Tower type prilling apparatus

A granulating device and tower-type technology, applied in the direction of fertilization device, fertilizer form, fertilizer mixture, etc., can solve problems such as nozzle hole blockage, and achieve the effects of convenient speed regulation, lower energy consumption, and lower dust rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, specific embodiment is described:

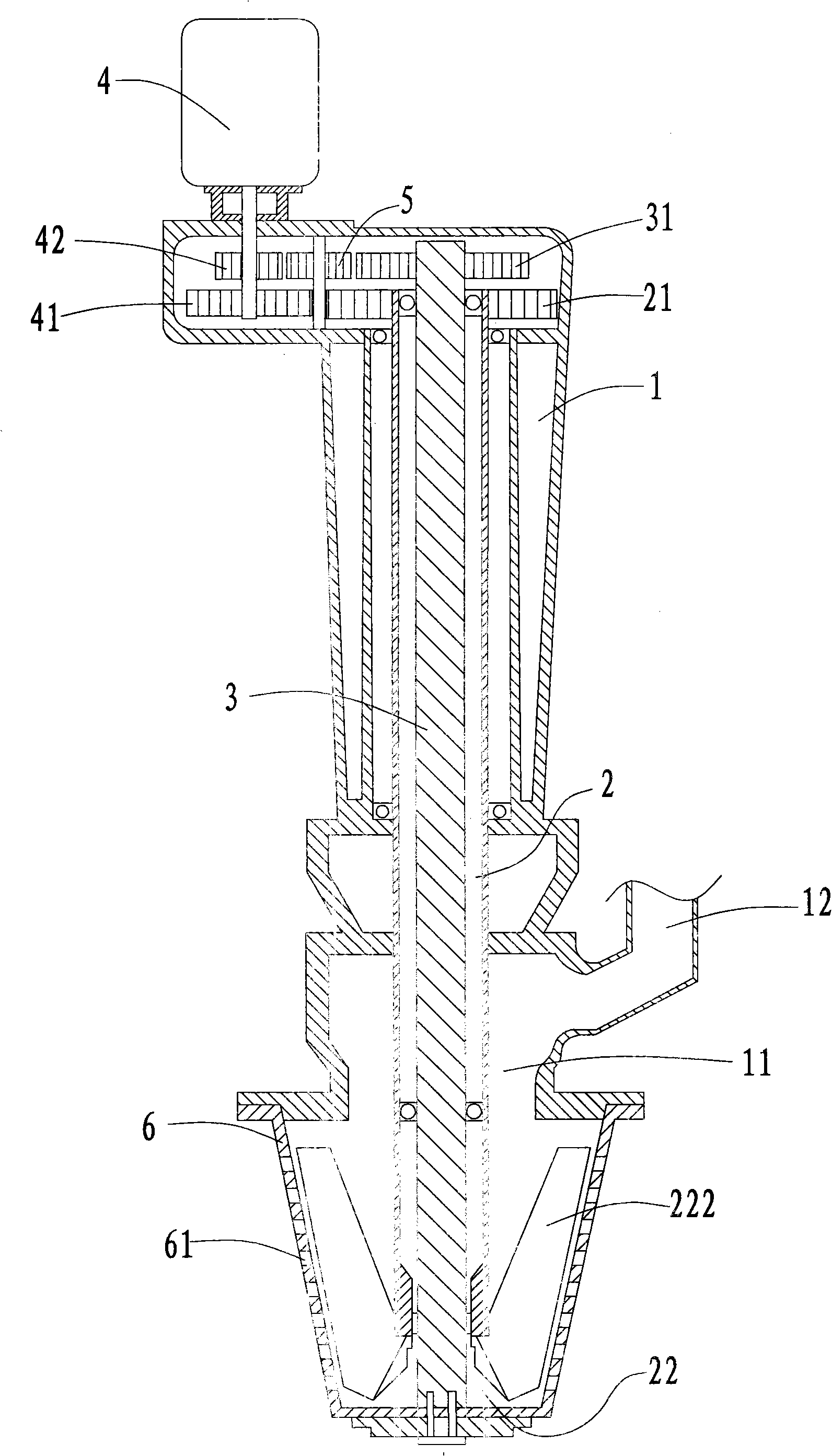

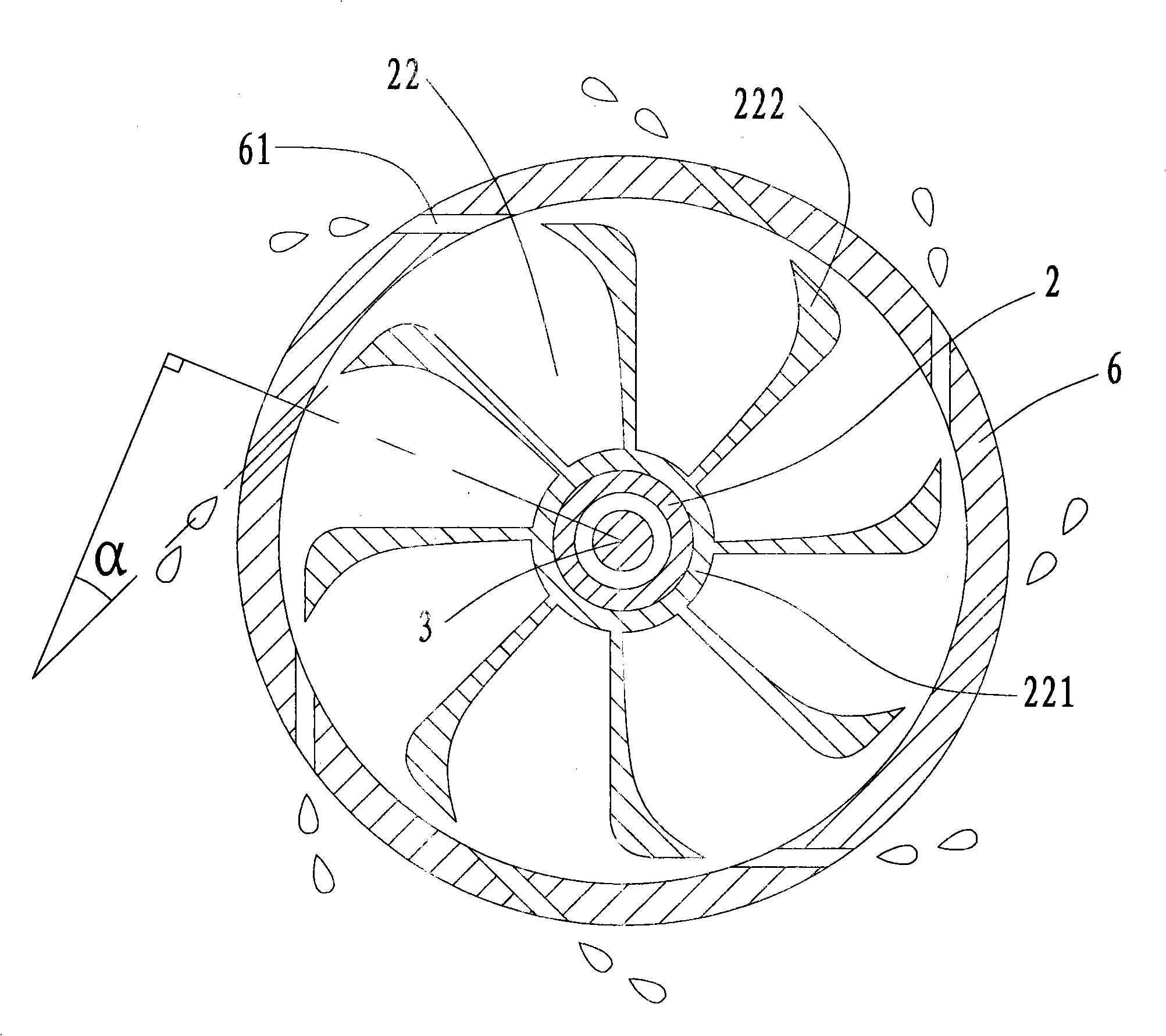

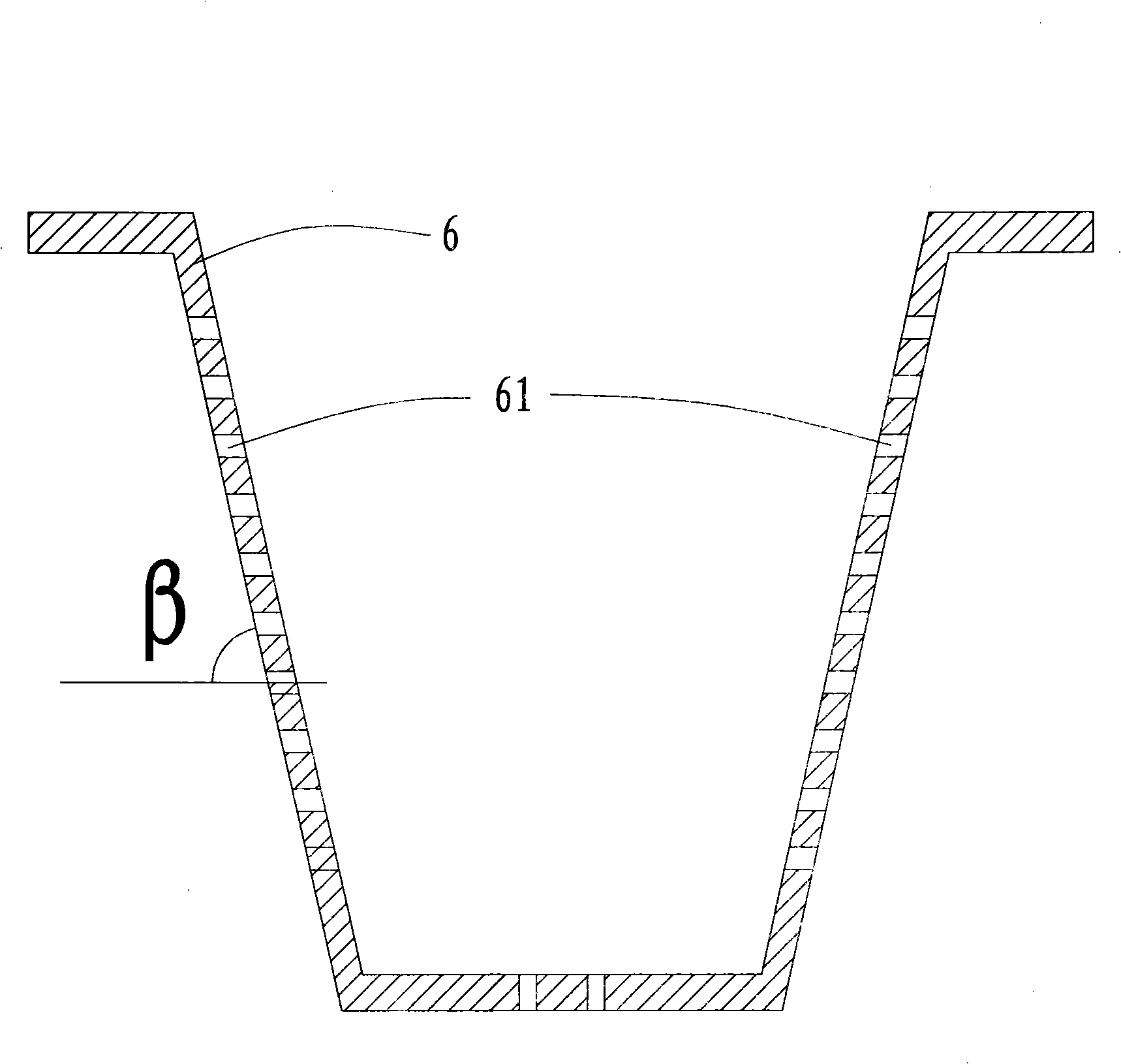

[0015] Such as figure 1 , figure 2 and image 3 As shown, a tower type granulation device includes a housing 1, an outer shaft 2 is installed inside the housing 1 through a bearing, the top end of the outer shaft 2 is connected with an outer shaft driven gear 21, and the bottom end is connected with a Rotating impeller 22; the outer rotating shaft 2 is a hollow cylinder, and a coaxial inner rotating shaft 3 is installed inside it through a bearing. The top end of the inner rotating shaft 3 is connected with an inner rotating shaft driven gear 31, and the bottom end is connected with a nozzle housing 6. The outer contour surface of the nozzle housing 6 has several small holes 61, and the rotating impeller 22 is located inside the nozzle housing 6, leaving a certain gap between the two; a motor 4 is installed on the top of the housing, and the motor The output shaft of 4 extends into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com