Preparation method of redispersible waterborne pressure sensitive rubber latex

A pressure-sensitive adhesive and redispersion technology, which is applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems of high cost and poor bonding strength of adhesive films, and achieve increased production efficiency, The effect of shortening the production cycle and reasonable production process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

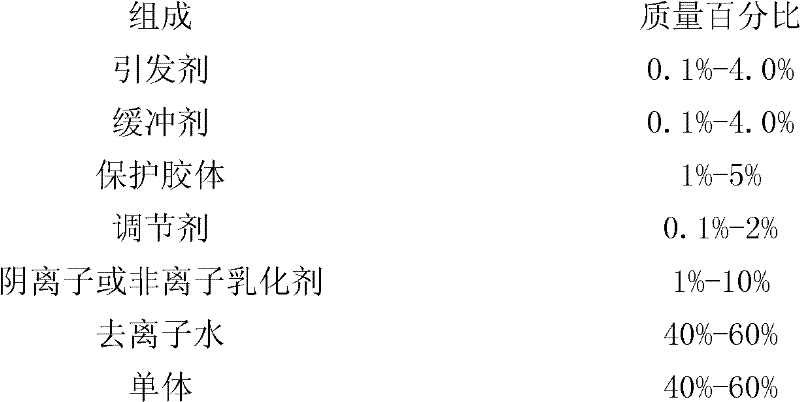

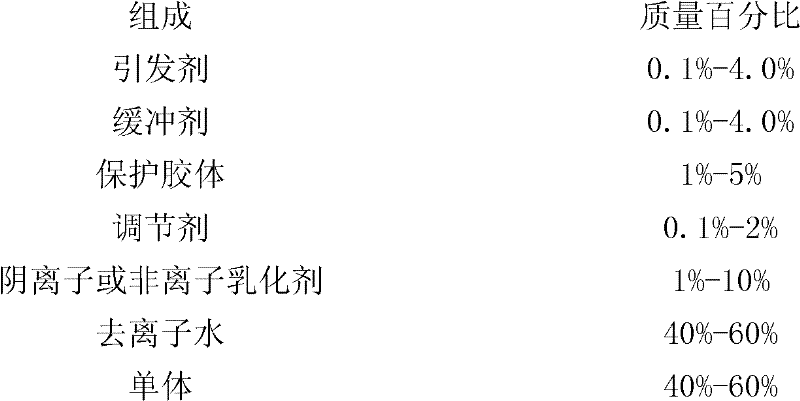

Method used

Image

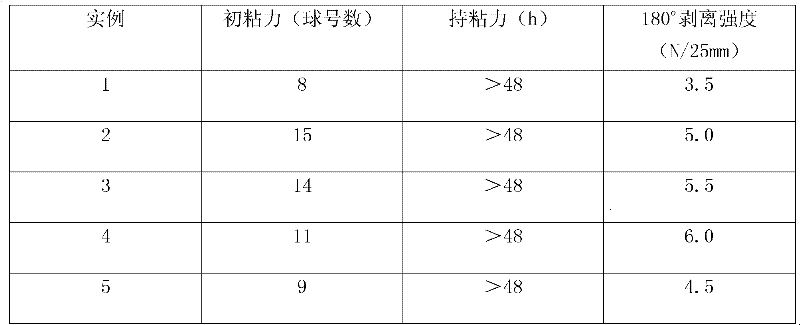

Examples

example 1

[0025] Add 70 grams of butyl acrylate, 10 grams of vinyl acetate, 10 grams of acrylic acid, and 10 grams of hydroxyethyl acrylate into the Erlenmeyer flask and mix evenly, take out 25% of the mixed solution and 0.4 grams of ammonium persulfate, 0.4 grams of sodium bicarbonate, Add 4 grams of polyvinyl alcohol, 1 gram of n-dodecyl mercaptan, 4 grams of sodium dodecylsulfonate, and 100 grams of deionized water into a three-necked flask equipped with a reflux condenser, stir and heat up to 85 ° C, and react After 30 minutes, slowly add the remaining mixed solution into the three-necked flask over 2 hours, react for 1 hour after the addition, cool down to below 60°C, and adjust the pH to 8 with ammonia water. The reducible water-based pressure-sensitive latex can be obtained.

example 2

[0027] Add 70 grams of isooctyl acrylate, 10 grams of vinyl acetate, 10 grams of acrylic acid, and 10 grams of hydroxyethyl acrylate into the conical flask and mix evenly, take out 25% of the mixed solution, 0.4 grams of ammonium persulfate, and 0.4 grams of sodium bicarbonate , 4 grams of polyvinyl alcohol, 1 gram of n-dodecyl mercaptan, 4 grams of sodium dodecylsulfonate, and 100 grams of deionized water were added to a three-necked flask equipped with a reflux condenser, stirred and heated to 85 ° C, After reacting for 30 minutes, slowly add the remaining mixture into the three-necked flask over 2 hours, and then react for 1 hour after the addition, lower the temperature to below 60°C, and adjust the pH to 8 with ammonia water. The reducible water-based pressure-sensitive latex can be obtained.

example 3

[0029] Add 65 grams of isooctyl acrylate, 5 grams of vinyl acetate, 10 grams of acrylic acid, and 20 grams of hydroxyethyl acrylate into the conical flask and mix evenly, take out 25% of the mixed solution, 0.4 grams of ammonium persulfate, and 0.4 grams of sodium bicarbonate , 4 grams of polyvinyl alcohol, 1 gram of n-dodecyl mercaptan, 4 grams of sodium dodecylsulfonate, and 100 grams of deionized water were added to a three-necked flask equipped with a reflux condenser, stirred and heated to 85 ° C, After reacting for 30 minutes, slowly add the remaining mixture into the three-necked flask over 2 hours, and then react for 1 hour after the addition, lower the temperature to below 60°C, and adjust the pH to 8 with ammonia water. The reducible water-based pressure-sensitive latex can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com