Method for producing polysilicon with silicon tetrafluoride reduced by plasmas

A technology of silicon tetrafluoride and plasma, applied in the direction of silicon, etc., can solve the problems of serious environmental pollution, high energy consumption, and high production cost, and achieve the effects of simple operation in the production process, reduced production cost, and low consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

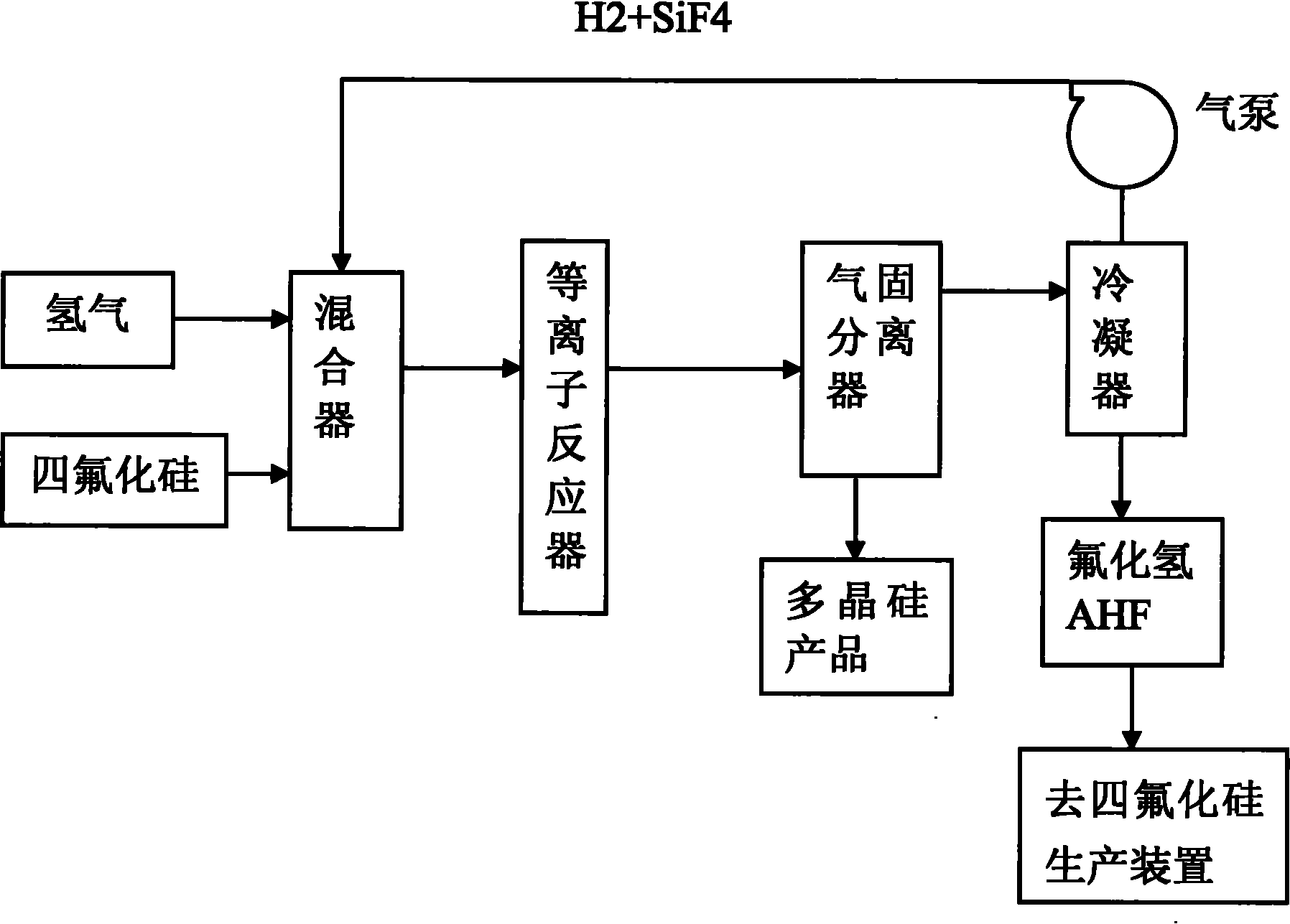

Image

Examples

Embodiment 1

[0039] 1. React silicon dioxide powder with a content of 99% with hydrogen fluoride to generate silicon tetrafluoride and water. Purify silicon tetrafluoride gas to a purity of 99.99%; purify industrial-grade hydrogen to high-purity hydrogen with a purity of 99.9999%.

[0040] 2. Mix the purified silicon tetrafluoride gas and hydrogen in the mixer.

[0041] 3. Vacuumize the plasma reactor and the whole system first, then pass in purified hydrogen to clean the system air flow, and fill the whole system with hydrogen after cleaning; then turn on the power of the plasma reactor to generate plasma in the plasma reactor.

[0042] 4. Pass the mixed hydrogen gas and silicon tetrafluoride gas into the reactor. The chemical reaction occurs immediately, and polysilicon powder appears.

[0043] 5. Under the action of the air pump, the mixed gas in the reactor and the polysilicon powder come out of the reactor together and enter the gas-solid separator, where the polysilicon solid is se...

Embodiment 2

[0047] 1. The purchased silicon tetrafluoride gas with a purity of 99.99% and the purchased hydrogen with a purity of 99.9999% are used as raw materials.

[0048] 2. Mix silicon tetrafluoride gas and hydrogen gas in a mixer.

[0049] 3. Put the substrate material used to produce solar cells into the plasma reactor.

[0050] 4. Vacuumize the plasma reactor and subsequent devices first, and then pass in purified hydrogen to clean the system with air flow. After cleaning, the entire system is filled with hydrogen; then turn on the power of the plasma reactor to generate plasma in the plasma reactor.

[0051] 5. Pass the mixed hydrogen gas and silicon tetrafluoride gas into the reactor. The chemical reaction occurs immediately, polysilicon powder appears, and is deposited on the substrate; when it is deposited to a certain thickness, the polysilicon wafer is taken out and directly becomes the material for manufacturing solar cells.

[0052] 6. Under the action of the air pump, the...

Embodiment 3

[0056] 1. Select silicon dioxide powder with a content of 85% to 99% and calcium fluoride powder with a content of 75% to 99%, and chemically react with sulfuric acid with a content of 92% to 100% to produce tetrafluoroethylene Silicon gas. Purify silicon tetrafluoride gas to a purity of 99.99%;

[0057] 2. Purchasing high-purity hydrogen with a purity of 99.9999% as raw material.

[0058] 3. Mix the purified silicon tetrafluoride gas and high-purity hydrogen in the mixer.

[0059] 4. Vacuumize the plasma reactor and subsequent devices first, and then pass in purified hydrogen to clean the system with air flow. After cleaning, the entire system is filled with hydrogen; then turn on the power of the plasma reactor to generate plasma in the plasma reactor.

[0060] 5. Pass the mixed hydrogen gas and silicon tetrafluoride gas into the reactor. The chemical reaction occurs immediately, and polysilicon powder appears.

[0061] 6. Under the action of the air pump, the mixed gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com