Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Reasonable production process design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

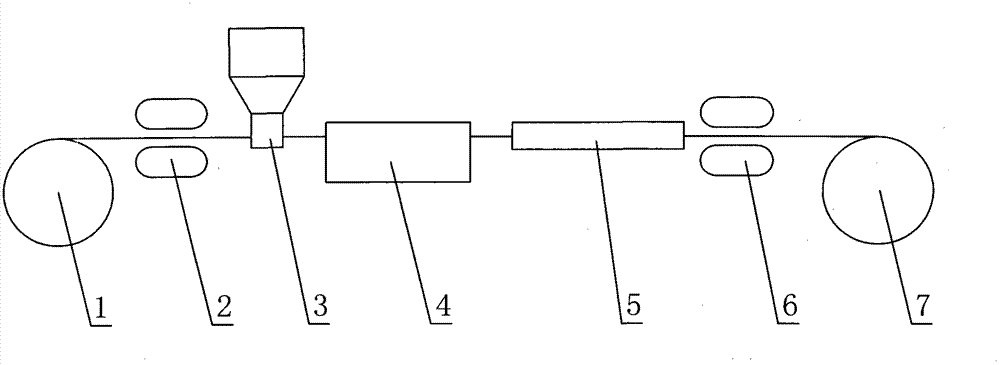

Fabrication process of cross-linked polyolefin insulation power cable

InactiveCN103247391AShorten the production cycleReduce manufacturing costInsulating conductors/cablesCross-linkElectric discharge

The invention provides a fabrication process of a cross-linked polyolefin insulation power cable, and belongs to the technical field of power cable manufacturing. The technological process comprises the steps that cable conductor paying-off is performed; upward traction is performed; heating extrusion insulation is performed by a plastic extruding machine with an electromagnetic method; when a main body box of cross-linked equipment is irradiated by ultraviolet light, defined amount of a photo-crosslinking sensitizer is added into a polyolefin-based resin, the characteristic that the polyolefin material is in a transparent state during heating extrusion is used to focus the ultraviolet light irradiation and transmit into the material, the high-energy ultraviolet light triggers the photo-crosslinking sensitizer to form free radicals and further induces a polyolefin unit to generate macromolecular free radicals, and the cross-linked polyolefin material is formed through a bonding function between the free radicals; the cross-linked polyolefin material enters a water tank for sizing and cooling; checking out is performed by an electric discharge machine; downward traction is performed; and wire gathering and laying is performed. The process replaces the traditional silane cross-linked polyethylene insulation power cable, is energy-saving, shortens the production cycle of the cable, saves the production cost, and increases the market competitiveness.

Owner:SHANDONG HUADONG CABLE GROUP

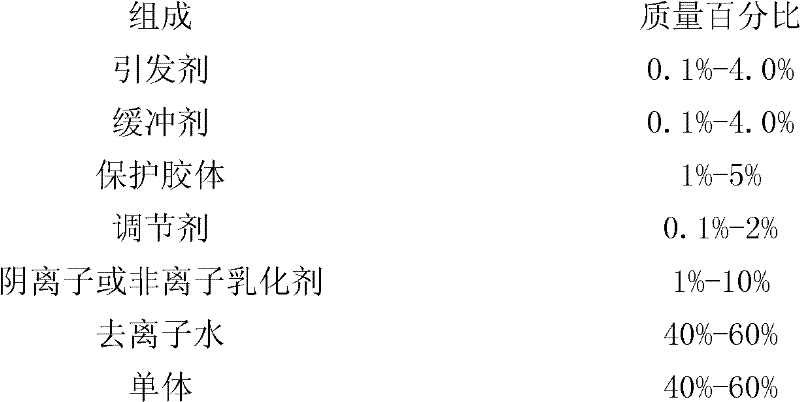

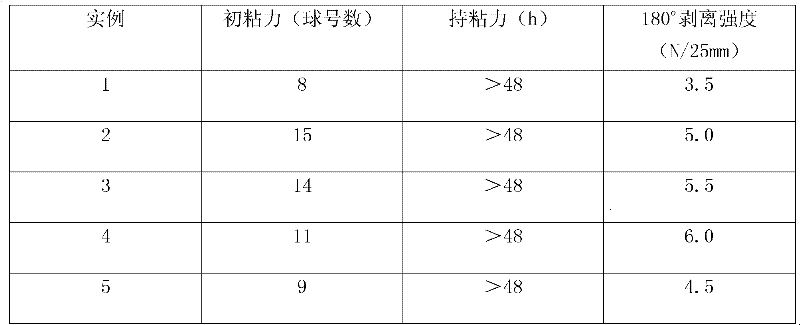

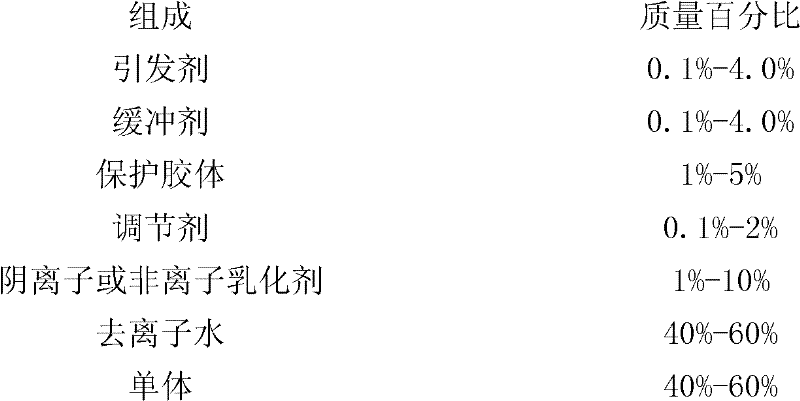

Preparation method of redispersible waterborne pressure sensitive rubber latex

InactiveCN102344771AReasonable production process designShorten the production cycleFilm/foil adhesivesEster polymer adhesivesPolymer scienceMonomer

The invention discloses a preparation method of redispersible waterborne pressure sensitive rubber latex. A mixed monomer is added in foundation latex at a constant speed for reacting by adopting a semicontinuous polymerization method to obtain the redispersible waterborne pressure sensitive rubber latex. According to the preparation method disclosed by the invention, the defects of traditional rubber latex are overcome; and in addition, the production process is quite reasonable in design, the production period is shortened and the production efficiency is improved. The pressure sensitive rubber latex has excellent pressure sensitive characteristic under the drying condition, is widely used for laminating and positioning crystallite glass products and the like and can be quickly dissolved, dispersed and cleared once the pressure sensitive rubber latex meets with water; and no trace is reserved on the products.

Owner:HEBEI UNIV OF TECH

Method for making black fungus snack food

The invention relates to a method for making black fungus snack food. The method includes the steps of selecting black funguses which conform to the production standards, cleaning the black funguses, stewing the black funguses at a high temperature, grinding the black funguses in a wet mode through a colloid mill to obtain pulp, adding seasoning or different types of vegetable juice to the pulp, conducting drying and dehydrating to enable the water content of the black fungus product to be kept within the range from 30% to 50%, conducting compression molding on the product through a hot press, and obtaining the ready-to-eat seasoned black fungus paper-like food. The obtained ready-to-eat seasoned black fungus paper-like food has the advantages of having rich nutrients and being diversified in taste, widely suitable for the crowd, light in weight, convenient to carry, convenient to eat and the like, and a novel method for enabling the black funguses to be eaten more conveniently and leisurely is provided for the black fungus deep processing.

Owner:JILIN ACAD OF AGRI SCI

Manufacturing technology of basketball

The invention relates to a manufacturing technology of a basketball. The manufacturing technology comprises the steps that firstly, a layer of yarn is wound on a basketball liner, then, the basketballliner is wrapped with rubber, a basketball liner workblank is formed, and vulcanization is not carried out; basketball skin pieces are bonded on the basketball liner workblank through heating and compression; and finally, vulcanization is carried out, so that the basketball skin pieces and the basketball liner workblank are bonded more firmly. The manufacturing technology has the beneficial effects that design of the basketball is reasonable, glue is not utilized, and the technology is more environmentally-friendly; vacuum package and transportation can be adopted, and transportation efficiency is improved; the basketball bounces higher, and rebound is more powerful; and bonding is firmer, and degumming and skin wrapping problems are avoided.

Owner:王冠华

Etimicin sulfate preparation and its preparing method

InactiveCN1569010AAdd new varietiesExpand the scope of clinical applicationOrganic active ingredientsAntipyreticChemistrySulfuric acid

The invention discloses etimicin sulfate preparation and its preparing method which comprises, charging acids or alkali as pH conditioning agent so as to increase the dissolving degree of the etimicin, charging right amount of isoosmotic adjustment agent, thus resulting the action of quick sterilization.

Owner:ZHEJIANG UNIV

Production method of pure-cotton bright-red extra-wide breadth woven fabric with high wet rubbing fastness

InactiveCN107326595AReasonable production process designEasy to operateMercerising of indefinite length fabricsSingeingBreaking strengthOperability

The invention discloses a production method of a pure-cotton bright-red extra-wide breadth woven fabric with high wet rubbing fastness. A main production process flow comprises: turnover sewing, primary singeing, alkali-rolling cold-batch desizing, scouring and bleaching, secondary singeing, pre-stentering for wrinkle removal, mercerizing, cold-rolled batch dyeing or dye jigger dyeing, formaldehyde-free shrink resistant finishing, stentering finishing, mechanical pre-shrinking, calendering, checking and packing. The pure-cotton bright-red extra-wide breadth woven fabric is high in surface gloss, the wet rubbing fastness of the product reaches a level 3, the warp and weft washing dimension change rate is in a range of -3.0 percent to +1.0 percent, the pilling resistance is more than or equal to a level 4, the breaking strength is more than or equal to 250N, and a cotton fabric printing and dyeing standard for a superior product is completely reached. The production process is reasonable in design, high in operability, and environmentally-friendly.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Manufacturing method of tempered thin glass film

InactiveCN104086076AReasonable production process designShort processing cycleEdge grinding machinesRevolution surface grinding machinesNumerical controlBatch processing

The invention relates to a manufacturing method of a tempered thin glass film. The method comprises the following steps: raw material glass is selected; a glass cutting machine is used for carrying out high-precision cutting upon the raw material glass according to corresponding length and width outline dimensions, such that rectangular glass sheets with various specifications are obtained; a laser cutting machine is used for carrying out button hole and earphone hole preliminary processing upon the obtained rectangular glass sheets; a numerical control machine tool is used for carrying out outline, button hole and earphone hole fine trimming upon the obtained glass sheets; the glass blank sheets obtained after fine trimming are subjected to tempering processing in a tempering furnace; an anti-bursting adhesive layer is adhered to the surfaces of the tempered glass sheets; and packaging is carried out. The manufacturing method provided by the invention has the advantages of reasonable design and short processing period. With the method, batch processing can be realized. The method and the product are safe and healthy, and the product has high quality.

Owner:ZHEJIANG LANTE OPTICS

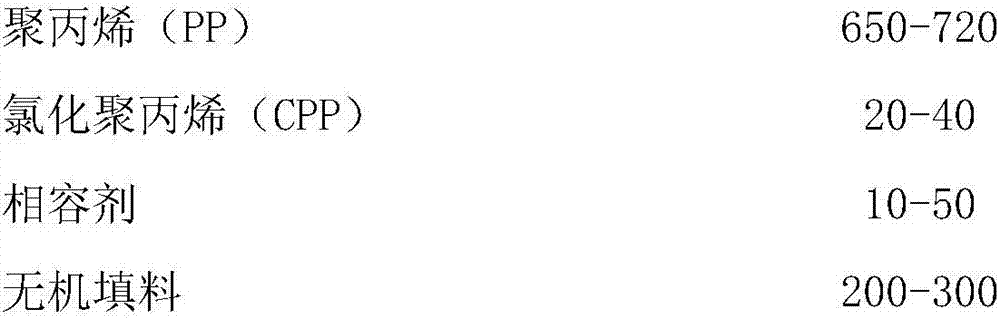

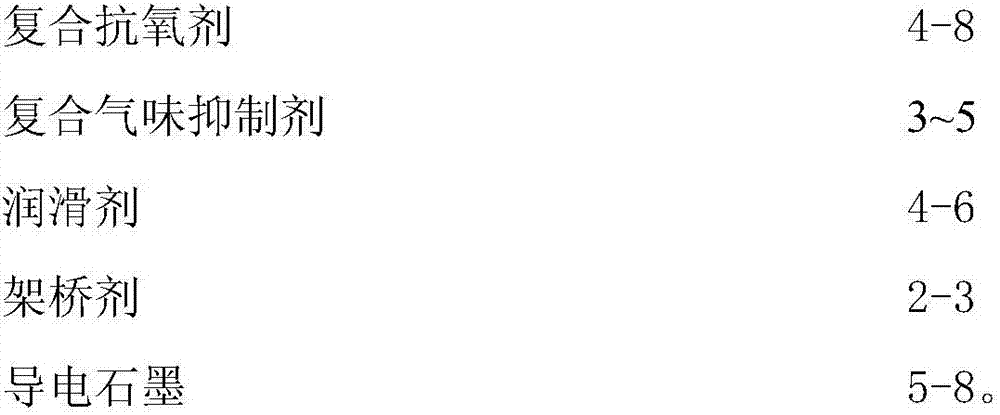

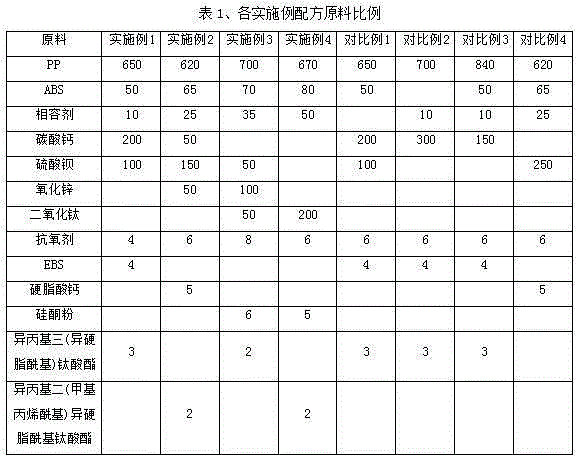

Low-smell platable polypropylene material and preparation method thereof

The invention discloses a low-smell platable polypropylene material. The low-smell platable polypropylene material comprises the following components in parts by weight: 650-720 parts of PP, 20-40 parts of CPP, 10-50 parts of a compatilizer, 200-300 parts of an inorganic filling material, 3-5 parts of a composite smell inhibitor, 4-8 parts of a composite anti-oxidant, 4-6 parts of a lubricant, 2-3 parts of a bridging agent, and 5-8 parts of conductive graphite. Through the addition of the composite smell inhibitor, the smell grade of the continuous glass fiber reinforced polypropylene composite material can reach more than 3, in addition, the polypropylene material has good electroplating performance, electroplating can be carried out according to an ABS electroplating technology, the adhesive force between a product after injection moulding with the material of the invention and a coating layer is strong, the surface gloss is high, the material cost is low, and the product after injection moulding can be recovered and used after being crushed.

Owner:HEFEI GENIUS NEW MATERIALS

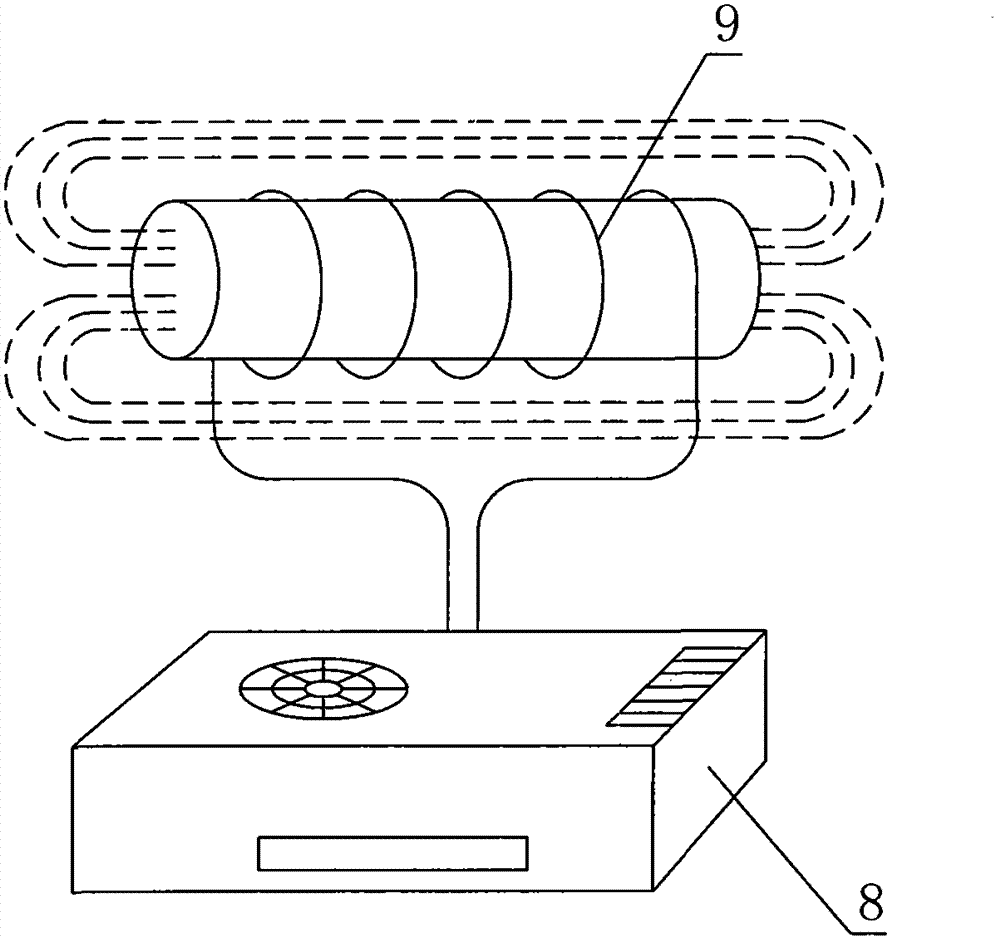

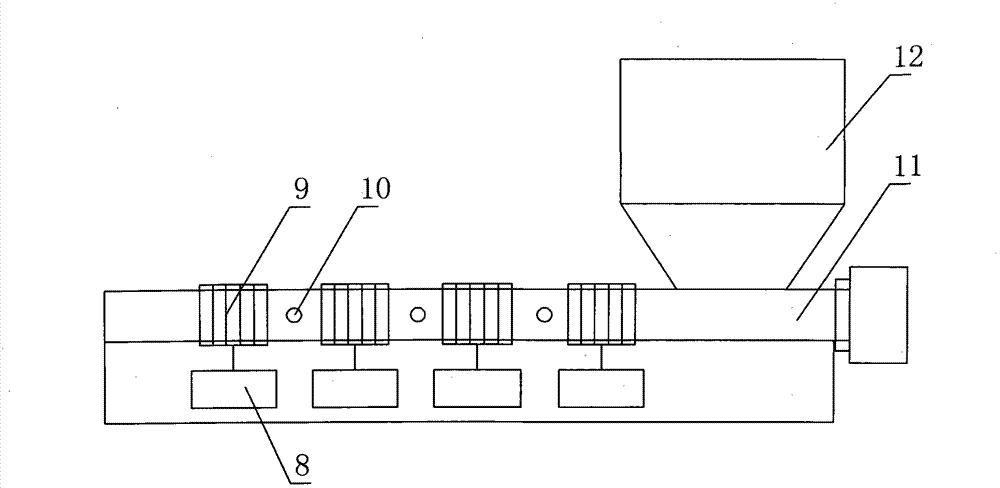

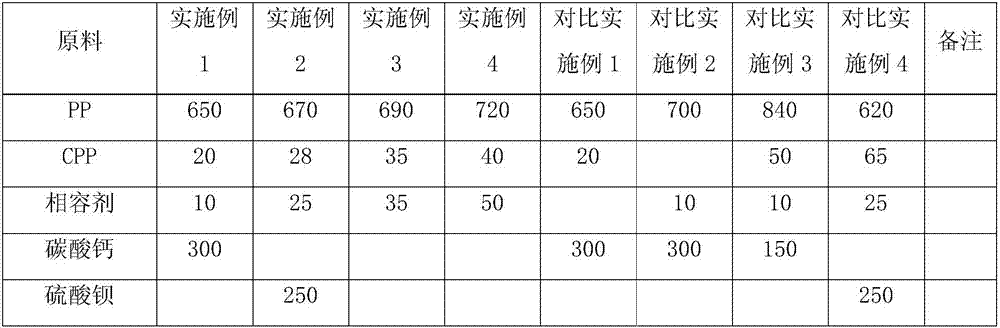

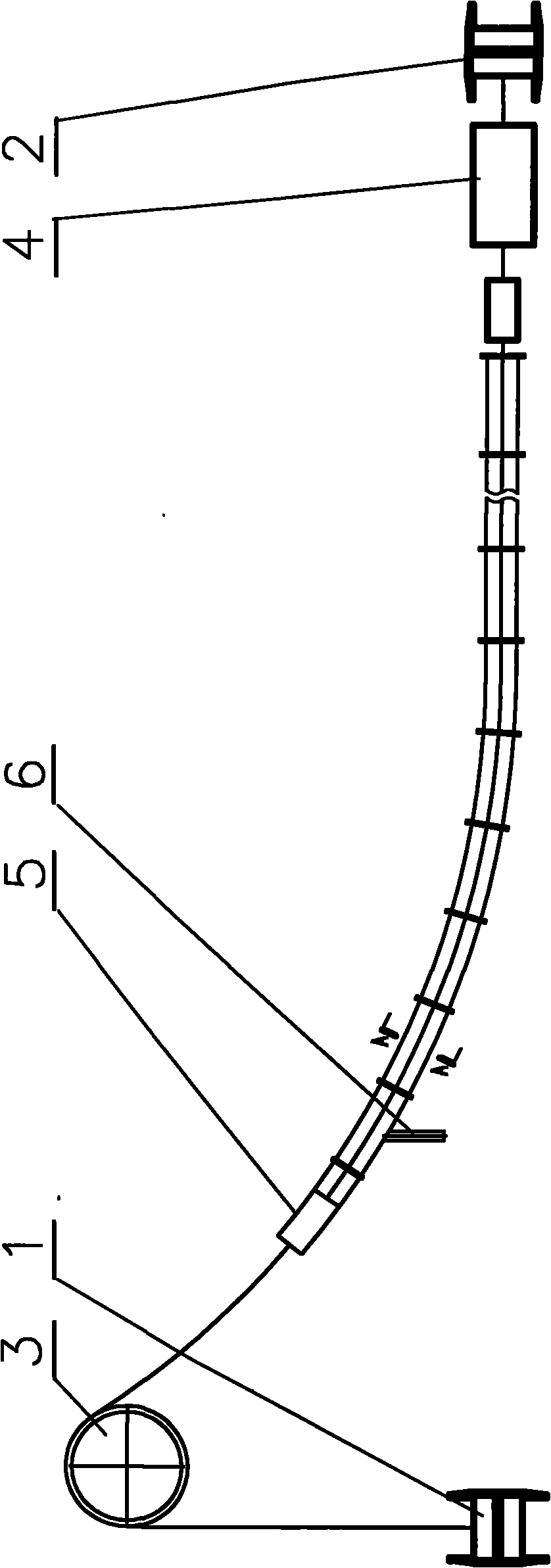

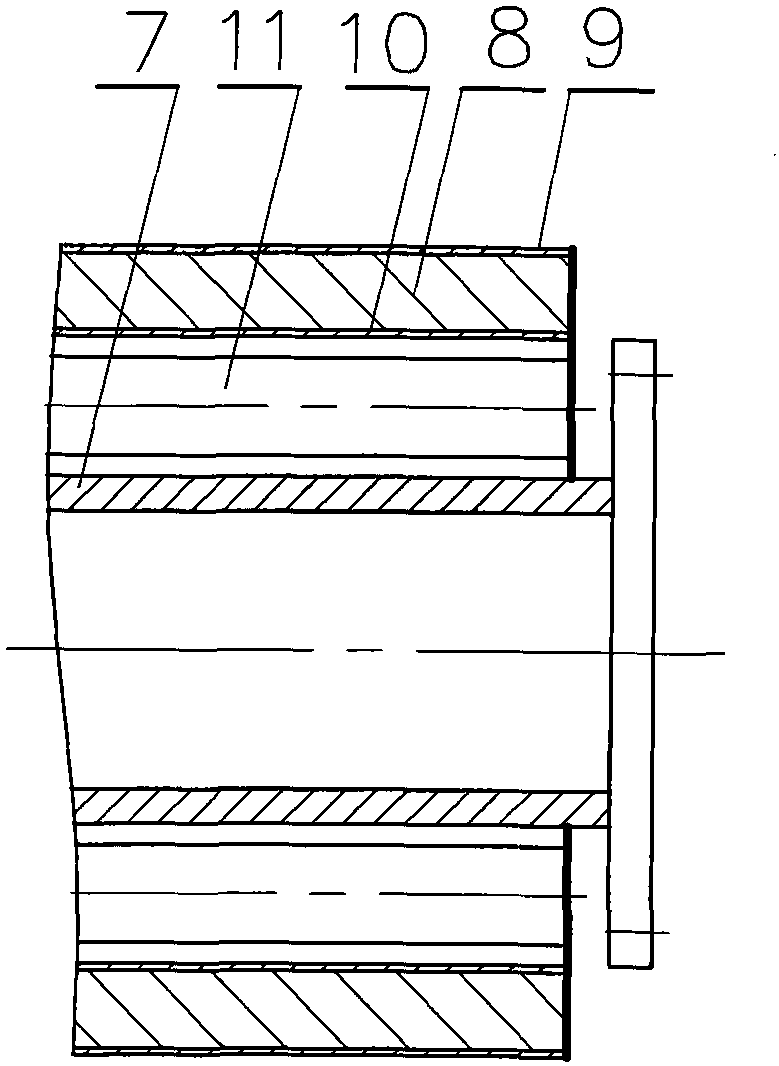

High-temperature low-pressure steam continuous vulcanization device for rubber wires and cables

InactiveCN102152433AReduce manufacturing costReasonable production process designDomestic articlesVulcanizationThermal insulation

The invention discloses a high-temperature low-pressure steam continuous vulcanization device for rubber wires and cables, which is characterized in that: low-pressure steam of 0.4MPa or below is input into a vulcanization pipeline, and each section of vulcanization pipe of a vulcanization section of the vulcanization pipeline is in electrified short circuit and is heated. The high-temperature low-pressure steam continuous vulcanization device for the rubber wires and cables comprises the vulcanization section which is connected by a plurality of vulcanization pipes, wherein each vulcanization pipe consists of a high temperature-resistant stainless steel seamless steel tube 7, an asbestos thermal insulation layer 8 coated at the periphery of the steel tube 7, and a thermally insulated fixed layer 9 fixed at the periphery of the asbestos thermal insulation layer 8; a temperature reflecting layer 10 is arranged between the steel tube 7 and the asbestos thermal insulation layer 8; a cavity is formed between the steel tube 7 and the temperature reflecting layer 10; an electric heating pipe 11 is arranged in the cavity; and the thermally insulated fixed layer 9 is made of an aluminum alloy. The device overcomes the defect that the rubber foams and cracks in the prior art, and is particularly suitable for production of cable products for railway traffic locomotives and production of other rubber wires and cables.

Owner:HENGYANG HENGFEI CABLE CO LTD

Iron tower production process based on three-dimensional space lofting

InactiveCN103526975AImprove accuracyReduce manufacturing costTowersThree-dimensional spaceWater resources

The invention discloses an iron tower production process based on three-dimensional space lofting. The iron tower production process includes the lofting procedure, the machining procedure, the trail assembling procedure, the batch machining procedure, the galvanizing procedure and the finished product detecting procedure, wherein the lofting is three-dimensional lofting based on CAD. The production process is reasonable in design, accuracy of components can be greatly improved, the machining period is shortened, work efficiency is improved, and production cost of an iron tower is reduced. Meanwhile, aeration oxidation, settling and biofilter process are conducted on waste water produced in a galvanizing workshop, and therefore waste water is recycled, and the iron tower production process has the advantages of saving the water resource, protecting the environment and reducing enterprise cost.

Owner:ANHUI HONGYUAN LINE EQUIP

Antibiosis compound, and application

InactiveCN101003534AImprove antibacterial propertiesStructure determinationBiocideOrganic chemistryChemistryQuinoline

This invention relates to an antibacterial compound, more specifically, 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1,3]thiazine[3,2-a]quinoline-3-carboxylic glutamine (compound I), its preparation method and its application. Compound I is prepared by reaction of 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1,3]thiazine[3,2-a]quinoline-3-carboxylic acid and glutamic acid. Compound I can be used as effective component and mixed with normal pharmaceutical carrier to manufacture antibacterial drug composition, which can be tablets, capsules, granules, injection, eye preparations, ear preparations, gynecological preparations, and external use preparations. Compound I has stable properties, and can be easily dissolved in water, thus can be easily manufactured into various preparations used in clinical treatment. The method has such advantages as simple and reasonable process.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY +1

Sterilization compound in broad spectrum and usage

InactiveCN101003542AStructure determinationStable in natureAntibacterial agentsOrganic active ingredientsPolyaspartic acidQuinoline

This invention relates to an antibacterial compound, more specifically, 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1,3]thiazine[3,2-a]quinoline-3-carboxylic aspartate (compound I), its preparation method and its application. Compound I is prepared by reaction of 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1,3]thiazine[3,2-a]quinoline-3-carboxylic acid and polyaspartic acid. Compound I can be used as effective component and mixed with normal pharmaceutical carrier to manufacture antibacterial drug composition, which can be tablets, capsules, granules, injection, eye preparations, ear preparations, gynecological preparations, and external use preparations. Compound I has stable properties, and can be easily dissolved in water, thus can be easily manufactured into various preparations used in clinical treatment. The method has such advantages as simple and reasonable process, and low cost.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY +1

Making process of collagen walnut milk beverage

The invention discloses a making process of a collagen walnut milk beverage. The making process is characterized in that the collagen walnut milk beverage contains 3-6% of walnut kernels, 4-5% of cane sugar, 0.2-0.3% of a emulsifier stabilizer, 0.1-0.5% of collagen, 0.03-0.07% of essence and the balance being purified water. The walnut milk beverage provided by the invention is complete in color, flavor and taste, pure in flavor and excellent in taste and has the special taste of the walnut milk beverage. The product contains no any preservatives, accords with the national standard and is a good natural nutritional beautifying item.

Owner:YUNNAN MOER GARDEN BIOLOGICAL SCI & TECH DEV

Antibacterial compound in broad spectrum and usage

InactiveCN101003541AStructure determinationStable in natureAntibacterial agentsPowder deliveryQuinolineGluconic acid

This invention relates to an antibacterial compound, more specifically, 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1, 3] thiazine [3, 2-a] quinoline-3-carboxylic glyconate (compound I), its preparation method and its application. Compound I is prepared by reaction of 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1,3]thiazine[3,2-a]quinoline-3-carboxylic acid and gluconic acid. Compound I can be used as effective component and mixed with normal pharmaceutical carrier to manufacture antibacterial drug composition, which can be tablets, capsules, granules, injection, eye preparations, ear preparations, gynecological preparations, and external use preparations. Compound I has stable properties, and can be easily dissolved in water, thus can be easily manufactured into various preparations used in clinical treatment. The method has such advantages as simple and reasonable process.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY +1

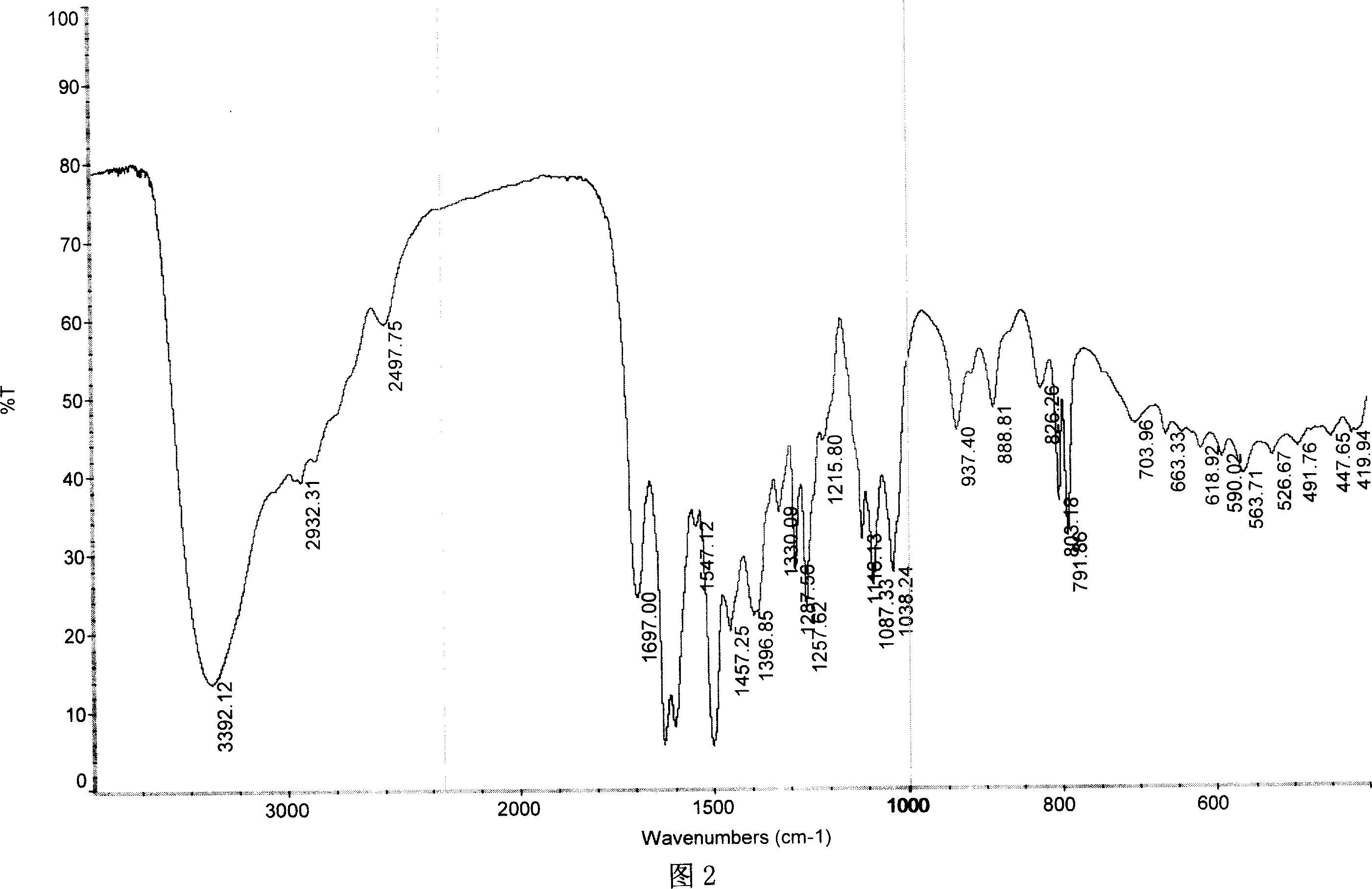

Electroplating polypropylene alloy material and preparation method thereof

InactiveCN106280012AReasonable production process designEasy to operateButadiene DioxideAcrylonitrile

The invention discloses an electroplating polypropylene alloy material and a preparation method thereof. The electroplating polypropylene alloy material is prepared from 620-700 parts of polypropylene, 50-80 parts of acrylnitrile-butadiene-styrene copolymer, 10-50 parts of compatilizer, 200-300 parts of inorganic filler, 4-8 parts of antioxidant, 4-6 parts of lubricant and 2-3 parts of bridging agent by mixing and extrusion pelletization. The prepared electroplating polypropylene alloy material has good electroplating appearance and coating strength, the cost can be replaced, and electroplating ABS can be replaced; adhesive force between an electroplating polypropylene plastic part and a coating is improved, the weight of a workpiece is reduced, and heat resistance of the electroplating polypropylene alloy material is improved.

Owner:HEFEI GENIUS NEW MATERIALS

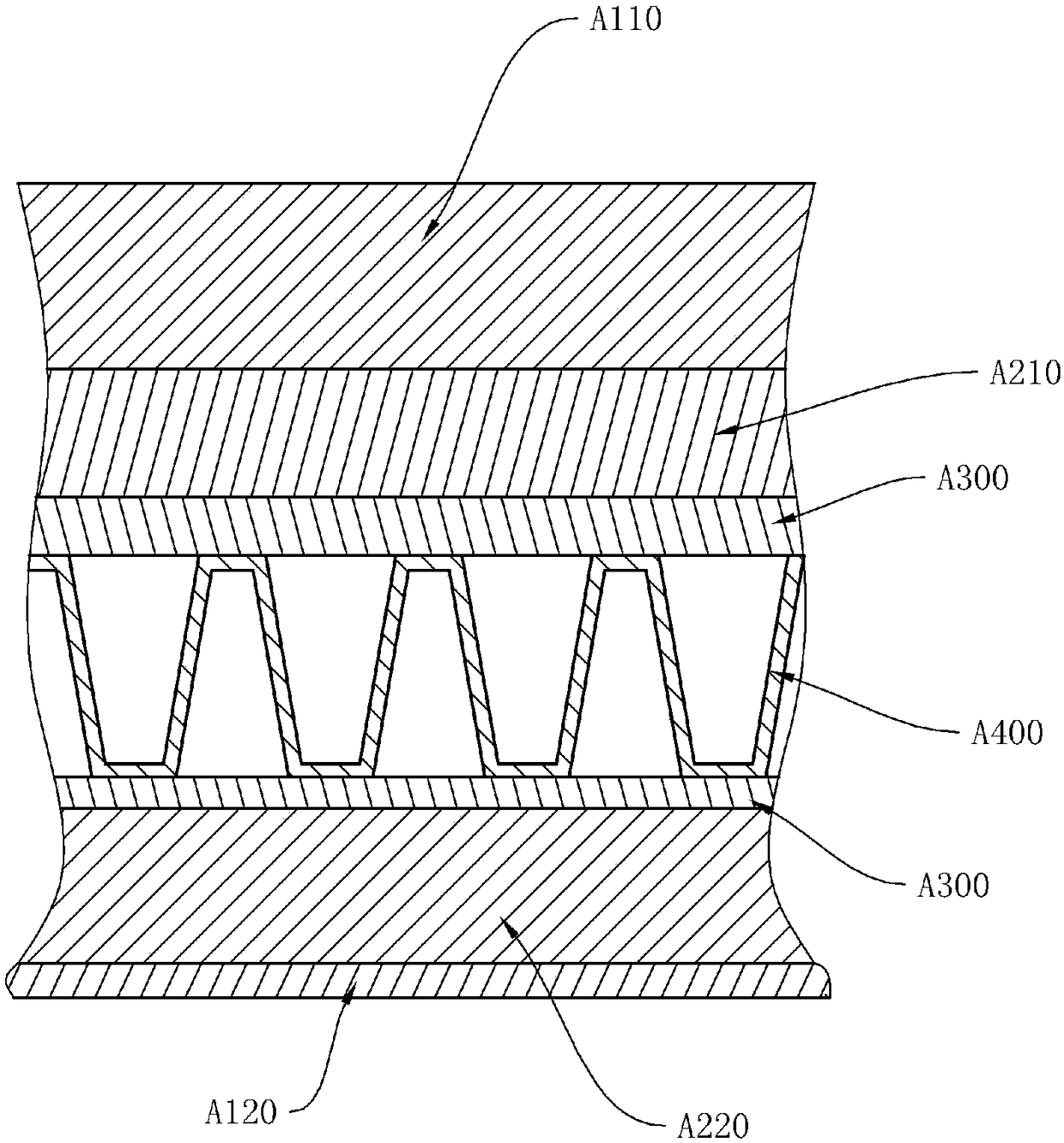

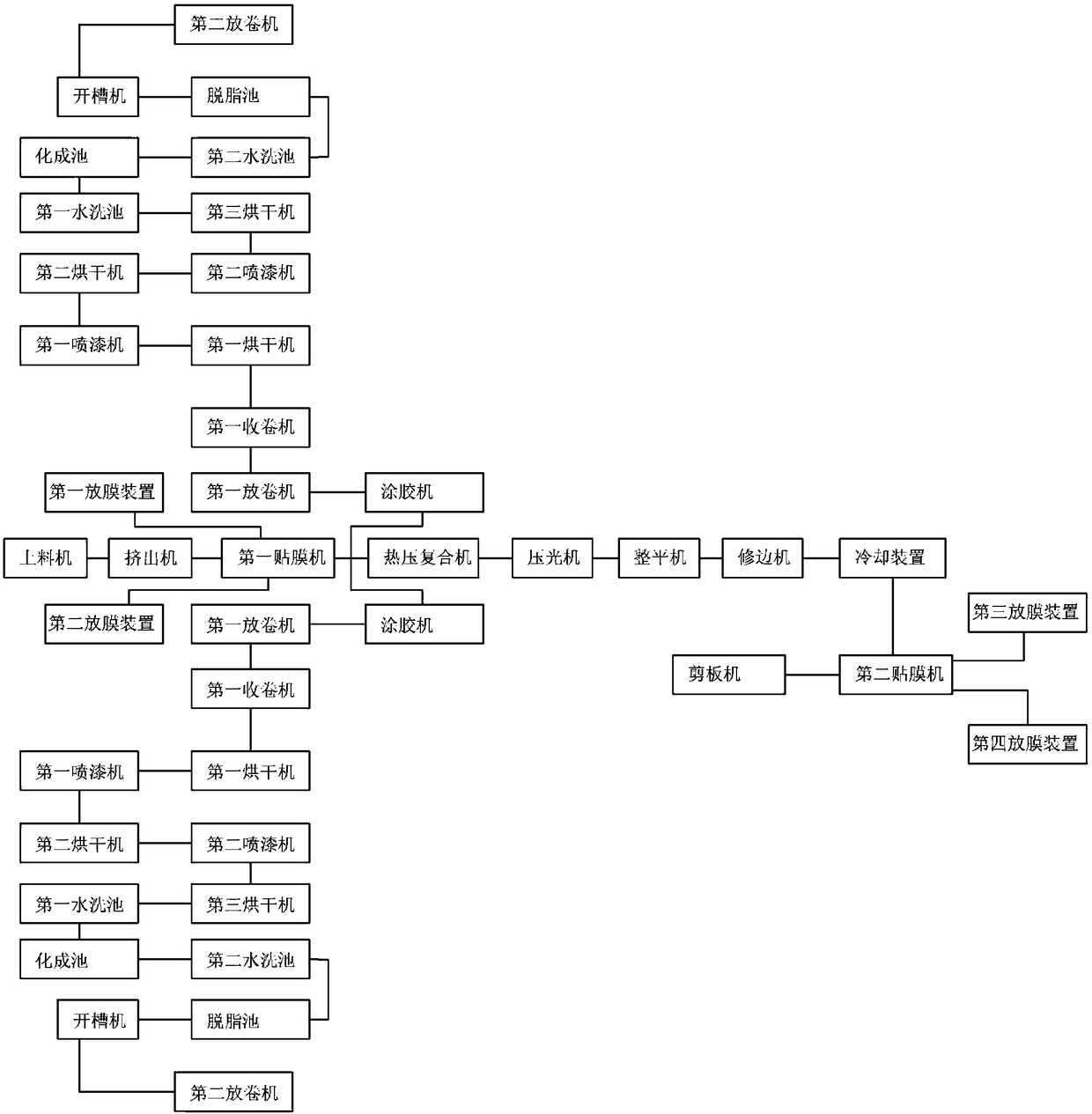

Suede aluminum-plastic composite board as well as production process and production equipment thereof

PendingCN108127992AImprove the decorative effectMeet needsCoatingsMetal layered productsLacquerPollutant emissions

The invention discloses a suede aluminum-plastic composite board. The suede aluminum-plastic composite board comprises a plastic board, wherein the section of the plastic board is in a corrugation fluctuated shape; two end surfaces of the plastic board are fixedly bonded with a second aluminum plate and a second aluminum plate by adhesive layers respectively; a suede layer is arranged on the top surface of the first aluminum plate; a protecting layer is arranged on the bottom surface of the second aluminum plate; the suede layer is suede paint. The invention further discloses production equipment and a production process for manufacturing the suede aluminum-plastic composite board. By adopting the suede, the suede aluminum-plastic composite board disclosed by the invention is higher in decorativeness and meets the demands of more people. A waste heat recovering system disclosed by the invention can be used for recycling heat, organic waste gases and the like of the production equipmentin the production process, so that energy consumption is reduced, pollutant discharge is prevented and the environment is protected. The production equipment disclosed by the invention has a completestructure; the production process is reasonable in design; by using the production process, a high-quality aluminum-plastic composite board can be produced.

Owner:SHANGHAI YARET IND GROUP

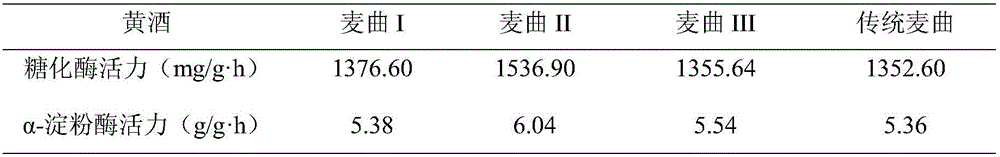

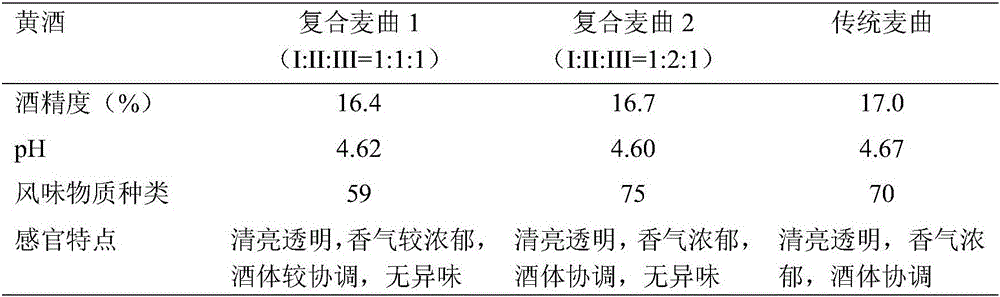

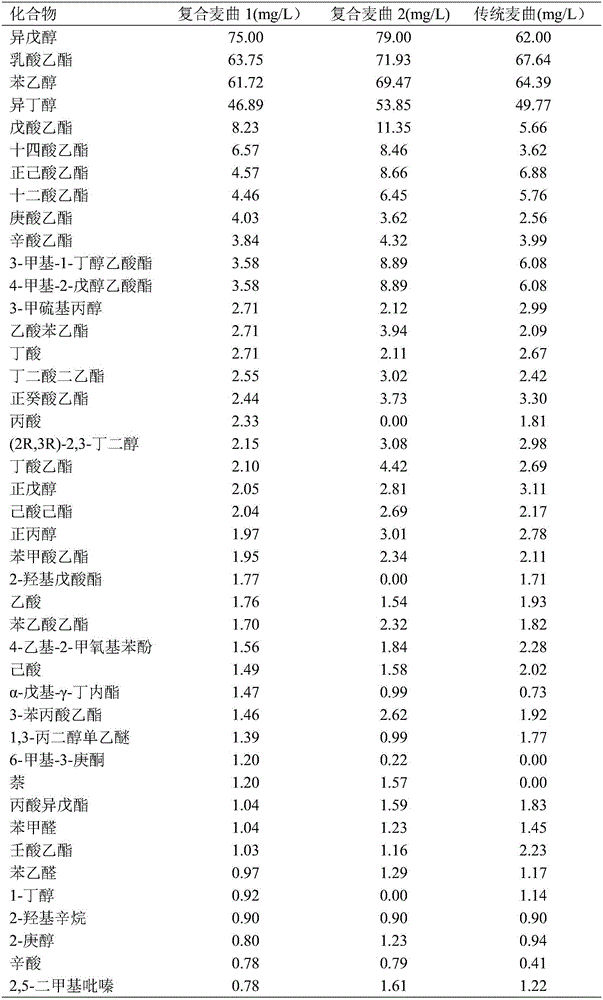

Composite raw wheat kojis and production method thereof

ActiveCN106591055AReasonable production process designEasy to operateAlcoholic beverage preparationBiotechnologyOxygen content

The invention discloses composite raw wheat kojis and a production method thereof, and belongs to the technical field of wine brewing. The production process comprises the steps of firstly, according to a traditional koji making method, rolling and crushing wheat, adding water, wetting the material, then dividing the wheat into 3 parts, respectively placing the 3 parts in drum fermenting devices, controlling the temperature, humidity and oxygen content by stages, and culturing to obtain the wheat kojis containing different microflora. The wheat kojis are mixed for use according to a certain proportion, and wine bodies with different flavors and tastes can be obtained. The method is easy to operate, saves manpower and is prone to realization of mechanized operation.

Owner:JIANGNAN UNIV

Melatonin composition and preparation method thereof

InactiveCN106619617AAnti agingShorten the timeOrganic active ingredientsNervous disorderIcing sugarMedicine

The invention discloses a melatonin composition and a preparation method thereof, and belongs to the technical field of health products. In an inventory ration of 1000 grains, the melatonin composition contains the following materials by weight: 2-3.5g of melatonin, 1.5-2.5g of vitamin B6, 80-120g of starch, 200-250g of powdered sugar, 5-9g of silicon dioxide, and 1.5-2.5g of magnesium stearate. By virtue of the composition having the effects of soothing the nerves and improving sleeping and prepared by mixing of the melatonin, the vitamin B6 and the like, disclosed by the invention, the problem of different injuries to a body due to long-time taking of sleeping pills is solved, and the composition has the advantages of improving sleeping, delaying senescence and adjusting immunity.

Owner:WUHU NOKAN BIOTECH

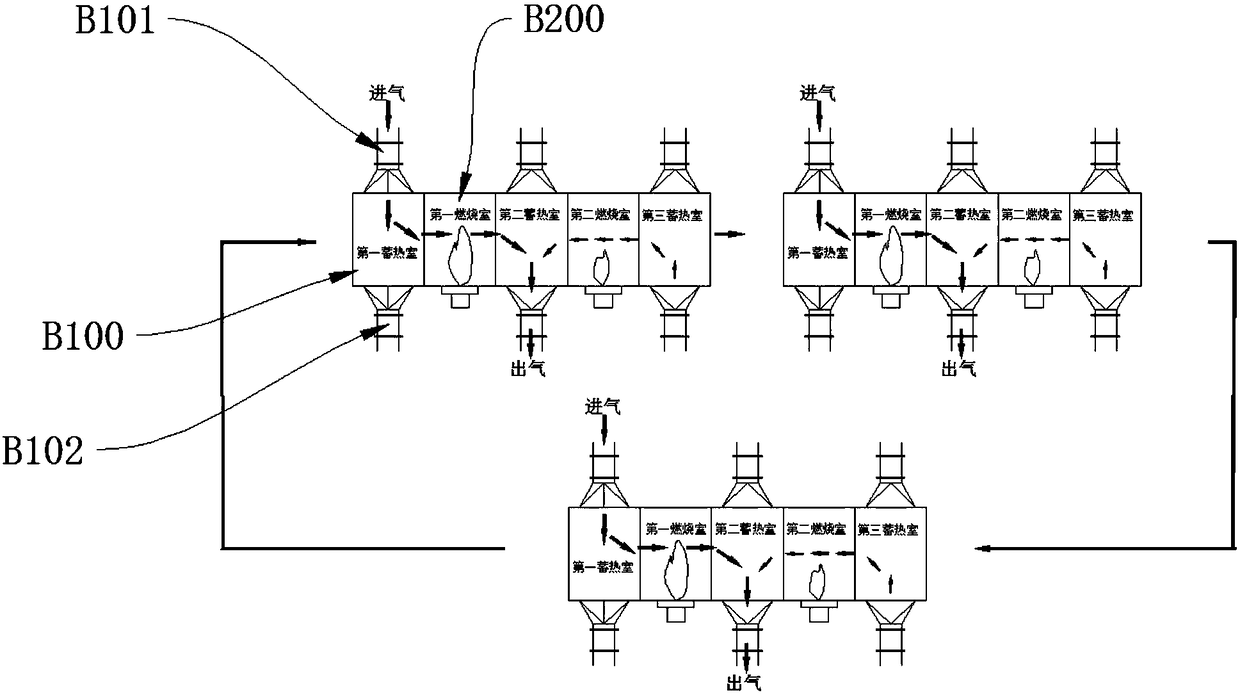

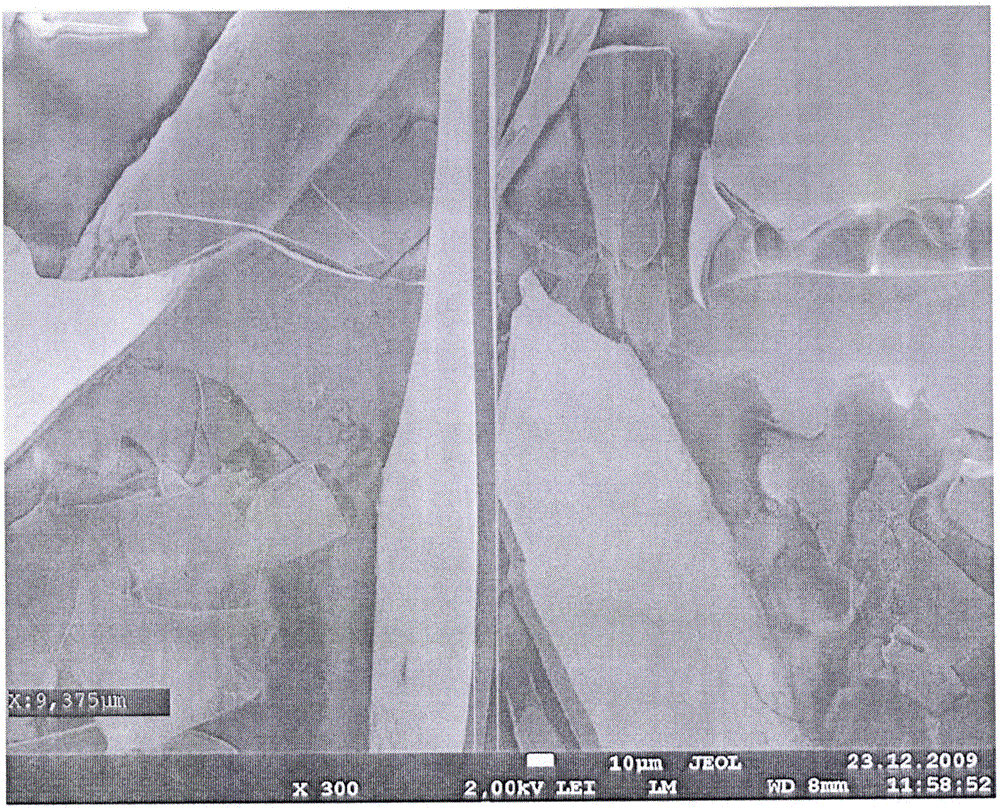

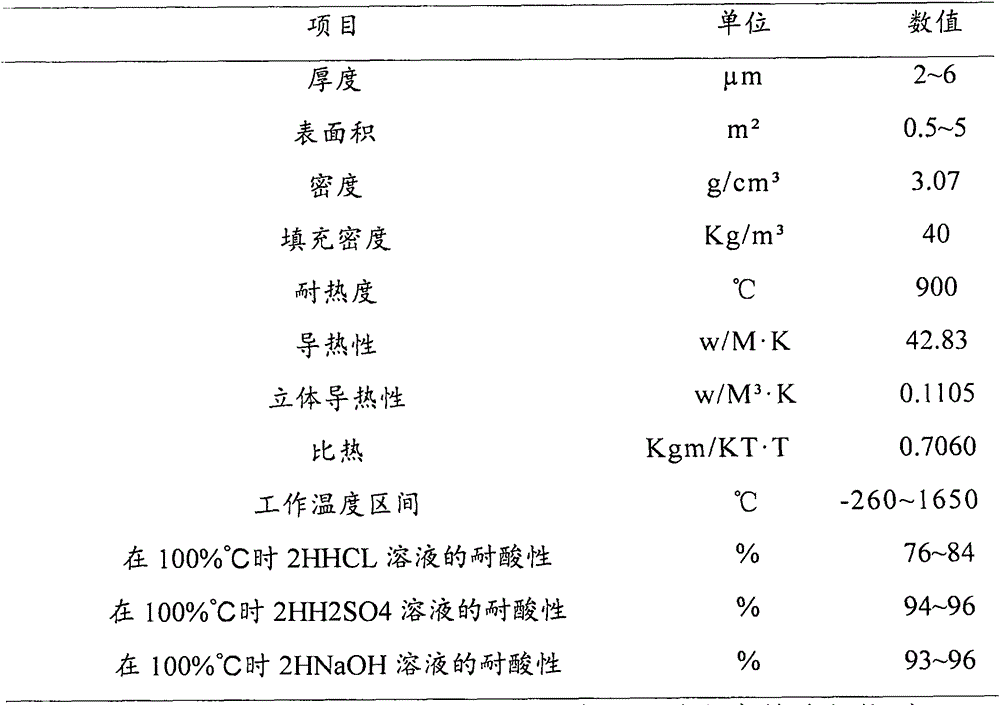

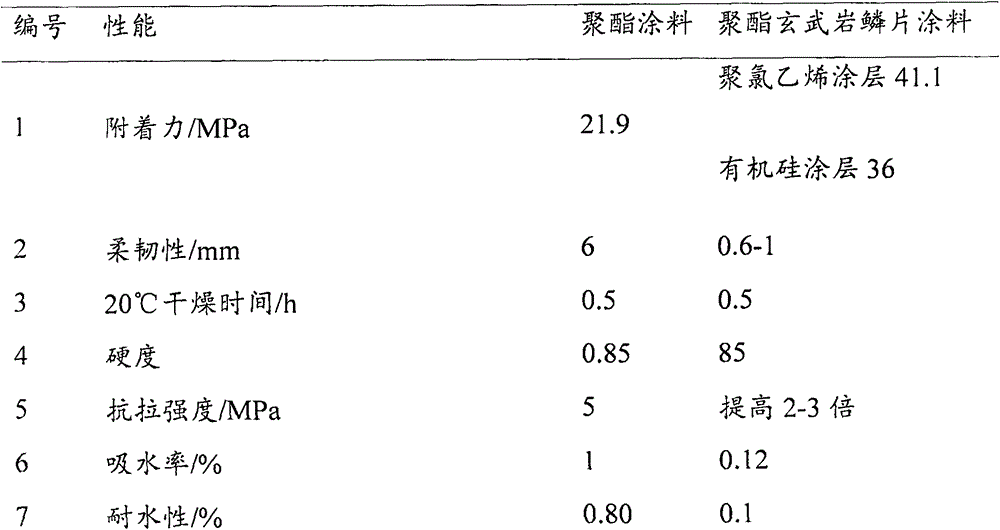

Production process of basalt scales

InactiveCN106430939AReasonable production process designEasy to processGlass making apparatusElectricityPre treatment

The invention belongs to the technical field of production of inorganic non-metal scales and particularly relates to a production process of basalt scales. The production process comprises the following effective steps: a, obtaining raw materials for preparation after pretreatment of basalt ores; b, placing selected basalt ores in a tank furnace and melting through electrical heating, wherein the temperature reaches 2,600 DEG C through electrical heating; c, conveying melted basalt melt by a separator, homogenizing by throats, outflowing by a wire-drawing bushing, cooling and puffing rapidly, so as to obtain the basalt scales. Compared with the prior art, the production process of the basalt scales disclosed by the invention has the advantages and beneficial effects that the invention provides the production process of the basalt scales, so that the production process of the basalt scales is not only limited to laboratory production and can really realize industrial production, so as to fill up a blank of industrial production of the basalt scales in China; meanwhile, the production process provided by the invention has reasonable design, convenience in processing and low production cost and is suitable for large-scale popularization and use.

Owner:倪长青

Composite material product of permanent magnetic ferrite material and ceramic material and its producing process

The present invention relates to composite material product of permanent magnetic ferrite material and ceramic material and its production process. The composite material product features its ceramic material layer, blue-and-white porcelain layer, familla-rose porcelain layer and glaze material layer sintered on the surface of the permanent magnetic ferrite. The production process includes the following steps: 1. mixing the material for permanent magnetic ferrite including Fe2O3 and adhesive PVA, pressing to form and high temperature sintering to obtain semi-finished permanent magnetic ferrite device; 2. coating ceramic material to the surface and high temperature sintering to combine the ceramic material onto the device; 3. coating blue-and-white porcelain material and familla-rose porcelain material and high temperature sintering; and 4. coating glaze material and high temperature sintering on the surface of the device.

Owner:石春沙

Production process of sweet potato turbid juice beverage

InactiveCN107549536ARetain nutrientsReasonable production process designFood scienceWater bathsFiltration

The invention provides a production process of sweet potato turbid juice beverage, which relates to the technical field of food processing, and comprises the following steps: 1) preparation of ingredients: washing and peeling fresh sweet potatoes, cutting into pieces, and blanching; 2) beating: a ratio of 1: 3. Beat sweet potatoes with boiling water to obtain turbid juice; 3) colloid mill: mix the additives and turbid juice evenly; 4) Homogenize: use a homogenizer to homogenize the turbid juice under the conditions of 25MPa and 70°C; 5) Degassing: Use a vacuum filter for 4 minutes to discharge the air in the slurry; 6) Preheating: Preheat the slurry to 75-80°C; 7) Filling and exhausting: Pour the slurry into the tank, and then Put in a boiling water bath for 3 minutes, keep the center temperature at 75°C, and discharge the air in the tank; 8) Sterilization and cooling: Sterilize at 120-125°C for 15 minutes, and then put the sterilized beverage into water at 70-80°C to cool for 10 minutes. Then it is cooled to room temperature with normal temperature water; the process design of the invention is reasonable, and the prepared sweet potato turbid juice drink has unique flavor and rich nutrition.

Owner:安徽省小咸匠食品有限公司

Manufacturing technique of 3D high-definition UV printing decoration product

InactiveCN106394104AReasonable production process designHigh precisionVisual indicationDecorative surface effectsProduction rateEngineering

The invention discloses a manufacturing technique of a 3D high-definition UV printing decoration product. The manufacturing technique comprises the following steps that (1) a relief painting formwork is built; (2) a relief painting abrasive tool is manufactured; (3) a sample blank is manufactured; (4) the sample blank is colored; and (5) a finished product is assembled. The manufacturing technique of the 3D high-definition UV printing decoration product is reasonable in design, the relief painting formwork is designed on a computer in advance according to a pattern needing to be printed on a decoration product, then the sample blank is manufactured by manufacturing the relief painting formwork, and the relief painting formwork is printed on the manufactured sample blank through a UV printer, so that a picture of the relief painting is more abundant in color, the picture quality is more stable, the color is bright, and the strong third-dimensional feeling and layering feeling are achieved; meanwhile, the labor cost is saved; and the UV printing technology is adopted, and the production rate and the product quality are improved.

Owner:何永新

Flame-retardant acrylic yarn textile equipment and textile process

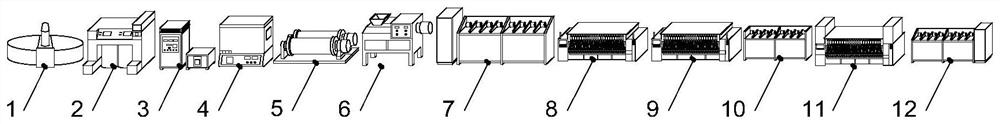

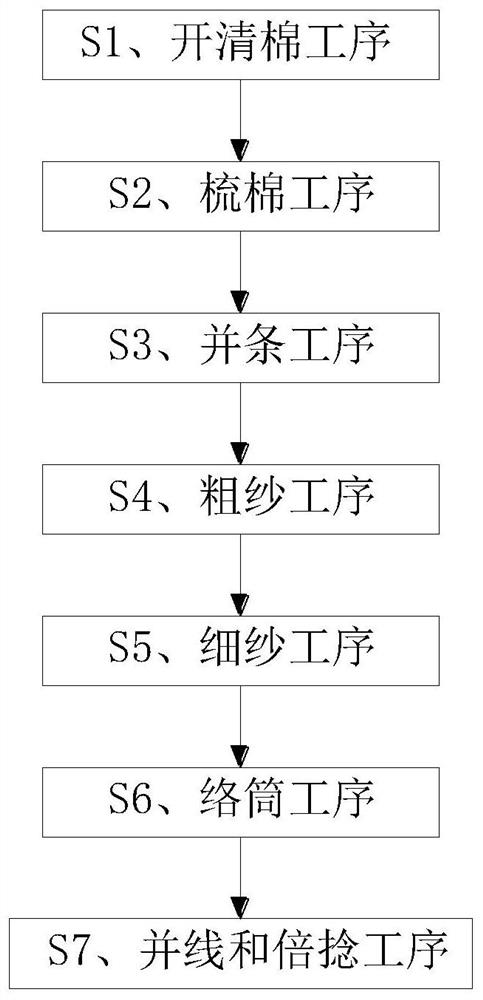

InactiveCN112779638AWith flame retardant functionReasonable production process designDrafting machinesYarnTextile technologyYarn

The invention discloses flame-retardant acrylic yarn textile equipment. The flame-retardant acrylic yarn textile equipment comprises a bale plucker, a mixing opener, an opener, a vibrating feeder, a lap former, a carding machine, a drawing frame, a roving frame, a spinning frame, a spooling machine, a doubling winder, a two-for-one twister and flame-retardant acrylic fibers. The input ends and the output ends of the bale plucker, the mixing opener, the opener, the vibrating feeder, the lap former, the carding machine, the drawing frame, the roving frame, the spinning frame, the spooling machine, the doubling winder and the two-for-one twister are sequentially connected. And the flame-retardant acrylic fibers are medium-long acrylic fibers of 2.2 dtex51 mm. An aviation seat blanket produced through the working procedures of opening picking, cotton carding, drawing, roving, spinning, spooling, doubling, two-for-one twisting and the like has the flame-retardant function, the whole production process is reasonable in design and ingenious in conception, and the problems that in a traditional textile technology, cotton falling, roll sticking and accidental extending are prone to occurring are effectively solved.

Owner:HEBEI HONGRUN NEW FABRIC

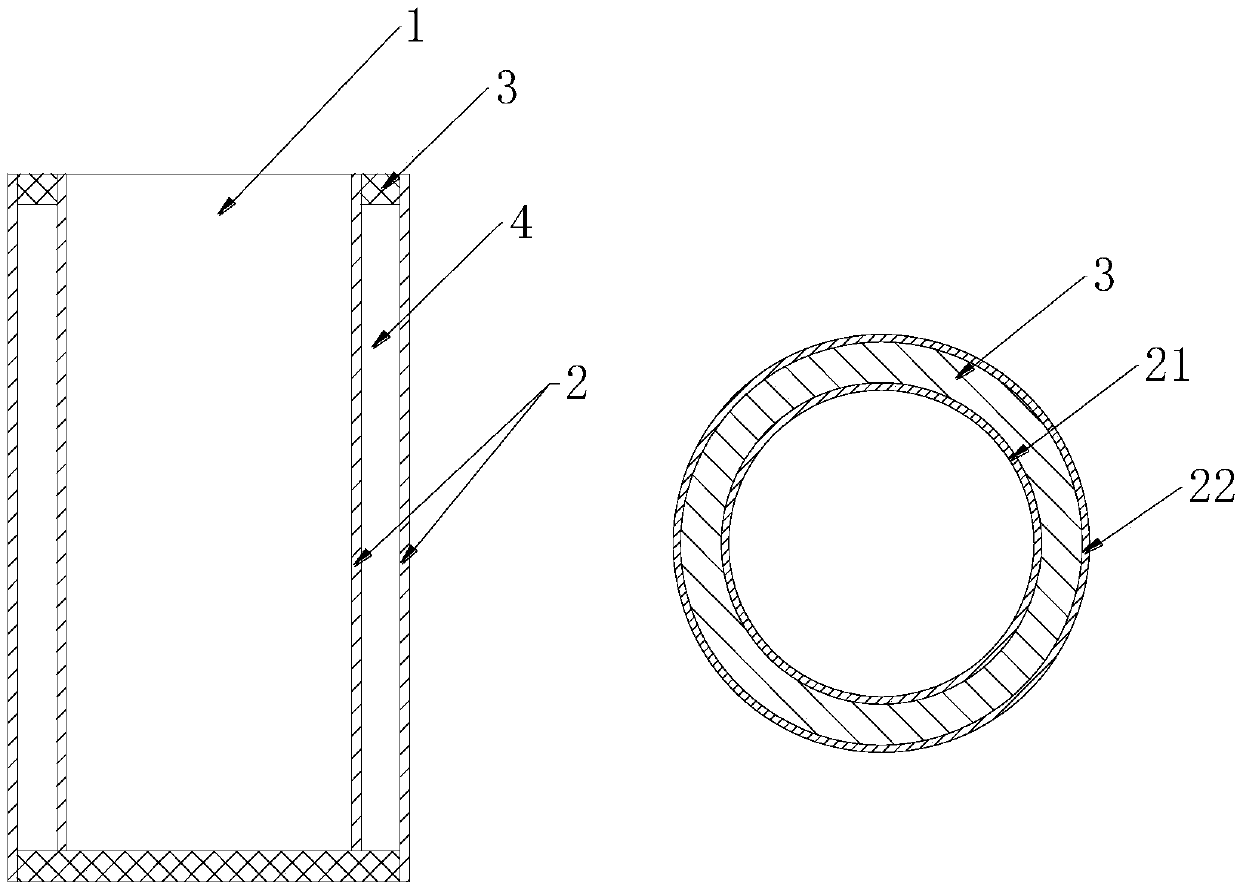

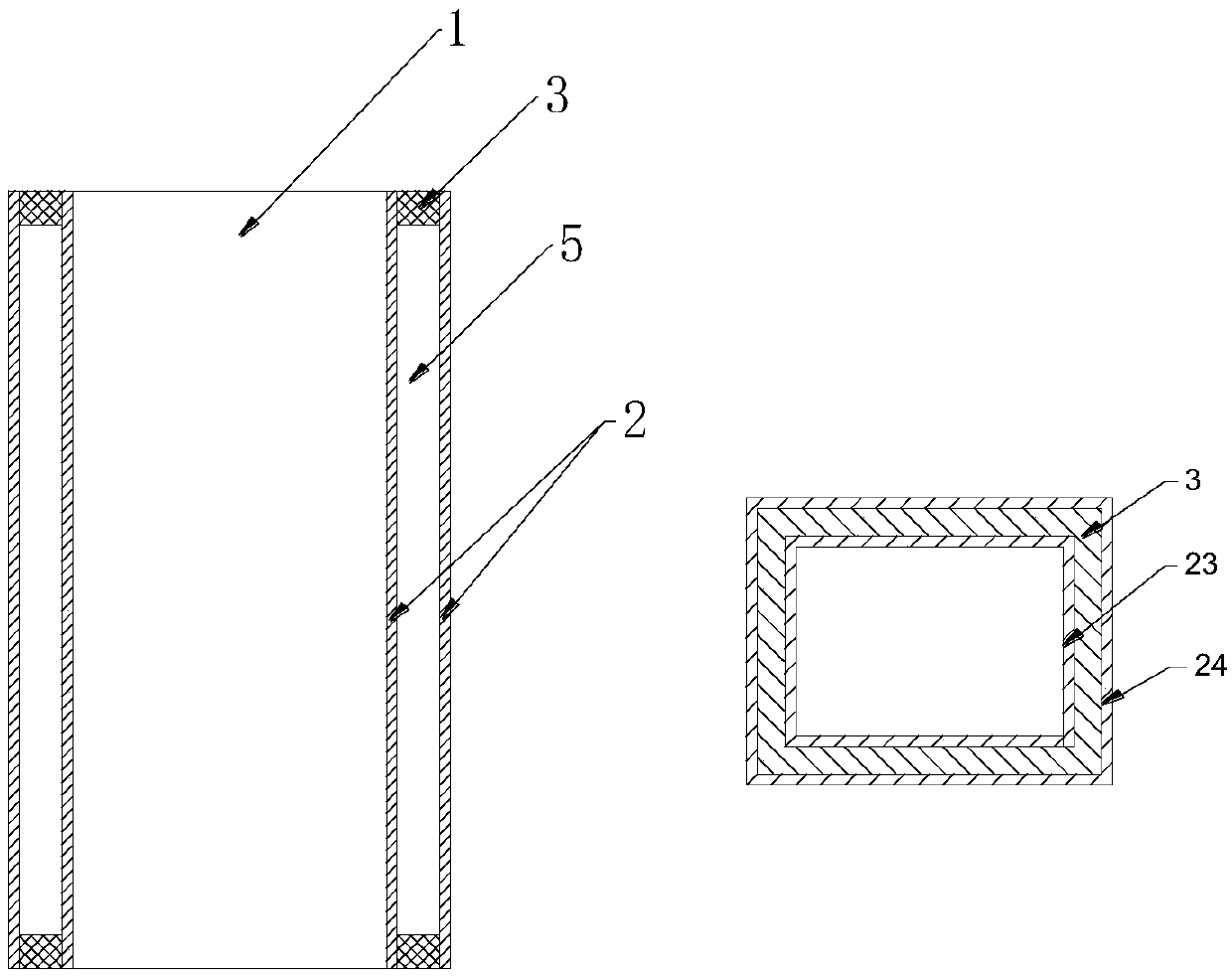

Vacuum thermal insulation device and production process thereof

InactiveCN109538881AHigh melting pointChemically stableThermal insulationPipe protection by thermal insulationThermal insulationConvection heat

The invention discloses a vacuum thermal insulation device and a production process thereof. The vacuum thermal insulation device comprises at least two thermal insulation bodies and an edge sealing material, wherein the side faces of every two adjacent thermal insulation bodies are spaced by a distance to form a vacuum area, and the edge sealing material seals the periphery of the vacuum area through vacuum high-temperature sintering so as to isolate the vacuum area from the outside world. In the production process, the thermal insulation bodies made of a high-temperature-resistant thermal insulation material are clamped by a jig, the side faces of every two adjacent thermal insulation bodies are spaced by a certain distance to form an isolation cavity, the edge sealing material is placedon the periphery of the isolation cavity, a vacuum high-temperature sintering furnace is placed for sintering, then cooling is conducted so that the edge sealing material can be solidified, and partof the periphery of the isolation cavity is sealed to form the vacuum area. Convection heat conduction and contact heat conduction are isolated through the vacuum area, heat can hardly be transmittedto the outside world, and the thermal insulation effect is realized; the thermal insulation bodies made of the high-temperature-resistant thermal insulation material is adopted and can be applied to the thermal insulation of the high-temperature environment.

Owner:广东国研新材料有限公司

Production process of antibacterial knitted garment

InactiveCN109281162AReasonable production process designSimple preparation processBiochemical fibre treatmentVegetal fibresEngineeringAntibacterial property

The invention discloses a production process of an antibacterial knitted garment. The process includes the following process steps: (1) preparing a traditional Chinese medicine liquid; (2) weaving cotton fibers into clothes, and performing degreasing treatment on the cotton fibers and soaking the cotton fibers by utilizing the traditional Chinese medicine liquid before cotton fiber spinning; (3) preparing a nano-antibacterial solution; (4) first placing the knitted garment in a container, and then adding the nano-antibacterial solution for soaking; (5) baking the knitted garment; and (6) subjecting the baked garment to scouring and bleaching treatment to obtain a nano-antibacterial knitted garment. The production process of the antibacterial knitted garment is reasonable in design, a preparation process is simple, the nano-antibacterial solution is adopted and is strong in bonding force with the knitted garment, the knitted garment is resistant to rinsing, has good antibacterial properties, has no side effects on a human body, does not pollute the environment and is good in safety, and the quality of the knitted garment can be improved; and in addition, the antibacterial knitted garment is strong in capability of killing mites and enables the added value of the garment to be increased.

Owner:上海亨谦实业发展有限公司

Concrete for road construction and preparation method of concrete

InactiveCN111574120AImprove stress resistanceExcellent quality control rateCement mixing apparatusPlant fibreArchitectural engineering

The invention relates to the technical field of concrete. The concrete for road construction is prepared from the following materials in parts by weight: 40 to 60 parts of cement; 30 to 40 parts of sand; 20 to 30 parts of mineral powder; 50 to 67 parts of stone; 18 to 32 parts of water; 1 to 3 parts of plant fiber; 0.5 to 2 parts of a water reducing agent; and 2.5 to 4 parts of montmorillonite. The concrete provided by the invention has the advantages of excellent compression resistance and high splitting strength.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

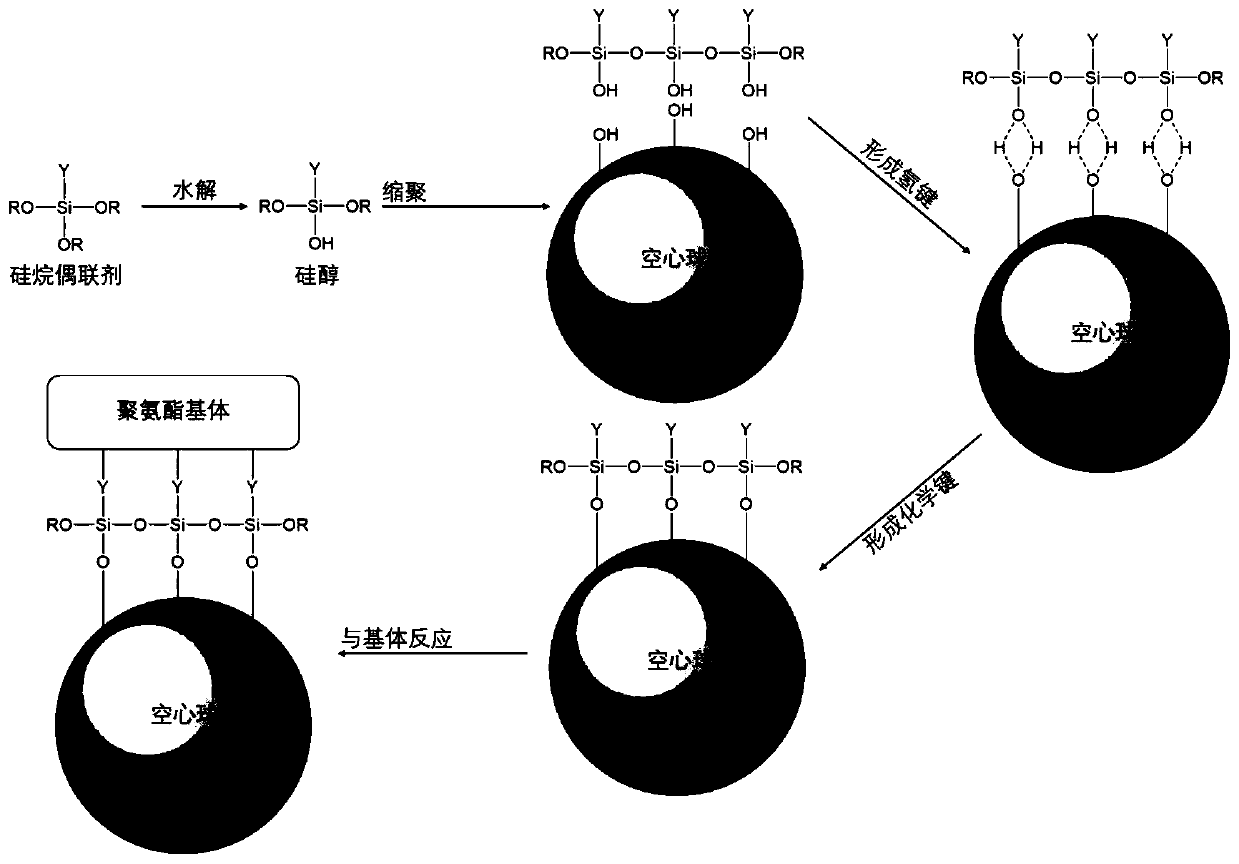

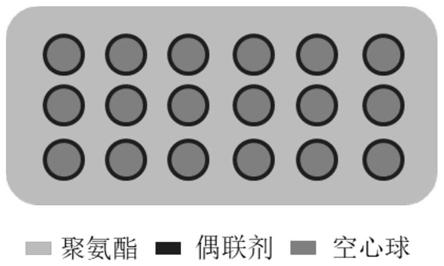

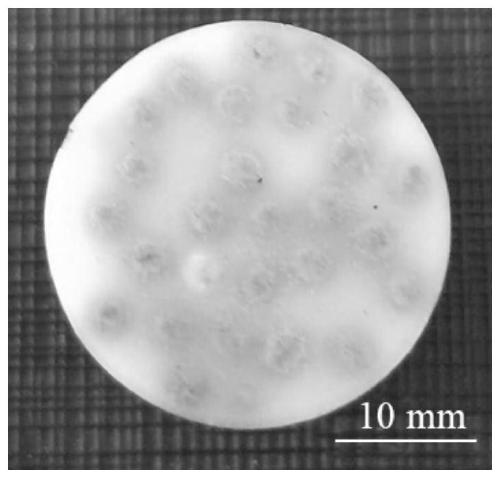

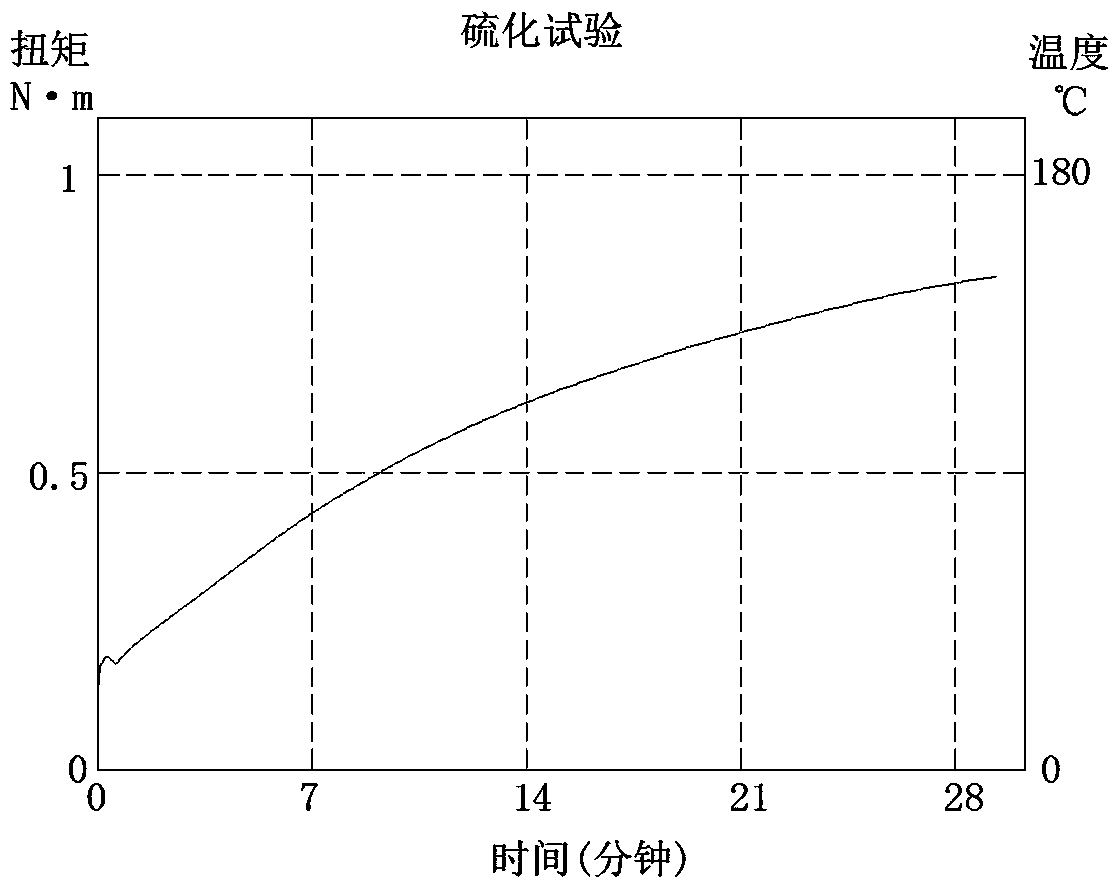

Preparation method of novel hollow sphere filled polyurethane-based composite material

The preparation method of the novel hollow sphere filled polyurethane-based composite material comprises the following steps: cleaning the surface of a hollow sphere to remove impurities and dirt on the surface, and drying for later use; wherein the used surface modifier is a silane coupling agent, and the silane coupling agent needs to be hydrolyzed; adding the hollow spheres into the hydrolyzedsilane coupling agent solution, stirring at a proper temperature, then putting the hollow spheres into a drying oven for drying, and taking out for later use; and adding the modified hollow spheres into a casting mold, sequentially adding isocyanate, hydroxyl-terminated polyester or hydroxyl-terminated polyether and other assistants, stirring to uniformly distribute the hollow spheres in the matrix, curing at room temperature, and demolding to obtain the hollow sphere filled polyurethane-based composite material. The production process is reasonable in design, and operation steps are simple and convenient; the components and the structural design of the composite material are controllable; the composite material has excellent mechanical and acoustic properties.

Owner:HARBIN ENG UNIV

Casting method applied to automobile engine cylinder head

InactiveCN108672653AShorten production timeReasonable production process designFoundry mouldsFoundry coresCylinder headSizing

The invention belongs to the technical field of production and application of automobile assembly parts, and particularly discloses a casting method applied to an automobile engine cylinder head. Thecasting method comprises the following steps of 1, manufacturing of a wax mould of the engine cylinder head, 2, immersing sizing, 3, casting, 4, machining, 5, grinding, and 6, packaging. The casting method applied to the automobile engine cylinder head has the beneficial effects that the production process of the casting method is reasonable in design, the production time of the automobile enginecylinder head is saved, the finished product rate of the automobile engine cylinder head is high, and the production cost is effectively reduced.

Owner:TAIZHOU BOSHITE PRECISION CASTING CO LTD

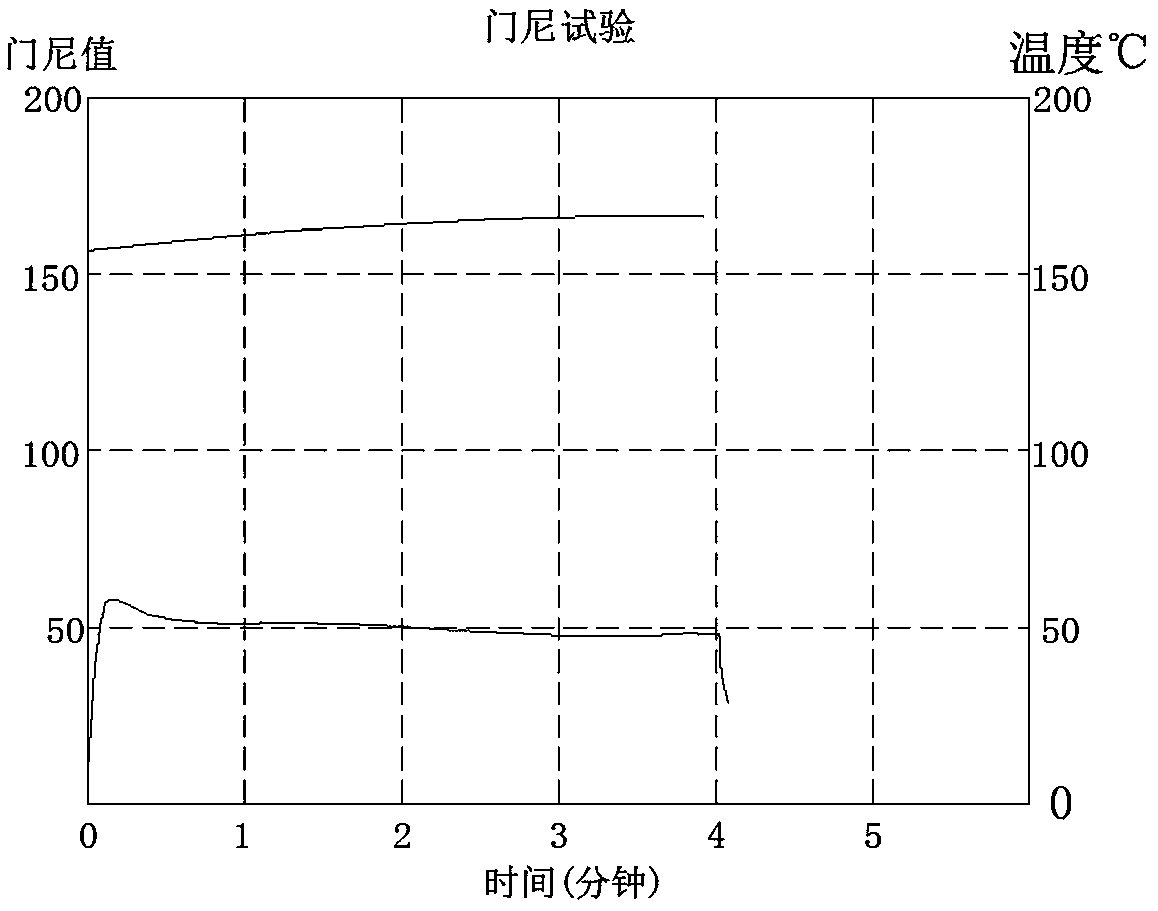

Tire curing bladder and preparation technology thereof

The invention provides a tire curing bladder and a preparation technology thereof, and belongs to the technical field of rubber tires. The technology includes two stages, wherein in the first stage, 268 butyl rubber IIR, 1 / 2 carbon black N330, 1 / 2 carbon black N330 and other materials except 202 resin are added in sequence; in the second stage, first-stage rubber is added, filtering is carried out, the 202 resin is added, standing is carried out, and curing is carried out. The curing bladder and the preparation technology thereof have the advantages that the materials are scientific and environmentally, the cost is low, the economic benefit is good, and the yield is high. The tire curing bladder and the preparation technology thereof are reasonable in design, the raw materials are easy toobtain, the formula is simple, the safety and reliability are achieved, the technology is convenient to operate and easy to master, and the application and popularization value is good.

Owner:山东汉正橡胶工业有限公司

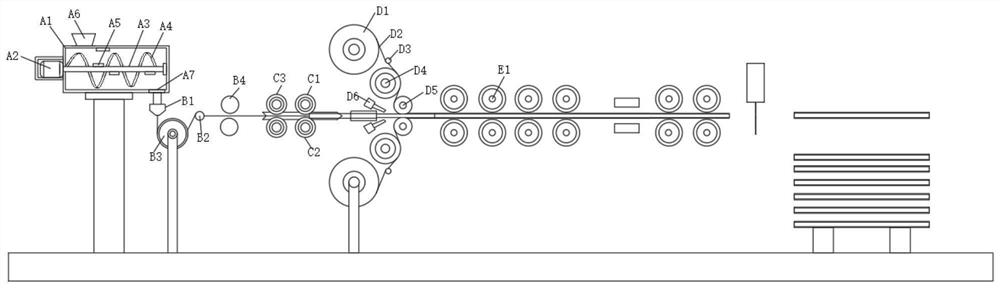

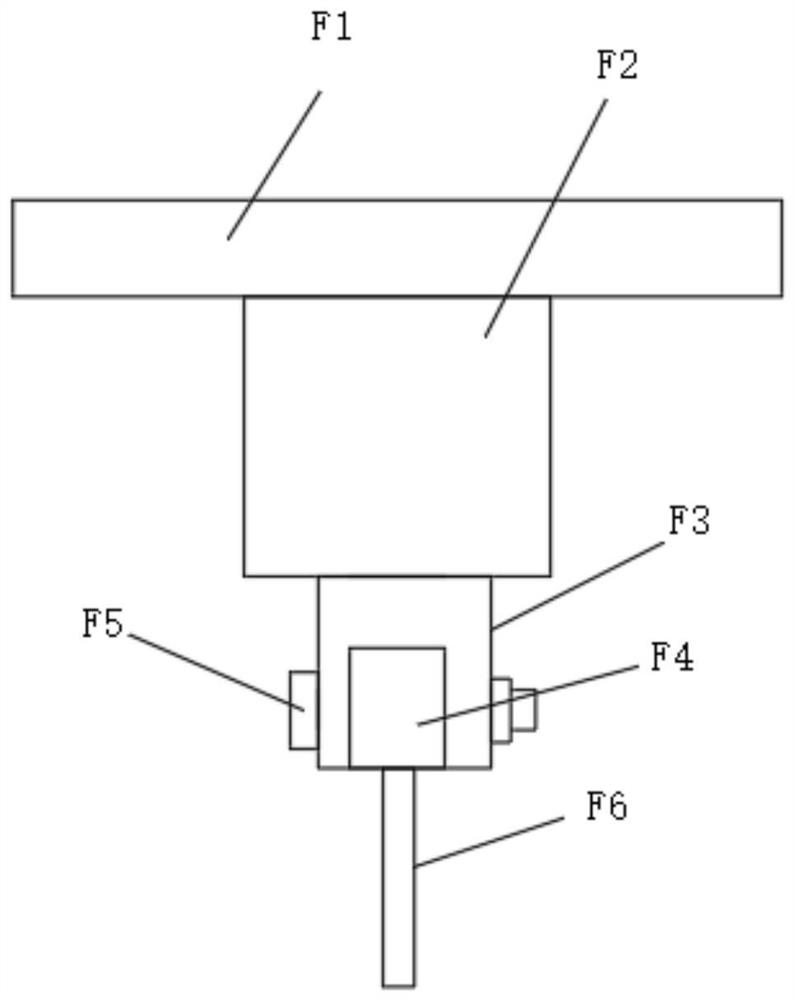

Production process of high-performance continuous fiber thermoplastic composite material

PendingCN113059831AIncrease productivityReasonable production process designManufactured materialResin coating

The invention discloses a production process of a high-performance continuous fiber thermoplastic composite material. The preparation method comprises the following steps of S1, mixing, stirring and heating raw materials by using mixing and heating equipment; S2, coating the roller surface of a hot-melt resin coating guide roller with the raw materials treated in S1 in an extrusion manner to form a hot-melt resin film layer with uniform thickness; S3, stamping the hot-melt resin film layer prepared in S2 by using stamping equipment; S4, coating the upper surface and the lower surface of a continuous fiber thermoplastic composite lattice structure core material prepared in S3 with films through film coating equipment; S5, rolling the continuous fiber thermoplastic composite material prepared in S4 by using continuous rolling and laminating equipment; S6, heating and forming the continuous fiber thermoplastic composite material prepared in S5 by using heating equipment; and S7, cutting the formed continuous fiber thermoplastic composite material by using cutting equipment.

Owner:常州贝嘉尔新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com