Interfacial agent for foam insulation board

A technology of interface agent and insulation board, which is applied in the direction of coating, chloroprene homopolymer coating, conjugated diene coating, etc., can solve the problem that the flame retardancy, water resistance and durability of the interface agent cannot be satisfied. Ideal and other issues, to achieve the effect of simple construction, enhanced bond strength, and enhanced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the preparation of the interface agent of the present invention, the mixing temperature is preferably carried out at normal temperature. In the present invention, the rotational speed of the shearing machine required for mixing the components is 600-1200r / min, preferably 700-1100r / min, more preferably 800-1000r / min.

[0034] In the preparation method of the interface agent according to the present invention, in the detection of the pH value of the third mixed solution, when the pH of the third mixed solution is 6.5-8, no pH regulator needs to be added; when the third mixed solution When the pH value of the mixed solution is less than 6.5, an alkali pH regulator is used as the pH regulator; when the pH value of the mixed solution is greater than 8, an acidic pH regulator is used as the pH regulator.

[0035]The interface agent provided by the invention has excellent water resistance and durability when applied to organic thermal insulation materials. At the same time...

Embodiment 1

[0039] Under normal temperature conditions, 100 g of styrene-butadiene latex with a solid content of 55%, 10 g of a phenolic resin adhesive, and 50 g of acrylic polymer self-crosslinking adhesive with a solid content of 48% were fully mixed by a shearing machine whose rotation speed was 800 r / min; Then add 10 g of 3000 mesh aluminum hydroxide as a flame retardant under the above mixing conditions; then add 1 g of water repellent; 0.3 g of hydroxyethyl cellulose ether as a thickener; 0.50 g of ammonia water as a pH regulator. The pH value of the obtained mixed solution is between 6.5 and 8 to obtain the interface agent of the present invention.

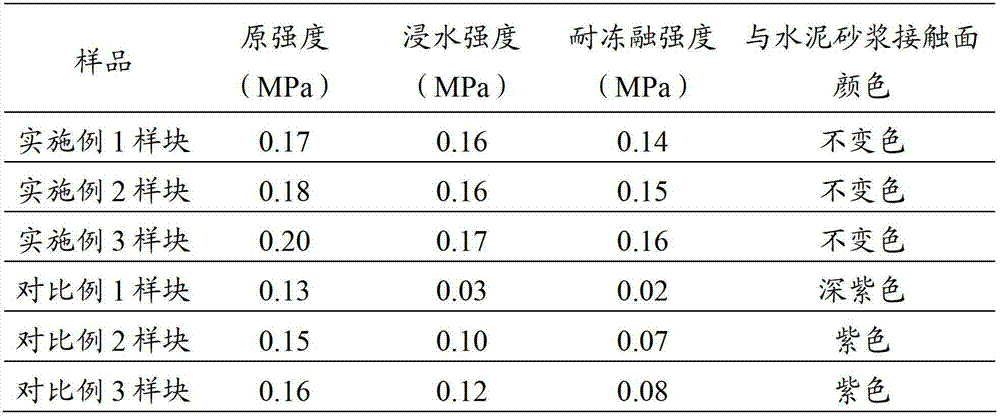

[0040] The interface agent was sprayed on the phenolic foam board, and bonded with cement mortar to form a sample block, and the above prepared sample block was subjected to a performance test, and the results are shown in Table 1. Table 1 shows the test results of the bond strength performance of the samples prepared in the examples o...

Embodiment 2

[0042] Under normal temperature conditions, 100 g of styrene-butadiene latex with a solid content of 55%, 15 g of a phenolic resin adhesive, and 50 g of acrylic polymer self-crosslinking adhesive with a solid content of 48% were fully mixed by a shearing machine whose rotation speed was 800 r / min; Then add 10 g of 3000 mesh aluminum hydroxide as a flame retardant under the above mixing conditions; then add 1 g of water repellent; 0.3 g of hydroxyethyl cellulose ether as a thickener; 0.50 g of ammonia water as a pH regulator. The pH value of the obtained mixed solution is between 6.5 and 8 to obtain the interface agent of the present invention.

[0043] The interface agent was sprayed on the phenolic foam board, and bonded with cement mortar to form a sample block, and the above prepared sample block was subjected to a performance test, and the results are shown in Table 1. Table 1 shows the test results of the bond strength performance of the samples prepared in the examples o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com