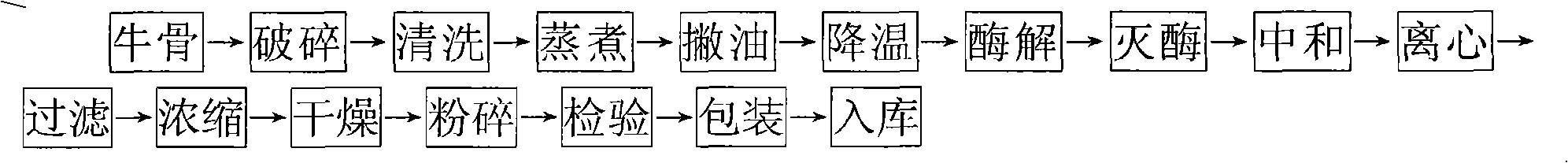

Method for producing bovine-bone peptone by enzyme technology

A technology of peptone and bovine bone, applied in the field of enzymatic technology to produce bovine peptone, can solve the problems of processing utilization rate less than 1%, neglecting the utilization of bovine bone, and low utilization rate of fresh bone, so as to achieve full utilization of raw materials and broad market application prospects , a wide variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 100kg of fresh beef bone.

[0030] ①Manually or mechanically crush the fresh beef bones to 5-10cm, wash them with running water, and put them into the cooking tank;

[0031] ② Add 3 to 4 times of water, cook for 5 hours, temperature 121 ° C, pressure 0.1 MPa;

[0032] ③ After cooking, skim off the foam and slick oil to separate the oil and water;

[0033] ④ Cool the soup to about 50°C, adjust the pH of the soup to 9.0 with caustic soda, weigh 0.3% animal tissue hydrolytic enzyme according to the weight of the bovine bone, dissolve it with an appropriate amount of soup, add it to the soup, stir evenly, and keep the enzyme warm Solution 4h;

[0034] ⑤ After the enzymolysis is completed, heat up and boil for 20 minutes to kill the enzyme; boiling can also denature and precipitate the remaining unenzymolyzed protein; add an appropriate amount of diatomaceous earth, heat up and boil under intermittent stirring; then cool down to below 50°C;

[0035] ⑦ Neutralize wit...

Embodiment 2

[0044] Weigh 100kg of fresh beef bone.

[0045] ①Manually or mechanically crush the fresh beef bones to 5-10cm, wash them with running water, and put them into the cooking tank;

[0046] ② Add 3 to 4 times of water, cook for 4 hours, temperature 130°C, pressure 0.12MPa;

[0047] ③ After cooking, skim off the foam and slick oil to separate the oil and water;

[0048] ④Reduce the temperature of the soup to about 60°C, adjust the pH of the soup to 7.0 with caustic soda, weigh 0.35% compound protease (papain and fig protease) hydrolyzing enzyme according to the weight of the bovine bone, dissolve it with an appropriate amount of soup, and add it to the soup medium, stir evenly, and keep warm for 5 hours for enzymatic hydrolysis;

[0049] ⑤ After the enzymolysis is completed, heat up and boil for 20 minutes to kill the enzyme; boiling can also denature and precipitate the remaining unenzymolyzed protein; add an appropriate amount of diatomaceous earth, heat up and boil under inte...

Embodiment 3

[0059] Weigh 100kg of fresh beef bone.

[0060] ①Manually or mechanically crush the fresh beef bones to 5-10cm, wash them with running water, and put them into the cooking tank;

[0061] ② Add 3 to 4 times of water, cook for 5 hours, temperature 150°C, pressure 0.15MPa;

[0062] ③ After cooking, skim off the foam and slick oil to separate the oil and water;

[0063] ④Reduce the temperature of the soup to about 50°C, adjust the pH of the soup to 6.0 with caustic soda, weigh 0.25% compound protease (trypsin and pepsin) hydrolytic enzyme according to the weight of the bovine bone, dissolve it with an appropriate amount of soup, and add it to the soup medium, stir evenly, and keep warm for 5 hours for enzymatic hydrolysis;

[0064] ⑤ After the enzymolysis is completed, heat up and boil for 20 minutes to kill the enzyme; boiling can also denature and precipitate the remaining unenzymolyzed protein; add an appropriate amount of diatomaceous earth, heat up and boil under intermitte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com