Tire curing bladder and preparation technology thereof

A technology of tire vulcanization and vulcanization bladder, which is applied in the field of rubber tires and can solve problems such as poor economic benefits, high cost, and failure to meet environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

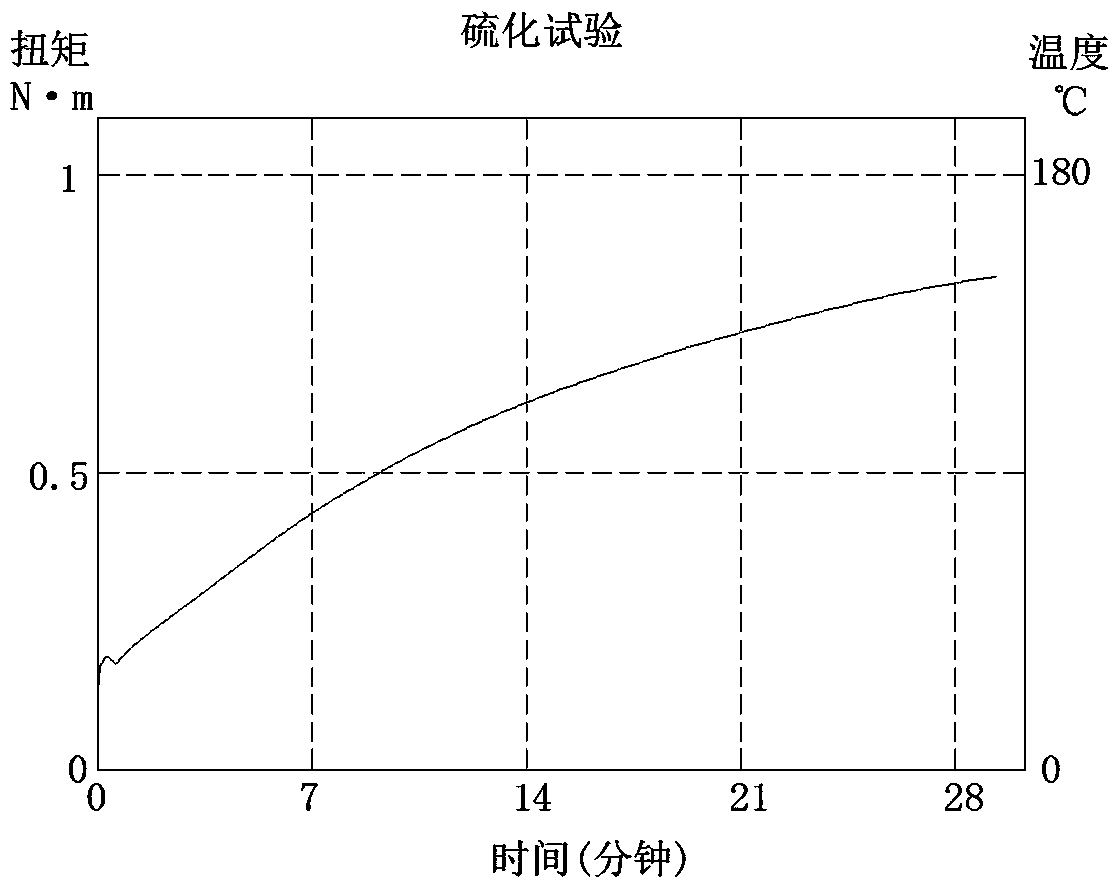

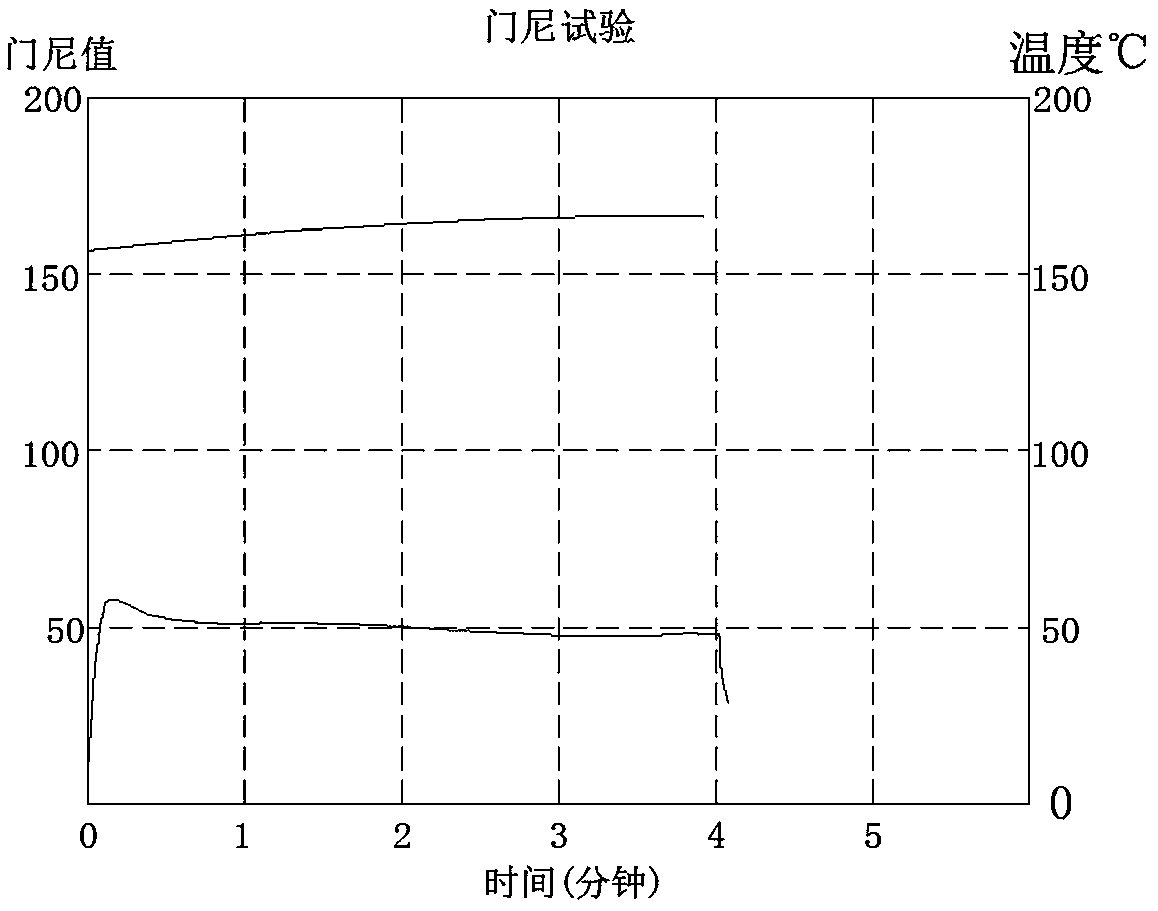

[0082] A tire curing bladder and its manufacturing process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0083] As shown in accompanying drawing, a kind of tire vulcanization bladder of the present invention and the basic formula of manufacture technology thereof:

[0084] Material name Material code Basic formula

[0085] 268 butyl rubber, IIR, 100.00kg;

[0086] S-40V neoprene, CR, 5.00 kg;

[0087] Indirect zinc oxide, ZnO, 5.00 kg;

[0088] Resin, 202Resin, 10.00 kg;

[0089] Stearic acid, SA, 1.50 kg;

[0090] Paraffin, PW, 1.00 kg;

[0091] Carbon black, N330 (220), 50.00 kg;

[0092] Castor oil, Castor-oil, 3.50 kg;

[0093] Magnesium oxide, MgO, 0.20 kg;

[0094] Total: 176.20 kg

[0095] Gum content: 56.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com