Low-smell platable polypropylene material and preparation method thereof

A polypropylene material and low-odor technology, which is applied in the field of low-odor electroplatable polypropylene material and its preparation, can solve the problem that the requirements of impact strength, tensile strength, and flexural modulus and mechanical properties cannot be met at the same time, and the cost of ABS material is high. problems such as poor coating adhesion, reasonable production process design, reduced filler density, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

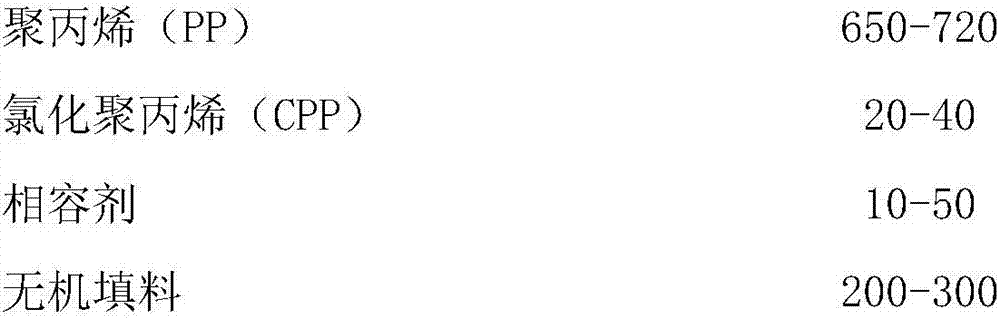

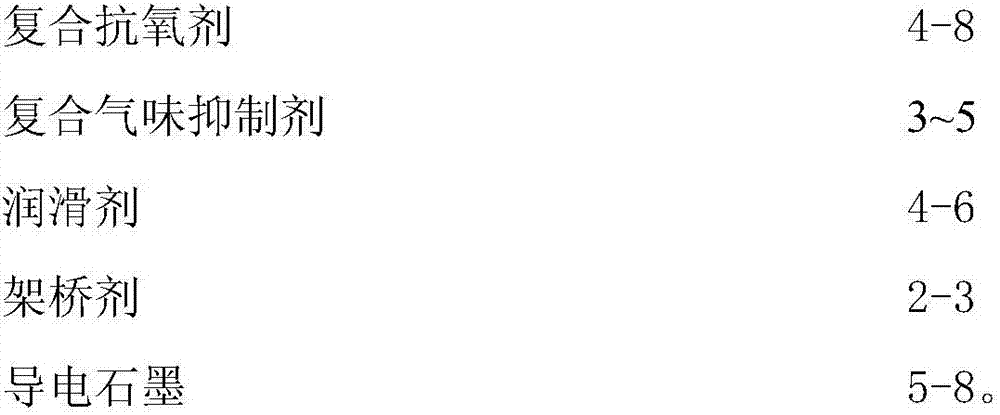

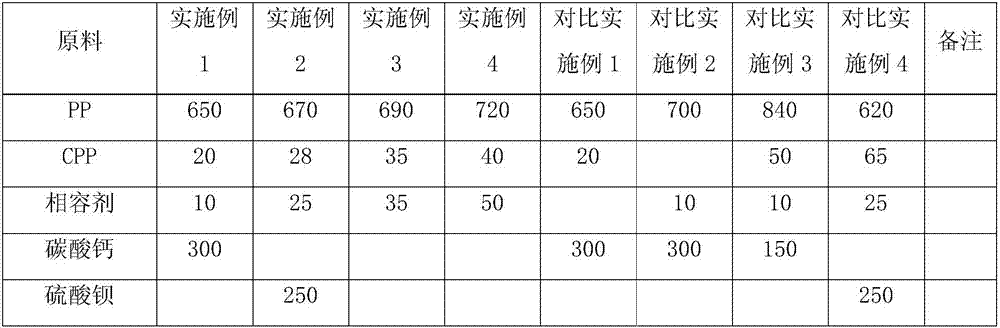

[0030] Below in conjunction with specific embodiment, the present invention is further described, and each embodiment formula contrast is as shown in table 1 below:

[0031] Table 1, each embodiment formula raw material ratio

[0032]

[0033]

[0034] Among them, the polypropylene resin is copolymerized polypropylene, and the melt index under the test temperature of 230°C and the test load of 2.16Kg is 15g / 10min; the chlorine content in the CPP resin is 22%, and the molecular weight is 65000; the compatibilizer is maleic anhydride grafted Polypropylene (PP-g-MAH), maleic anhydride graft rate 0.8%, test temperature 230 ℃, test load 2.16Kg under the melt index of 110g / 10min; inorganic fillers are zinc oxide, titanium dioxide, calcium carbonate, sulfuric acid One or more mixtures of barium, the filler particle size is about 5-7 microns; the composite antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol A mixture of ester (antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com