Urban construction dust control method

A control method and urban technology, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of sprinkling and dust reduction indicators that do not cure the root cause, are not conducive to construction on construction sites, etc., and achieve reduced dust rate, good mechanical properties, and good control of dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

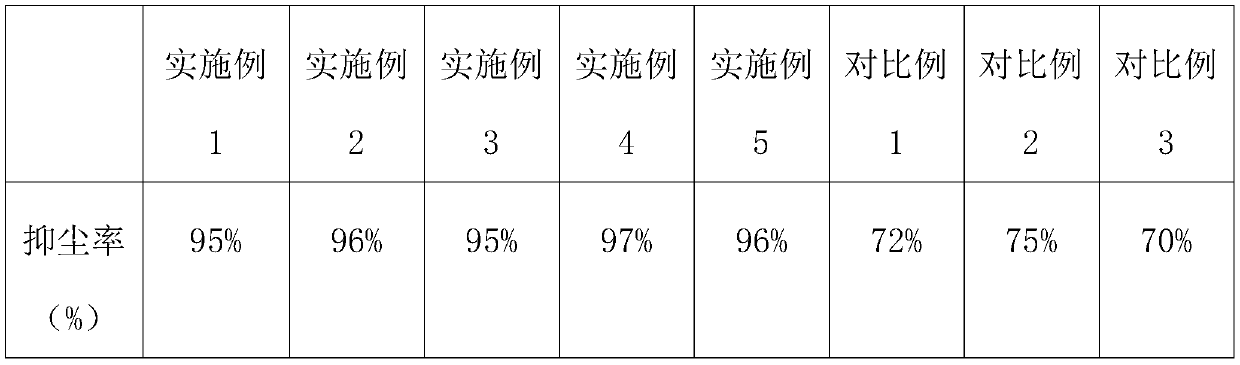

Examples

Embodiment 1

[0025] A method for controlling urban construction dust, comprising the following steps:

[0026] (1) 40 parts by weight of polyvinyl alcohol resin, 1 part by weight of tributyl citrate, 20 parts by weight of calcium carbonate, 20 parts by weight of starch, 0.5 parts by weight of aluminate and 400 parts by weight of water are mixed Finally, the film-forming liquid is formed under the condition of 70°C, and then the film-forming liquid is cast and coated on the glass plate, dried under the condition of 75°C, and the film is peeled off after drying to obtain a water-soluble film. Through holes with a diameter of 100 μm and a film thickness of 2 mm;

[0027] (2) Lay a layer of water-soluble film on the excavated ground surface and water it to moisten it;

[0028] (3) Lay a layer of water-soluble film on the excavated surface after excavating to a depth of 1m, and water it to moisten it.

Embodiment 2

[0030] A method for controlling urban construction dust, comprising the following steps:

[0031] (1) After mixing the polyvinyl alcohol resin of 50 weight parts, the polycaprolactone of 2 weight parts, the asbestos of 30 weight parts, the starch of 25 weight parts, the borate of 1 weight part and the water of 560 weight parts Form a film-forming solution at 80°C, then cast the film-forming solution onto a glass plate, dry at 80°C, peel off the film after drying to obtain a water-soluble film, and open a water-soluble film with a diameter of 200μm through hole, water-soluble film thickness is 4mm;

[0032] (2) Lay a layer of water-soluble film on the excavated ground surface and water it to moisten it;

[0033] (3) Lay a layer of water-soluble film on the excavated surface after excavating to a depth of 1m, and water it to moisten it.

Embodiment 3

[0035] A method for controlling urban construction dust, comprising the following steps:

[0036] (1) The polyvinyl alcohol resin of 45 parts by weight, the polytrimethylene adipate of 1.5 parts by weight, the talc of 25 parts by weight, the starch of 25 parts by weight, the zirconate of 0.5 parts by weight and the water of 400 parts by weight are mixed Finally, the film-forming solution is formed at 75°C, and then the film-forming solution is cast and coated on a glass plate, dried at 78°C, and the film is peeled off after drying to obtain a water-soluble film. A through hole with a diameter of 100 μm and a water-soluble film thickness of 3 mm;

[0037] (2) Lay a layer of water-soluble film on the excavated ground surface and water it to moisten it;

[0038] (3) Lay a layer of water-soluble film on the excavated surface after excavating to a depth of 1m, and water it to moisten it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com