Production method of nanometer silver wire material

A nano-silver wire and production method technology, applied in the field of nano-material production technology, can solve the problems of high production cost, low production efficiency, and non-single shape of finished products, and achieve good quality, improve production efficiency, and save time and labor in the processing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

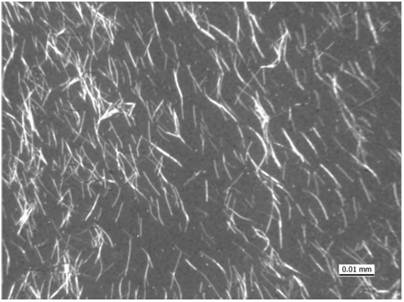

Image

Examples

Embodiment 1

[0028] (1) Solution phase reduction

[0029] At room temperature, weigh the raw materials according to the molar ratio of 1:0.001:0.02:0.002:0.0001, put glycerin, water, polyvinyl pyrrolidone, silver nitrate, and sodium chloride with a total volume of 5 liters into a 10-liter container In the glass reactor, the order of feeding is glycerin, polyvinyl alcohol pyrrolidone, water, silver nitrate, sodium chloride, under the mechanical stirring of the polytetrafluoroethylene stirring rod (the speed is 100 rpm), until all the raw materials are completely dissolved The mixture was obtained, and the reactor was heated by means of a circulating oil bath, and the temperature of the mixture was increased from room temperature to 200° C. within 10 minutes, and then continued to stir for 30 minutes to obtain a silver nanowire stock solution. During this process, an air condenser is placed on the top of the reactor with an open top for condensing volatiles back. Wherein the number average ...

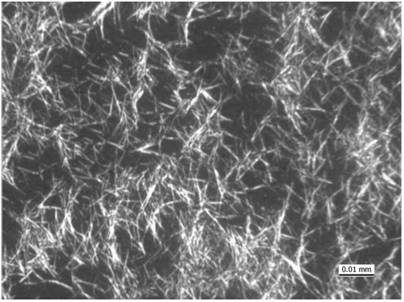

Embodiment 2

[0039] (1) Solution phase reduction

[0040] At room temperature, weigh the raw materials according to the molar ratio of 1:0.001:0.02:0.003:0.0002, put a total volume of 5 liters of glycerin, water, polyvinyl pyrrolidone, silver nitrate, and potassium chloride into 10 liters of reaction In the still, the order of feeding is glycerin, polyvinyl pyrrolidone, water, silver nitrate, potassium chloride, stirring continuously at room temperature for 30 to 50 minutes, under the mechanical stirring of polytetrafluoroethylene stirring rod (rotating speed is 100 rpm / minutes) and mix, when all the raw materials are completely dissolved, the temperature of the mixture is increased from room temperature to 190°C within 10 minutes, and then the stirring is continued for 30 minutes to obtain a stock solution containing silver nanowires. In this process, an air condenser is placed on the top of the reactor, and the top is open. .Wherein the number average molecular weight of polyvinyl alco...

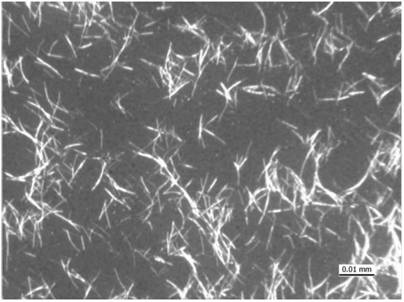

Embodiment 3

[0048] (1) Solution phase reduction

[0049] At room temperature, weigh the raw materials according to the molar ratio of 1:0.001:0.02:0.003:0.00075, put glycerin, water, polyvinyl alcohol pyrrolidone, silver nitrate, and calcium chloride into a 10-liter reactor, and feed The order is glycerin, polyvinyl alcohol pyrrolidone, water, silver nitrate, calcium chloride, under the mechanical stirring of polytetrafluoroethylene stirring rod (100 rpm), stirring at room temperature for 30 to 50 minutes, when After all the raw materials were completely dissolved, the temperature of the mixture was increased from room temperature to 190° C. within 10 minutes, and then the stirring was continued for 25 minutes to obtain a stock solution containing silver nanowires. In this process, an air condenser is arranged on the top of the reactor, and the top is open; the number average molecular weight of polyvinyl alcohol pyrrolidone is 40,000.

[0050] (2) cooling

[0051] Send the nano-silver wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com