Preparation method for electronic-grade high-purity chlorine from industrial liquid chlorine

An electronic-grade, liquid chlorine technology, applied in chlorine/hydrogen chloride, chlorine/hydrogen chloride purification and other directions, can solve the problems of dependence on imports, high price, weak purification technology, etc., and achieve the effect of high income, low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

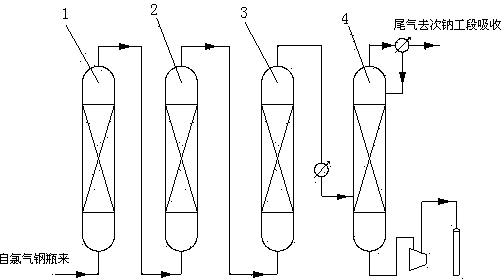

[0031] figure 1 It is a process flow diagram of the preparation method of the present invention. Such as figure 1 Shown, preparation method of the present invention comprises the following steps:

[0032] a. Chlorine gasification of raw material industry, removal of most metal ions, at 0.4MP pressure and 20°C temperature at 1 M 3 The flow rate of / h enters from the bottom of the first-stage drying tower 1 equipped with 13X zeolite molecular sieve numbered DH05, and comes out from the top of the tower after removing most of the water through adsorption;

[0033] b. Then enter the bottom of the secondary drying tower equipped with 13X type zeolite molecular sieve numbered DH06, after deep dehydration, remove trace moisture and come out from the top of the tower. After removal, the moisture content in chlorine gas is less than 0.5ppm;

[0034] c. Then it enters from the bottom of the adsorption tower equipped with SSZ-13 zeolite molecular sieve, absorbs and removes carbon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com