Gas protecting device for welding

A technology of air inlet and air outlet, which is applied in the field of gas protection devices, can solve the problems of weakening of weld strength and corrosion resistance, unprotected welding area, and inability to isolate air in the weld area, so as to reduce chronic radioactivity. The effect of preventing disease and preventing threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

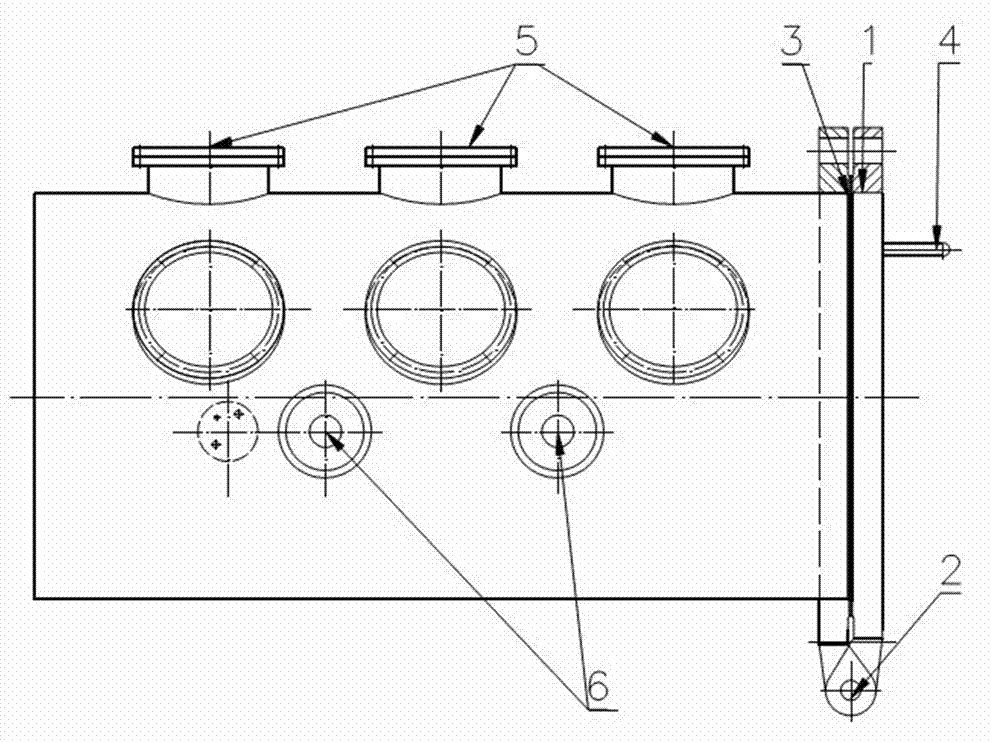

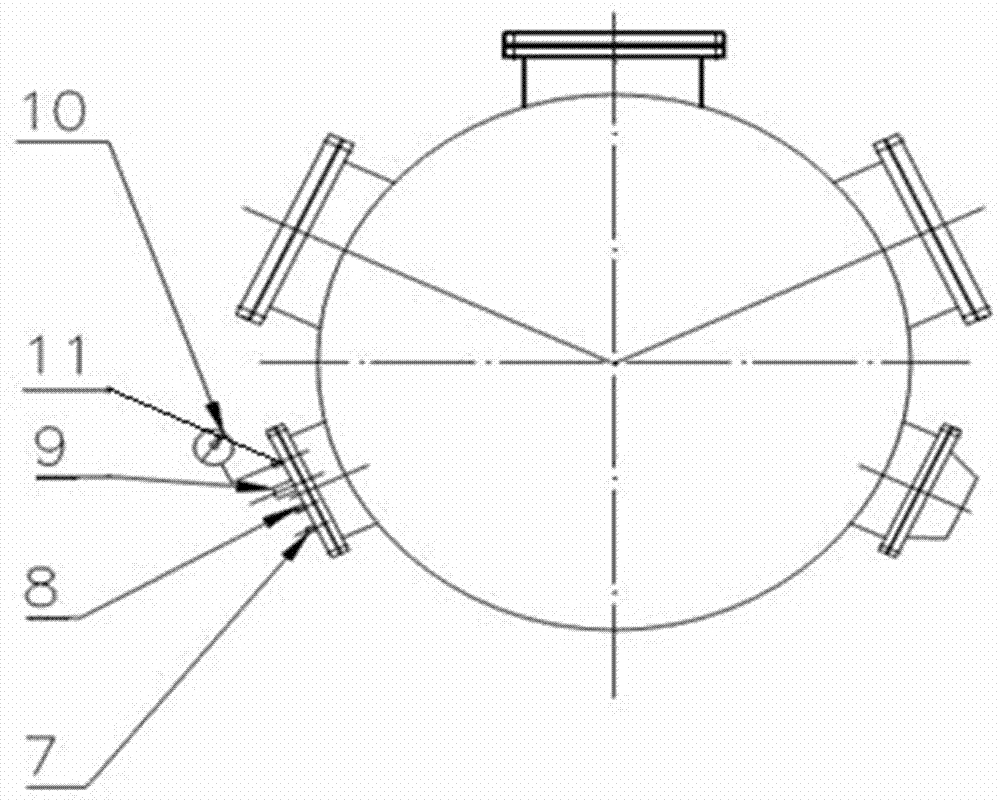

[0010] Such as figure 1 , 2 As shown, the present invention relates to a gas protection device for welding, which consists of an operating door 1, a cover shaft lug 2, a gasket 3, a handle 4, a sight glass 5, an operating hole 6, an air inlet hole 7, an air outlet hole 8, The pressure gauge 10, the cooling water inlet 9, and the cooling water outlet 11 are characterized in that: the whole device is a cylindrical design, and one end is provided with an operating door 1, and the operating door 1 is connected to the cylindrical part through the cover lug 2, and the operation There is a handle 4 on the door 1, a sealing ring 3 is arranged between the operating door 1 and the cylinder, three viewing mirrors 5 and two operating holes 6 are evenly distributed in the middle part of the outer circle of the cylinder, and there is also an inlet on the outer circle of the cylinder. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com