Flame-retardant acrylic yarn textile equipment and textile process

A flame-retardant acrylic fiber and textile equipment technology, applied in the direction of drafting equipment, textiles and papermaking, yarn, etc., can solve the problems of sticky rolls, aviation seat blankets not having flame retardant properties, noil and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

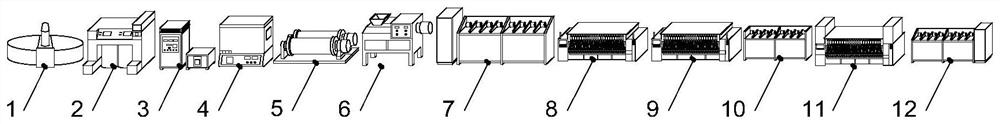

[0027] Example: such as figure 1 As shown, a kind of flame-retardant acrylic yarn textile equipment, comprises cotton grabbing machine 1, mixed cotton opening machine 2, cotton opening machine 3, vibrating cotton feeder 4, lapping machine 5, carding machine 6, drawing frame 7, Roving frame 8, spinning frame 9, winder 10, doubling frame 11, two-for-one twister 12 and burning acrylic fiber 13, described plucking machine 1, mixed cotton opener 2, cotton opener 3, vibrating cotton feeder 4, the input end and the output end of lapping machine 5, carding machine 6, drawing frame 7, roving frame 8, spinning frame 9, winder 10, doubling frame 11 and two-for-one twisting machine 12 are connected successively; Flame-retardant acrylic fiber 13 selects 2.2dtex51mm middle and long type acrylic fiber for use.

[0028] The cotton opening machine 1 adopts the A002D type cotton opening machine, the mixed cotton opener 2 adopts the SFA035 type mixed cotton opener, the cotton opener 3 adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com