Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Reasonable process route" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

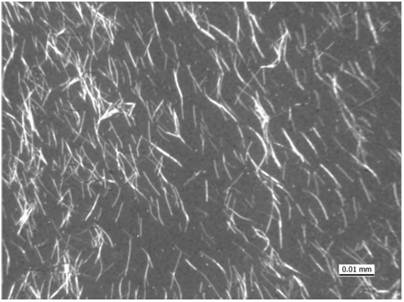

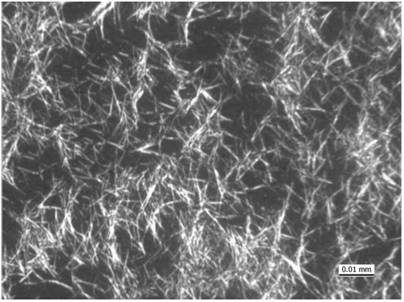

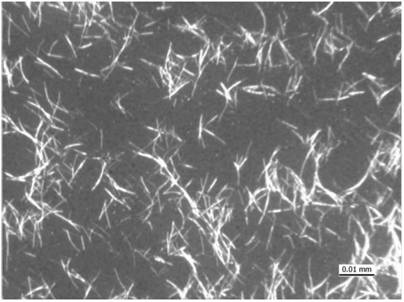

Production method of nanometer silver wire material

The invention discloses a production method of a nanometer silver wire material. The production method comprises the following steps:(1) mixing glycerol, water, polyvinyl alcohol pyrrolidone, silver nitrate and chlorine salt and heating to 180-240 DEG C, and stirring for 30-50 minutes so as to obtain a nanometer silver wire stock solution; (2) cooling the nanometer silver wire stock solution to below 80 DEG C, and diluting with water so as to obtain a diluted nanometer silver wire solution; (3) carrying out desalting and surface active agent removing treatment on the diluted nanometer silver wire solution, and concentrating to obtain a finely purified nanometer silver wire solution; and (4) carrying out spray drying on the finely purified nanometer silver wire solution obtained in step (3) so as to obtain nanometer silver wire powder, and cooling so as to obtain a finished production of nanometer silver wire powder. The production method provided by the invention has the advantages that the process is simple and reliable, the nanometer silver wire is single in shape, the production efficiency is high and the production cost is low; and the produced products have the characteristics of high purity, good quality, uniform size distribution and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for producing liquid calcium chloride by using industry waste acid

InactiveCN101254937AControllable reaction speedEliminate the pulping processCalcium/strontium/barium chloridesSpent acidAcid washing

The invention relates to a preparation method of liquid calcium chloride, in particular to a method for producing the liquid calcium chloride by using the waste industrial acid, which belongs to the technology field of chemical industry. The preparation method is characterized in allowing massive limestone and waste hydrochloric acid obtained by acid washing strip steel to react at a certain ratio and neutralizing with lime cream to obtain calcium chloride at a certain concentration. Proved by the production, the preparation method is capable of effectively reducing the production cost and achieving comprehensive utilization of the waste industrial acid and remarkable economic and social benefits.

Owner:KUNMING IRON & STEEL

Comprehensive waste cell utilizing treamtent process

InactiveCN1349271ANo secondary pollutionSimple methodSolid waste disposalReclaiming serviceable partsCadmium sulfateSulfate

The invention is to process various kinds of waste battery in classifications and uses chemical or physical method to extract zinc salt, chalcanthite, carbon black, manganese bioxide and mercury etc.from zinc-manganese battery, ferrisulphas, potion and nickel sulfate etc. from ferronickel battery, potion, cadmium sulfate and nickel sulfate etc. from cadmium-nickel battery, potion, silver salf and white copperas etc. from silver-zinc battery. Said technology can be used to proces waste battery and make the resource obtd. fully utilization. The advantages are: simple and reasonable processing technology and low cost, no three waste problem, no secondary pollution.

Owner:王宗良 +1

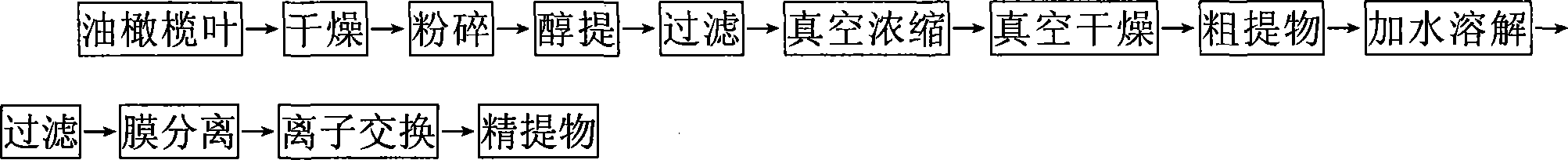

Technique for producing extractive of olive growing leaves

InactiveCN101049328AReasonable process routeHigh extraction rateAntimycoticsMetabolism disorderRefluxOlive leaf

A process for preparing the extract of olive leaf includes such steps as low-temp drying in dark condition, pulverizing, extracting in ethanol or methanol by reflux, immersing, seeping, or ultrasonic wave, filtering, vacuum concentrating, vacuum drying to obtain coarse extract, pulverizing, sieving, dissolving in water, filtering, membrane separation, and purifying by ion exchange.

Owner:TIANYUAN OIL OLIVE TECH DEV LONGMAN

Ginkgo leaf extract and its extracting method

ActiveCN1586548AScientifically feasibleHigh extraction rateUnknown materialsCardiovascular disorderVascular diseaseGinkgo leaf extract

The present invention belongs to the field of Chinese medicine preparing technology. The ginkgo leaf extract has total flavone and total terpene lactone content over 80 %, total flavone content over 70 %, flavonoid glycoside content over 40 % and total terpene lactone content over 10 %. The extraction process includes the following steps: extracting, purifying and separating, concentration, drying, etc. Compared with available technology, the present invention has the advantages of reasonable technological path, being suitable for industrial production, low production cost, high extracting rate of effective components, etc. The present invention also discloses the infusion liquid and powder for injection with the ginkgo leaf extract and their preparation process. The ginkgo leaf extract has wide application in medicine for treating cardiac vascular diseases.

Owner:AOLING BODA MEDICINE SCI & TECH DEV BEIJING

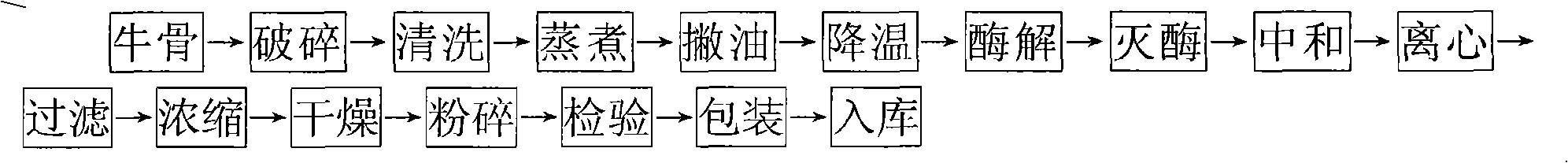

Method for producing bovine-bone peptone by enzyme technology

InactiveCN101538601ATake advantage ofHigh yieldPeptide preparation methodsFermentationTotal nitrogenPre treatment

The invention discloses a method for producing bovine-bone peptone by enzyme technology, which belongs to the technical field of bioengineering. The method comprises the steps of pretreating fresh bovine bones and then adding enzyme for enzymolysis. The method has the advantages of advanced technique, reasonable process route, thorough enzymolysis, sufficient raw-material utilization, high yield of peptone products, good quality, high amino nitrogen content, high total nitrogen content, plentiful species of amino acid, proper proportion and high biological potency, and reaches reagent-grade product standards. The method takes the bovine bones as raw materials, changes waste into valuables, improves the utilization ratio of the bovine bones in China, reduces environmental pollution, drives the development of the livestock breeding industry and other industries, and remarkably improves the comprehensive benefit of farming and animal husbandry industrialization.

Owner:BEIJING KEWEIHUA FOOD ENG TECH

Process for processing tea seed oil

InactiveCN1667105AReduce storage timeLess investmentFatty-oils/fats productionOil processingFiltration

This invention is a new technique of tea oil processing. Precipitate contained by crude tea oil can be thoroughly removed through phosphoric acid degumming, alkali refining, filtration at low temperature, decolorization and other procedures, and effective dead time of tea oil can be reduced. The technical route is reasonable, it can reduce tea oil standing time greatly, and reduce warehouse invest, accelerate fund turnover and boost up manufacturer economic benefit. There is great advancement to the processing of lixiviated tea oil.

Owner:朱少新

Manufacturing technology for high-speed and high-temperature precision deep groove ball bearing

The invention discloses a manufacturing technology for a high-speed and high-temperature precision deep groove ball bearing. A complete set of bearing product is manufactured by processing a forge piece blank into a workpiece billet with an outer ring and an inner ring, then respectively performing technical processes of respective technologies of cold rolling, thermal treatment, coarse grinding, thermal stabilization, fine grinding, grinding and the like, performing inspection and then performing cleaning and assembling. In the cold rolling technique, a cold rolling machine tool is used, a main driving forming rolling wheel is used as an outer die of a mold, and a driven forming mandril is used as an inner die of the mold, so that the forming rolling wheel drives the workpiece billet to rotate, and a supporting wheel pushes the forming mandril to forwards feed and extrude the workpiece billet to roll and form a product; in the thermal stabilization technique, the workpiece subjected to coarse grinding is subjected to heat preservation in a tempering furnace at temperature of 400 DEG C for 4 hours and then is taken out for natural cooling. The limit rotating speed of the complete set of bearing is 12,000 r / min, and the limit working temperature is 160 DEG C; the working noise is less than or equal to 45 dB; the rated load is Cr41.2KN and Cor24KN. The manufacturing precision is high, and the matching performance is high.

Owner:山东鑫兴精密轴承科技有限公司

Novel method for performing vacuum crystallization on ferrous sulfate from titanium liquid in titanium dioxide production process

InactiveCN105289036ARealize cleaner productionReduce manufacturing costSolution crystallizationIron sulfatesSulfatePhysical chemistry

The invention discloses a novel method for performing vacuum crystallization on ferrous sulfate from titanium liquid in titanium dioxide production. According to the method, the conventional ferrous sulfate vacuum crystallization process and equipment are innovated. The process innovation refers to the operation of replacing the conventional method for generating vacuum by virtue of steam jet by a method for condensing water vapor above titanium liquid in a crystallization kettle so as to generate vacuum by virtue of cryogenic refrigeration. The equipment innovation refers to the operation of replacing the conventional secondary steam jet equipment and circulating cooling water equipment for cooling high-temperature acid containing liquid by the complete refrigerating equipment generating a certain low temperature. According to the method disclosed by the invention, ferrous sulfate is separated from the titanium liquid in the crystallization kettle, lots of high-temperature high-pressure steam can be saved, and the production cost of titanium dioxide by sulfuric acid method is greatly reduced. In addition, the acidic condensate extracted from the crystallization kettle by vacuum can return to be used for an ilmenite powder sulfuric acid dissolving process, so that the amount of sulfuric acid in the process of generating titanium dioxide by a sulfuric acid method is reduced, the emission amount of acid waste liquid is greatly reduced, and clean production is realized.

Owner:NANJING BAIYUN CHEM ENVIRONMENTAL MONITORING

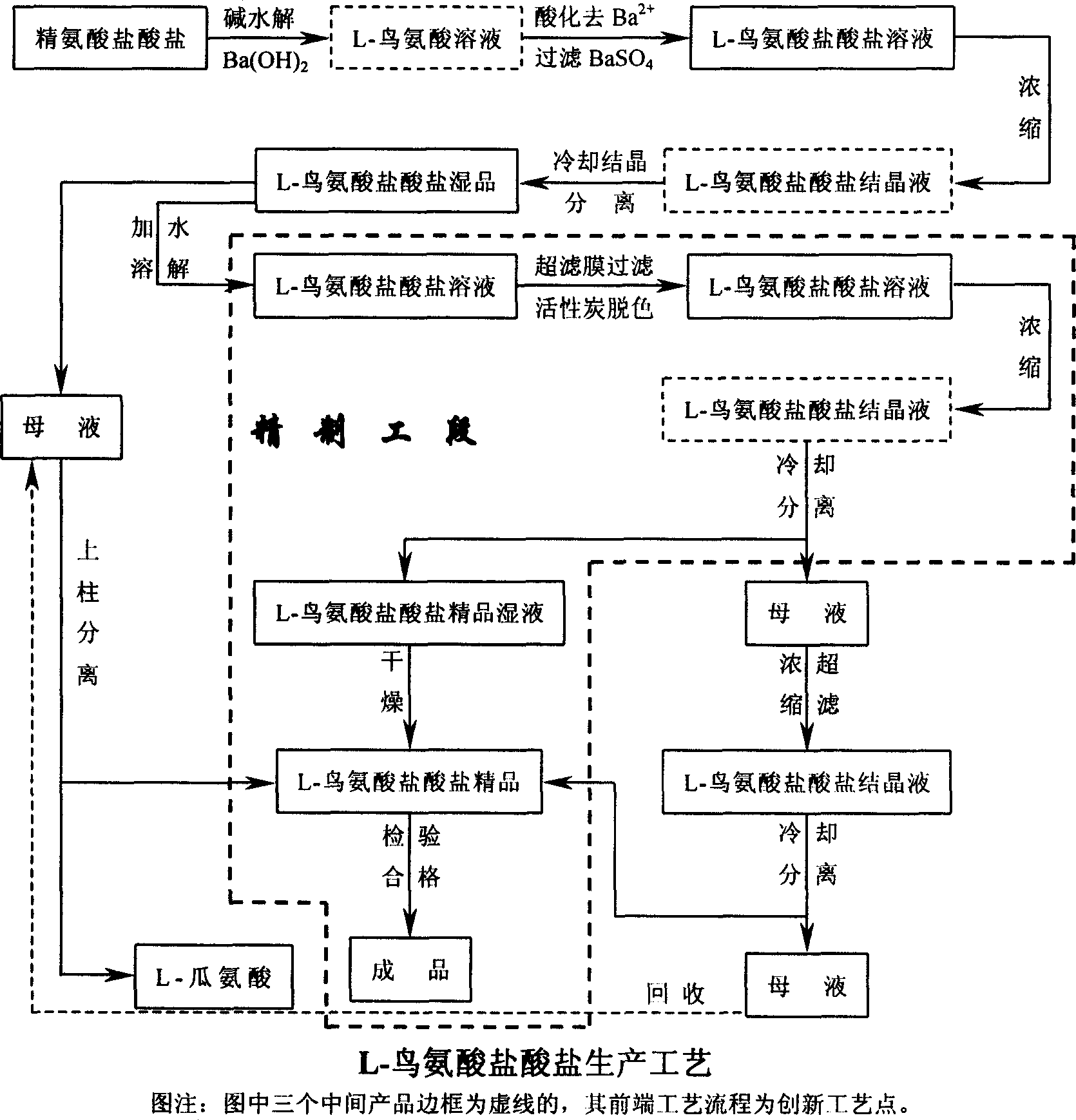

Method for producing L-ornithine hydrochloride

InactiveCN1594282AReduce solubilityNo pollutionOrganic compound preparationAmino-carboxyl compound preparationOrnithine synthesisArginine

The invention discloses a method for producing L-ornithine hydrochloride through weak Ba(OH)2 hydrolysis L-arginine hydrochloric salts, neutralizing with dilute sulfuric acid, removing Ba2+, obtaining L-ornithine hydrochloride crystallized crude product through concentrated crystallization, re-crystallizing in pure water to obtain the pure product.

Owner:WUHAN GRAND HOYO

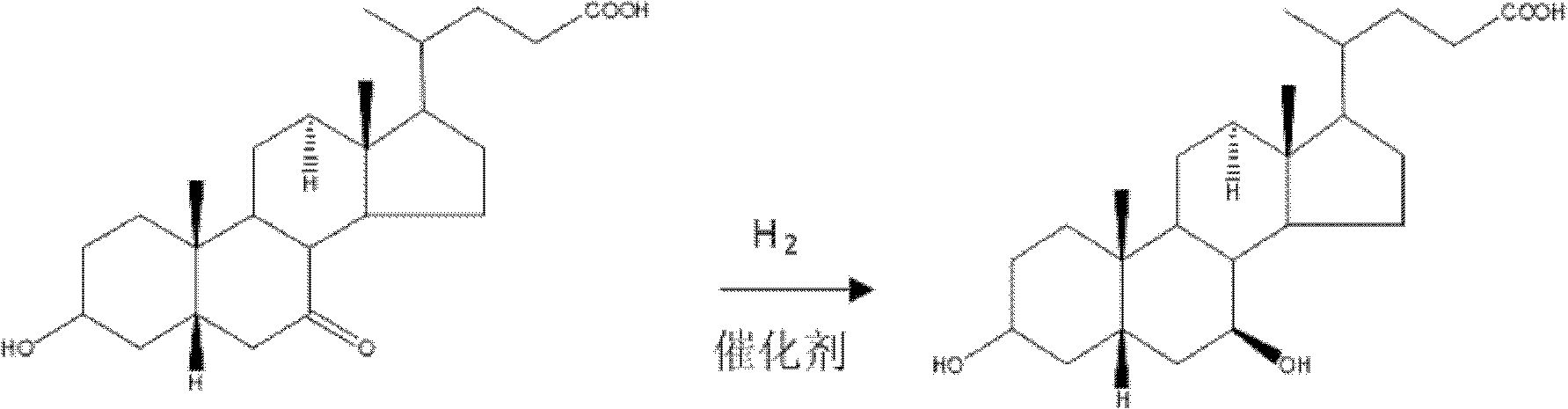

Method for preparing ursodesoxycholic acid by chiral catalytic hydrogenation of 7-ketodesoxycholic acid

InactiveCN102070693AReduce generationReduced purification stepsSteroidsChenodeoxycholic acidDistillation

The invention discloses a method for preparing an ursodesoxycholic acid by the chiral catalytic hydrogenation of a 7-ketodesoxycholic acid, which is characterized by comprising the following steps of: performing oxidation to prepare the 7-ketodesoxycholic acid from a chenodeoxycholic acid serving as an initiative raw material by using a common method; dissolving the 7-ketodesoxycholic acid into a solvent, adding a chiral catalyst, maintaining the pressure of 0 to 20 MPa under alkali condition, introducing nitrogen to perform hydrogenation reduction reaction at 10 to 80 DEG C, and performing distillation after the reaction is finished to remove the solvent; adding purified water in a volume which is 10 to 100 times that of a hydrogenation reduction reaction product, and adding acid liquor to crystallize the hydrogenation reduction reaction product; and separating solids from liquid, and performing washing and drying to obtain solid powder which is the ursodesoxycholic acid. The method for preparing the ursodesoxycholic acid by the chiral catalytic hydrogenation of the 7-ketodesoxycholic acid aims to overcome the shortcomings of the prior art, and ensures a short production flow, high yield and high quality.

Owner:ZHONGSHAN BAILING BIOTECHNOLOGY CO LTD

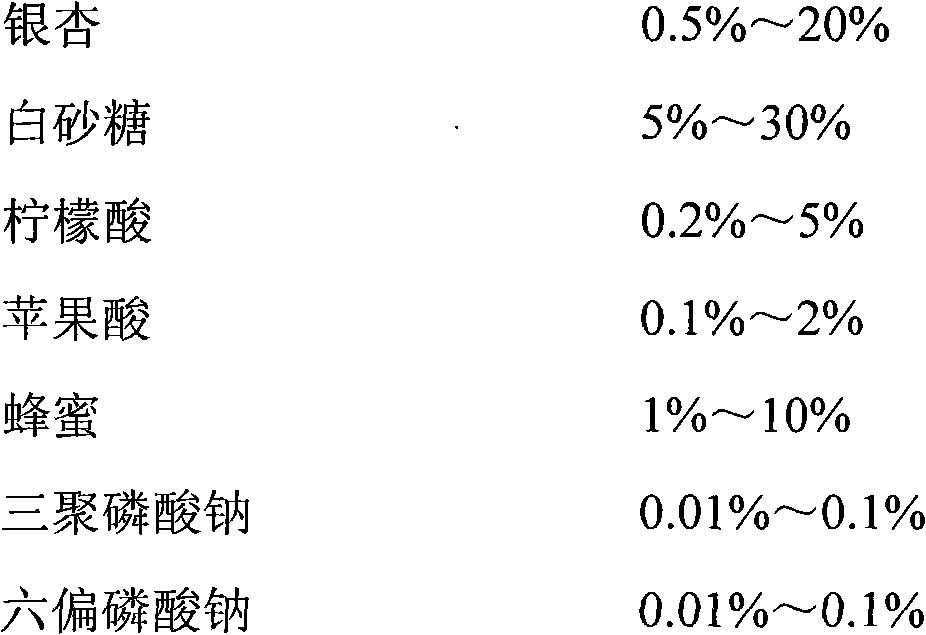

Gingko beverage

The invention discloses a gingko beverage and a processing technology thereof, which belong to the technical field of beverage processing. Technological parameters are optimized by using integrated comprehensive applying of technologies of rinsing, ultrasonic lixiviation, homogenization, rubber milling and the like, the original nutrition and flavor of the gingko are kept, and the beverage product quality is improved; the product of the beverage is scour and sweet, tasty and refreshing, has rich flavor, pure mouthfeel and strong palatability, contains rich active ingredients of gingko flavone, gingko lactone compound and the like and nutritive substances of vitamins, mineral substance and the like, has extremely high health care function and medicinal value, and can improve blood circulation, soften blood vessel, clear free radical in vivo, clear heat and detoxicate, tonify middle-jiao and qi, moisturize lung and relieve asthma, resist aging and prolong life after long-term drinking. The product is stable in quality; deposits and demixing are not produced after long-term storage at normal temperature; the state is stable; and the shelf life and the quality guarantee period are prolonged.

Owner:云南宏坤天然绿色保健食品有限公司

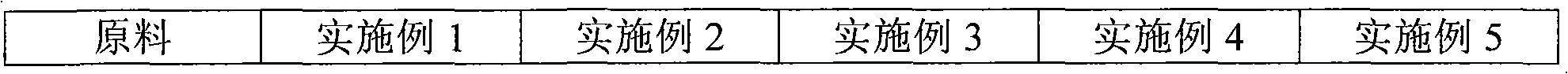

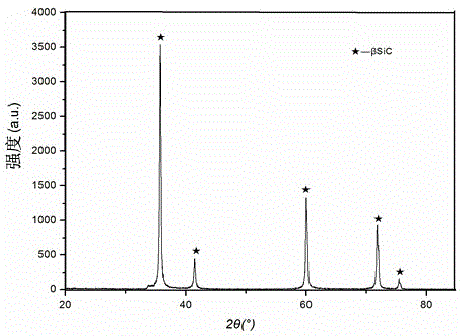

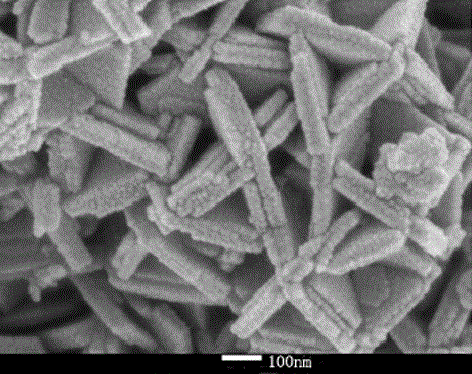

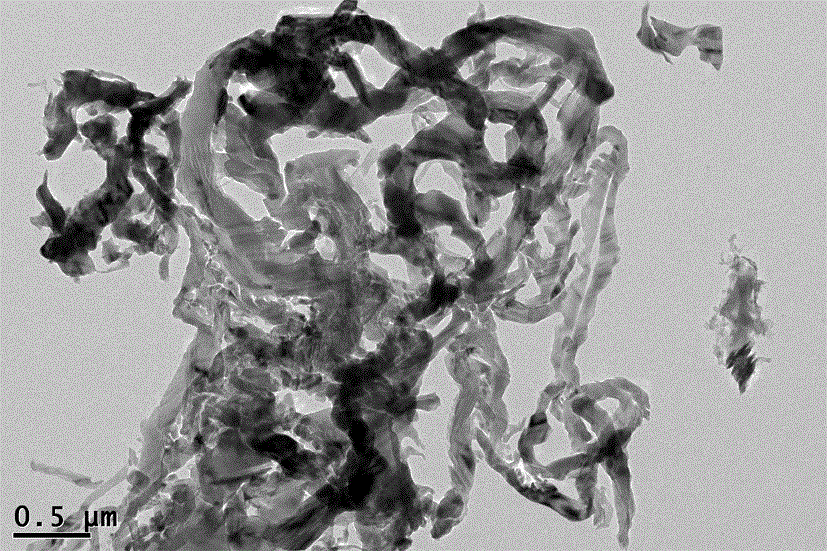

Preparation method of nanoscale silicon carbide particles and product of nanoscale silicon carbide particles

The invention relates to a silicon carbide product and a preparation method thereof, in particular to a preparation method of nanoscale silicon carbide particles and a product of the nanoscale silicon carbide particles. The method comprises the process steps of feed coal pretreatment, silicon carbide precursor preparation, silicon carbide crude product preparation through a cabothermal reduction method, purification and the like, the obtained product is beta-SiC particles, the particle size ranges from 30 nm to 80 nm, and the morphology is shaped like a sphere or a line or a rod. The preparation method of the nanoscale silicon carbide particles and the product of the nanoscale silicon carbide particles have the advantages that low-ash Taixi coal or electrically calcined Taixi coal fine powder which is high in carbon content, low in price and easy to obtain serves as a carbon source, the production cost can be reduced, and the obtained nanoscale beta-SiC product is high in purity, uniform in particle distribution and reasonable in process route.

Owner:NINGXIA UNIVERSITY

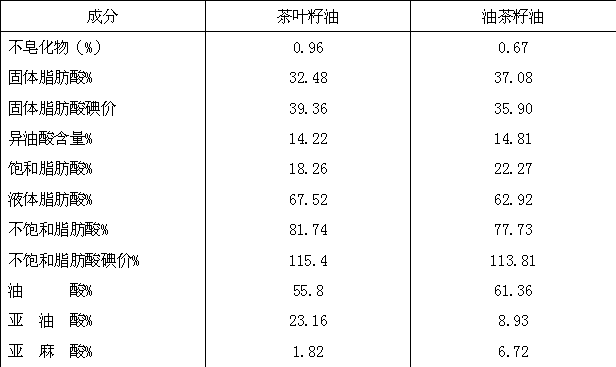

Method for squeezing edible tea seed oil at normal temperature

ActiveCN102766524AReasonable process routeImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionCamellia oleiferaTea leaf

The invention provides a method for squeezing edible tea seed oil at normal temperature. The method comprises the following steps of: airing tea seeds at the normal temperature, separating seed hulls, extruding for squeezing at the normal temperature, refining crude oil, namely (1) filtering the crude oil to remove impurities; (2) mixing, acidifying, washing and degumming; (3) decolorizing by using a mixed decolorant; (4) standing the crude oil, separating to remove moisture and the impurities from the oil, dehydrating the crude oil from which the impurities are removed at the normal temperature under vacuum; (5) standing the dehydrated crude oil at the temperature of 5 DEG C, crystallizing, growing crystals for 48 hours, precipitating wax and ester in the oil and separating; and (6) performing diaphragm filter pressing on the tea seed oil from which the crystals are removed to obtain the refined tea seed oil. According to the method, a process is performed at the temperature of below 65 DEG C, so the process is simple, low in energy consumption and high in oil yield and belongs to an environment-friendly process; and the squeezed oil tea is high in quality.

Owner:ANHUI HUAYIN CAMELLIA OIL

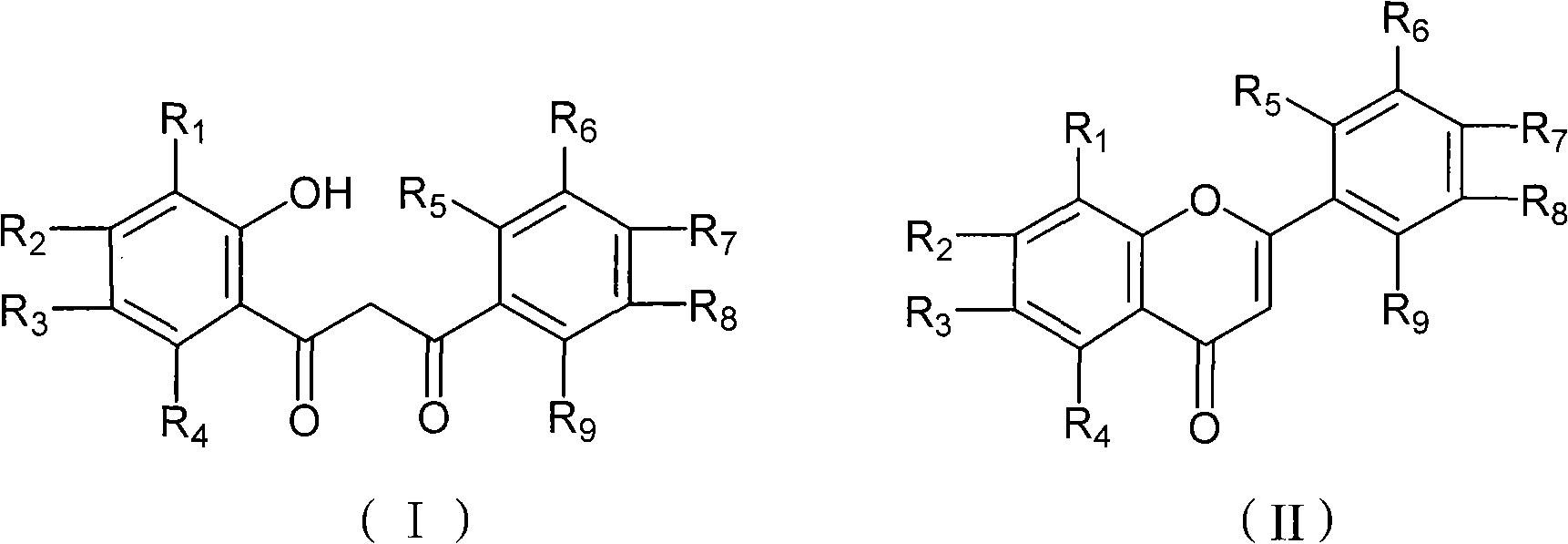

Chemical synthesis method of flavonoid compound

InactiveCN101555240AHigh reaction yieldReasonable process routeOrganic chemistryChemical recyclingChemical synthesisOrganic solvent

The invention discloses a chemical synthesis method of a flavonoid compound shown by a formula (II). The synthesis method comprises the following steps : under the catalysis of trifluoromethanesulfonic salt, a beta-propanedione derivant shown by a formula (I) fully reacts in an organic solvent under temperature of 0 DEG C to 100 DEG C, and the flavonoid compound shown by the formula (II) is obtained after reaction solution is separated and purified. The synthesis method has the advantages of reasonable technology, low production cost, simple operation, high reaction yield, little catalyst amount, environment protection, and has a favorable popularization and application prospect; in addition, the catalyst can be recycled and reused.

Owner:WENZHOU UNIVERSITY

Process for making light-weight high-strength common gypsum board mask paper

The invention discloses a process for making light-weight high-strength common gypsum board mask paper, which comprises three procedures of material preparation, pulping and paper making. By adding various assistants to domestic waste newspaper and imported American waster paper based on a certain ratio and adjusting corresponding processes, the invention rationalizes the process route, realizes the reasonable matching of long and short fibers, improves the product quality, reduces the weight of the finished paper product, improves the physical strength, saves the resources, and greatly reduces the production cost of the gypsum board. The gypsum board mask paper produced by the process has the characteristics of light weight, high strength, attractive appearance and the like, and can completely substitute the imported product.

Owner:TAISHAN GYPSUM CO LTD

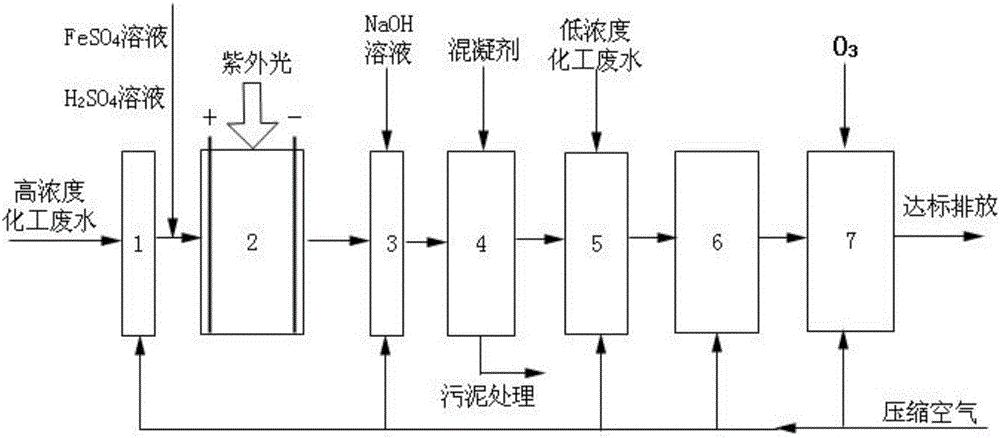

Wastewater treatment system and wastewater treatment method based on photoelectric Fenton-biological enhancement

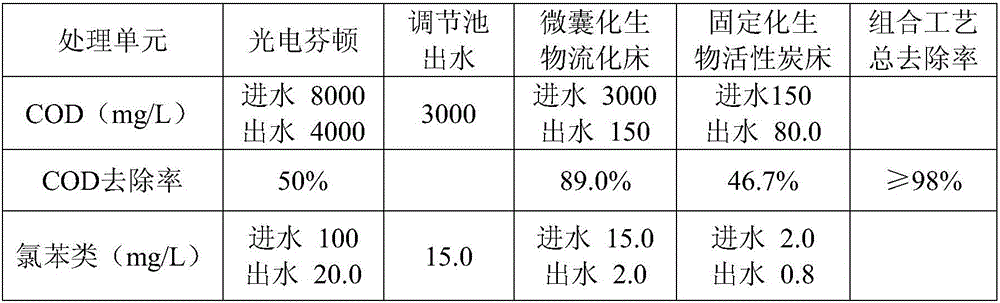

PendingCN106830563AReasonable process routeThe processing mechanism is clear and orderlyWater treatment compoundsWater aerationWater pipePrecipitation

The invention discloses a wastewater treatment system and a wastewater treatment method based on photoelectric Fenton-biological enhancement. The system comprises a preaeration tank (1), a photoelectric Fenton reactor (2), a degassing neutralizing tank (3), a coagulative precipitation tank (4), an adjustment tank (5), a microencapsulation biological fluidized bed (6) and an immobilization biological active carbon bed (7) which are connected in sequence through water pipes. The photoelectric Fenton-biological enhancement-based wastewater treatment system is reasonable in structural design, convenient to operate, high in working efficiency, low in cost and good in wastewater treatment effect and orderly, and organically combines physical and chemical treatment, biochemical treatment and guarantee treatment; the photoelectric Fenton reactor, the microencapsulation biological fluidized bed and the immobilization biological active carbon bed support and promote one another functionally, so that the removal efficiency for refractory characteristic organic pollutants is over 98 percent, the sludge yield is low, the sludge treatment cost is low, the sewage treatment effect is good, and the wastewater treatment system based on photoelectric Fenton-biological enhancement has important significance for environmental protection.

Owner:YANCHENG INST OF TECH

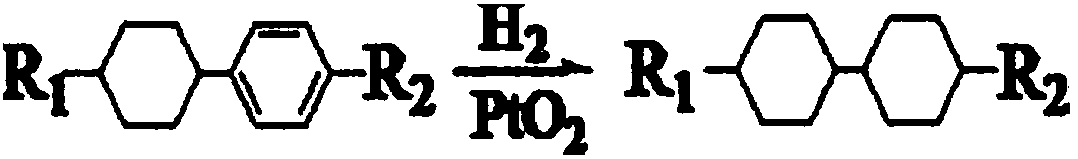

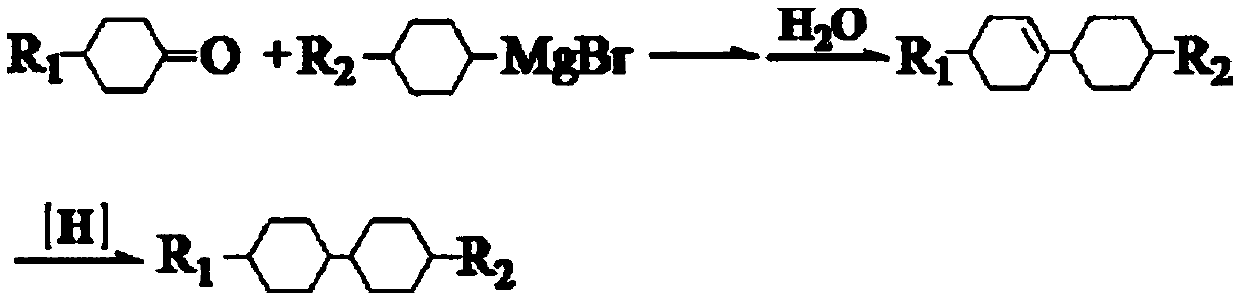

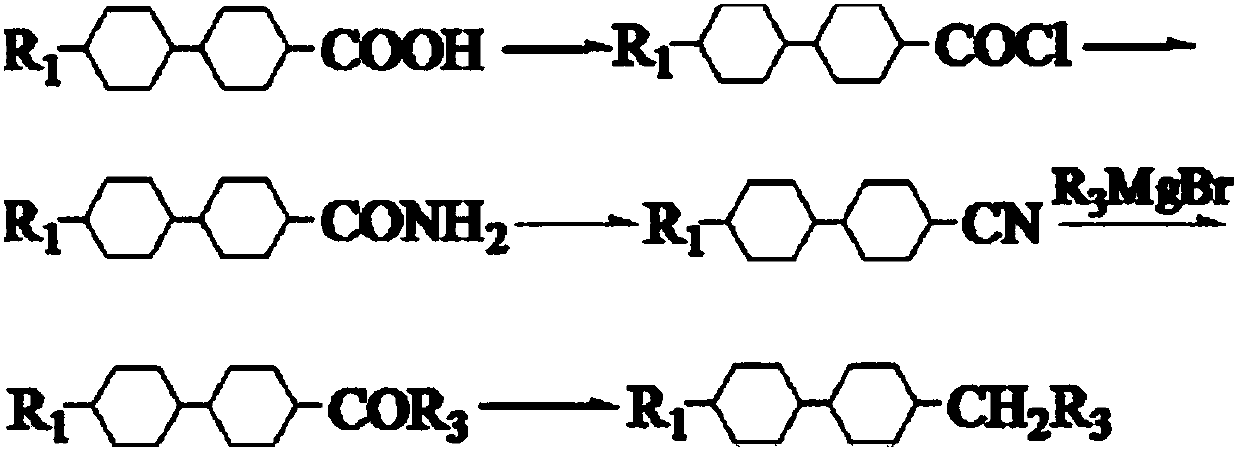

New preparation method of trans-trans dicyclohexyl alkane liquid crystal compounds

InactiveCN109534948ARealize green chemical industryHigh yieldLiquid crystal compositionsPreparation by isomerisationAlkaneChemical industry

The invention discloses a preparation method of trans-trans dicyclohexyl alkane liquid crystal compounds. According to the preparation method, 1-(4-(4-alkylcyclohexyl)phenyl)alkyl-1-one is used as a raw material; a benzene ring is converted into a cyclohexyl ring by means of a catalytic hydrogenation reaction; transposition is performed under the alkaline condition, so that 1-(4-(4-alkylcyclohexyl)cyclohexyl)alkyl-1-ol is obtained; the trans-trans dicyclohexyl alkane liquid crystal compounds are finally obtained by carrying out an oxidation reaction and a reduction reaction. The preparation method provided by the invention is unique in synthetic route, not only realizes green chemical industry, but also enables the product yield to be greatly increased, improves the product quality, and reduces the cost.

Owner:YANTAI DERUN LIQUID CRYSTAL MATERIALS

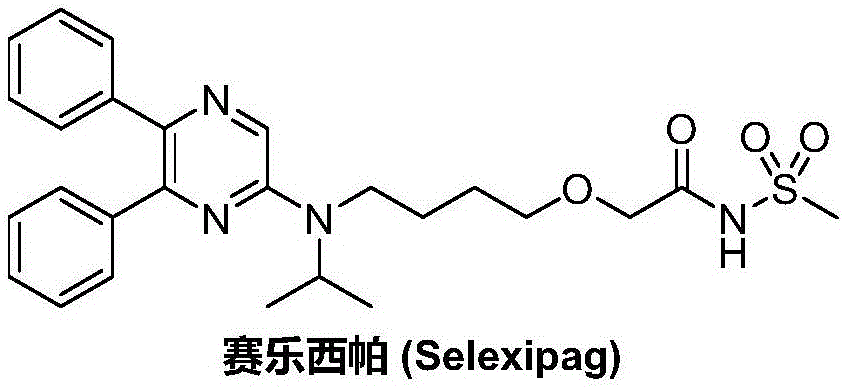

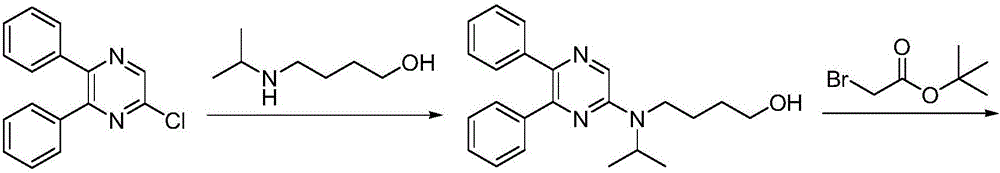

Synthetic method of selexipag

The invention discloses a synthetic method of selexipag. According to the method, 4-[(t-butyloxycarboryl)(isopropyl) amino]-1-butanol and tert-butyl bromoacetate are subjected to a condensation reaction, and obtained 4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl] tert-butyl acetate is subjected to a hydrolysis reaction under an alkaline reaction; obtained 4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl] acetic acid and methanesulfonamide are subjected to a condensation reaction; obtained 2-[4-[(t-butyloxycarboryl)(isopropyl) amino butoxyl]-N-(methylsulfonyl) acetamide is subjected to a deprotection reaction under an acid condition, obtained 2-[4-(isopropyl) amino butoxyl]-N-(methylsulfonyl) acetamide and 5-chloro-2,3-diphenyl pyrazine are subjected to a substitution reaction, and the finished product selexipag is obtained. The method has a reasonable and concise process route and is environment-friendly and suitable for industrial production, the operation is simplified, and the cost is relatively low.

Owner:湖南欧亚药业有限公司

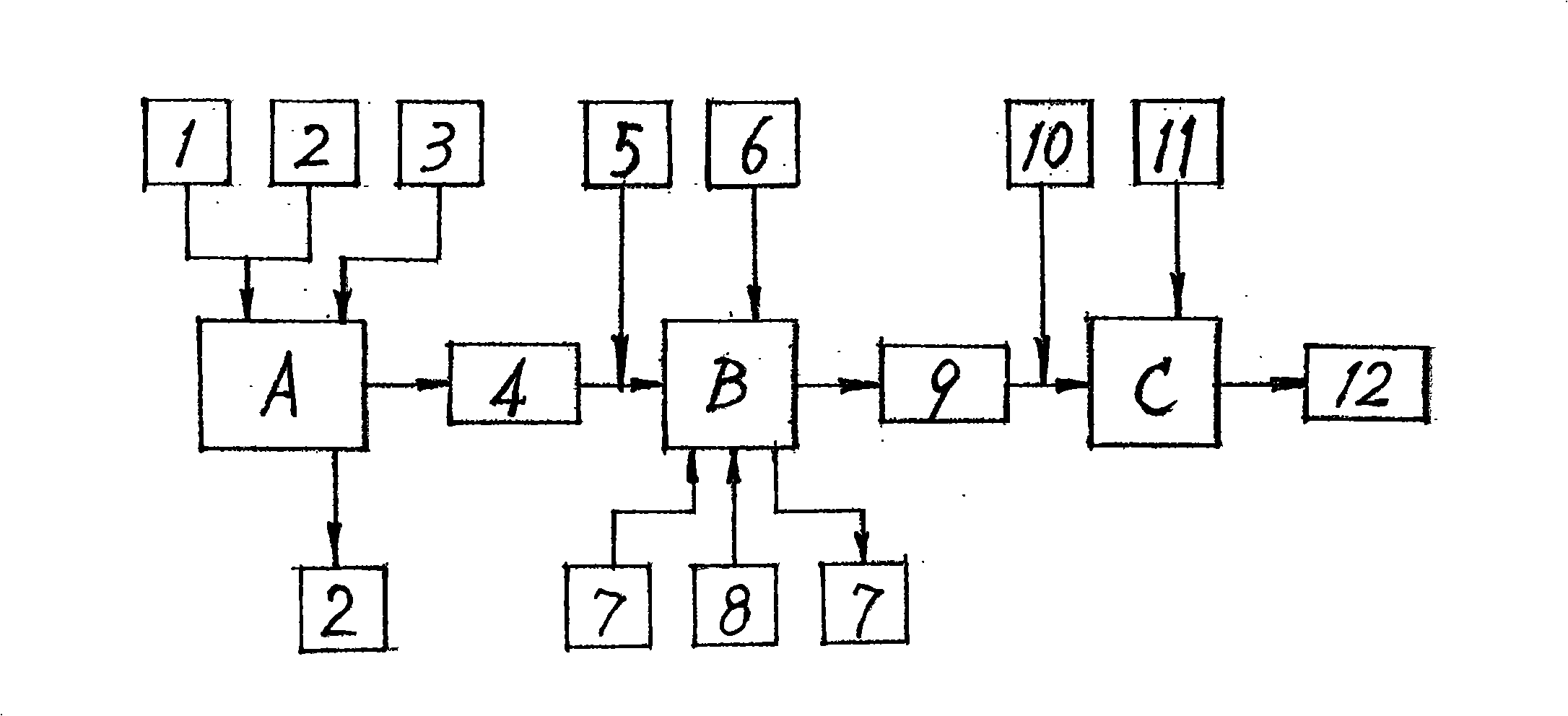

Preparation process of deoxycholeic acid of bear

InactiveCN101289488AThe process steps are simpleReasonable process routeSteroidsChemical recyclingChenodeoxycholic acidChemical reaction

A preparation method for ursodeoxycholic acid regards chenodeoxycholic acid (1) as raw materials; in technological processes, after adopting corresponding equipment and adding excipient according to the proportional variety and dosage, chemical reactions are carried out through the process flow of an oxidation process (A), a hydrogenation process (B), and a purification process (C) in particular temperature and environmental conditions. In the oxidation process (A), an oxidant (3) and a solvent I 2 are added for oxidation reaction to generate an intermediate (4); in the hydrogenation process (B), a catalyst (6) and a solvent II(5) are added for hydrogenation reaction to get ursodeoxycholic acid crude products (9); in the purification process (C), a passivating agent (11) and a solvent III (10) are added for producing the products of ursodeoxycholic acid (12). The process route of the invention is reasonable; the chemical reactions are mild and safe; the operating conditions are easy to be controlled; the yield is high and the invention makes great progress in the research and production of artificially synthesizing ursodeoxycholic acid (12).

Owner:SHANDONG AOCTER CHEM

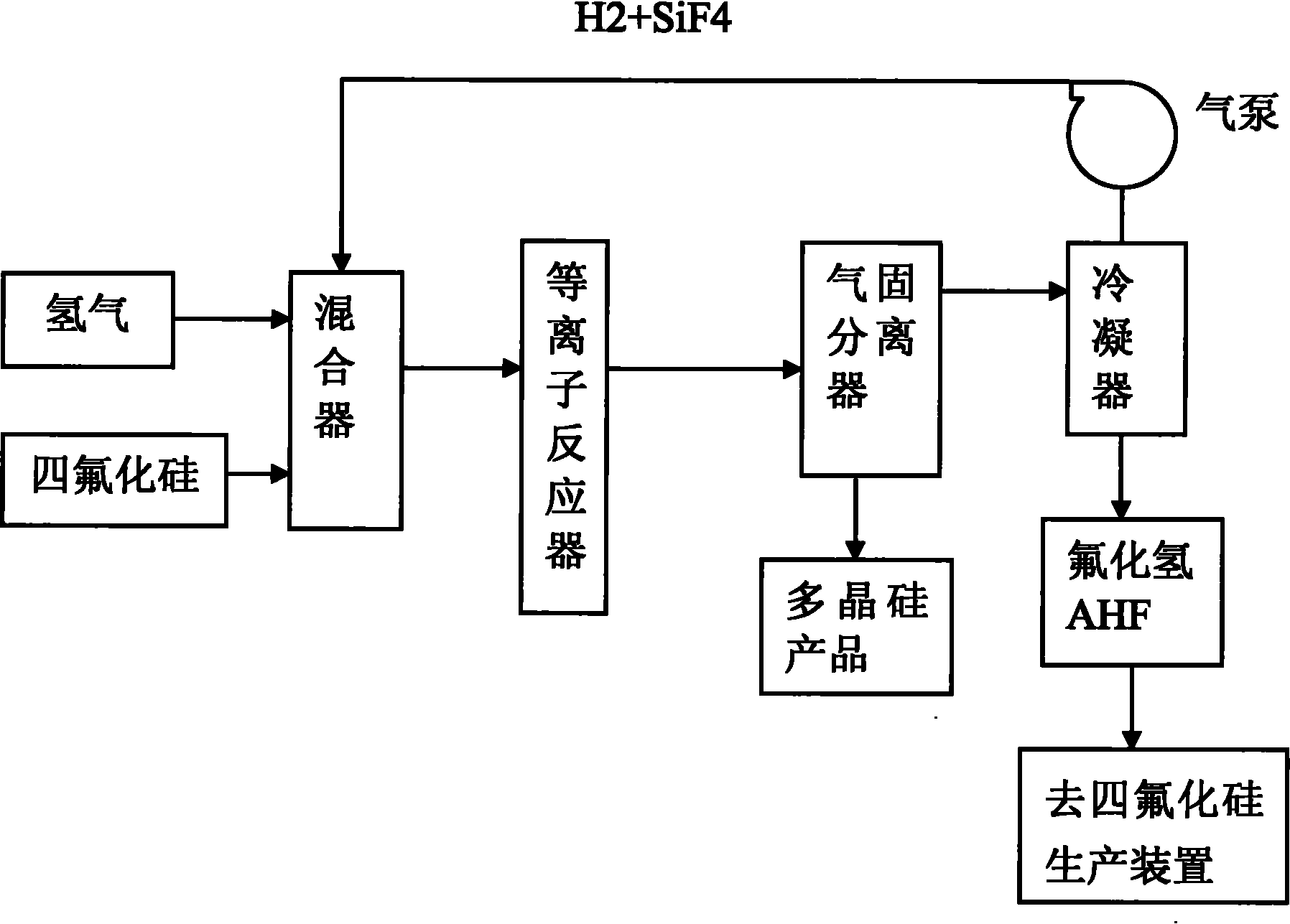

Method for producing polysilicon with silicon tetrafluoride reduced by plasmas

The invention discloses a method for producing polysilicon with silicon tetrafluoride reduced by plasmas, specifically comprising the following steps: pumping the mixture of the silicon tetrafluoride gas and hydrogen as the raw materials into a plasma reactor filled with hydrogen, heating the silicon tetrafluoride gas and hydrogen to 1200-3500 DEG C instantaneously under the action of the plasmas and the silicon tetrafluoride gas and hydrogen carrying out chemical reaction to produce the polysilicon solid and the hydrogen fluoride gas; the produced polysilicon solid and hydrogen fluoride gas and the unreacted silicon tetrafluoride gas and hydrogen jointly entering into a gas-solid separation device, separating the polysilicon solid from the gases, the purity being more than 99.9999% and producing the finished product; and the hydrogen fluoride gas and the unreacted silicon tetrafluoride gas and hydrogen jointly entering into a condenser, condensing the hydrogen fluoride gas to liquid and the silicon tetrafluoride gas and hydrogen returning to the plasma reactor. The method has the advantages of novel and reasonable process routes, low equipment requirements, easy industrialization realization and low energy consumption.

Owner:应盛荣

Bagasse composite soil conditioner preparation method

InactiveCN104388096AImprove utilizationThe preparation process route is reasonableOrganic fertilisersSoil conditioning compositionsCelluloseEnvironmental resistance

The present invention discloses a bagasse composite soil conditioner preparation method, wherein the main byproduct bagasse of sugar production from sugarcane is adopted as a raw material, and is combined with starch and kaolin through a graft copolymerization method so as to prepare the soil conditioner having high heavy metal adsorption capacity, wherein the bagasse contains a lot of cellulose, such that the application of the bagasse to prepare the soil repair agent has economic values and significant environmental significance. According to the present invention, the main byproduct bagasse of the sugar production industry and the natural products such as starch and kaolin are adopted as the raw materials, the characteristics of reasonable process route and reliable product performance are provided, the prepared composite material has the high heavy metal adsorption and the high soil repair capability, the method has advantages of increase of the comprehensive utilization of the sugar mill byproduct, no secondary pollution and the like, and the soil repair agent prepared by using the method can effectively absorb heavy metals in the soil, wherein the cadmium adsorption rate achieves more than 45%, and the copper adsorption rate achieves more than 52%.

Owner:GUANGXI UNIV

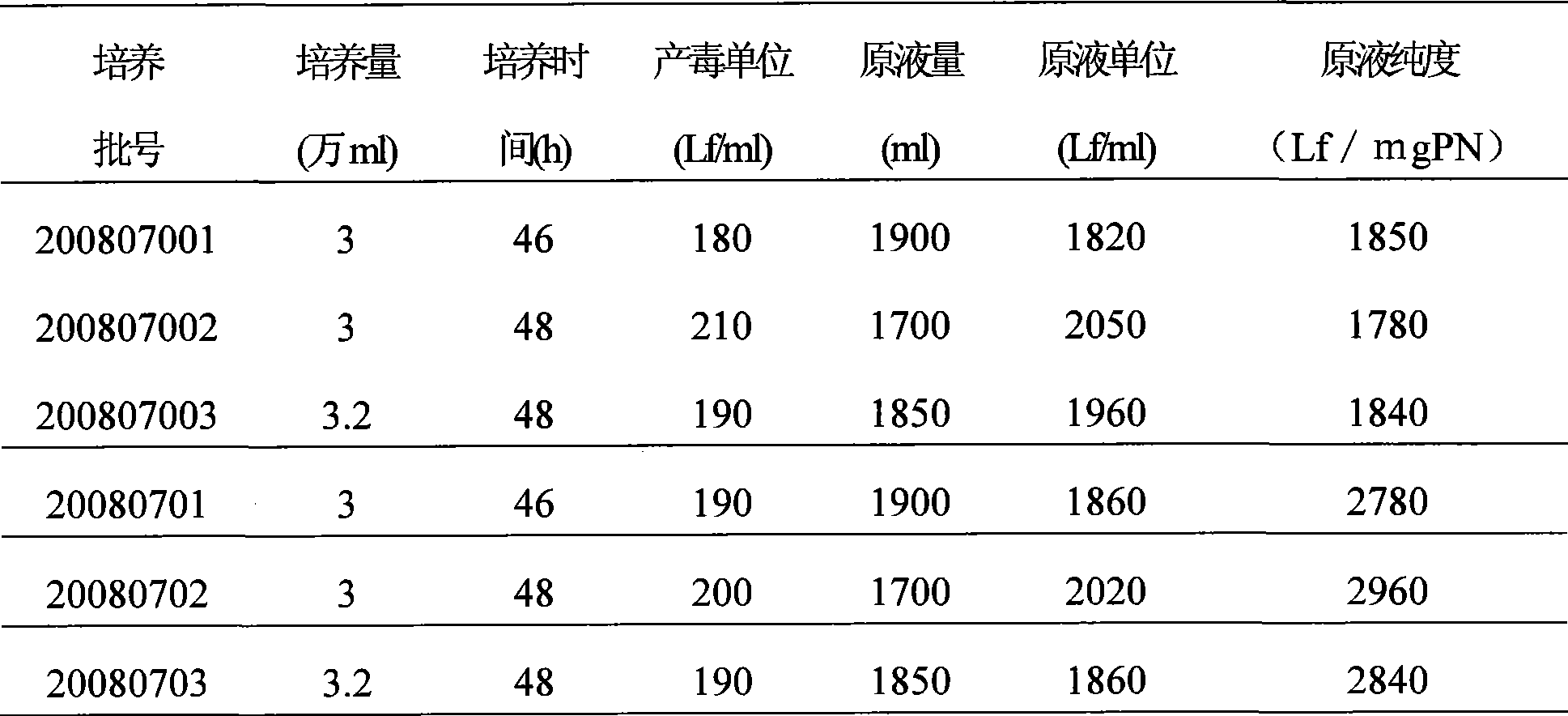

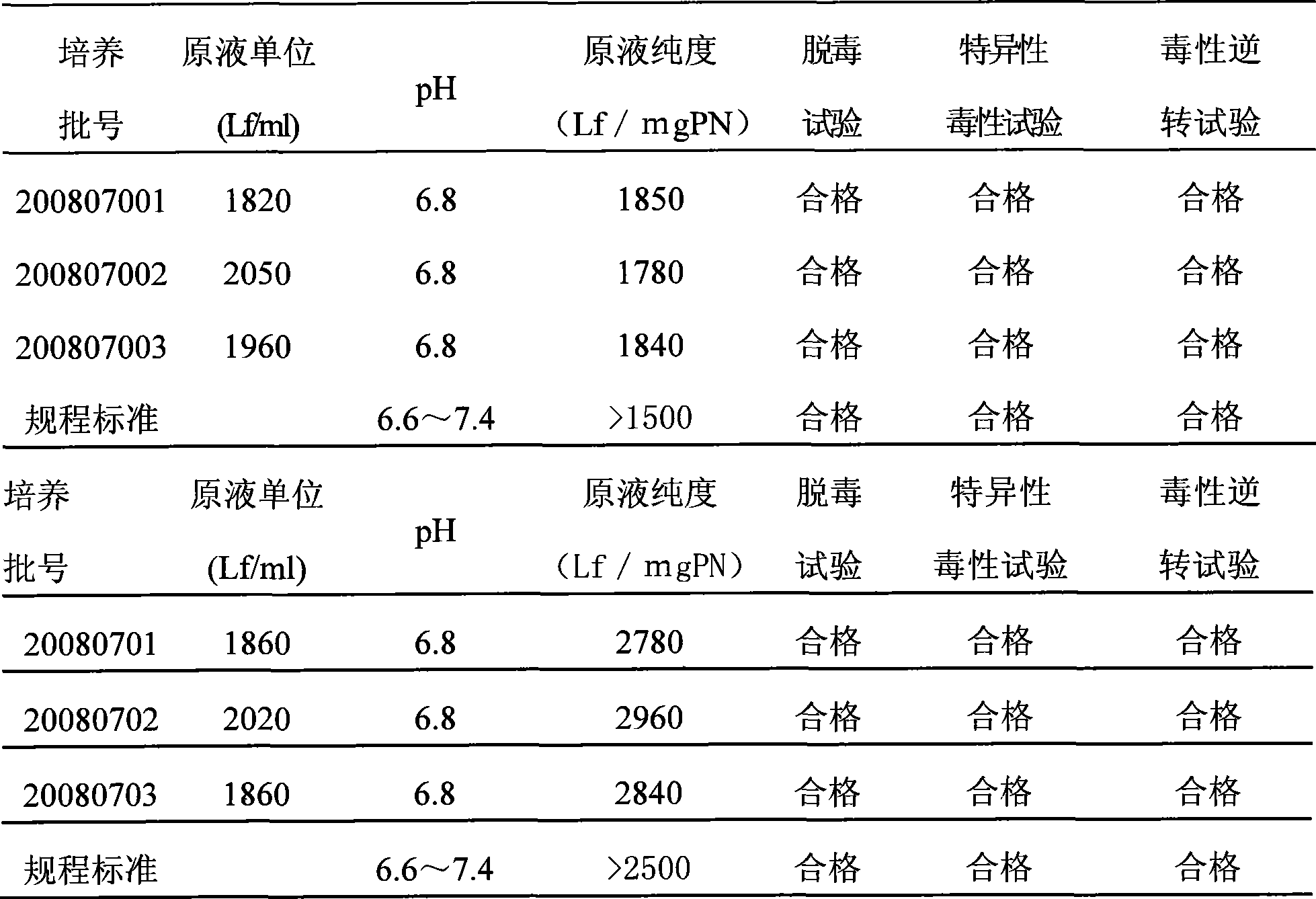

Technique for improving purity of diphtheria toxoid

ActiveCN101503725AHigh purityReasonable process routeAntibacterial agentsDepsipeptidesLiquid productUltrafiltration

The invention relates to a process for improving the purity of diphtheria toxin. The manufacture process comprises the following steps of solid culture medium transfer, culture in a liquid culture medium fermentor, removal of thalli by centrifugation, primary salting-out, secondary salting-out, ultrafiltration desalting, gel filtration, aseptic filtration, removal of toxin, detection and storage stock solution, preparation of semi-finished products, finished products, wherein the liquid culture medium in the liquid culture medium fermentor is treated to remove proteins with the molecular weight of more than 50,000, and the culture products are almost diphtheria toxin with the molecular weight of more than 50,000; and by salting out and gel filtration, the proteins and other impurity proteins of which the molecular weight is less than 50,000 in the liquid product are further removed, so that the diphtheria toxin with high purity is obtained.

Owner:ZHEJIANG TIANYUAN BIO PHARM CO LTD

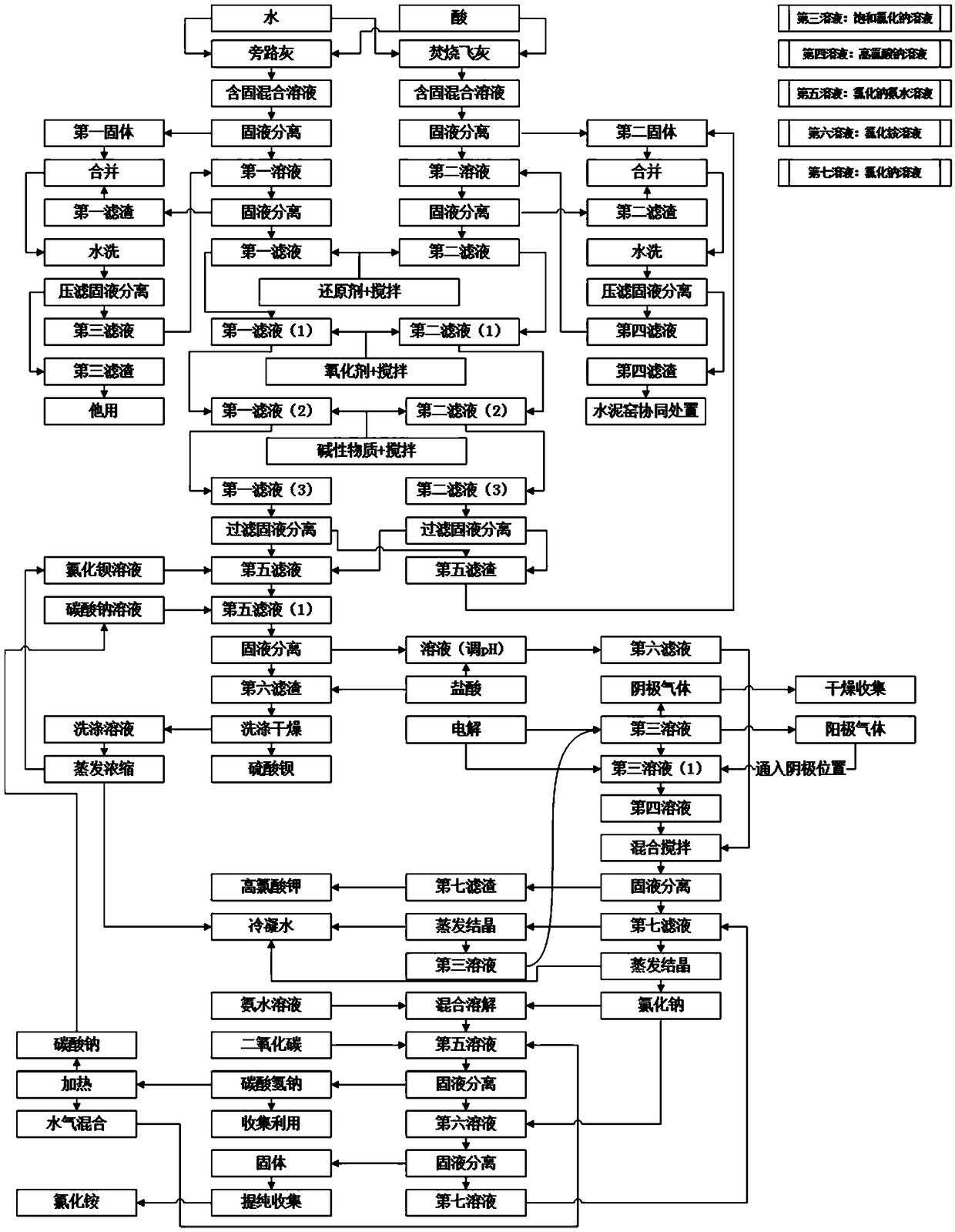

Method for utilizing incineration fly ash and bypass ash in combined manner

ActiveCN109500061AIncrease usageConvenient sourceSolid waste disposalTransportation and packagingAdditional valuesChemical products

The invention relates to a method for utilizing incineration fly ash and bypass ash in a combined manner. According to the method for utilizing the incineration fly ash and the bypass ash in the combined manner, based on full utilizing of existing resources and conditions of a cement enterprise, by reasonably arranging work procedures, stable running of the process is guaranteed, influences of rawmaterial component fluctuation on the process are avoided, various chemical products can also be obtained, and the additional value of the products is improved. In the method, sources of raw materials are convenient, the process route is reasonable, utilizing manners of the incineration fly ash and the bypass ash can be effectively expanded, emission reduction of carbon dioxide is achieved, and universal applicability and popularizing value are achieved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Production process of low-ration high-strength waterproof plaster board mask paper

ActiveCN101824765AGuaranteed lengthAvoid cutsCellulosic pulp after-treatmentSpecial paperFiberPulp and paper industry

The invention discloses a production process of low-ration high-strength waterproof plaster board mask paper, comprises the three steps of material preparation, pulp production and paper making. National waste newspaper, imported American wastepaper and various addictives are added according to a certain ratio and can be adjusted by corresponding processes, so that the invention has reasonable process path, realizes reasonable matching of long and short fibers, improves the quality of products, reduces the paper ratio of finished products, improves the physical strength, also saves resources, and greatly reduces the production cost of a plaster board. The plaster board mask paper produced by using the process has the characteristics of low ratio, high strength, favorable fireproof performance, attractiveness and the like and can completely replace imported products.

Owner:TAISHAN GYPSUM CO LTD

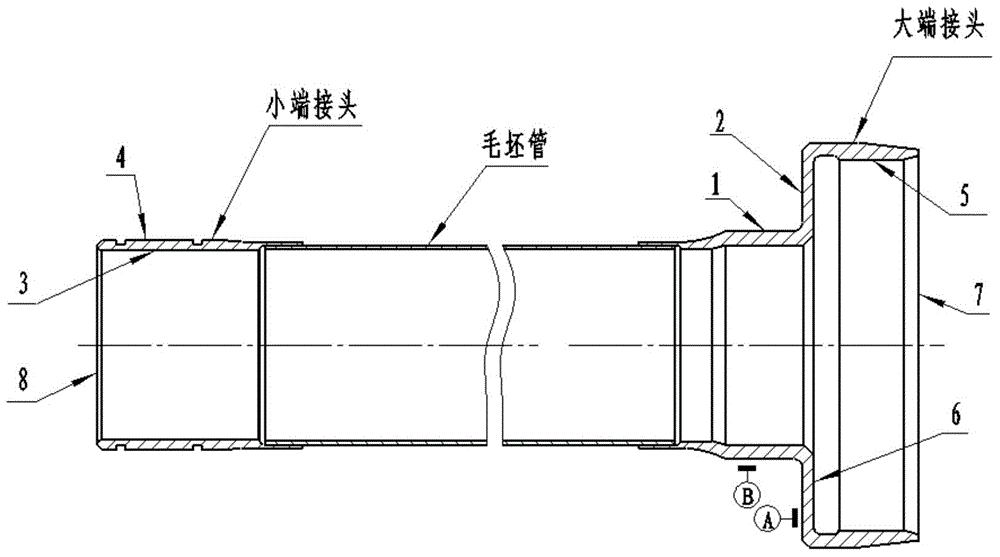

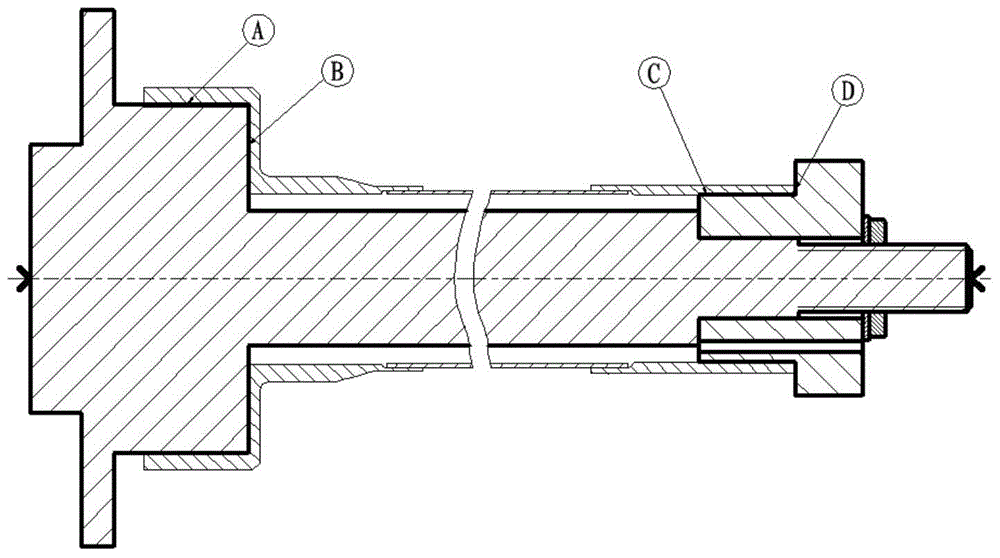

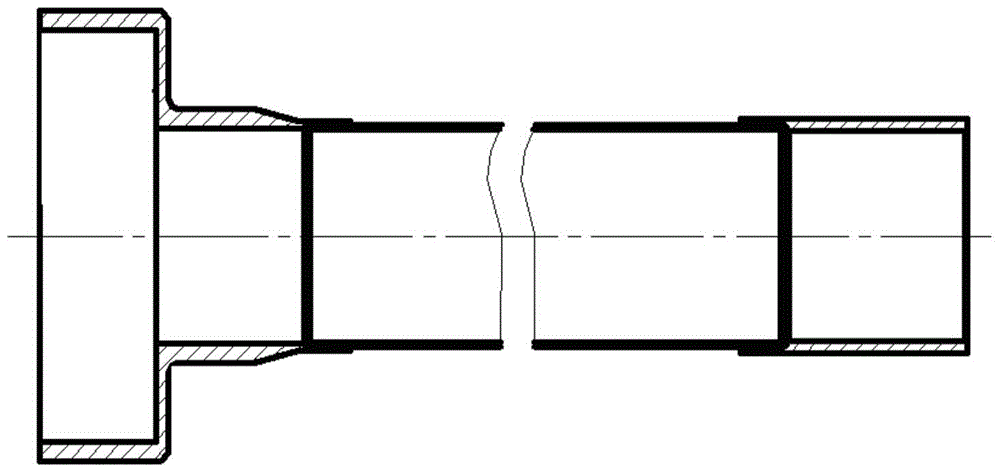

Processing technology method of precise large-size rigid pipe assembly

Provided is a processing technology method of a precise large-size rigid pipe assembly. The processing technology method comprises following steps: pipe material examination; part preparations; attachment cleaning; polishing of positions to be welded; flaring and necking; assembly and positioned welding; electron beam welding; overlap grinding; X-ray examination; repair welding; stress-relief heat treatment; marking; turning references at two ends; polishing and edge sharpening; turning a big-end inner cavity; polishing and edge shaping; bore grinding; four bore drilling; polishing and edge shaping; cleaning; magnetic crack detection; cleaning; final examination and oil seal. The processing technology method of the precise large-size rigid pipe assembly has following advantages: the processing technology method is reasonable in process route and suitable for precision processing of carburizing bores; processing difficulty of the precise large-size rigid pipe assembly is solved; the processing requirement is satisfied; and processing cost is decreased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Double resin process for preparing high quality active gingko leaf component extract

ActiveCN1931199AReasonable process routeHigh extraction rateGinkgophyta medical ingredientsGinkgo GenusGinkgo biloba preparation

The present invention relates to modern extracting and purifying process for preparing gingko leaf extract with rich active component. Compared with available process including organic solvent extraction and single resin adsorption, the modern extracting and purifying process has the advantages of reasonable technological path, high extracting rate and high effective component content in the product, and the prepared ginkgo leaf preparation has effectively controlled quality, determined curative effect and tacking convenience.

Owner:辽宁亿邦制药有限公司

Technique for producing peach gum powder

InactiveCN101148564AThorough and stable decolorizationHigh purityNatural resin purificationReverse osmosisCeramic membrane

The present invention discloses peach gum producing process, which includes the technological steps of depurating and crushing, hydrolyzing, decolorizing, centrifugally depuration, purifying with ceramic membrane, desalting and concentrating with ceramic membrane or reverse osmosis membrane, spray drying, cooling, etc. The present invention has reasonable technological path, low production cost and high production efficiency, and the product has high purity, high quality, stable molecular weight and other features.

Owner:丁乃利

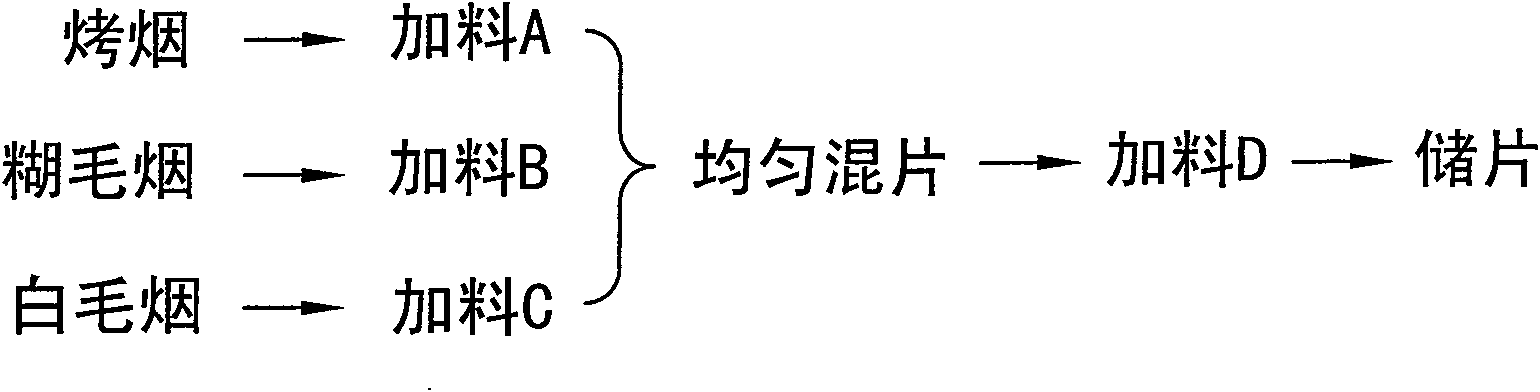

Combined treatment process for flue-cured tobacco, burnt hairy tobacco and white hairy tobacco

ActiveCN101589843AImprove taste qualityEnsure consistencyTobacco preparationEngineeringCombined treatment

The invention discloses a combined treatment process for flue-cured tobacco, burnt hairy tobacco and white hairy tobacco, which comprises the following steps: loosening and dampening flue-cured tobacco flakes, burnt hairy tobacco flakes and white hairy tobacco flakes respectively, and then treating the tobacco flakes by adding treatment materials respectively; evenly mixing the material-adding treated flue-cured tobacco flakes, burnt hairy tobacco flakes and white hairy tobacco flakes to form mixed tobacco flakes; carrying out secondary treatment for the mixed tobacco flakes by adding the treatment material; and storing and treating the mixed tobacco flakes. The combined treatment process for the flue-cured tobacco, burnt hairy tobacco and white hairy tobacco can improve the taste absorption quality of the integral formulation once, and can keep the integral consistency of the formulation, maintain the product quality stable, improve the quality of tobacco leaves, increase the moisture retentiveness of the tobacco leaves and reduce the cutting treatment of the tobacco leaves. The process of the invention has compact and reasonable process route, and can remarkably promote the comprehensive quality of the formulation.

Owner:CHINA TOBACCO ANHUI IND CO LTD

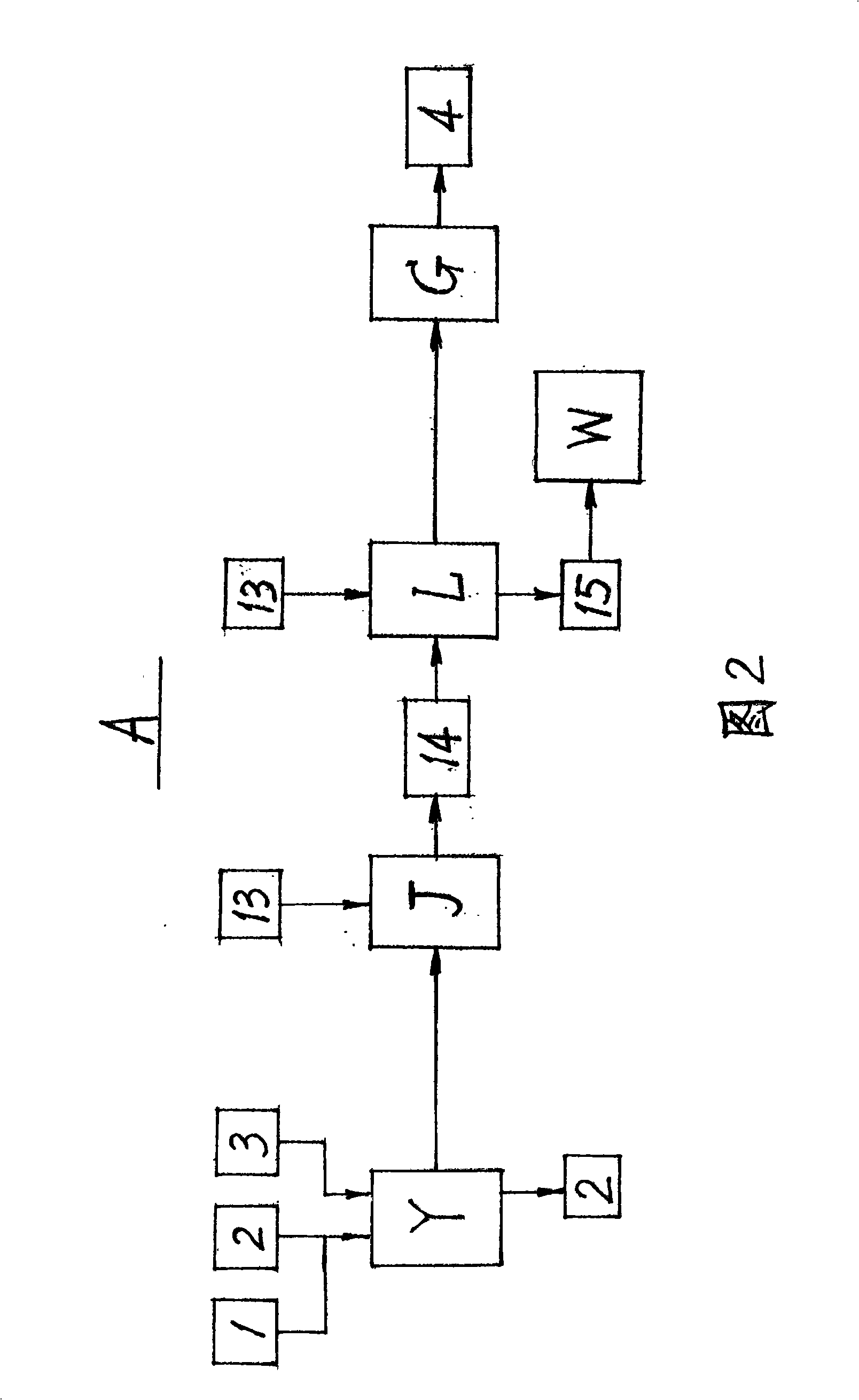

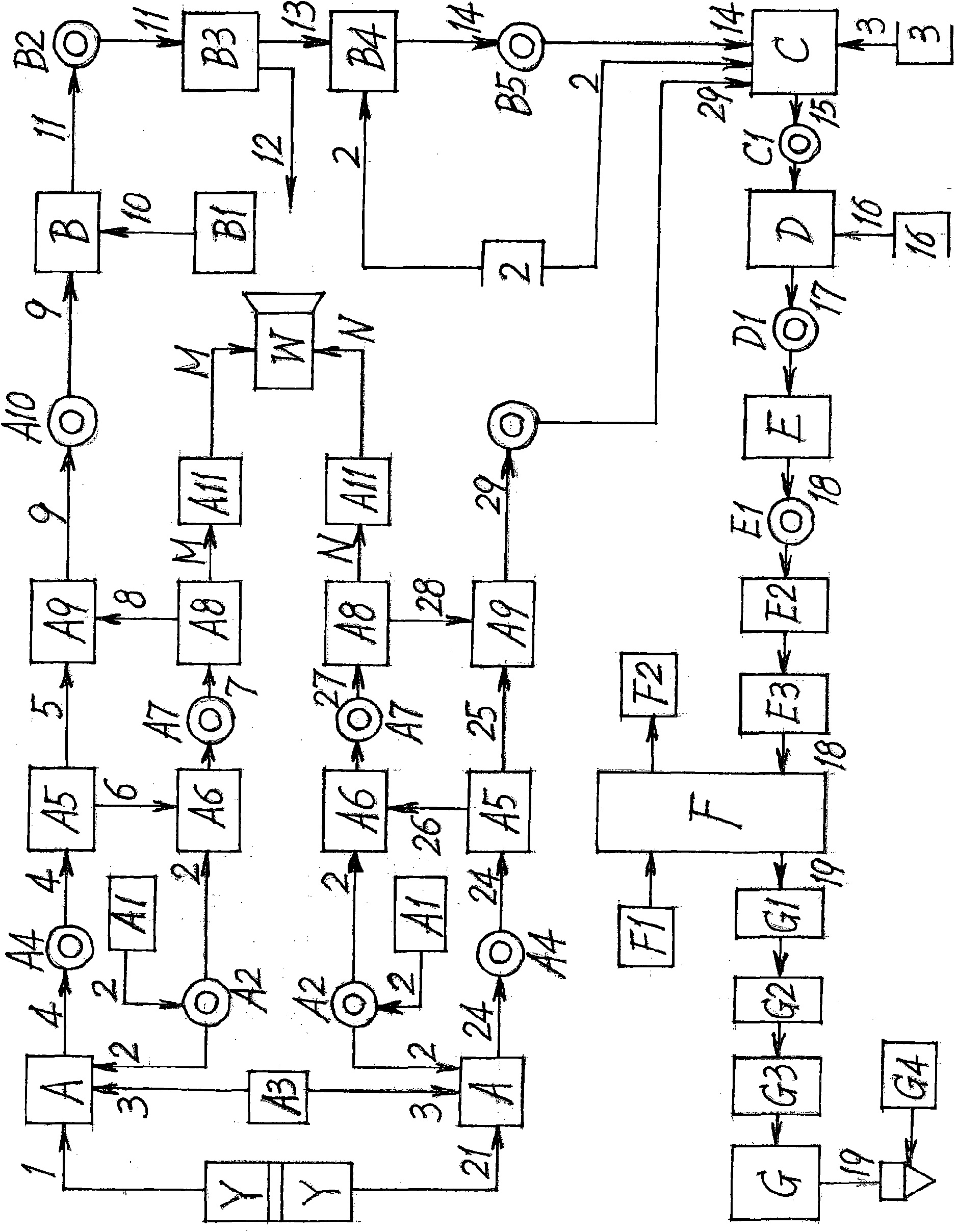

Production technology of dual-crop compound protein isolates

ActiveCN101558814AReasonable process routeClosely connectedProtein composition from vegetable seedsFood preparationProtein isolateProtein C

The invention relates to a production technology of dual-crop compound protein isolates, which comprises the followings: low-temperature soybean meals (1) are prepared into soybean emulsion of acid sediment (14) through extraction and acid sediment procedures; peanut flour (21) can be prepared into peanut extractive and mixed emulsion (29) through an extraction procedure; the soybean emulsion of acid sediment (14) and the peanut extractive and mixed emulsion (29) are added into a neutralization tank (C) based on the proportion for mixing, stirring and confecting; the emulsions are prepared into neutralized solution (15) through a neutralization procedure; the neutralized solution (15) is prepared into enzyme solution (17) through an enzymolysis procedure; the enzyme solution (17) is prepared into flashing liquid (18) through a sterilization procedure; the flashing liquid (18) is prepared into compound protein isolates (19) with protein content more than or equal to 90% through a drying procedure and finally the compound protein isolates (19) enter warehouses after being packed and detected through packing and detecting procedures. The production technology features compact procedure linkage and complete device configuration, can fit the demand of scale serial production, promotes the increase of deep processing conversion rate and utilization factor of farm products and conduces to optimizing industrial structures and product structures of soybeans and peanuts to realize industrialization. The prepared product combines the characteristics of both soybean protein isolates and peanut protein isolates and has rich nutrition, wide application and high added value of products.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com