Preparation method of high-quality environment-friendly dust-free shell chalk prepared from waste shells

A high-quality, shell powder technology, applied in applications, pencil leads, household appliances, etc., can solve the problem of reducing chalk dust rate, achieve the effect of reducing chalk dust rate, solving environmental protection problems, and eliminating hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method that utilizes discarded shell to prepare high-quality environment-friendly dust-free shell chalk, concrete steps are as follows:

[0026] 1. Preparation of shell powder

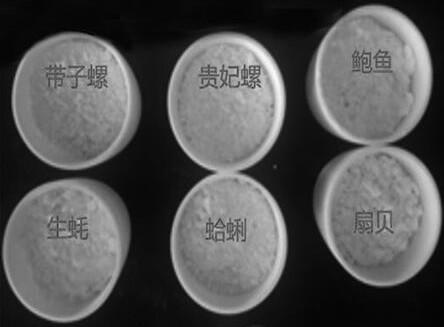

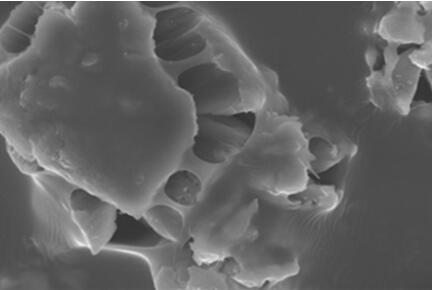

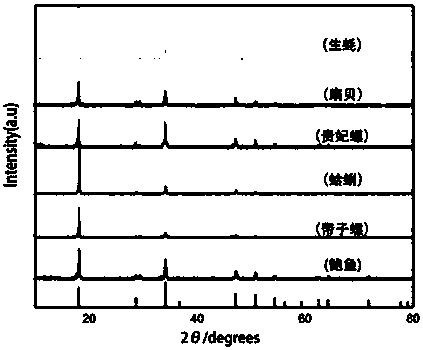

[0027] Ultrasonic cleaning, hydrogen peroxide bleaching of discarded shells, and mechanical crushing into 200-mesh shell powder;

[0028] 2. Preparation of water-soluble binder

[0029] Add polyvinyl alcohol and water into the aluminum pot at a ratio of 1:50, put the pot on the stove to heat, and stir for 30-50 minutes while heating, until the polyvinyl alcohol is completely melted, and the total weight of the reagent accounts for the unboiled 75%-80% of the time of preparation, and take the white solution as the standard to obtain the water-soluble binder;

[0030] 3. Preparation steps of shell chalk

[0031] (1) After fully mixing the shell powder and water-soluble binder, add talcum powder, if you need to make colored chalk, you can add an appropriate amount of pigmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com