Method and apparatus for manufacturing vacuum insulation panel

A technology of vacuum thermal insulation material and manufacturing method, which is applied to heat exchange equipment, protected pipelines through thermal insulation, thermal insulation, etc., can solve the problem of limited size of miniaturized outer skin materials, minimize the edge, reduce dust rate, reduce The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

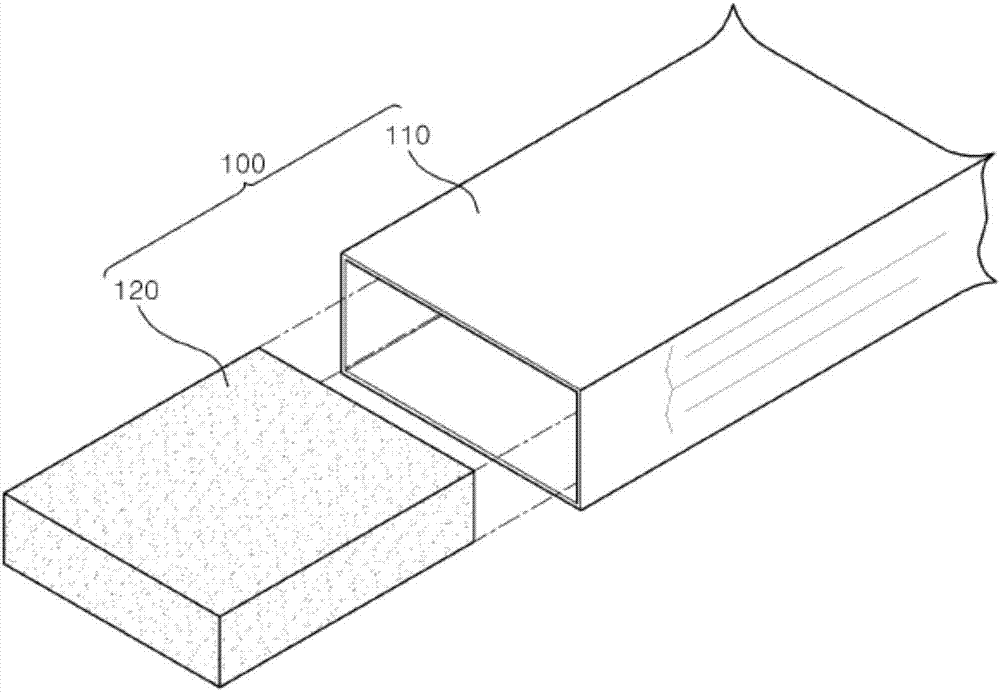

[0071] The core material containing the gas adsorbent is compressed under low vacuum and inserted into the outer skin material in the form of a bag, and the core material is 1.0×10 -3 torr vacuum packaging to make vacuum insulation.

[0072] At this time, the structure of each surface of the above-mentioned skin material is as shown in Table 1 below, and the gas adsorbent and core material are the same as those of Comparative Example 1.

[0073] Table 1

[0074]

[0075] Vm-PET: aluminum-evaporated polyethylene terephthalate (PET)

[0076] LLDPE: Linear Low Density Polyethylene

[0077] From the experimental results in Table 1, in order to minimize the excess area of the outer skin material of the vacuum insulation material, when performing plate-shaped compression (compression in which a plate is placed on the upper end of the core material and pressed with UTM or similar force), the fiber The dust rate shows 0.95% and 0.44% when compressed under low vacuum. That is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com