Fabrication process of cross-linked polyolefin insulation power cable

A cross-linked polyolefin and power cable technology, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve problems such as high energy consumption, obstacles to market competitiveness, and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

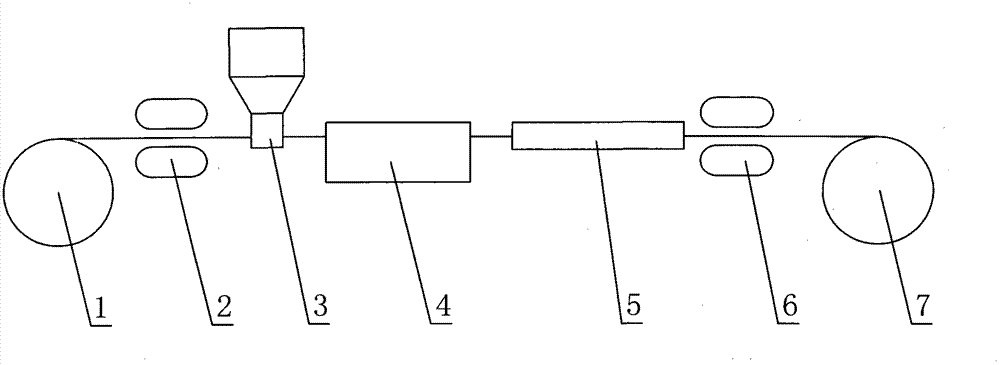

[0027] The manufacturing process of the cross-linked polyolefin insulated power cable of the present invention will be described in detail below in conjunction with the accompanying drawings.

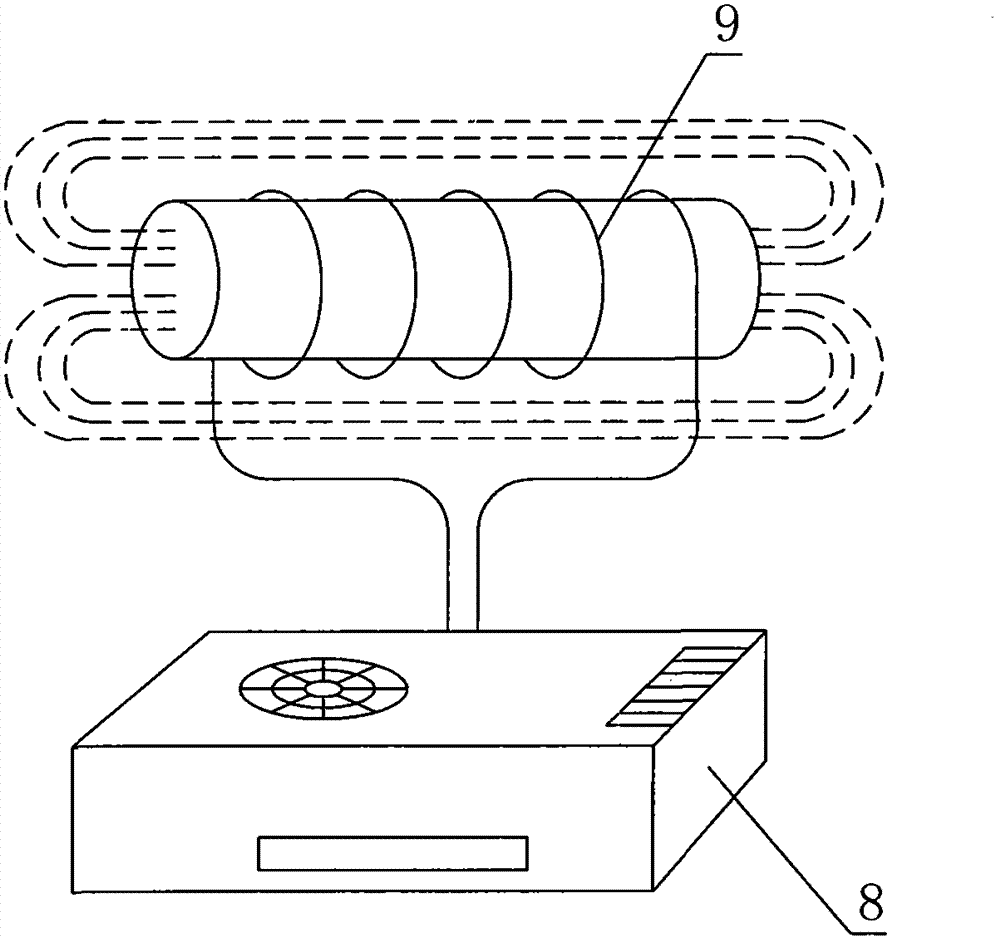

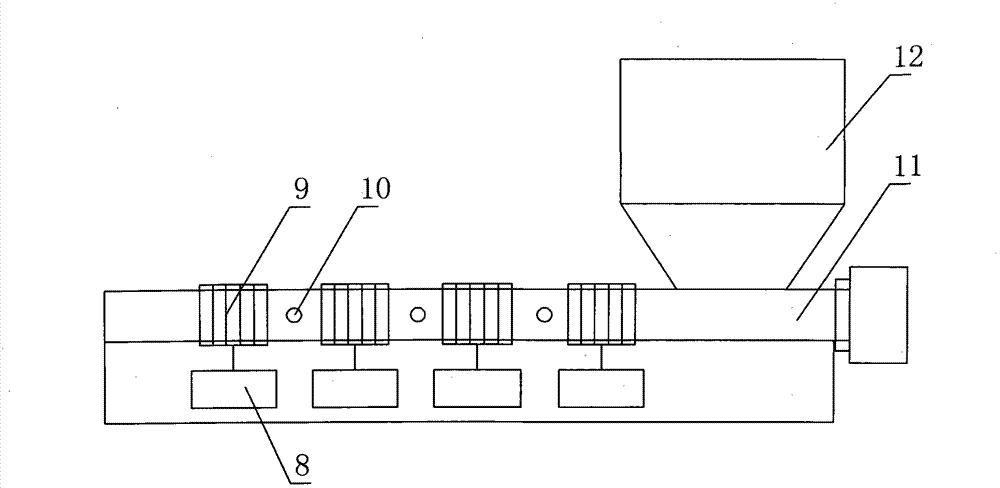

[0028] The manufacturing process of the cross-linked polyolefin insulated power cable of the present invention is as follows: cable conductor unwinding—upward traction—extruder electromagnetic heating and extruding insulation—when the main box of the crosslinking equipment is irradiated by ultraviolet light, the polyolefin Add an appropriate amount of photocrosslinking sensitizer to the base resin, and utilize the property that the polyolefin material is in a transparent state when heated and extruded to focus and transmit ultraviolet light radiation into the material, and the high-energy ultraviolet light triggers the photocrosslinking sensitizer to form freely Radicals and further induce polyolefin units to generate macromolecular free radicals, and the free radicals form cross-linked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com