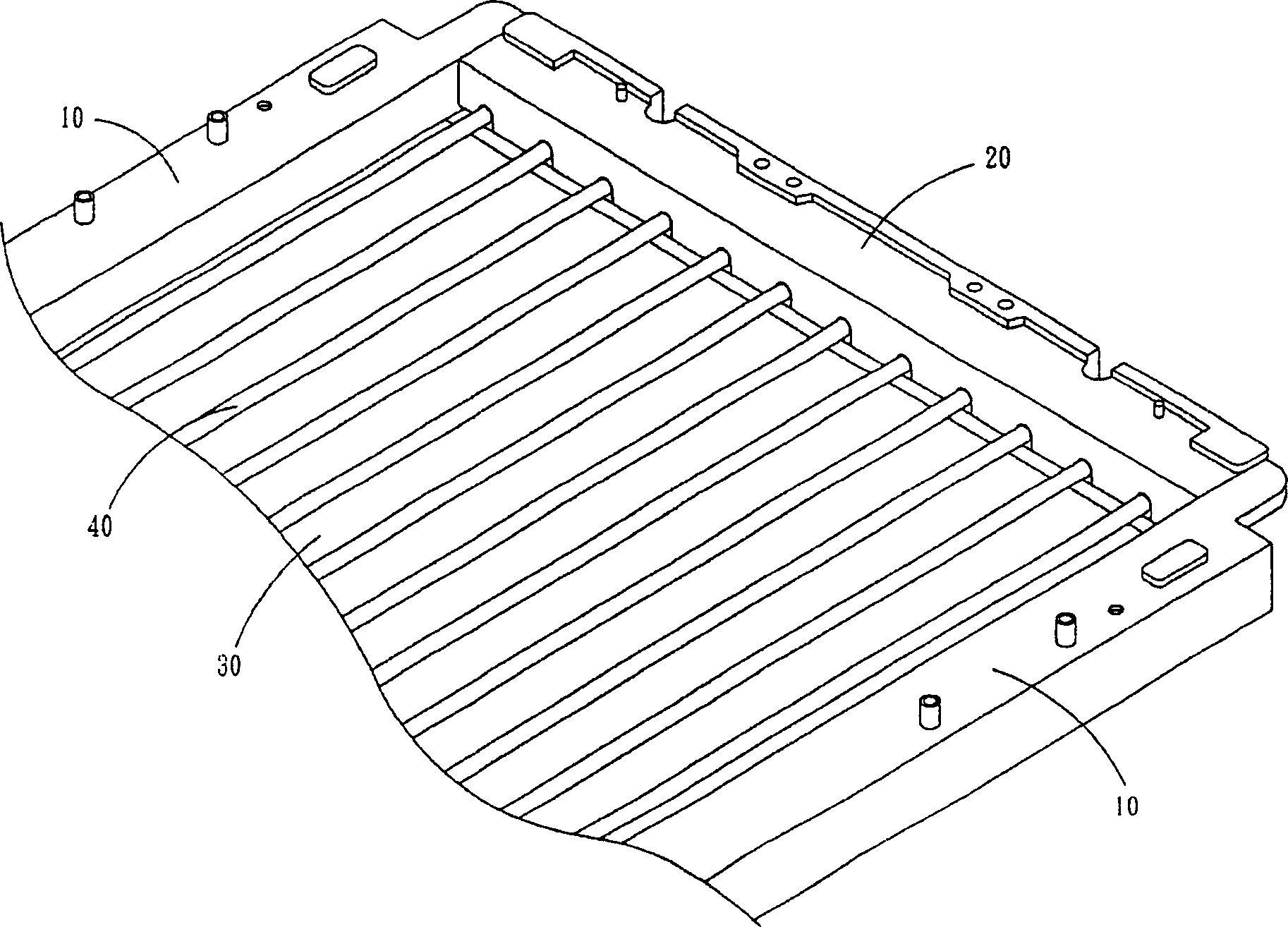

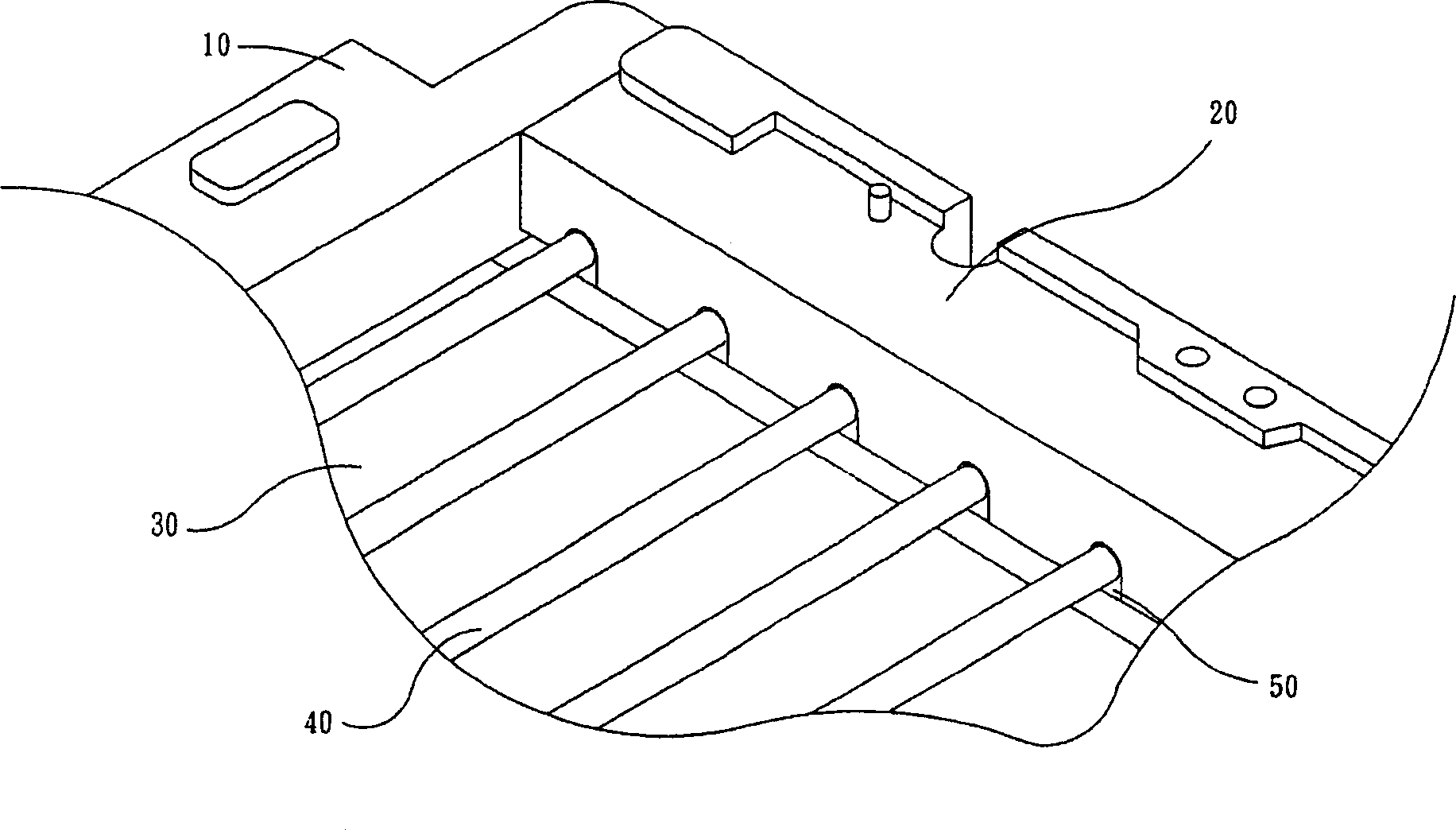

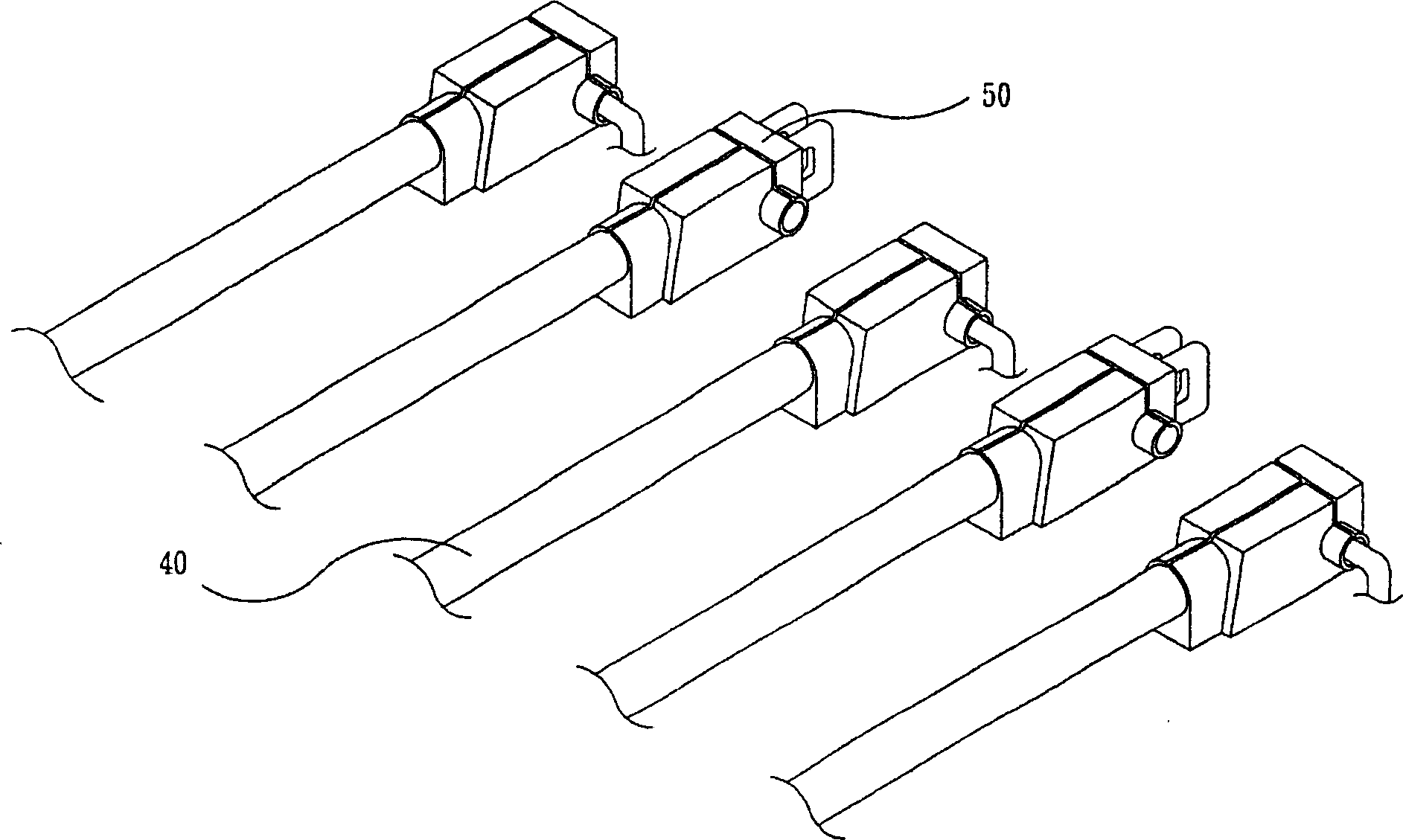

[0017] refer to Figure 4 , which shows an embodiment of applying the present invention in a backlight module. For the sake of illustration, Figure 4 The illustrated embodiment is relative to the image 3 It is drawn with the known technology shown in order to clearly illustrate the technical features of the present invention. Figure 4 It shows a noise reduction device 500 used in the backlight module and a lamp tube group for providing the light source required by the backlight module. The lamp tube group preferably includes a plurality of parallel arranged lamp tubes 400, wherein the noise reduction device 500 The main components include a plurality of bodies 510 and extensions 520 . And each body 510 includes a groove, in order to provide the embedding space (not shown in the figure) of each lamp tube 400 end, and fix these lamp tubes 400, dispose in the structure of the body 510 the circuit that conducts with the backlight module ( not shown in detail), and further f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com