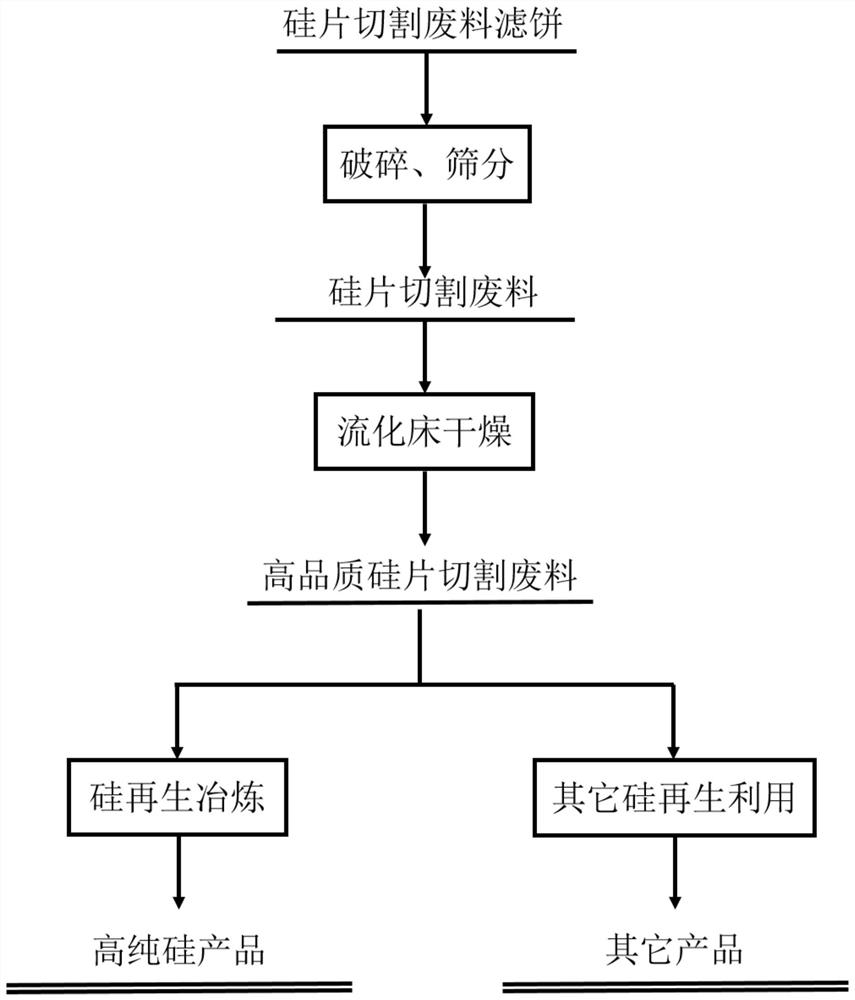

Method for drying silicon wafer cutting waste by fluidized bed

A technology of fluidized bed drying and silicon wafer cutting, which is applied in the directions of drying solid materials, heating to dry solid materials, and drying gas arrangement, etc. It can solve the problems of secondary oxidation, incomplete water removal, and low drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

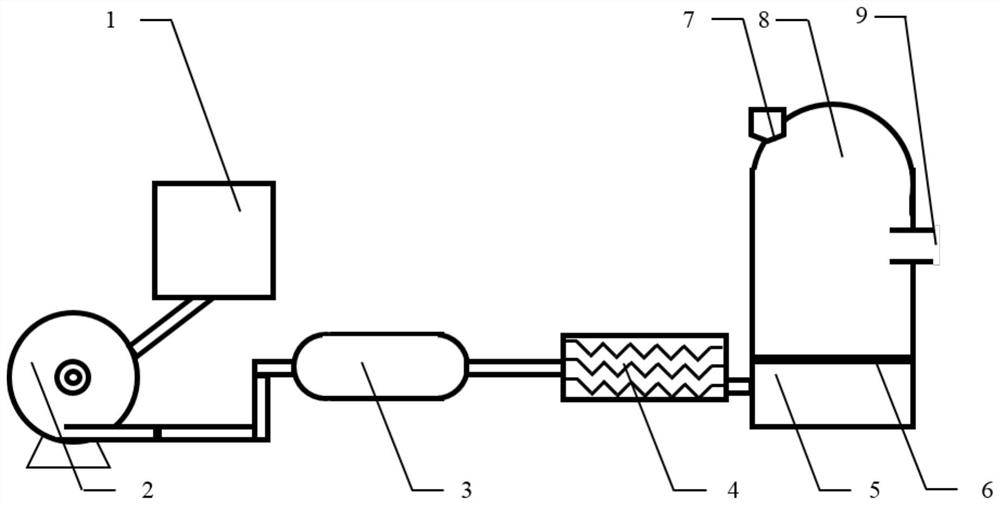

[0032] Embodiment 1: a kind of method of fluidized bed drying silicon chip cutting waste (see figure 1 ),Specific steps are as follows:

[0033] (1) Use a plate and frame filter press to remove water from the silicon wafer cutting waste slurry (solid content > 40%) in a certain place in Yunnan, remove liquids such as water-based lubricants, and achieve preliminary liquid-solid separation to obtain a silicon wafer cutting waste filter cake (moisture content is about 30%);

[0034] (2) Mechanically crushing and sieving the silicon wafer cutting waste filter cake in step (1) to obtain silicon wafer cutting waste powder with a particle size of 0.5-30 mm;

[0035] (3) The fresh or recovered and purified nitrogen drying medium is stored in the protective gas storage device, the nitrogen is boosted and supplied by the booster fan, and the air pressure buffer device adjusts the supplied gas to the required pressure and flow before supplying it to the hot blast stove It is used with ...

Embodiment 2

[0037] Embodiment 2: a kind of method of fluidized bed drying silicon chip cutting waste (see figure 1 ),Specific steps are as follows:

[0038] (1) Use a plate and frame filter press to remove water from the silicon wafer cutting waste slurry (solid content > 50%) in a certain place in Jiangsu, remove liquids such as water-based lubricants, and achieve preliminary liquid-solid separation to obtain a silicon wafer cutting waste filter cake (moisture content is about 22%);

[0039] (2) Mechanically crushing and sieving the silicon wafer cutting waste filter cake in step (1) to obtain silicon wafer cutting waste powder with a particle size of 0.5-30 mm;

[0040] (3) The fresh or recovered and purified nitrogen drying medium is stored in the protective gas storage device, the nitrogen is boosted and supplied by the booster fan, and the air pressure buffer device adjusts the supplied gas to the required pressure and flow before supplying it to the hot blast stove Used with a flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com