High-temperature low-pressure steam continuous vulcanization device for rubber wires and cables

A wire and cable and low-pressure steam technology, which is applied to the field of high-temperature and low-pressure steam continuous vulcanization devices for rubber wires and cables, can solve the problems of production failure, rupture, and rubber foaming of rubber wire and cable products, and achieves reasonable production process design, low production costs, and low production costs. The effect of method science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

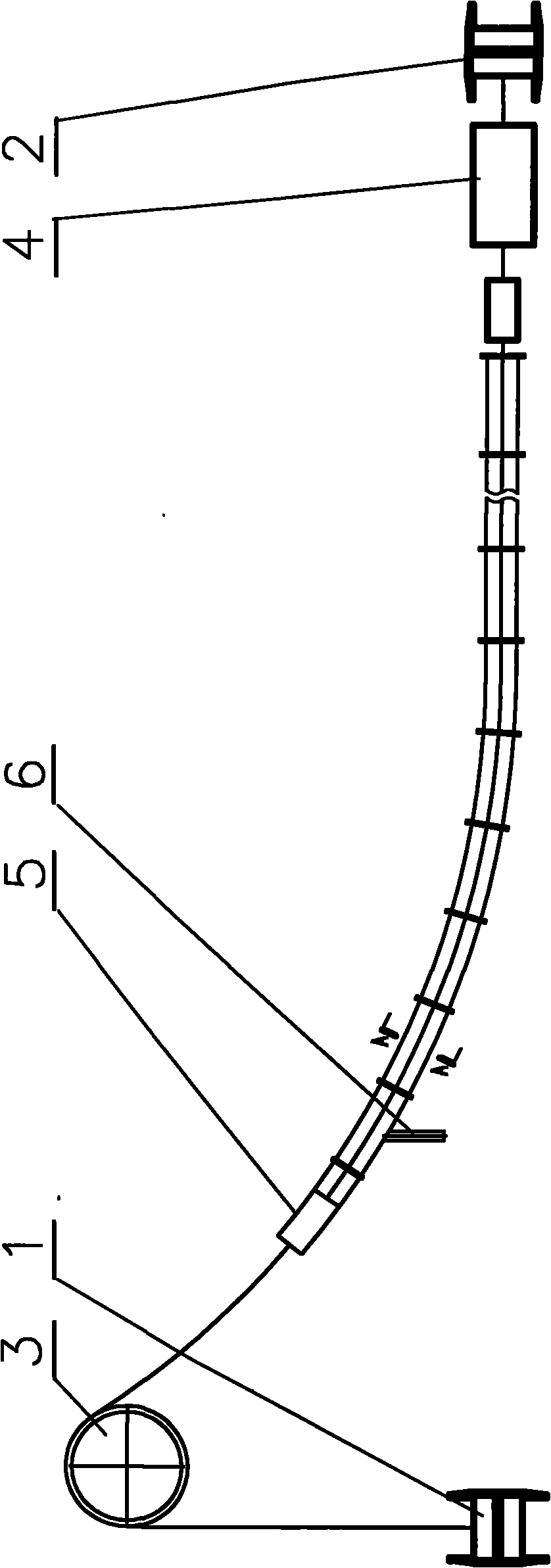

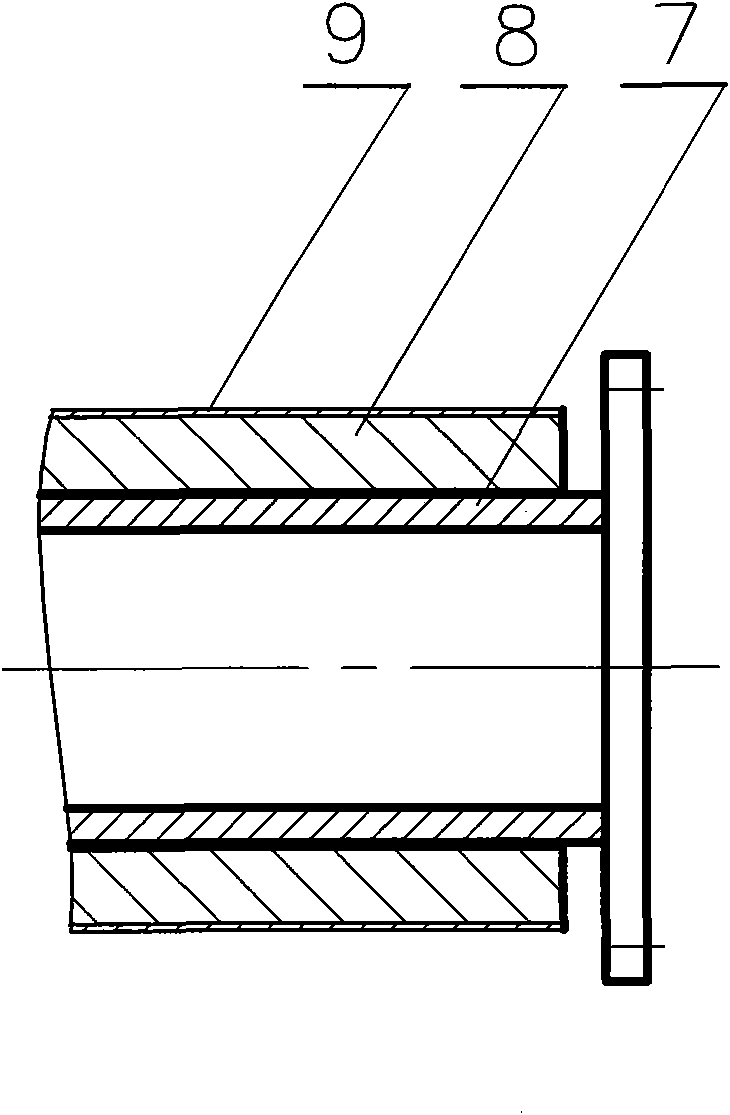

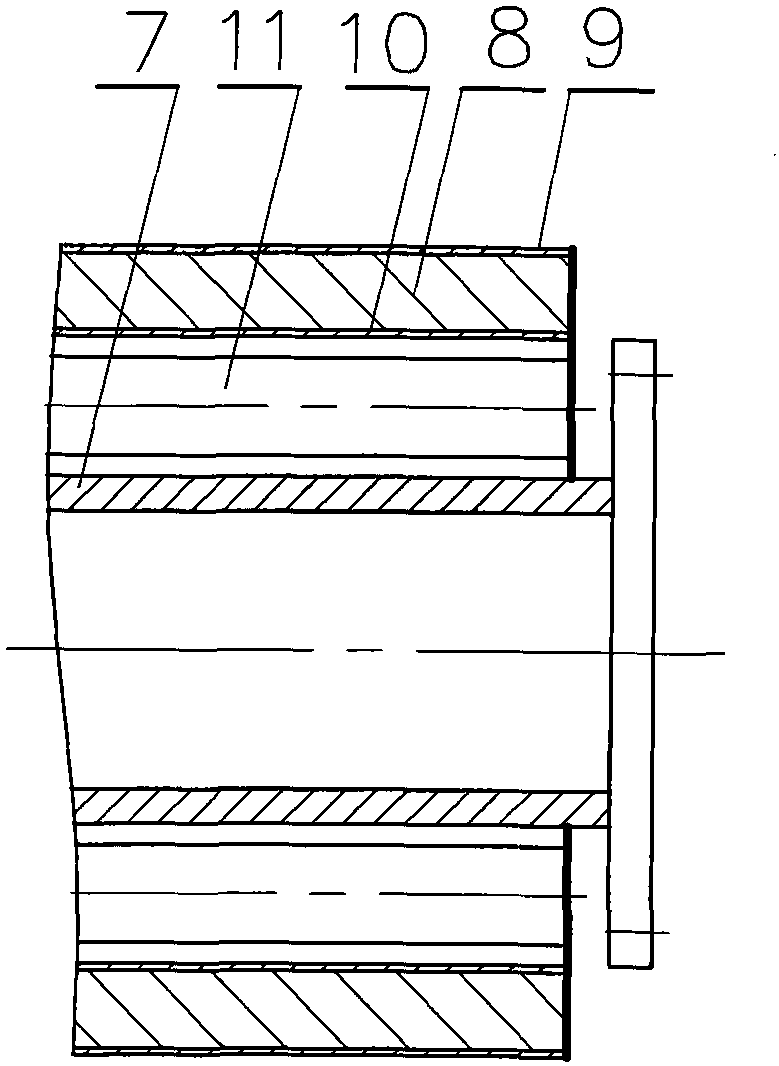

[0020] A continuous vulcanization method of high-temperature and low-pressure steam for rubber wire and cable, which is to input low-pressure steam of 0.4Mpa and below into the vulcanization pipeline, and at the same time conduct short-circuit heating on each section of the vulcanization pipe in the vulcanization section of the vulcanization pipeline, and control the vulcanization pipe section by section. temperature, that is: each section of vulcanized pipe is equipped with a converter to control the short-circuit current, each section of the pipe must be insulated, and each section of the pipe is insulated to ensure that the current passing through each section of the pipe is not the same , in order to ensure the temperature control of each section of the pipeline, to achieve the rubber wire and cable vulcanization process from high temperature to low temperature, while using low-pressure steam as the temperature transfer medium, the movement of low-pressure steam in the pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com