Coal seam water injection method of coal mining working face

A coal seam water injection and working face technology, which is applied in mining equipment, earthwork drilling, gas discharge and other directions, can solve problems affecting the normal and orderly progress of mining work, hidden dangers to the life safety and safety of workers, and impact on the health of workers, etc. The effect of preventing gas gushing is remarkable, the effect is good, and the effect of eliminating the generation of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The coal seam water injection method in the coal mining working face, the water injection method is as follows:

[0024] (1) Before the mining operation, use a pneumatic drill or a pneumatic coal drill to drill water injection holes in the coal seam of the excavation working face at the place where the coal wall is not loose and relatively complete. On the wall, 0.8m from the top of the roadway and 2 / 3 of the height of the bottom; the hole depth is 2.5m; the distance between two adjacent water injection holes is 2m.

[0025] (2) Seal the water injection hole with a hole sealer;

[0026] (3) The hydraulic system of the working face hydraulic pump is used to provide water source, and the high-pressure water injection is performed with a water pipe, and one hole is injected into one hole, and another hole is drilled after one hole is filled with water. The water injection time is until the adjacent holes or the coal wall seep water, so that the water content of the excava...

Embodiment 2

[0028] The coal seam water injection method in the coal mining working face, the water injection method is as follows:

[0029] (1) Before the mining operation, use a pneumatic drill or a pneumatic coal drill to drill water injection holes in the coal seam of the excavation working face at the place where the coal wall is not loose and relatively complete. On the wall, 1m away from the top of the roadway and 2 / 3 of the height of the bottom; the hole depth is 2m; the distance between two adjacent water injection holes is 2.5m.

[0030] (2) Seal the water injection hole with a hole sealer;

[0031] (3) The hydraulic system of the working face hydraulic pump is used to provide water source, and the high-pressure water injection is performed with a water pipe, and one hole is injected into one hole, and another hole is drilled after one hole is filled with water. The water injection time is until the water comes out of the adjacent hole or the coal wall seeps, so that the water c...

Embodiment 3

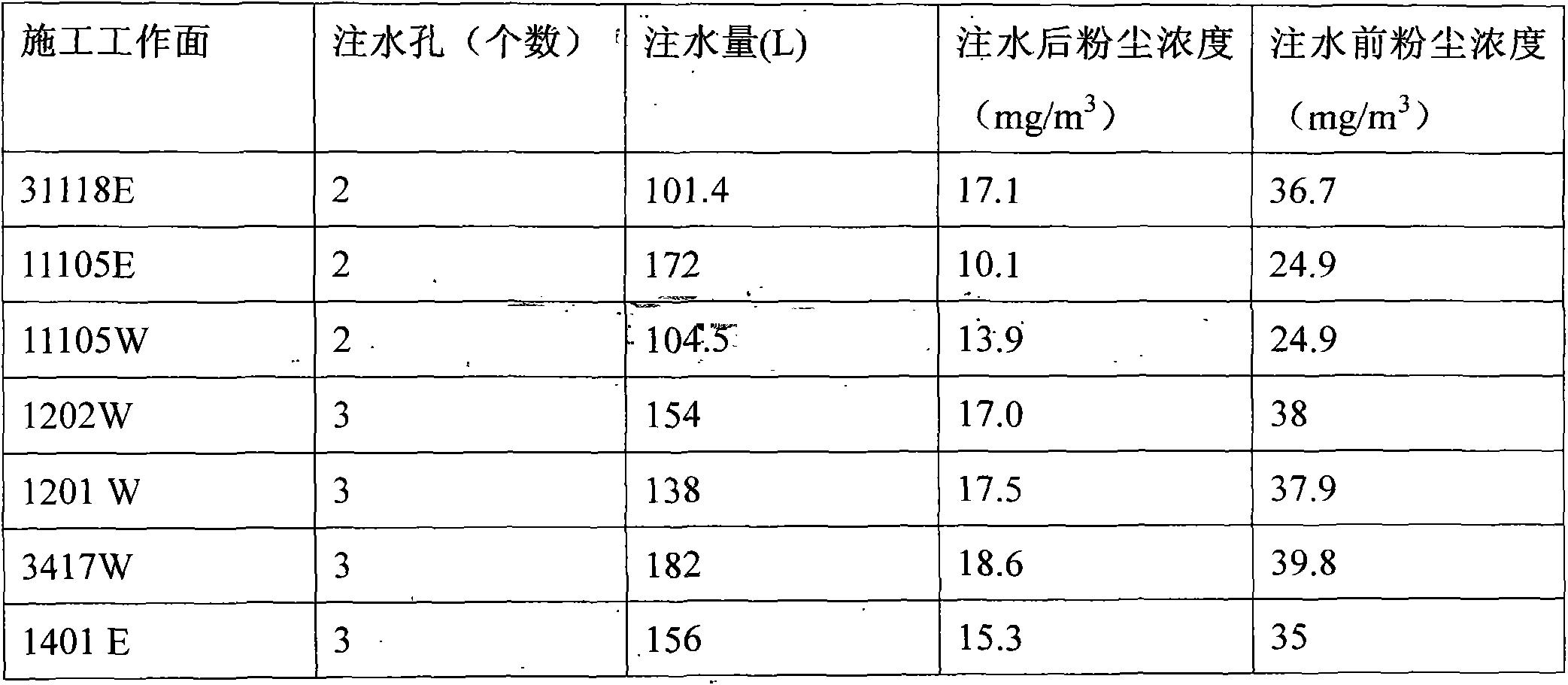

[0033] The coal seam water injection method of the present invention is compared with the dust concentration after blasting when not injecting water, and its contrasting situation is shown in Table 1:

[0034] Table 1: Dust comparison table of coal seam water injection method and non-water injection blasting operation in each blasting face

[0035]

[0036] It can be seen from the above table that through the coal seam water injection process of the blasting face, the dust concentration of each blasting face is reduced to 15.26mg / m3 on average, and the dust reduction rate is 53.49%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com